Professional Documents

Culture Documents

A Balanced Approach: by Ketan Varia

A Balanced Approach: by Ketan Varia

Uploaded by

Amber PreetOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Balanced Approach: by Ketan Varia

A Balanced Approach: by Ketan Varia

Uploaded by

Amber PreetCopyright:

Available Formats

040-043_ME_AprMay05_EN 8/4/05 10:25 am Page 40

A Balanced

Approach By Ketan Varia

www.iee.org/manufacturing

40 IEE Manufacturing Engineer | April/May 2005

040-043_ME_AprMay05_EN 8/4/05 10:26 am Page 41

Special report: Manufacturing management

THE BALANCED SCORECARD, OFTEN CONSIDERED THE DOMAIN OF THE BOARD, IS A

CRUCIAL METHODOLOGY FOR MANUFACTURING MANAGERS TO IDENTIFY BOTTLENECKS AND

EXCEPTIONS, AND SOMETHING AGAINST WHICH IMPROVEMENT TOOLS CAN BE TARGETED

G

overnment driven ‘top down’ targets,

continue to attract criticism from people

at the coalface, particularly in the

Financial Customer

education and health fields. The

announcement of overstated results

recently in the private sector – such as oil

reserves – shows us that target setting is rife, with

spectacular consequences following when reality hits. Is

there an alternative to business performance improvement

Process People

from the head office target driven approach to a process

that actually drives improvement?

During the early part of the 20th century, performance

focus was primarily result driven and this did not matter

as huge growth and demand dictated financial results, not

the effectiveness of underlying process. However, with the Fig 1: The concept of balance

maturity of manufacturing and commodity markets,

internal processes and organisation culture became a

significant lever to financial outcomes. The concept of the Measurement Improved Reduced work Increased

of velocity velocity in progress cash

Balanced scorecard was first introduced by Robert Kaplan

in 1992 in the Harvard Business Review, in which the

premise was that a business should not only measure its Average Reduced

Reduced Reduced

batch batch Less scrap

financial output but also other areas of performance space costs

size size

(process, customer and people). Furthermore it should give

these areas the same focus as financial performance.

Technical Improved Improved

Kaplan showed that these measures are interdependent quality of Reduced

competency competency costs

output

and, without a balance on all areas, world-class sustainable

performance cannot be created. Thus, the balanced

Less

scorecard concept is a unique way of measuring dissatisfied Increased

customer revenue

performance – a visual, sustainable and accountable

process, managed locally – yet with a direct impact on the

bottom line. This approach is different from traditional Fig 2: Process/Output diagram

target setting that often focuses on pure output rather than

on improving and sustaining the underlying process. performance improvement and will form the basis of

In a process/output diagram for a discrete creating scorecards.

manufacturing company, measurement and improvement Scorecards themselves can be created for a look and feel

of velocity (ratio of value add time to lead time), results in that suits the business. The most important things are that

increased cash and reduced costs as subsequent output they should be visual and straightforward to understand. I

results (fig 2). A process/output diagram of this nature like to think that the scorecard should pass the ‘two minute

helps business units understand the underlying drivers to test’ – a casual observer should be able to pick up the key

message from the scorecard in this time. A typical scorecard

is illustrated in fig 3 and, as can be seen, complaints in

‘customers’ and absenteeism in ‘people’ vividly stand out,

‘‘ The premise was that a business

should not only measure its

financial output but other areas

of performance

with the process area all on ‘green’. Attached to the

scorecard would be actions from meetings and detailed

history of measures giving further information as required.

