Professional Documents

Culture Documents

135 Embedded

Uploaded by

AfshaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

135 Embedded

Uploaded by

AfshaCopyright:

Available Formats

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Website: www.ijareeie.com

Vol. 6, Issue 6, June 2017

Embedded Based Flow Control Using Fuzzy

Dr.G.Prathyusha

Dept. of Instrumentation and USIC, Sri Krishna Devaraya University, Anantapur, Andhra Pradesh, India

ABSTRACT: The industrial application of flow rate measurement and control is very important and essential,

especially in petroleum refineries, pharmaceutical and chemical process industries. Flow control is very important in

medical appliances also. For maintaining the saline and blood flow rate is play a very crucial role in hospitals. In

pharmaceutical and chemical process industries also the flow rate maintenance is essential for perfectness of medicine

composition . The flow rate is measured and control is developed by implementing software programming Fuzzy.

KEYWORDS: Flow, Fuzzy logic, Microcontroller.

I.INTRODUCTION

The flow measurement and control system can be developed by microcontroller using software fuzzy logic choosing

Mean of Maxima method. Implementing software we the system avoid the hardware complexity and easily understood

the logic application with flexibility. The total control system is most applicable in industrial applications and medical

applications. The steady state error is very less to maintain the entire process in flow control system.

II.PROCEDURE

The flow measurement and control system is developed by using flow sensor, the output of sensor which is in the form

of pulses is given to the Arduino Mega2560 microcontroller implementing Fuzzy logic the PWM of the controller is

given the signal to DC water pumping motor through ULN2003 current driver. The hardware system consists of

different modules and explanation for each module is given in detail. They are

1. YF-S201 Flow sensor

2. Arduino MEGA2560 Microcontroller

3. ULN 2003 Relay driver

4. DC motor

5. Personal computer as display unit

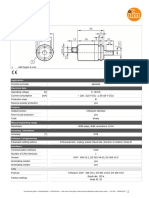

YF-S201 Hall Effect Water Flow Meter / Sensor

This sensor placed in line with the water line and contains any simple level sensor to measure how much

liquid has pumped through it. There's an integrated magnetic Hall Effect sensor that outputs an electrical pulse with

every revolution. The Hall Effect sensor is sealed from the water pipe and allows the sensor to stay safe and dry. The

sensor comes with three wires: red (5-24VDC power), black (ground) and yellow (Hall Effect pulse output). By

counting the pulses from the output of the sensor, you can easily calculate water flow. YF-S201 Water Flow Sensor can

be used to measure the flow of liquids in both industrial and domestic applications. This sensor basically consists of a

plastic valve body, a rotor and a Hall Effect sensor. The pinwheel rotor rotates when liquid flows through the valve and

its speed will be directly proportional to the flow rate.

Fig 1. YF-S201 Hall Effect Flow Sensor

Copyright to IJAREEIE DOI:10.15662/IJAREEIE.2017.0606135 4958

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Website: www.ijareeie.com

Vol. 6, Issue 6, June 2017

Fig 2. Connection for YF-S201 Flow Sensor

The flow sensor placed in line with the water line and contains a pinwheel sensor to measure how much liquid has

pumped through it. There's an integrated magnetic Hall Effect sensor that outputs an electrical pulse with every

revolution. The Hall Effect sensor is sealed from the water pipe and allows the sensor to stay safe and dry. The sensor

consists of three wires. They are Red wire: +5V, Black wire: GND, Yellow wire : PWM. Hall-effect transistors also

can be used. These transistors change their state when they are in the presence of a very low strength (on the order of

25 gauss) magnetic field. By counting the pulses from the output of the sensor, we can easily calculate water flow.

Each pulse gives approximately in milliliters and the pulse rate does vary a bit depending on the flow rate, fluid

pressure and sensor orientation. It will need careful calibration if better than 10% precision is required.YF-S201 Water

Flow Sensor can be used to measure the liquid flow in both industrial and domestic applications. This sensor basically

consists of a plastic valve body, a rotor, a Hall Effect sensor, inlet and outlet. The pinwheel rotor rotates when water or

liquid flows through the valve and the speed of sensor will be directly proportional to the flow rate. The Hall Effect

sensor will provide an electrical pulse with every revolution of the pinwheel rotor. The rate of water flow will be

directly proportional to the number of pulses counted . The pulse signal is a simple square wave so it’s quite easy to log

and convert into liters per minute.

