Professional Documents

Culture Documents

TF-DG CALPAK New DRO

Uploaded by

Mariangel Rodríguez Gómez0 ratings0% found this document useful (0 votes)

24 views20 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views20 pagesTF-DG CALPAK New DRO

Uploaded by

Mariangel Rodríguez GómezCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 20

MIC TRAC MT-3000

TF-DG Depth Micrometer

Fixture

CAL-PAK Fixture Manual

TF-DG CAL-PAK Fixture Manual

© 2014 Gagemaker, LP

MIC TRAC™ MT-3000

2

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Setup

Materials Needed:

• MIC TRAC™ MT-3000 base unit and DRO • 5/32" hex wrench

• Depth micrometer • 50 in/lb torque wrench

• Depth gage fixture (TF-DG) and cap screws • Cloth

• Flat face anvil (TF-1F Block) cap screws and washers • ZEP I.D. Red cleaner

• Depth gage support (TF-SS Block), for rods 6” and up

1. Inspect the depth micrometer visually as

follows:

• Check for damage and excessive wear.

• Check for burrs, nicks and wear on measuring

faces.

• Check for damage to measuring rods, rod

seating surfaces, and rod reading surfaces.

• Inspect for slack in the spindle thread by

pushing the assembly in and out. Adjust to

remove excess play.

• Check for proper function of the friction or

ratchet stop and spindle locking device.

• Check for smoothness of travel by rotating the

thimble throughout the range.

• Ensure all rods are straight.

2. Clean both of the receiver pads and the

mounting surfaces of the flat face anvil using

the cloth and ZEP I.D. Red cleaner.

3. Locate the left flat face anvil. Place the

shoulder side of the anvil against the left

receiver pad shoulder.

MIC TRAC™ MT-3000

3

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Setup

4. While holding the anvil against the receiver pad

shoulder, insert the two cap screws with

washers into the holes on either side of the

fixture.

5. While applying pressure toward the receiver

pad shoulder, use a 5/32" hex wrench to

slightly tighten the screws.

6. Use a 50 in/lbs torque wrench to secure the

cap screws.

7. Locate the depth gage fixture and clean the

mounting surfaces with the cloth and ZEP I.D.

Red cleaner.

8. Place the depth gage fixture against the right

receiver pad shoulder with the thumb screws

facing to the right. Insert the cap screws.

MIC TRAC™ MT-3000

4

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Setup

9. While applying pressure toward the receiver

pad, use a 5/32" hex wrench to slightly tighten

the screws.

10. Use a 50 in/lb torque wrench to secure the cap

screws.

11. Clean the depth micrometer using the cloth and

ZEP I.D. Red cleaner.

MIC TRAC™ MT-3000

5

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Setup

12. Zero the depth micrometer on a flat surface

and lock the spindle.

13. Retract the thumb screws on the depth gage

fixture enough to fit the depth micrometer.

14. Mount the depth micrometer in the depth gage

fixture, aligning the depth micrometer’s rod with

the center of the flat face anvil.

MIC TRAC™ MT-3000

6

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Setup

15. Secure the depth micrometer by holding down

on the base and tightening the thumb knob on

each side of the depth gage fixture.

16. Turn the coarse adjust knob counterclockwise

until the depth micrometer barely touches the

flat face anvil.

17. Apply slight pressure until the in the

display lights up. The display will read 0.00000

and the gaging force will be preset to 2.0 lbs of

force.

MIC TRAC™ MT-3000

7

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

If using a computer with

Calibration the MT-3000, go to page 9.

Materials Needed:

• MIC TRAC™ MT-3000 base unit and DRO • 5/32" hex wrench

• Depth Micrometer • Lightweight gage oil

• Gage Calibration Record •

1. Turn the fine adjust knob clockwise to bring the

depth micrometer face in contact with the flat

face anvil.

2. Verify that the readout on the DRO displays

0.00000.

3. Loosen the coarse adjust lock and turn the

coarse adjust knob clockwise to slide the

movable carriage to the right.

4. Adjust the depth micrometer to the first

calibration value.

Note: If you pass the calibration value, turn the

spindle back and approach the value again,

from the same direction. This practice will

increase the accuracy of the calibration.

