Professional Documents

Culture Documents

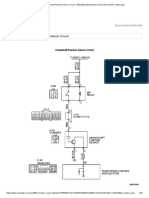

TF-CA CALPAK New DRO

Uploaded by

Mariangel Rodríguez GómezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TF-CA CALPAK New DRO

Uploaded by

Mariangel Rodríguez GómezCopyright:

Available Formats

MIC TRAC MT-3000

TF-CA Caliper Fixture

CAL-PAK Fixture Manual

TF-CA CAL-PAK Fixture Manual

©2013 Gagemaker, LP

MIC TRAC™ MT-3000

2 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Setup

Materials Needed:

• MIC TRAC™ MT-3000 base unit • 5/32" hex wrench

• Caliper • 50 in/lb torque wrench

• Caliper fixture (TF-CA) and cap screws • Cloth

• Jaw alignment block • ZEP I.D. Red cleaner

• Support arm base (TF-SA), for calipers 12” and up

1. Inspect the caliper visually as follows:

• Check for damage and excessive wear.

• Check for burrs, nicks and wear on the inside

and outside jaws.

• Check for smooth travel of the slider throughout

the range.

• If there is excess play in the slider, tighten the

gib screws until there is no more play and the

slider moves smoothly.

• Inspect the bezel for clarity and smooth

adjustment.

• Check parallelism of the OD jaws and ID jaws.

• Check straightness and accuracy of the depth

rod.

2. Clean both of the receiver pads, mounting

surfaces of the caliper fixtures, and the jaw

alignment block using the cloth and ZEP I.D.

Red cleaner.

3. Locate the left caliper fixture. With the

Gagemaker logo facing you, place the caliper

fixture against the left receiver pad shoulder.

MIC TRAC™ MT-3000

3 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Setup

4. While holding the fixture against the receiver

pad shoulder, insert the two cap screws into

the holes on either side of the fixture.

5. While applying pressure toward the receiver

pad shoulder, use a 5/32" hex wrench to

slightly tighten the screws.

6. Use a 50 in/lbs torque wrench to secure the

cap screws.

7. Repeat the same process with the right caliper

fixture. But, before totally tightening the fixture,

align both fixtures as follows:

• Turn the coarse adjust knob

counterclockwise to bring the right caliper

fixture in contact with the left caliper fixture

and check alignment.

• If not aligned, loosen the right caliper fixture

and align. Once the fixtures are aligned,

secure with the torque wrench.

8. Using the coarse adjust knob, bring the caliper

fixtures within 1 inch of each other.

9. Insert the jaw alignment block between the

caliper fixtures, with the thinner side up. Make

sure that ¼ inch of the jaw alignment block

extends above the fixtures.

MIC TRAC™ MT-3000

4 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Setup

10. Apply enough force on the coarse adjust knob,

to hold the jaw alignment block between the

caliper fixtures.

11. Tighten the coarse adjust lock.

12. Clean the caliper with the cloth and ZEP I.D.

Red cleaner.

13. Clamp the caliper jaws to the jaw alignment

block.

Note: For calipers 12” or longer, use the support

arm base to support the caliper arm during

calibration.

14. Using the left caliper fixture, align the post on

the caliper fixture clamp in the slot on top of the

fixture. Use a 5/32” hex wrench to tighten the

caliper fixture clamp so it holds the caliper jaw

tightly.

15. Repeat the same process with the right caliper

fixture to secure the right caliper jaw.

16. Loosen the coarse adjust lock and turn the

coarse adjust knob clockwise to remove the Align Post in Slot Left Caliper Fixture

jaw alignment block.

17. Turn the coarse adjust knob counterclockwise

to bring the jaws of the caliper together until the

dial of the caliper reads zero.

MIC TRAC™ MT-3000

5 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

If using a computer with

Calibration the MT-3000, go to page 6.

Materials Needed:

• MIC TRAC™ MT-3000 base unit and DRO • 5/32" hex wrench

• Caliper • Lightweight gage oil

• 1 inch cylindrical ring gage • Gage Calibration Record

Tip: To save time when calibrating gages, gather all like sizes of the same type from your facility, for

example, all 6 inch calipers. This method requires setting up the MT-3000 once, since sizes or

types of gages are not being changed during the calibration process.

1. On the front panel of the DRO, press the

internal zero button. The readout displays

0.0000.

2. Turn the coarse adjust knob clockwise to

separate the caliper jaws until the caliper

indicator is close to the first calibration value.

3. Secure the coarse adjust lock.

4. Turn the fine adjust knob clockwise until the

caliper indicator reads the first calibration

value.

Note: If you pass the calibration value, turn the

dial back and approach the value again,

from the same direction. This practice will

increase the accuracy of the calibration.