Arduino Mega2560 microcontroller

It is the heart of the module of the entire system. It is controlled total parameter value and provides a

communication between client and server by interfacing this to the PC. The YF-S201 water flow sensor module can be

easily interfaced with Arduino Mega2560 microcontroller Connect the PWM output of this module to interrupt pin of

microcontroller unit and count the number of pulses or interrupt per unit time. The rate of water flow will be directly

proportional to the number of pulses counted. Based on the pulses, derive an expression for flow rate in milliliter (ml).

The signal which is connected to the PWM as an output signal which fed to DC pumping motor which is attached to the

flow sensor through the ULN 2003 driver.

Dc Motor

A water pumping DC Motor which operates with +12V by 1Amp power supply for pumping the liquid. It

consists of one inlet and one outlet for maintaining the Flow rate in a tank by pumping water. In this work the motor

controlled by a controller line of PWM which operates with +5V/+12V by using Fuzzy with PID software. The

application software for the present work developed through communication interfacing with PC and USB .One

advantage of it is, its operating voltage is +5V same as controller.

ULN 2003 Relay Driver

The ULN2003A devices are high-voltage, high-current Darlington transistor arrays. Each consists of seven

NPN Darlington pairs that feature high-voltage outputs with common-cathode clamp diodes for switching inductive

loads. It has a 2.7-kΩseries base resistor for each Darlington pair for operation directly with TTL or 5-V CMOS

devices. The controlled signal which is followed by PWM of microcontroller is given to the input pin of the ULN 2003

driver. The output pin of it is connected to the water pumping DC motor.

Personal Computer

The computer is the most important and integral part of the entire control system as it plays a vital role in data

acquisition, display, record, and generate graphs. The predominant interfaces between personal computer and

microcontroller are USB and Ethernet. In this contest USB communication is implemented to transfer data to and from

controller to PC to display and store in database. Computer is loaded with windows 2008 operating system, Arduino

and Processing software.

Copyright to IJAREEIE DOI:10.15662/IJAREEIE.2017.0606135 4959

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Website: www.ijareeie.com

Vol. 6, Issue 6, June 2017

III.SOFTWARE

Algorithm

Initialization the microcontroller and Flow sensor

Count the number of pulses

Calculate the flow rate based on pulses

By using ULN 2003 through PWM driver controller control the motors for pumping of the liquid for

controlling the flow rate of the pipe.

If the flow rate is greater than or less than the set point, the DC motor controlled by the PWM of

microcontroller which is depending on the Fuzzy signal.

If flow rate reached set point the motor will be in stable state

Stop

Fig 3. Flowchart for Flow rate measurement and control using Hall Effect sensor implemented with Fuzzy logic

Copyright to IJAREEIE DOI:10.15662/IJAREEIE.2017.0606135 4960

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Website: www.ijareeie.com

Vol. 6, Issue 6, June 2017

IV.FUZZY LOGIC APPLICATION

Table 1. Matrix arrangement of flow

Flow in Low Medium High Very high

milliliter/sec

Low No Pumping Pumping IN Pumping IN Pumping IN

Medium Pumping OUT NO Pumping Pumping IN Pumping IN

High Pumping OUT Pumping OUT NO Pumping Pumping IN

Very high Pumping OUT Pumping OUT Pumping OUT No Pumping

Fig 4. Membership Functions for

F (flow) = {Low, Medium, High, Very high}

V. RESULT AND DISCUSSION

The below table shows the steady state error and accuracy of total control system with response, set time and controlled

time.