MIC TRAC™ MT-3000

8

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Calibration

5. Turn the coarse adjust knob counterclockwise

until the depth micrometer rod barely touches

the flat face anvil.

6. Secure the coarse adjust lock.

7. Turn the fine adjust knob clockwise until the

in the display lights up. If you have a

Seiko Printer attached to your MIC TRAC™ a

permanent record of the measurement prints.

8. Record any deviations on the Gage Calibration

Record or in-house calibration report. Continue

with remaining measurements for the first

depth rod.

Note: It is recommended that depth rods 6” and

longer be supported during calibration.

9. Locate and mount the TF-SS support. With the

thumbscrew facing forward, slide the support

over the flat face anvil.

10. Remove the depth rod from the depth

micrometer and insert the next depth rod.

Adjust the height of the depth gage support to

hold the end of the depth rod, so it does not

bend during calibration. Tighten the thumb

screw.

MIC TRAC™ MT-3000

9

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Calibration

11. Adjust the height of the depth gage support to

hold the end of the depth rod, so it does not

bend during calibration. Tighten the thumb

screw.

12. Turn the coarse adjust knob counterclockwise

until the depth micrometer rod barely touches

the flat face anvil. Secure the coarse adjust

lock.

13.

14. Continue turning the fine adjust knob until the

in the axis display lights up.

15. Record any deviations on the Gage Calibration

Record or in-house calibration report.

16. Continue with the same calibration process for

all remaining depth rods.

17. Remove the depth micrometer and continue

with the same calibration process for the next

depth micrometer.

18. After calibrating all depth micrometers, be sure

to remove the depth gage fixture and flat face

anvil from the MT-3000. Oil the fixture and anvil

and return them to the storage case.

MIC TRAC™ MT-3000

10

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

\

Calibration If using a computer with

the MT-3000, begin here.

Materials Needed:

• MIC TRAC™ MT-3000 base unit • Depth Micrometer

• Computer • 5/32" hex wrench

• CERTIFI™ software • Lightweight gage oil

• MT-4-USB Digital Data Acquisition Card • Brother P-Touch Label Printer (optional)

1. Start Certifi by double clicking the Certifi icon.

CERTIFI Icon

2. Click the New Calibration Report icon.

New Report Icon

3. With the cursor in the Gage Template field,

press the Enter key.

4. Highlight the Depth Micrometer line and click

on the OK button.

MIC TRAC™ MT-3000

11

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Calibration

5. Complete the following Client information:

• Company name and address.

• OEM #

• Contact name.

• PO/Account - purchase order or account

number.

• Calibration Date - automatically displays,

but can be changed by typing over the

displayed date.

• Print #

6. Enter the following information about the gage

you are calibrating:

• Serial Number

• Location

• Gage Manufacturer

• Model

• Description

7. You may change the tolerances for the caliper

if you wish.

8. You can enter additional master values by right

clicking your mouse over an existing master

value. Select Insert to insert a new line. Then

type in the new master value in that line.

MIC TRAC™ MT-3000

12

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Calibration

9. Click on the CERTIFI Monitor icon to open the

CERTIFI Monitor Window.

10. Choose the “Y” axis from the pull down box.

11. Bring the MIC TRAC™ jaws together and click

the Zero button twice.

12. Turn the X axis adjust knob clockwise and pull

out.

13. Turn the Y axis adjust knob counterclockwise

until the depth micrometer contacts the flat face

anvil.

MIC TRAC™ MT-3000

13

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Calibration

14. Enter the first measurement in the Measured

column as follows:

• Continue turning the Y axis adjust knob

until the X axis moves approximately ½

inch. Secure Locks 1 and 2.

• Click the Send to Table bar.

CERTIFI™ records the value and displays a

green box in the Pass/Fail column if the value

is within tolerance. A red box displays if the

value is not within tolerance. The Deviation

column shows the deviation of the measured

value from the master value.

15. Adjust the depth micrometer to the first

calibration value.

Note: If you pass the calibration value, turn the

spindle back and approach the value again,

from the same direction. This practice will

increase the accuracy of the calibration.

16. Turn the Y axis adjust knob counterclockwise

until the depth micrometer rod contacts the flat

face anvil.

