Professional Documents

Culture Documents

Material Composition

Uploaded by

subrataOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Composition

Uploaded by

subrataCopyright:

Available Formats

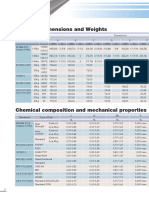

Material C Si Mang Ni Cr Mo Al Va Niob ITS Yeld Hardness

A-105 0.35 .10~.3 .60~1.35 0.4 0.3 0.12 0.08 70 KSI 36 KSI 137~185 BHN

A-106 0.3 0.1 .29~1.06 0.4 0.4 0.06 60 KSI 35 KSI

A-4140 .38~.43 .15~.30 .75~1.0 .80~1.10 .15~.25 95 KSI 60 KSI 197 BHN

A-420 J2 .15~.36 1 1 1 12.5~14 400 BHN

A-410 0.15 1 1 0.75 13.5 65 KSI 30 KSI

EN-19 .35~.45 .10~.35 .50~.80 .90~1.40 .20~.40

EN-24 .35~.45 .10~.35 .45~.70 1.30~1.80 .90~1.40

EN41B .35~.45 .10~.35 .60 Max .40 Max 1.50~1.80 .10~.25 .90~1.30

ASTM-4340 .38~.43 .15~.35 .60~.80 1.65~2.0 .70~.90 .20~.30 930 mps 700 mps 300 BHN

ASTM-A193 GR B7 .37~.49 .15~.35 .65~1.10 .75~1.20 .15~.25 750 MPA 600 MPA 35 HRC

17-4 PH 0.07 1 1 5 17.5 0.45 160 KSI 145 KSI 35 HRC

ASTM A182 F11 .50~.80 .40~.65 .40~.65 1.0~1.5 .44~.65

ASTM A182-F9 0.15 .50~1.0 .3~.6 8~10 .90~1.10

ASTM A182-F304 0.08 1 2 8~11

ASTM A182-F310 0.25 1 2 19~22

ASTM A-312 TP304

You might also like

- Chemical Composition of Carbon SteelDocument2 pagesChemical Composition of Carbon SteelAkilanNo ratings yet

- Cutting Data BoringDocument4 pagesCutting Data BoringFabricio0310No ratings yet

- Powder Metallurgy Material MPIF StandardDocument2 pagesPowder Metallurgy Material MPIF Standardidanfri100% (1)

- American Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialDocument10 pagesAmerican Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialjleonosNo ratings yet

- Katalog Komposisi Lengkap New VersionDocument8 pagesKatalog Komposisi Lengkap New VersionSontani PurnamaNo ratings yet

- Spring Steel Chemical CompositionDocument5 pagesSpring Steel Chemical CompositionSunil Dinanath Joshi100% (1)

- WWW Wollastonalloys Com Materials 2Document8 pagesWWW Wollastonalloys Com Materials 2Mark RomeroNo ratings yet

- Sucker Rod SpecificationsDocument2 pagesSucker Rod SpecificationsAngelosNo ratings yet

- SuckerRodSpecifications PDFDocument2 pagesSuckerRodSpecifications PDFRudiStevenPardosiNo ratings yet

- Introduction of Fine Blanking & Formability SteelDocument16 pagesIntroduction of Fine Blanking & Formability Steeleko wahyudiNo ratings yet

- Special Steel Products PDFDocument4 pagesSpecial Steel Products PDFArijit MajumdarNo ratings yet

- Rail Section PropertiesDocument5 pagesRail Section Propertiesalpha innNo ratings yet

- Carbon and Low Alloy SteelsDocument3 pagesCarbon and Low Alloy Steelspratapkumar333No ratings yet

- Mill Test Certificate Certificate Conform To: EN 10204/3.1Document1 pageMill Test Certificate Certificate Conform To: EN 10204/3.1GLORIA MONSALVE SALAZARNo ratings yet

- AtoZ Alloys Pvt. LTDDocument1 pageAtoZ Alloys Pvt. LTDuksrajNo ratings yet

- Spring Materials (Round Wire)Document6 pagesSpring Materials (Round Wire)Kishore BhatNo ratings yet

- Alloys 2016Document1 pageAlloys 2016Dany ArriantoNo ratings yet

- Tabela Acos Carbono PDFDocument1 pageTabela Acos Carbono PDFRafael PaivaNo ratings yet

- Sa 517Document2 pagesSa 517sepackltdaNo ratings yet

- Reaming Speeds and Feeds PDFDocument1 pageReaming Speeds and Feeds PDFWarrior TempurNo ratings yet

- CHEMISTRY Raw MaterialDocument6 pagesCHEMISTRY Raw Materialaditya18decNo ratings yet

- 6-Carbon SteelsDocument20 pages6-Carbon SteelsMunim DarNo ratings yet

- EA Material SpecificationsDocument1 pageEA Material SpecificationssubbusenthilNo ratings yet

- Aisi 4140Document8 pagesAisi 4140ViruzTrisnaNo ratings yet

- Steel PlatesDocument10 pagesSteel PlateshassanNo ratings yet

- Nisshin Steel Cold Rolled Special Steel StripDocument28 pagesNisshin Steel Cold Rolled Special Steel StripekopujiantoeNo ratings yet