Set FUZZY

Flow Response Set Time Controlled Time Steady State

rate Time (sec) (ml) Error

(ml) (sec) (ml)

60 12 15 64 4

50 19 24 54 4

40 29 33 42 2

30 38 41 34 4

20 47 49 24 4

10 58 63 15 5

5 64 68 9 4

Copyright to IJAREEIE DOI:10.15662/IJAREEIE.2017.0606135 4961

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Website: www.ijareeie.com

Vol. 6, Issue 6, June 2017

VI.CONCLUSION

The design of software Fuzzy implementing flow controller with active rule selection mechanism. The proposed system

is tested in real time environment and the output performances are evaluated. In this system which is key point to

reduce the cost by implementing software algorithm. We have successfully experiment this system in lab and therefore

proposed a web based flow monitoring and controlling network with flexibility. This could have a substantial benefit

from this research work for efficient management of liquid flow.

REFERENCES

[1] “Level Measurements Systems”. Omega Complete Flow and Level Measurement Handbook and Encyclopedia Vo.29, Stanford, CT, Omega

Engineering Inc, 1995.

[2] “Flow measurements”, Fuzi Technology September 2004.

[3] Furness, Richard A. (1989). Fluid flow measurement. Harlow: Longman in association with the Institute of Measurement and Control. p. 21.

ISBN 0582031656.

[4] Holman, J. Alan (2001). Experimental methods for engineers. Boston: McGraw-Hill. ISBN 978-0-07-366055-4.

[5] American Gas Association Report Number 3 and 7

[6] Arregui, Cabrera, Cobacho, Integrated Water Meter Management, p. 33

[7] Miller, Richard W. (1996). Flow Measurement Engineering Handbook (3rd ed.). Mcgraw Hill. p. 6.16-6.18. ISBN 0070423660.

[8] Bean, Howard S., ed. (1971). Fluid Meters, Their Theory and Application (6th ed.). New York: The American Society of Mechanical

Engineers. pp. 77–78.

[9] Severn, Richard. "Environment Agency Field Test Report – TIENet 360 LaserFlow" (PDF). RS Hydro. RS Hydro-Environment Agency.

Retrieved 3 August 2015.

[10] Drost, CJ (1978). "Vessel Diameter-Independent Volume Flow Measurements Using Ultrasound". Proceedings of San Diego Biomedical

Symposium 17: 299–302.

Copyright to IJAREEIE DOI:10.15662/IJAREEIE.2017.0606135 4962

You might also like

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- 39 A SensorlessDocument8 pages39 A SensorlessANUSHA NAIDUNo ratings yet

- Arduino Speed Control DC Motor LabVIEWDocument4 pagesArduino Speed Control DC Motor LabVIEWFaraheddine BelkacemNo ratings yet

- Smart Wireless Water Level Monitoring & Pump Controlling SystemDocument11 pagesSmart Wireless Water Level Monitoring & Pump Controlling Systemsumanth reddyNo ratings yet

- Smart Wireless Water Level Monitoring & Pump Controlling SystemDocument11 pagesSmart Wireless Water Level Monitoring & Pump Controlling Systemkaibalya sahooNo ratings yet

- Monitoring of Corrosions and Leakages in Gas Pipelines and A Safety Technique Using LabviewDocument7 pagesMonitoring of Corrosions and Leakages in Gas Pipelines and A Safety Technique Using LabviewSinn RavenNo ratings yet

- Role of SCADA in Hydro Power PlantDocument6 pagesRole of SCADA in Hydro Power PlantIndin HasanNo ratings yet

- Solar Power Control & Monitoring Using Iot & Automatic Stret Light ControlDocument6 pagesSolar Power Control & Monitoring Using Iot & Automatic Stret Light ControlNusrat NehaNo ratings yet

- Feeder Protection From Over Load and Earth Fault RelayDocument6 pagesFeeder Protection From Over Load and Earth Fault RelayrajeshNo ratings yet

- 74 13 DesignDocument8 pages74 13 DesignLeonel MessiNo ratings yet

- Low Power VLSI Architectures For Digital PID Controller ApplicationsDocument8 pagesLow Power VLSI Architectures For Digital PID Controller ApplicationsAbrar Ul HaqNo ratings yet