MIC TRAC™ MT-3000

6 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Calibration

5. Record any deviations on the Gage Calibration

Record or in-house calibration report. Continue

with remaining measurements.

6. Loosen the caliper fixture and remove the

caliper.

7. Measure the ID of a 1 inch cylindrical ring

gage, using the ID jaws of the caliper.

8. Record any deviations on the Gage Calibration

Record or in-house calibration report.

9. Continue with the same calibration process for

the next caliper.

10. After calibrating all calipers, be sure to remove

the caliper fixtures from the MT-3000. Oil the

fixtures and return them to the storage case.

MIC TRAC™ MT-3000

7 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Calibration If using a computer with

the MT-3000, begin here.

Materials Needed:

• MIC TRAC™ MT-3000 base unit • 1 inch cylindrical ring gage

• Computer • 5/32" hex wrench

• Certifi™ Software • Lightweight gage oil

• MT-4-USB Digital Data Acquisition Card • Brother P-Touch Label Printer (optional)

• Caliper

Tip: To save time when calibrating gages, gather all like sizes of the same type from your facility, for

example, all 6 inch calipers. This method requires setting up the MT-3000 once, since sizes or

types of gages are not being changed during the calibration process.

1. Start CERTIFI™ software by double clicking

the CERTIFI icon.

CERTIFI Icon

2. Login to the program with your username and

password.

3. Click the New Calibration Report icon.

New Report Icon

MIC TRAC™ MT-3000

8 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Calibration

4. With the cursor in the Gage Template field,

press the Enter key.

5. Highlight the Caliper 6” line and click on the OK

button.

6. Complete the following Client information:

• Company name and address.

• OEM #

• Contact name.

• PO/Account - purchase order or account

number.

• Calibration Date - automatically displays,

but can be changed by typing over the

displayed date.

• Print #

7. Enter the following information about the gage

you are calibrating:

• Serial Number

• Location

• Gage Manufacturer

• Model

• Description

8. You may change the tolerances for the caliper

if you wish.

9. You can enter additional master values by right

clicking your mouse over an existing master

value. Select Insert to insert a new line. Then

type in the new master value in that line.

MIC TRAC™ MT-3000

9 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Calibration

10. Click on the CERTIFI Monitor icon to open the

CERTIFI Monitor Window

11. Choose the “Y” axis from the pull down box. CERTIFI

Monitor Icon

12. Bring the MIC TRAC™ jaws together and click

the Zero button once.

13. Turn the coarse adjust knob clockwise to

separate the caliper jaws until the caliper

indicator is close to the first calibration value.

14. Secure the coarse adjust lock.

15. Enter the gage measurements in the Measured

column as follows:

• Turn the fine adjust knob clockwise until the

caliper indicator reads the first calibration

value.

Note: If you pass the calibration value, turn the

dial back and approach the value again,

from the same direction. This practice will

increase the accuracy of the calibration.

CERTIFI™ records the value and displays a

green box in the In/Out column if the value is

within tolerance. A red box displays if the value

is not within tolerance. The Deviation column

shows the deviation of the measured value

from the master value.

MIC TRAC™ MT-3000

10 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Calibration

16. Using each master value, continue measuring

the caliper until all values are recorded in

CERTIFI™.

17. Click the Next button. The ID Jaw Value

window displays.

18. Loosen the caliper fixture and remove the

caliper.

19. Measure the ID of a 1 inch cylindrical ring

gage, using the ID jaws of the caliper.

20. Type the value in the Measured Value box.

MIC TRAC™ MT-3000

11 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Calibration

21. Change the Next Calibration Date, if

necessary, by typing over the displayed date.

22. Enter NIST information as necessary. With the

cursor in the single box press the Enter key to

bring up a list of current NIST information. For

new NIST information select Edit from the

menu and press the Preferences box. Select

the NIST tab to enter new information.

23. Click the Save button

Note: CERTIFI™ automatically assigns a filename

to each calibration. DO NOT change the

filename to avoid problems with the

CERTIFI™ database.

MIC TRAC™ MT-3000

12 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Calibration

24. When the confirm window displays, click the

Yes button if you want to print the calibration

report.

Note: If you have a Brother P-Touch Label Printer

for printing calibration stickers, the Confirm window

for printing a calibration tag displays.

25. Click the Yes button to print the calibration tag.

Affix the Calibration Tag to the caliper.

26. Continue with the same calibration process for

the next caliper.

27. After calibrating all calipers, be sure to remove

the caliper fixtures from the MT-3000. Oil the

fixtures and return them to the storage case.

MIC TRAC™ MT-3000

13 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

Notes:

MIC TRAC™ MT-3000

14 2013 Gagemaker, LP.