MIC TRAC™ MT-3000

14

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Calibration

17. Enter the gage measurements in the Measured

column as follows:

• Continue turning the Y axis adjust knob

until the X axis moves approximately ½

inch. Secure Locks 1 and 2.

• Click the Add Value button.

18. Then, using each master value, continue

measuring the depth micrometer until the

values for the first depth rod are recorded in

CERTIFI™.

19. Loosen Lock 1 and 2 and turn the Y axis adjust

knob clockwise to slide the Y axis to the right.

Note: It is recommended that depth rods 6” and

longer be supported during calibration.

20. Locate the depth gage support. With the

thumbscrew facing forward, slide the support

over the left flat face anvil.

21. Remove the depth rod from the depth

micrometer and insert the next depth rod.

MIC TRAC™ MT-3000

15

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Calibration

22. Adjust the height of the depth gage support to

hold the end of the depth rod, so it does not

bend during calibration. Tighten the thumb

screw.

23. Turn the Y axis adjust knob counterclockwise

until the depth micrometer rod touches the flat

face anvil.

24. Enter the gage measurement for the depth rod

in the Measured column as follows:

• Continue turning the Y axis adjust knob

until the X axis moves approximately ½

inch. Secure Locks 1 and 2.

• Click the Add Value button.

• Continue calibrating the remaining depth

rods as in the previous five steps.

25. Change the Next Calibration Date, if

necessary, by typing over the displayed date.

MIC TRAC™ MT-3000

16

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Calibration

26. Enter NIST information as necessary. With the

cursor in the single box press the Enter key to

bring up a list of current NIST information. For

new NIST information select Edit from the

menu and press the Preferences box. Select

the NIST tab to enter new information.

27. Click the Save button.

Note: CERTIFI™ automatically assigns a filename

to each calibration. DO NOT change the

filename to avoid problems with the

CERTIFI database.

28. When the confirm window displays, click the

Yes button if you want to print the calibration

report.

MIC TRAC™ MT-3000

17

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

Calibration

Note: If you have a Brother P-Touch Label Printer

for printing calibration stickers, the Confirm window

for printing a calibration tag displays.

29. Click the Yes button to print the calibration tag.

Affix the Calibration Tag to the caliper.

30. Continue with the same calibration process for

the next caliper.

31. After calibrating all depth micrometers, be sure

to remove the depth gage fixture and flat face

anvil from the MT-3000. Oil the fixture and anvil

and return them to the storage case.

MIC TRAC™ MT-3000

18

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

TF-DG CAL-PAK Fixture Manual

NOTES:

MIC TRAC™ MT-3000

19

2014

2013Gagemaker,

Gagemaker,LP.

LP

RCDMMT300010-13

RCCMT30009-99

Gagemaker, LP, P.O. Box 87709, Houston, Texas 77287-7709

712 East Southmore Ave., Pasadena, Texas 77502

Phone: 713-472-7360

Fax: 713-472-7241

Web site: www.gagemaker.com

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Math 7 - Summative Test Q2Document5 pagesMath 7 - Summative Test Q2Brian Mary100% (5)

- Real-Time Monitoring Security System Integrated With Raspberry Pi and E-Mail Communication LinkDocument12 pagesReal-Time Monitoring Security System Integrated With Raspberry Pi and E-Mail Communication LinkIJRASETPublicationsNo ratings yet

- Unit 3 SolvedDocument13 pagesUnit 3 SolvedSHAHUL HAMEED.SNo ratings yet

- TP-20 For Protective RelaysDocument20 pagesTP-20 For Protective RelayssathiyaseelanNo ratings yet

- Increase Conversions With Performance PlannerDocument8 pagesIncrease Conversions With Performance PlannerMujNo ratings yet

- DBDocument60 pagesDBsd4tsfNo ratings yet

- Alma Lasers Accent Prime Service ManualDocument164 pagesAlma Lasers Accent Prime Service Manualcankutayhotmail.com100% (1)

- CCNA Routing and Switching 200 125 Official Cert Guide Library PDF DownloadDocument5 pagesCCNA Routing and Switching 200 125 Official Cert Guide Library PDF Downloadhusny perketansan50% (4)