- 99_Final ManuscriptDocument6 pages99_Final ManuscriptDEBARATI DAMNo ratings yet

- ARM Based Automatic Critical Health Care Service System Using Wireless CommunicationDocument7 pagesARM Based Automatic Critical Health Care Service System Using Wireless CommunicationjormnNo ratings yet

- Study of Speed Control of DC Series Motor Using DC ChopperDocument9 pagesStudy of Speed Control of DC Series Motor Using DC ChopperKedari Sri Chaithanya ReddyNo ratings yet

- PLC Based Sequence Detection and Monitoring SystemDocument4 pagesPLC Based Sequence Detection and Monitoring SystemKanisetty JanardanNo ratings yet

- Model Predictive Control For Process Flow Application Using LabviewDocument6 pagesModel Predictive Control For Process Flow Application Using LabviewTanNguyễnNo ratings yet

- 97 Design PDFDocument8 pages97 Design PDFKhaled RabeaNo ratings yet

- Ijireeice 2022 10642Document5 pagesIjireeice 2022 10642Bhavya ParekhNo ratings yet

- Transformer Health Monitoring and Protection Using IoTDocument7 pagesTransformer Health Monitoring and Protection Using IoTIJRASETPublicationsNo ratings yet

- Real Time Temperature Monitoring Using LABVIEW and ArduinoDocument7 pagesReal Time Temperature Monitoring Using LABVIEW and Arduinojarwo kuatNo ratings yet

- Design of A Low Cost Automatic Servo Controlled Stabilizer With Quick Response To Voltage VariationsDocument6 pagesDesign of A Low Cost Automatic Servo Controlled Stabilizer With Quick Response To Voltage VariationsRANAIVOARILALA FanomezantsoaNo ratings yet

- PLC & SCADA Based Condition Monitoring of Three Phase Induction MotorDocument7 pagesPLC & SCADA Based Condition Monitoring of Three Phase Induction MotorBui Hong PhongNo ratings yet

- A Study On Variable Frequency Drive and It's ApplicationsDocument6 pagesA Study On Variable Frequency Drive and It's ApplicationsAyaan KhanNo ratings yet

- IJIREEICE.2024.12308Document8 pagesIJIREEICE.2024.12308MD NahidNo ratings yet

- IOT Based Single Phase Induction Motor Protection SystemDocument6 pagesIOT Based Single Phase Induction Motor Protection SystemIJRASETPublicationsNo ratings yet

- IOT Based Remote Monitoring For HT Motors in ThermDocument7 pagesIOT Based Remote Monitoring For HT Motors in ThermGokulnathan NNo ratings yet

- 170 - Automatic Coal Conveyor Control Using PLCDocument6 pages170 - Automatic Coal Conveyor Control Using PLCOsa CastrenaNo ratings yet

- Blynk 2.0 Based Smart Electricity Monitoring MeterDocument14 pagesBlynk 2.0 Based Smart Electricity Monitoring MeterIJRASETPublicationsNo ratings yet

- V/F Speed Control Technique of Three Phase Induction Motor: IjireeiceDocument5 pagesV/F Speed Control Technique of Three Phase Induction Motor: IjireeiceNam Trịnh HồngNo ratings yet

- Speed and Direction Control of DC Motor Without Using MicrocontrollerDocument5 pagesSpeed and Direction Control of DC Motor Without Using MicrocontrollerNitesh ChaurasiyaNo ratings yet

- 32_Power_NCDocument10 pages32_Power_NCArnold RosenbergNo ratings yet

- Role of SCADA in Hydro Power Plant Automation: October 2015Document7 pagesRole of SCADA in Hydro Power Plant Automation: October 2015Skshukla ShuklaNo ratings yet

- IoT Based Health Monitoring SystemDocument11 pagesIoT Based Health Monitoring SystemakashlogicNo ratings yet

- IoT Based Substation Monitoring and ControlDocument8 pagesIoT Based Substation Monitoring and ControlIJRASETPublicationsNo ratings yet