The period that a scorecard is refreshed is very dependent

on the business unit processes, in my experience a monthly

’’ update is one that works well in almost all ➔

IEE Manufacturing Engineer | April/May 2005 41

040-043_ME_AprMay05_EN 8/4/05 10:26 am Page 42

‘‘ ...Most pernicious of all, targets are based on the illusion that the centre

can drive change... The opposite is true. Improvements in...services will

generally come from individuals and teams finding better ways to work

organisations, although a greater frequency could be

’’

The Economist (editorial) April 2001

are involved in the day to day processes and measures, that

applicable to intensive service industries. The scorecard need control and improvement. It is this cross-functional

should be located strategically for each business unit (the team that brainstorms and debates the balanced measures,

foyer for example) and I have seen the potential takes ownership and agrees its own considered targets.

opportunities this generates for interesting discussion Targets should be based on the ‘capability of the process’

during customer, supplier and head office visits. and also ‘the voice of the customer’ – and, more

importantly, measurement of these values trigger process

COMPARING CARDS improvement, and not blame. This is clear distinction from

One interesting aspect of local scorecards is that these, arbitrary calculated targets, which occur frequently in all

created in different divisions of a business, can be linked sectors of industry, to one that relates to the local execution

to a head office scorecard. A scorecard for the head office and is defined by the local customer. Hence this way of

will of course look much different than one that exists at target setting reduces the risk of sub optimisation, where

the coalface – however the head office scorecard should focus on meeting an arbitrary set target to the detriment

have a direct process/output link to local scorecards. This of another measure resulted in sub optimisation of the

integrated approach can help head office review the effect whole process. At the outset business managers must buy

of improvement on business outcomes and strategies. A in to the concept of the scorecard as, without this,

huge benefit of this approach is that irrelevant measures sustainability is not possible. One useful way of doing this

are eliminated, freeing management across all units and is to give the unit manger the overall accountability for

head office to focus on what really matters to the business. implementation, together with the support framework to

So far, I have explained the concept of the scorecard, make it happen. Indeed, thorough consideration needs to

be made to what Key

Performance Measures

already exist, whether

Customer People they are relevant, who

On

ism

tim

ntee

collects data and the use

e an

Abse

Cu

s

er of measures. Some

d in

st

av

om

Le

er

output driven measures

full

re

fe

deli

rr

may actually need to

al

Next steps from

s

ver

Review Meeeting Custom etence

er com Comp continue to exist, due to

y

plaints Detail measures

Action Who spreadsheet

Xxx ffff e

legal or regulatory

chin

Fff ffff e ma Unit

S e t u p tim

b l y s so

ld requirements. On a

em

a ss recent visit to a client I

of

e

Paym

tim

M

ar discovered that defects

ad gi

n

Le

ent o

were measured against

%

n ti

p

Process Performance the overall percentage of

Scra

me

scrap, and was set by

corporate standards. No

consideration was given

to what the customer’s

Fig 3: An example of a scorecard that could be used by a discrete manufacturing process

view was of the process,

www.iee.org/manufacturing

which, on the face of it, seems relatively straightforward what was acceptable yield to the customer for each stock

to execute. However, the implementation of the scorecard keeping unit and the actual capability of the existing

(fig 4) can often be more challenging than execution of the process or machinery. The consequence was that local

scorecard itself. It is important that the implementation management played a numbers game, hiding the true scrap

approach should be focused around a team of people who and underlying problems via extra inspection, and clever

42 IEE Manufacturing Engineer | April/May 2005

040-043_ME_AprMay05_EN 8/4/05 10:27 am Page 43

Special report: Manufacturing management

massaging of numbers. The amount of overall waste these A client of mine recently spent a full day reviewing

games generate is still frighteningly visible in many performance, and managed to cover less then 20% of

companies. agenda; classic paralysis by analysis and a resulting

Enhancing the scorecard occurs during a meeting with blame culture. Following the implementation of the

key stakeholders, consider inviting customer and suppliers scorecard the meeting was remodelled as a two-hour

of the processes, where the work done to date is presented. monthly meeting focusing only on red and amber status

The stakeholders present will be asked to take full measures with an emphasis on improvement teams to

accountability of agreeing measures, targets, accountability tackle underlying problems and report back on results.

and improvement. The measures agreed This freed up a huge amount of management time,

so far go through

validation and debate

– this is critical, as

people who are close

Assess Review

to the process (not a Brief Agree Agree Fig 4: Steps to

capability Enhance and

business on scorecard accountability

and customer scorecard sustain implementing a

performance manager) scorecard segments for measures

targets scorecard scorecard

will execute the

measurement. The

three measures of

process capability,

customer target and customer tolerances are the key empowered people and gave confidence to senior

indicators to assess the state of a balance scorecard segment. managers that a process existed for improvement.