RCCMT300010-13

TF-CA CAL-PAK Fixture Manual

MIC TRAC™ MT-3000

15 2013 Gagemaker, LP.

RCCMT300010-13

Gagemaker, LP, P.O. Box 87709, Houston, Texas 77287-7709

712 East Southmore Ave., Pasadena, Texas 77502

Phone: 713-472-7360Fax: 713-472-7241

Web site: www.gagemaker.com

You might also like

- TF-LG3 LG5003Document12 pagesTF-LG3 LG5003Mariangel Rodríguez GómezNo ratings yet

- SmallMicrometer CRC TrainingDocument16 pagesSmallMicrometer CRC TrainingshifaNo ratings yet

- Lead Calibration With MictracDocument12 pagesLead Calibration With Mictracfajar_92100% (1)

- MT 3000 After 2012 Operations ManualDocument36 pagesMT 3000 After 2012 Operations Manualrick.pepper3948No ratings yet

- MT-3000 Operations ManualDocument36 pagesMT-3000 Operations Manualاحمد محمد100% (1)

- enCORE v18 Software - TBS Calibration Tool User Guide - Febru - UM - LU45786 - enCORE - v18SP5 - 2Document15 pagesenCORE v18 Software - TBS Calibration Tool User Guide - Febru - UM - LU45786 - enCORE - v18SP5 - 2Sandro RebecNo ratings yet

- Mslog V.7 For The MGX Ii Quick Operating InstructionsDocument8 pagesMslog V.7 For The MGX Ii Quick Operating InstructionsMohamedNo ratings yet

- Matrix Logger With Logger Version 11 Quick Operating InstructionsDocument11 pagesMatrix Logger With Logger Version 11 Quick Operating InstructionsMohamedNo ratings yet

- Manual Takometro MegelliDocument21 pagesManual Takometro MegelliPablo Hernan Acuña25% (4)

- Precision-9 IG EN 988-10984-002Document8 pagesPrecision-9 IG EN 988-10984-002akhilNo ratings yet

- Mcii Nu-FloDocument4 pagesMcii Nu-FloMARIO FABRISNo ratings yet

- Philips MicroDose-L30-full CalibrationDocument12 pagesPhilips MicroDose-L30-full CalibrationTony Kututo100% (1)

- Multiphan Ug 8.5 X 5.5Document20 pagesMultiphan Ug 8.5 X 5.5Aida Cristiana SanduNo ratings yet

- How To - Replace A Broken Transmitter Using A New Tiger TG-T9-2 TransmitterDocument11 pagesHow To - Replace A Broken Transmitter Using A New Tiger TG-T9-2 TransmitterWilson RsmNo ratings yet

- ST400 Series Tachometers: User ManualDocument22 pagesST400 Series Tachometers: User ManualEdison100No ratings yet

- Vacuum TC Measurement Kit Instructions V3.1Document20 pagesVacuum TC Measurement Kit Instructions V3.1Francisco javier DiazNo ratings yet

- G-Jaszczak Phantom DataDocument25 pagesG-Jaszczak Phantom DataAgnieszka KluzaNo ratings yet

- Torquimetro MARK-10 CTA100Document12 pagesTorquimetro MARK-10 CTA100Stiven Giraldo NuñezNo ratings yet

- Manual Flujometro Gpi Hby-007 PDFDocument35 pagesManual Flujometro Gpi Hby-007 PDFvicthor2No ratings yet

- ST400 Series Tachometers: User ManualDocument22 pagesST400 Series Tachometers: User ManualPuspak MohapatraNo ratings yet

- Premium Tech Tool Calibration FunctionsDocument7 pagesPremium Tech Tool Calibration FunctionsImran Mehboob100% (2)

- PDF Manual190+160Document15 pagesPDF Manual190+160torbenNo ratings yet

- Calibrating The Multi-Function Camera (MFC) - V3.0 - EngDocument12 pagesCalibrating The Multi-Function Camera (MFC) - V3.0 - EngCosmyn IpsilatNo ratings yet

- TMP 4500 eDocument9 pagesTMP 4500 eLuis LugoNo ratings yet

- MGF ST TSDocument49 pagesMGF ST TSFrancisco Aravena HuertaNo ratings yet

- 3300 S Tech Time Timing Unit Operating Instructions Tiempo DieselDocument4 pages3300 S Tech Time Timing Unit Operating Instructions Tiempo DieselJean CarlosNo ratings yet

- Feeder CalibrationDocument6 pagesFeeder CalibrationPragneshNo ratings yet

- Mg540 CalibrationDocument40 pagesMg540 CalibrationIvkmi MezaNo ratings yet

- Torsion Testing Machine (A)Document13 pagesTorsion Testing Machine (A)Daniel Mabengo100% (1)