- A Study On DC Motor Operations and Speed Control Using MicrocontrollerDocument5 pagesA Study On DC Motor Operations and Speed Control Using MicrocontrollerabsalnabiNo ratings yet

- BLDC Motor Speed Control Using Co-Simulation of Multisim and LabviewDocument5 pagesBLDC Motor Speed Control Using Co-Simulation of Multisim and LabviewJanet WaldeNo ratings yet

- Ijireeice 2021 9711Document4 pagesIjireeice 2021 9711Rohan J EEE-2019-23No ratings yet

- Automation of VFD Based Sugarcane Crusher With PLC and SCADA ControlDocument6 pagesAutomation of VFD Based Sugarcane Crusher With PLC and SCADA ControlratnikleoNo ratings yet

- Iarjset 2021 8714Document4 pagesIarjset 2021 8714Amit KumarNo ratings yet

- Boiler AutomationDocument5 pagesBoiler Automatione-park research centreNo ratings yet

- Electricity Theft Detection and High Alert SMS System Using GSM Module-IJAERDV04I0865297Document5 pagesElectricity Theft Detection and High Alert SMS System Using GSM Module-IJAERDV04I0865297Arji BosnaNo ratings yet

- Electrical Current Signature Analysis: September 2018Document7 pagesElectrical Current Signature Analysis: September 2018jide.atolagbe3737No ratings yet

- Auto Tuning High Current Motor Control Unit, Journal ArticleDocument9 pagesAuto Tuning High Current Motor Control Unit, Journal ArticleShreyas BorseNo ratings yet

- Arduino Based Wireless Robotic Hand Using ZigbeeDocument8 pagesArduino Based Wireless Robotic Hand Using Zigbeeshaik nayeemNo ratings yet

- Engine Battery Super Charging From Exhaust GasDocument4 pagesEngine Battery Super Charging From Exhaust GasIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Patient Health Monitoring System Using GSMDocument5 pagesPatient Health Monitoring System Using GSMJames KazoobaNo ratings yet

- Iot Technology Based Underground Cable Fault Distance Detection System Using Atmega328P MicrocontrollerDocument11 pagesIot Technology Based Underground Cable Fault Distance Detection System Using Atmega328P MicrocontrollerLaxmi jambagiNo ratings yet

- A New Active Power Factor Correction Controller Using Boost ConverterDocument8 pagesA New Active Power Factor Correction Controller Using Boost ConverterLeonard Young-Khaled SendeNo ratings yet

- Tap Changing in Parallel Operated Transformers Using SCADADocument5 pagesTap Changing in Parallel Operated Transformers Using SCADAswarupkumarnayakNo ratings yet

- Auto Selection of Any Available Phase, in 3 Phase Supply System-Ijaerdv05i10703Document9 pagesAuto Selection of Any Available Phase, in 3 Phase Supply System-Ijaerdv05i10703Bøññïe Ådë Cöloñêl100% (1)

- Auto Selection of Any Available Phase, in 3 Phase Supply SystemDocument9 pagesAuto Selection of Any Available Phase, in 3 Phase Supply Systemmosub fudolNo ratings yet

- Analysis of Fault in Centrifugal Pump Using Voltage Current AnalysisDocument3 pagesAnalysis of Fault in Centrifugal Pump Using Voltage Current AnalysisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Aurdino Based Automatic Plant Watering System With Internet of ThingsDocument8 pagesAurdino Based Automatic Plant Watering System With Internet of ThingsAanam FathimaNo ratings yet

- Speed Monitoring and Controlling of Motor Using Internet of Things (Iot) Enhanced With Wi-FiDocument6 pagesSpeed Monitoring and Controlling of Motor Using Internet of Things (Iot) Enhanced With Wi-FiDarshanNo ratings yet

- Monitor and control induction motor using IoTDocument28 pagesMonitor and control induction motor using IoTSatyanarayana GurramNo ratings yet

- Article 15Document7 pagesArticle 15vigneshNo ratings yet

- "Speed Control of DC Motor by Using PWM": IjarcceDocument3 pages"Speed Control of DC Motor by Using PWM": IjarcceRishi GaddaNo ratings yet