Based on the results, the scorecard is lit red, green or amber.

A red status is for when customer tolerances are breached. WHAT IF IT ALL GOES RIGHT?

An amber status should be applied when the measurement I am often asked by clients what would happen once their

meets customer requirements but is statistically out of teams have resolved all their issues and all scorecard

control, thus the chances of future defects is high. Examples segments are green. If all improvements come into fruition

of amber status issues include recent rail crashes, where the and all measurements are lit at green, then there are

underlying processes were on amber and shown to be out of several options. Perhaps stabilised measures and

control...waiting for failure to occur. A green status is when sustainable processes can be replaced with others. It is

the process is in statistical control and within customer possible to reduce variability for specific activities to

tolerances. further reduce costs from the business. However, it is more

likely that customer requirements will become more

DIGESTING AND IMPROVING exacting or evolution of needs will throw up further

Reviewing and sustaining of the scorecard should take challenges in improvement for the long term of the

place in regular management team reviews, involving the balanced scorecard.

relevant people. The focus of attention should be on red The balanced scorecard approach is a relevant and

and amber measures only. Improvement action teams practical way of measuring and sustaining business

should be set up to look at underlying causes of the issue performance. However, it needs management involvement,

using problem solving tools such as process mapping and patience and facilitation to succeed. Companies as diverse

root cause analysis. In a facilitated framework these can as food retailers (Tesco) to engineering and maintenance

often yield surprisingly good results. Some of the issues (Network Rail) have successfully implemented their own

may just be down to the way measurements are being versions of such scorecards. If implemented correctly

carried out, or a small difference in process methods scorecards free up management time, stop ‘paralysis by

between workers that creates widely different results. It analysis’ and empower people who have the ability to make

is important that senior management shows support for, improvements. Overall this approach, like the approaches

and has patience with, this activity, as quick fixes never of lean, agility, ERP, kaizen, Six Sigma and so forth, should

prove sustainable. If there is a lack of history in a be used with discrimination, it is certainly not the answer

particular measure, it can take time to monitor the trends to all challenges faced in the business world. ■

and create targets. It is not important to have all the

measurement segments in place before launching the Ketan Varia is an independent consultant specialising in

scorecard – in fact, if 50% of measures are available, the process improvement and & previously worked for Ernst &

scorecard should be launched, with the outstanding Young Management Consulting. He runs a one day tailored

measures following in due course. workshop on the balanced scorecard.

IEE Manufacturing Engineer | April/May 2005 43

You might also like

- Management Accounting by CabreraDocument420 pagesManagement Accounting by CabreraRose Dee100% (7)

- Smart PDFDocument11 pagesSmart PDFSachin KambleNo ratings yet

- Balanced Scorecard For AIESECDocument15 pagesBalanced Scorecard For AIESECsandrolourencoNo ratings yet

- What Is The Balanced ScorecardDocument21 pagesWhat Is The Balanced ScorecardAndi Yanuar100% (1)

- SCM225 Project-StructureDocument3 pagesSCM225 Project-StructureAmber PreetNo ratings yet

- Banking System: Arturas BulavkoDocument48 pagesBanking System: Arturas BulavkoAmber PreetNo ratings yet

- Port Conceptual Development Cost EstimatesDocument6 pagesPort Conceptual Development Cost EstimatesklynchelleNo ratings yet

- Roteq Capability StatementDocument10 pagesRoteq Capability StatementRoozbeh PNo ratings yet

- Space Investment QuarterlyDocument8 pagesSpace Investment QuarterlyFederico MuiñaNo ratings yet

- A201 - 1 - Intro To Cost Accounting (Jamero 2022)Document23 pagesA201 - 1 - Intro To Cost Accounting (Jamero 2022)MARIAN DORIANo ratings yet