- Gb6654-1996 Steel Plate For PVDocument14 pagesGb6654-1996 Steel Plate For PVsiens2304No ratings yet

- Nachi Bearing MaterialDocument5 pagesNachi Bearing Materialtradingview2hourlyNo ratings yet

- Certificado de Calidad Brida WN SCH-80 2.5Document1 pageCertificado de Calidad Brida WN SCH-80 2.5Jackelin MayraNo ratings yet

- Ca-24 Codo Acero 90°Document2 pagesCa-24 Codo Acero 90°Luis Felipe Sanchez BernalNo ratings yet

- Corten A Steel Weather Resistant Steel PDFDocument8 pagesCorten A Steel Weather Resistant Steel PDFadihindNo ratings yet

- 3Document4 pages3Madirley PimentaNo ratings yet

- Certificate EN 10204-3.1: Item Charge Nr. Q'ty Mechanishe Eignenschappen/mechanical Properties Tensile Strength (Mpa)Document1 pageCertificate EN 10204-3.1: Item Charge Nr. Q'ty Mechanishe Eignenschappen/mechanical Properties Tensile Strength (Mpa)Carlos Andres RojasNo ratings yet

- Astma Grades HardnessDocument2 pagesAstma Grades HardnessDavindRa SoniNo ratings yet

- Attributes of Ductile Reinforcing SteelDocument9 pagesAttributes of Ductile Reinforcing Steelengr.moinul.hossainNo ratings yet

- Renold Inox Catalogo PDFDocument1 pageRenold Inox Catalogo PDFsawnico sawNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- Brochure Bohler BeneluxDocument8 pagesBrochure Bohler Beneluxmohsen_267No ratings yet

- Certificado de Calidad Brida Anillo GhasDocument1 pageCertificado de Calidad Brida Anillo GhasJKarlos Barrientos ÑufloNo ratings yet

- En Series Chemical CompositionDocument3 pagesEn Series Chemical CompositionAyanBiswas22No ratings yet

- Steel GradesDocument12 pagesSteel GradesDidar Singh Thethi100% (1)

- Nor-Cal To SBSC NW (KF) Fittings Cross-ReferenceDocument5 pagesNor-Cal To SBSC NW (KF) Fittings Cross-Referenceherysyam1980No ratings yet

- Part Number Deskripsi HET Baru HET Lama SelisihDocument1 pagePart Number Deskripsi HET Baru HET Lama SelisihmomoNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetprabhu vijayanNo ratings yet

- Mag General Business: Quality CertificateDocument1 pageMag General Business: Quality CertificateAnonymous 6LwW4qi6TiNo ratings yet

- Alloy Material GradeDocument2 pagesAlloy Material GradeSuleman Khan100% (1)

- Mag General Business: Certificate of QualityDocument1 pageMag General Business: Certificate of QualityManuel ColanNo ratings yet

- Alloy Steel ChartDocument4 pagesAlloy Steel Chartmodi_mihirNo ratings yet

- SAIL StructuralsDocument10 pagesSAIL StructuralsKonathala RajashekarNo ratings yet

- Welding Consumables For Steels With Yield Strength 460MPa PDFDocument75 pagesWelding Consumables For Steels With Yield Strength 460MPa PDFali509No ratings yet

- Analysis of Rate Building 23.10Document314 pagesAnalysis of Rate Building 23.10Chobwe Stephano KanyinjiNo ratings yet

- JIS DIN ASTM Steel, Alloy, Cast Iron SpecificationsDocument1 pageJIS DIN ASTM Steel, Alloy, Cast Iron SpecificationsBao Duy NguyenNo ratings yet

- Forged Engineering DataDocument4 pagesForged Engineering DataretrogradesNo ratings yet

- Seleccionar PTCDocument5 pagesSeleccionar PTCAldimir AcopaNo ratings yet

- Urea Stripper GasketsDocument1 pageUrea Stripper GasketssubrataNo ratings yet

- Dynamics of MachinesDocument100 pagesDynamics of MachinessubrataNo ratings yet

- Value of Cylinder Pressure Measurement For CompressorDocument7 pagesValue of Cylinder Pressure Measurement For CompressorsubrataNo ratings yet

- Best Practice Pumps V4Document11 pagesBest Practice Pumps V4subrataNo ratings yet

- Anti-Friction Bearings FundamentalsDocument21 pagesAnti-Friction Bearings FundamentalssubrataNo ratings yet

- Worthington Manual PDFDocument71 pagesWorthington Manual PDFsubrataNo ratings yet

- K P S R S: EY Roduct Upply Eferences and NapshotsDocument44 pagesK P S R S: EY Roduct Upply Eferences and NapshotssubrataNo ratings yet

- IRD811D User ManualDocument33 pagesIRD811D User ManualsubrataNo ratings yet

- Seminar On Non-Destructive Testing: Submitted To: Submitted byDocument25 pagesSeminar On Non-Destructive Testing: Submitted To: Submitted bysubrataNo ratings yet

- Crankcase SafetyDocument7 pagesCrankcase SafetysubrataNo ratings yet

- Blind Flange Thickness CalculationDocument5 pagesBlind Flange Thickness CalculationsubrataNo ratings yet