- Internet of Things Based Real Time Transformer Health Monitoring SystemDocument4 pagesInternet of Things Based Real Time Transformer Health Monitoring SystemDhaneeshNo ratings yet

- Speed Control of Single Phase Induction Motor Using Infrared Receiver ModuleDocument6 pagesSpeed Control of Single Phase Induction Motor Using Infrared Receiver ModuleSanjay ShelarNo ratings yet

- Multichannel Data Acquisition SystemDocument11 pagesMultichannel Data Acquisition SystemIJRASETPublicationsNo ratings yet

- Automation and Design of Real-Time ControllersDocument6 pagesAutomation and Design of Real-Time ControllersAfshaNo ratings yet

- Effects of oxalic acid and seawater on xylose and arabinose dehydration kinetics (40 charactersDocument10 pagesEffects of oxalic acid and seawater on xylose and arabinose dehydration kinetics (40 charactersAfshaNo ratings yet

- Hardwarex: R.J. Lesuer, K.L. Osgood, K.E. Stelnicki, J.L. MendezDocument14 pagesHardwarex: R.J. Lesuer, K.L. Osgood, K.E. Stelnicki, J.L. MendezAfshaNo ratings yet

- Hardwarex: R.J. Lesuer, K.L. Osgood, K.E. Stelnicki, J.L. MendezDocument14 pagesHardwarex: R.J. Lesuer, K.L. Osgood, K.E. Stelnicki, J.L. MendezAfshaNo ratings yet

- 1678 4383 Bjce 35 02 0631Document10 pages1678 4383 Bjce 35 02 0631AfshaNo ratings yet

- Jung2015 (B)Document6 pagesJung2015 (B)AfshaNo ratings yet

- Design of A Multi-Model Observer-Based Estimator For Fault Detection and Isolation (Fdi) Strategy: Application To A Chemical ReactorDocument12 pagesDesign of A Multi-Model Observer-Based Estimator For Fault Detection and Isolation (Fdi) Strategy: Application To A Chemical ReactorAfshaNo ratings yet

- A Low-Tech Bioreactor System For The Enrichment and Production of Ureolytic MicrobesDocument8 pagesA Low-Tech Bioreactor System For The Enrichment and Production of Ureolytic MicrobesAfshaNo ratings yet

- Arduino and Labview Based Control For Efficient Drive of Cooling Fan SystemDocument11 pagesArduino and Labview Based Control For Efficient Drive of Cooling Fan SystemAfshaNo ratings yet

- Control System Laboratory With Arduino: 2018 International Symposium On Computer, Consumer and Control (IS3C)Document4 pagesControl System Laboratory With Arduino: 2018 International Symposium On Computer, Consumer and Control (IS3C)AfshaNo ratings yet

- Innovative Sodium Fast Reactors Control Rod Design: October 2018Document11 pagesInnovative Sodium Fast Reactors Control Rod Design: October 2018AfshaNo ratings yet

- A Real-Time Monitoring System Controller For Medical Tissue Engineering BioreactorsDocument2 pagesA Real-Time Monitoring System Controller For Medical Tissue Engineering BioreactorsAfshaNo ratings yet

- A Controllable and Integrated Pump-Enabled Microfluidic Chip and Its Application in Droplets GeneratingDocument8 pagesA Controllable and Integrated Pump-Enabled Microfluidic Chip and Its Application in Droplets GeneratingAfshaNo ratings yet

- Low-Budget 3d-Printed Equipment For Continuous Flow ReactionsDocument9 pagesLow-Budget 3d-Printed Equipment For Continuous Flow ReactionsAfshaNo ratings yet

- A Comparative Analysis of GA-PID, Fuzzy and PID For Water Bath SystemDocument6 pagesA Comparative Analysis of GA-PID, Fuzzy and PID For Water Bath SystemAfshaNo ratings yet

- Characterization of Syringe-Pump-Driven Induced Pressure Fluctuations in Elastic MicrochannelsDocument7 pagesCharacterization of Syringe-Pump-Driven Induced Pressure Fluctuations in Elastic MicrochannelsAfshaNo ratings yet