- Making It StickDocument12 pagesMaking It Sticktoya.incorporatedNo ratings yet

- Iia Whitepaper - Auditing Operational EffectivenessDocument6 pagesIia Whitepaper - Auditing Operational EffectivenessTendai ChirambaNo ratings yet

- Implementing Agile in An Agile Way-V2Document4 pagesImplementing Agile in An Agile Way-V2Charbel BoumitriNo ratings yet

- LO27 Epstein & Wisner 2011 Using A BSC To Implement SustainabilityDocument11 pagesLO27 Epstein & Wisner 2011 Using A BSC To Implement SustainabilitymiguelNo ratings yet

- The Balanced Scorecard-Measures That Drive PerformanceDocument9 pagesThe Balanced Scorecard-Measures That Drive Performancezeel patelNo ratings yet

- MS 3407 Balanced Scorecard and Responsibility AccountingDocument7 pagesMS 3407 Balanced Scorecard and Responsibility AccountingMonica GarciaNo ratings yet

- CPO Dashboards: Ensuring Alignment, Driving ExcellenceDocument8 pagesCPO Dashboards: Ensuring Alignment, Driving ExcellenceajNo ratings yet

- Lean Accounting: What'S It All About?Document8 pagesLean Accounting: What'S It All About?ANGELICANo ratings yet

- Module 1 Business Environment and Managerial AccountingDocument43 pagesModule 1 Business Environment and Managerial AccountingadeepcdmaNo ratings yet

- Address Each Below: Process Flow AnalysisDocument5 pagesAddress Each Below: Process Flow AnalysisHum NjorogeNo ratings yet

- Session 18 MGN600Document48 pagesSession 18 MGN600Manjit KaurNo ratings yet

- P I M A: Erformance Mprovement From Easurement To CtionDocument23 pagesP I M A: Erformance Mprovement From Easurement To Ctionsckajala7483No ratings yet

- The Role of Performance Appraisal System in Hindustan Unilever LimitedDocument5 pagesThe Role of Performance Appraisal System in Hindustan Unilever LimitedSaahi Seenivasan100% (1)

- M A: A O: Understanding of Financial StatementsDocument428 pagesM A: A O: Understanding of Financial StatementsErika Joyce Dela Cruz100% (1)

- CHAPTER-5 MGT Acct Basic FrameworkDocument82 pagesCHAPTER-5 MGT Acct Basic FrameworkSisay DeresaNo ratings yet

- Maximizing The Value of G and ADocument5 pagesMaximizing The Value of G and AjrmachareNo ratings yet

- Everest Group Exela Your Complete Guide To Accounts Payable Transformation PDFDocument19 pagesEverest Group Exela Your Complete Guide To Accounts Payable Transformation PDFlaks_maniNo ratings yet

- Finance Effectiveness Benchmark 2017Document72 pagesFinance Effectiveness Benchmark 2017aditya mishraNo ratings yet

- Chapter 1 - IntroductionDocument19 pagesChapter 1 - IntroductionGiang TrầnNo ratings yet

- AccountancyDocument67 pagesAccountancyDhananjay SinghNo ratings yet

- Topic # 1: Bench Marking: DefinationDocument9 pagesTopic # 1: Bench Marking: DefinationTalal Ahmed FarooquiNo ratings yet

- WP Operational Excellence in Manufacturing PDFDocument21 pagesWP Operational Excellence in Manufacturing PDFSudeshna BiswasNo ratings yet

- Total Marginal UtilityDocument30 pagesTotal Marginal UtilitychamithNo ratings yet

- Balanced Scorecard-Kaplan & Norton PDFDocument3 pagesBalanced Scorecard-Kaplan & Norton PDFRochelle Ciudad BaylonNo ratings yet

- 67539bos54275 cp1Document31 pages67539bos54275 cp1harshaNo ratings yet

- Lecture 18 MGNM571Document33 pagesLecture 18 MGNM571Devyansh GuptaNo ratings yet

- Optimized Financial Reporting in A Dynamic WorldDocument12 pagesOptimized Financial Reporting in A Dynamic Worldkalina hNo ratings yet