- ROUNDTEST RA-2100 SERIES - Mitutoyo America CorporationDocument12 pagesROUNDTEST RA-2100 SERIES - Mitutoyo America CorporationMariangel Rodríguez Gómez100% (1)

- ABS Coolant Proof Digimatic Indicator - Mitutoyo America CorporationDocument6 pagesABS Coolant Proof Digimatic Indicator - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- Mitutoyo New Products Guide - Mitutoyo America CorporationDocument20 pagesMitutoyo New Products Guide - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- QV APex SeRieS - Mitutoyo America CorporationDocument19 pagesQV APex SeRieS - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- CNC Vision Measuring System - Precision Tool DistributorsDocument24 pagesCNC Vision Measuring System - Precision Tool DistributorsMariangel Rodríguez GómezNo ratings yet

- BX-1000 BXG-1000 Operation Manual0 PDFDocument36 pagesBX-1000 BXG-1000 Operation Manual0 PDFMariangel Rodríguez GómezNo ratings yet

- TF-CA CALPAK New DRODocument16 pagesTF-CA CALPAK New DROMariangel Rodríguez GómezNo ratings yet

- TF-LG3 LG5003Document12 pagesTF-LG3 LG5003Mariangel Rodríguez GómezNo ratings yet

- Practice Problems For Hardware EngineersDocument177 pagesPractice Problems For Hardware Engineersdon benenoNo ratings yet

- Dynamic Pricing SoftwareDocument12 pagesDynamic Pricing SoftwaremuhammadNo ratings yet

- Raspberry Pi Based OscilloscopeDocument5 pagesRaspberry Pi Based OscilloscopeTSA32 SYBSCIT Rasika TambeNo ratings yet

- Skybox Partner Training - PersonasDocument9 pagesSkybox Partner Training - PersonasPrashant BiswasNo ratings yet

- Los Angeles Abrasion Test AASHTO 96Document4 pagesLos Angeles Abrasion Test AASHTO 96Lava HimawanNo ratings yet

- SkyrimDocument4 pagesSkyrimhusni_312No ratings yet

- Electrical 8 Years Bits PDFDocument65 pagesElectrical 8 Years Bits PDFSasi Kanth Kola100% (1)

- Secu ExtenderDocument9 pagesSecu ExtenderAlvaro De Paz FernandezNo ratings yet

- LogDocument131 pagesLogDoncri1234No ratings yet

- 7.1.6 Lab4 - Use Wireshark To Examine Ethernet FramesDocument8 pages7.1.6 Lab4 - Use Wireshark To Examine Ethernet FramesPham Quang Huy (K16HL)No ratings yet

- Business AnalysisDocument18 pagesBusiness AnalysisNadeem khanNo ratings yet

- Web Development ReportDocument26 pagesWeb Development Reportscam567321No ratings yet

- Revenue and Expenditure Management - ProposalDocument35 pagesRevenue and Expenditure Management - ProposalTyron PillayNo ratings yet

- GX - iX-500H (S) IV-2,4 EngDocument117 pagesGX - iX-500H (S) IV-2,4 EngJon Fer BezNo ratings yet

- ID Analisis Swot Pada Industri Jagung Manis PDFDocument14 pagesID Analisis Swot Pada Industri Jagung Manis PDFMuhammad Sul VikramNo ratings yet

- 40QB/QD Series: Floor Standing Split SystemDocument2 pages40QB/QD Series: Floor Standing Split SystemalexmilarNo ratings yet

- Making Type 1 Fonts For VietnameseDocument6 pagesMaking Type 1 Fonts For VietnameseMihaiLeonteNo ratings yet

- UdemyDocument13 pagesUdemyle hoang0% (1)

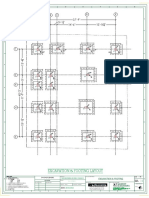

- Excavation and Footing LayoutDocument1 pageExcavation and Footing LayoutSandeep VarmaNo ratings yet

- Inter M CatalogDocument100 pagesInter M CatalogJack WyhNo ratings yet

- 2 FE - Foundation TypesDocument15 pages2 FE - Foundation TypesYang ZhengNo ratings yet

- Delivery and Forwarding of IP PacketsDocument33 pagesDelivery and Forwarding of IP PacketsRashika KhannaNo ratings yet