- New Prototype of Photovoltaic Solar Tracker BasedDocument13 pagesNew Prototype of Photovoltaic Solar Tracker BasedAfshaNo ratings yet

- Labview (Programming and Interfacing)Document3 pagesLabview (Programming and Interfacing)AfshaNo ratings yet

- Hardwarex: R.J. Lesuer, K.L. Osgood, K.E. Stelnicki, J.L. MendezDocument14 pagesHardwarex: R.J. Lesuer, K.L. Osgood, K.E. Stelnicki, J.L. MendezAfshaNo ratings yet

- 2211068215594770Document11 pages2211068215594770AfshaNo ratings yet

- Bombas de Presión de Inyección de Bajo Costo Con Control de Retroalimentación para Aplicaciones de MicrofluidosDocument13 pagesBombas de Presión de Inyección de Bajo Costo Con Control de Retroalimentación para Aplicaciones de MicrofluidosNelson AmazoNo ratings yet

- A Control Scheme For Variable-SpeedDocument19 pagesA Control Scheme For Variable-SpeedAfshaNo ratings yet

- Emerging Droplet Micro Uidics: Chemical Reviews May 2017Document78 pagesEmerging Droplet Micro Uidics: Chemical Reviews May 2017AfshaNo ratings yet

- Calibration of An Ultrasonic Flow Meter For Hot Water PDFDocument8 pagesCalibration of An Ultrasonic Flow Meter For Hot Water PDFMalouk CheniouniNo ratings yet

- Auctioneering Temperature Control Using Labview: AbstractDocument3 pagesAuctioneering Temperature Control Using Labview: AbstractAfshaNo ratings yet

- Medical Engineering and Physics: S. Drost, B.J. de Kruif, D. NewportDocument5 pagesMedical Engineering and Physics: S. Drost, B.J. de Kruif, D. NewportAfshaNo ratings yet

- Development of A Sensitive Induction-BasedDocument7 pagesDevelopment of A Sensitive Induction-BasedAfshaNo ratings yet

- Sensors: A Fog Computing and Cloudlet Based Augmented Reality System For The Industry 4.0 ShipyardDocument18 pagesSensors: A Fog Computing and Cloudlet Based Augmented Reality System For The Industry 4.0 ShipyardAfshaNo ratings yet

- PT. LOTTE IndonesiaDocument10 pagesPT. LOTTE IndonesiaAfshaNo ratings yet

- Yaesu FT 80C Service ManualDocument80 pagesYaesu FT 80C Service ManualRobert/YG2AKR82% (11)

- Multiturn Solid Shaft Encoder: 1 M4 Depth 6 MMDocument2 pagesMultiturn Solid Shaft Encoder: 1 M4 Depth 6 MMSoha EzzaldenNo ratings yet

- Introduction To Analog Design: 1-1 Ching-Yuan Yang / EE, NCHU Analog-Circuit DesignDocument3 pagesIntroduction To Analog Design: 1-1 Ching-Yuan Yang / EE, NCHU Analog-Circuit DesignDeepa YagainNo ratings yet

- Available IC List 03-11-2019Document18 pagesAvailable IC List 03-11-2019R. R. ArivazhaganNo ratings yet

- Installation, Operation & Maintenance Instructions: 1100°C - 1300°C Chamber Furnaces Types CWF, BWF & RWFDocument16 pagesInstallation, Operation & Maintenance Instructions: 1100°C - 1300°C Chamber Furnaces Types CWF, BWF & RWFdev-nullNo ratings yet

- Ge Packaged Power, L.P.: Worksheet, Control SystemDocument3 pagesGe Packaged Power, L.P.: Worksheet, Control Systemabhaymehta67100% (1)

- Manual Power MeterDocument109 pagesManual Power Meteremed produtos médicosNo ratings yet

- Type Test Certificate for 145kV SF6 Circuit BreakerDocument143 pagesType Test Certificate for 145kV SF6 Circuit BreakerNavaneeth NagarajanNo ratings yet