- Unit 8 Balanced Score Card in Retail Operations: StructureDocument21 pagesUnit 8 Balanced Score Card in Retail Operations: StructureAnika GuptaNo ratings yet

- Balanced Scorecard and Project ManagerDocument27 pagesBalanced Scorecard and Project ManagerRajat Mehta100% (1)

- Procurement PerformanceDocument4 pagesProcurement PerformanceJMSchultzNo ratings yet

- Impact of Employee Productivity Analysis On Service Quality Telecom IndustryDocument3 pagesImpact of Employee Productivity Analysis On Service Quality Telecom IndustryDr-Abhijit SinhaNo ratings yet

- Performance Measurement: From Philosophy To PracticeDocument12 pagesPerformance Measurement: From Philosophy To Practicededdy_irawan037601No ratings yet

- 2020-Coupa BSM Benchmark ReportDocument28 pages2020-Coupa BSM Benchmark ReportAngel Guirao NavarroNo ratings yet

- ARTIGO Lean AccountingDocument9 pagesARTIGO Lean AccountingAmanda LimaNo ratings yet

- Why BSCs FailDocument6 pagesWhy BSCs Failshepherd junior masasiNo ratings yet

- Business Process Reengineering (A Prerequisite For Process Model Design)Document31 pagesBusiness Process Reengineering (A Prerequisite For Process Model Design)Milind Gadhavi100% (1)

- 2003 Management-Control-SystemDocument11 pages2003 Management-Control-SystemMAHENDRA SHIVAJI DHENAKNo ratings yet

- Measuring The Cost of Quality For ManagementDocument12 pagesMeasuring The Cost of Quality For ManagementgaborinNo ratings yet

- CH 13Document40 pagesCH 13Ehab hobaNo ratings yet

- Chapter 4Document4 pagesChapter 4Mixx MineNo ratings yet

- Group 7 SCM Written Report 1Document19 pagesGroup 7 SCM Written Report 1Kriza CabilloNo ratings yet

- Rol de Compras en La Captura de Valor en Las CDSDocument28 pagesRol de Compras en La Captura de Valor en Las CDSCesar CondeNo ratings yet

- S T R A T e G I C M A N A G e M e N T A C C o U N T I N G (C - 2)Document4 pagesS T R A T e G I C M A N A G e M e N T A C C o U N T I N G (C - 2)Zubair AhmedNo ratings yet

- Budget Process2012Document5 pagesBudget Process2012Santiago Fernandez MorenoNo ratings yet

- TEI of Microsoft Dynamics 365 Business CentralDocument26 pagesTEI of Microsoft Dynamics 365 Business Centraljain0287ankitNo ratings yet

- Ch1 - Managerial Accounting and The Business EnvironmentDocument29 pagesCh1 - Managerial Accounting and The Business EnvironmentehtikNo ratings yet

- Cross 1988Document11 pagesCross 1988deltanueveNo ratings yet

- Management Accounting Solman Cabrera Management Accounting Solman Cabrera PDF FreeDocument421 pagesManagement Accounting Solman Cabrera Management Accounting Solman Cabrera PDF FreeROSEMARIE CRUZ100% (1)

- Objectivity in Performance Parameters Capsule 2Document24 pagesObjectivity in Performance Parameters Capsule 2MulusaNo ratings yet

- Coupa Benchmark 2019 PDFDocument49 pagesCoupa Benchmark 2019 PDFMiguelNo ratings yet

- Chapter 1 Introduction To Strategic Cost ManagementDocument27 pagesChapter 1 Introduction To Strategic Cost Managementmdgc100% (1)

- Balanced Scorecard LiveDocument6 pagesBalanced Scorecard LiveEscobedo Medina Willam PercyNo ratings yet

- Business Process Mapping: How to improve customer experience and increase profitability in a post-COVID worldFrom EverandBusiness Process Mapping: How to improve customer experience and increase profitability in a post-COVID worldNo ratings yet

- R&D Productivity: How to Target It. How to Measure It. Why It Matters.From EverandR&D Productivity: How to Target It. How to Measure It. Why It Matters.No ratings yet

- Innovating Business Processes for Profit: How to Run a Process Program for Business LeadersFrom EverandInnovating Business Processes for Profit: How to Run a Process Program for Business LeadersNo ratings yet

- GaganDocument9 pagesGaganAmber PreetNo ratings yet

- TI-Online Session Outline WK 7 007-1 MKDocument3 pagesTI-Online Session Outline WK 7 007-1 MKAmber PreetNo ratings yet

- Running Head: Leadership: Compare & Contrast Group Project Student Name: Unit Name: University Name: DateDocument17 pagesRunning Head: Leadership: Compare & Contrast Group Project Student Name: Unit Name: University Name: DateAmber PreetNo ratings yet

- Employee Motivation and Customer SatisfactionDocument40 pagesEmployee Motivation and Customer SatisfactionAmber PreetNo ratings yet

- Food OnlineDocument12 pagesFood OnlineAmber PreetNo ratings yet

- Module Assignment Cover Sheet Matriculation NumberDocument27 pagesModule Assignment Cover Sheet Matriculation NumberAmber PreetNo ratings yet

- Student DubaiDocument8 pagesStudent DubaiAmber PreetNo ratings yet

- QuestionsDocument4 pagesQuestionsAmber PreetNo ratings yet

- ERP Implementation Student Name: Unit Name: University Name: DateDocument14 pagesERP Implementation Student Name: Unit Name: University Name: DateAmber PreetNo ratings yet

- Data Warehousing Strategy Is Used To Enhance The Functionality ofDocument5 pagesData Warehousing Strategy Is Used To Enhance The Functionality ofAmber PreetNo ratings yet

- Law & Justice: Business and Corporate Law Student Name: Unit Name: University Name: DateDocument14 pagesLaw & Justice: Business and Corporate Law Student Name: Unit Name: University Name: DateAmber PreetNo ratings yet

- Topic: National Quality Stratergy: Student Name: Unit Code: University Name: DateDocument7 pagesTopic: National Quality Stratergy: Student Name: Unit Code: University Name: DateAmber PreetNo ratings yet

- Bibliographies/References: Barriers & Derivers of Innovation in Digital MediaDocument5 pagesBibliographies/References: Barriers & Derivers of Innovation in Digital MediaAmber PreetNo ratings yet

- HLTARO001 HLTAROO05 Student Assessment Booklet 1 1Document68 pagesHLTARO001 HLTAROO05 Student Assessment Booklet 1 1Amber PreetNo ratings yet

- XY Decision Matrix - Group Exercise 6th October 2020Document3 pagesXY Decision Matrix - Group Exercise 6th October 2020Amber PreetNo ratings yet

- Aromatherapy: HLT42015 - Certificate IV in Massage TherapyDocument12 pagesAromatherapy: HLT42015 - Certificate IV in Massage TherapyAmber PreetNo ratings yet

- Health and Safety Policy Statement PDFDocument6 pagesHealth and Safety Policy Statement PDFAmber PreetNo ratings yet

- BPP Coursework Cover Sheet: (Please Attach The Confirmation of Any Extension Received)Document19 pagesBPP Coursework Cover Sheet: (Please Attach The Confirmation of Any Extension Received)Amber PreetNo ratings yet

- Write A Scholarly Paper On One of The Following Topics: Collaborating With Families OR Collaborating With Professionals From Other DisciplinesDocument1 pageWrite A Scholarly Paper On One of The Following Topics: Collaborating With Families OR Collaborating With Professionals From Other DisciplinesAmber PreetNo ratings yet

- CrystallizationDocument43 pagesCrystallizationKathleen May Dayao0% (1)

- ISSUE: JUL 01/13 General IntroductionDocument31 pagesISSUE: JUL 01/13 General IntroductionAhrarNo ratings yet