- Roshan Kumar Yadav - EeDocument1 pageRoshan Kumar Yadav - EeBHARAT TANWARNo ratings yet

- Hypercharger 225 Hypercharger 300: Key FeaturesDocument5 pagesHypercharger 225 Hypercharger 300: Key FeaturesVlad BuracNo ratings yet

- Manual Onkyo - Drc500Jp-SmDocument56 pagesManual Onkyo - Drc500Jp-SmAugus BeCaNo ratings yet

- Concept of Subtransient, Transient & Steady State - Electrical ConceptsDocument7 pagesConcept of Subtransient, Transient & Steady State - Electrical Conceptsajitkalel1986No ratings yet

- ROP Lab ManualDocument6 pagesROP Lab ManualMr. Jeetendra P. Dhamone DYPITNo ratings yet

- Circuitos para Ventilação E Anestesia (Compatíveis Dräger) : 006386 - Circuito Paciente Anestesia Sil Ad Dreno DGRDocument7 pagesCircuitos para Ventilação E Anestesia (Compatíveis Dräger) : 006386 - Circuito Paciente Anestesia Sil Ad Dreno DGRRobson De Campos SantosNo ratings yet

- 6 National CatalogDocument10 pages6 National CatalogHalfsharkNo ratings yet

- Al Lab Manual-2023Document73 pagesAl Lab Manual-2023wisari7978No ratings yet

- DSE BC2410Ei Installation InstructionsDocument2 pagesDSE BC2410Ei Installation InstructionsthaiNo ratings yet

- Development of A Motor Test Bench To Measure Electrical Mechanical ParametersDocument4 pagesDevelopment of A Motor Test Bench To Measure Electrical Mechanical ParametersBalan SelvanNo ratings yet

- 01620EU 05MicrochipPetFeeder2UserManual DigitalDocument142 pages01620EU 05MicrochipPetFeeder2UserManual DigitalNadir GRNo ratings yet

- The 8284a Clock GeneratorDocument32 pagesThe 8284a Clock GeneratorBETHWEL KIPROTICH100% (1)

- Introduction and NoiseDocument65 pagesIntroduction and NoiseBAHARUDIN BURAHNo ratings yet

- Beetronics Manual WEB Version 2Document68 pagesBeetronics Manual WEB Version 2Tulia Concepcion PerezNo ratings yet

- Effective Load Control With Time Using Fuzzy LogicDocument11 pagesEffective Load Control With Time Using Fuzzy LogicK.YogeshNo ratings yet

- Variation Aware Custom Ic Design PVT Corners Monte CarloDocument6 pagesVariation Aware Custom Ic Design PVT Corners Monte CarloSyed Murtuza HasnainNo ratings yet

- AIR-Intelligence Manual - 33-308100-003 - ASD-640Document84 pagesAIR-Intelligence Manual - 33-308100-003 - ASD-640Andrew PanjaitanNo ratings yet

- Extension Cord Safety TipsDocument2 pagesExtension Cord Safety TipsHtoo Htoo KyawNo ratings yet

- Atp 11A: Site Id Site Name CircleDocument18 pagesAtp 11A: Site Id Site Name CircleVineet KumarNo ratings yet

- PIC16F873 Flash MicrocontrollerDocument4 pagesPIC16F873 Flash MicrocontrollerAswathy CjNo ratings yet

- Product Specification of SLPBA642124 3.7V 6800mah 15C V1Document9 pagesProduct Specification of SLPBA642124 3.7V 6800mah 15C V1David Matthew Kurniawan BEngNo ratings yet

- PREPRINTNO: 951 (D-3) : Roy F. Allison Allison Acoustics Inc. Wayland, MassachusettsDocument16 pagesPREPRINTNO: 951 (D-3) : Roy F. Allison Allison Acoustics Inc. Wayland, Massachusettsdonald141No ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Learning Robotics, with Robotics, by Robotics: Educational RoboticsFrom EverandLearning Robotics, with Robotics, by Robotics: Educational RoboticsNo ratings yet

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- RoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingFrom EverandRoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingNo ratings yet