- LiftingDocument2 pagesLiftingZed VFNo ratings yet

- 2019 Intl DesignDocument73 pages2019 Intl DesigniabhiuceNo ratings yet

- 2507 Super Duplex SSDocument3 pages2507 Super Duplex SSm_senthilNo ratings yet

- Maintenance Policy Optimization-Literature Review and Direction - 2015 PDFDocument21 pagesMaintenance Policy Optimization-Literature Review and Direction - 2015 PDFCristian GarciaNo ratings yet

- IDFCFIRSTBankstatement 10051513509Document7 pagesIDFCFIRSTBankstatement 10051513509Saurabh DugarNo ratings yet

- Computer Programmer SamplesDocument3 pagesComputer Programmer SamplesVandana SharanNo ratings yet

- R12.1.3: Understanding and Using HRMS Security in Oracle HRMS (Oracle Note ID 394083.1)Document9 pagesR12.1.3: Understanding and Using HRMS Security in Oracle HRMS (Oracle Note ID 394083.1)appsloaderNo ratings yet

- Rail Track Kinematic EnvelopDocument35 pagesRail Track Kinematic Envelopgerfreecalls100% (1)

- North Carolina Wing - Jun 2013Document19 pagesNorth Carolina Wing - Jun 2013CAP History LibraryNo ratings yet

- Simulation of Electric Arc Furnace Characteristics For Voltage Flicker Study Using MATLAB PDFDocument8 pagesSimulation of Electric Arc Furnace Characteristics For Voltage Flicker Study Using MATLAB PDFRamin Goudarzi100% (1)

- Global Sources - 2010 June - Home ProductsDocument212 pagesGlobal Sources - 2010 June - Home Productsdr_twiggyNo ratings yet

- L&T Realty: L&T Construction Godrej & Boyce Mfg. Co. Ltd. - MEP DeptDocument22 pagesL&T Realty: L&T Construction Godrej & Boyce Mfg. Co. Ltd. - MEP DeptrakeshamechNo ratings yet

- Brochure TTR 11-2013 - Rev3Document24 pagesBrochure TTR 11-2013 - Rev3Tamil SelvanNo ratings yet

- Chapter: 1 Introduction: 1.1 Project SummaryDocument35 pagesChapter: 1 Introduction: 1.1 Project SummaryAnand PatelNo ratings yet

- 20040923-What Is Control Chart - PpsDocument2 pages20040923-What Is Control Chart - PpsSanjay DhawasNo ratings yet

- Merni TrougaoDocument9 pagesMerni TrougaoNeven BausNo ratings yet

- Quotation: Airblast B.V. - P.O. Box 1075 - 1700 BB Heerhugowaard - The NetherlandsDocument2 pagesQuotation: Airblast B.V. - P.O. Box 1075 - 1700 BB Heerhugowaard - The Netherlandsmekhman mekhtyNo ratings yet

- PT BELT 96pp Cat121219 v01b LRDocument96 pagesPT BELT 96pp Cat121219 v01b LRCarla MendezNo ratings yet

- Open Access in GujaratDocument19 pagesOpen Access in GujaratJoshi DhvanitNo ratings yet

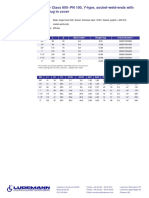

- Strainer Class 800 PN 100, Y-Type, Socket-Weld-Ends With Drain-Plug in CoverDocument2 pagesStrainer Class 800 PN 100, Y-Type, Socket-Weld-Ends With Drain-Plug in CoverFery FebryantoNo ratings yet

- 6200 Magnetic ArrayDocument8 pages6200 Magnetic ArrayRanaNo ratings yet

- EGL ProgrammingDocument4 pagesEGL ProgrammingSujith NairNo ratings yet

- Normas ISO Sobre Vibraciones Mecánicas en MaquinariaDocument2 pagesNormas ISO Sobre Vibraciones Mecánicas en MaquinariaAdrian Rodrigo Jofre AlvarezNo ratings yet

- SC476 HF2LDF (DXX) Di PDFDocument2 pagesSC476 HF2LDF (DXX) Di PDFmicrajacutNo ratings yet

- DFD Rules and GuidelinesDocument25 pagesDFD Rules and GuidelinesJohn Mayo BonganayNo ratings yet