- 8375 - MTG-9900 and MTG-9900A TimegrapherDocument11 pages8375 - MTG-9900 and MTG-9900A Timegraphermcuzic2002No ratings yet

- Operating Manual: Nuclear Gauge Calibration and Verification SystemDocument45 pagesOperating Manual: Nuclear Gauge Calibration and Verification SystemSuale Sole KaungaNo ratings yet

- Instruction - Laser Alignment: 30.06.2014 Gma / Smpe Gma / PHJ InstructionDocument10 pagesInstruction - Laser Alignment: 30.06.2014 Gma / Smpe Gma / PHJ InstructionPrifian Budi RNo ratings yet

- ACM-200 Web Operating InstructionsDocument4 pagesACM-200 Web Operating InstructionsEmmanuel BocheNo ratings yet

- Nuflo Mc-Ii 1Document2 pagesNuflo Mc-Ii 1Anonymous Wu6FDjbNo ratings yet

- PTO BZ 1000 Service ManualDocument28 pagesPTO BZ 1000 Service ManualalfonsofelipesaraviaNo ratings yet

- Safety: Service LetterDocument15 pagesSafety: Service LetterBart JohnNo ratings yet

- 4000 GC/MS: Pre-Installation InstructionsDocument9 pages4000 GC/MS: Pre-Installation InstructionsZia HaqNo ratings yet

- Service Note 13Document4 pagesService Note 13Brezhnev AguilarNo ratings yet

- QC For Techs JAN 2007Document3 pagesQC For Techs JAN 2007Nelson J Silva ANo ratings yet

- Site Master S311D Cable and Antenna Analyzer Maintenance ManualDocument20 pagesSite Master S311D Cable and Antenna Analyzer Maintenance ManualNAPEN SIMONNo ratings yet

- Fuel Injector Timing: NoticeDocument5 pagesFuel Injector Timing: Noticeعمار العماريNo ratings yet

- Gagemaker 2004 CatalogDocument32 pagesGagemaker 2004 CatalogAnonymous D5QForitcNo ratings yet

- MS4 Certification - Verification ProcedureDocument4 pagesMS4 Certification - Verification ProcedureBrahmananda ChakrabortyNo ratings yet

- Cours #6 Anesthesia PresentationDocument55 pagesCours #6 Anesthesia PresentationIMINo ratings yet

- MX 8000Document307 pagesMX 8000GyannkNo ratings yet

- Pro-Ject Essential III Flexi-Range: Instructions For UseDocument17 pagesPro-Ject Essential III Flexi-Range: Instructions For UseTomás CastilloNo ratings yet

- MTM Transmission Air Supply Pressure Sensor Repair Rrmt0045Document11 pagesMTM Transmission Air Supply Pressure Sensor Repair Rrmt0045Julijus AleknaNo ratings yet

- RTP9006S Eng 1Document22 pagesRTP9006S Eng 1Leiden O'SullivanNo ratings yet

- Cryostat Operations Manual - Minotome Plus - OM2563Document23 pagesCryostat Operations Manual - Minotome Plus - OM2563ATR Assistência Técnica (ATR)No ratings yet

- FaroArm and ScanArm Performance Verification ChecklistDocument6 pagesFaroArm and ScanArm Performance Verification ChecklistNik JakeNo ratings yet

- Pin On Disk Tribometer ManualDocument53 pagesPin On Disk Tribometer Manualanhntran4850100% (1)

- Epson Stylus Pro 9800 Error CodeDocument9 pagesEpson Stylus Pro 9800 Error CodeBkh DesignNo ratings yet

- Instruction Manual For Globe Price Computing Scale Models GS30 and GS30TDocument12 pagesInstruction Manual For Globe Price Computing Scale Models GS30 and GS30TManuel MoriniNo ratings yet

- ManualesDocument20 pagesManualessimon ramirezNo ratings yet

- Calibration FailureDocument24 pagesCalibration FailureDante NuevoNo ratings yet

- 456 Guia de Uso Medidor de Espesores PDFDocument126 pages456 Guia de Uso Medidor de Espesores PDFALESSANDRO DEL PIERONo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingFrom EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingRating: 4.5 out of 5 stars4.5/5 (9)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Absolute Digimatic Scale Units - Indd - Mitutoyo America CorporationDocument12 pagesAbsolute Digimatic Scale Units - Indd - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- 293 Series Digimatic MicrometerDocument2 pages293 Series Digimatic MicrometerNita AntonioNo ratings yet

- ABS Coolant Proof Digimatic Indicator - Mitutoyo America CorporationDocument6 pagesABS Coolant Proof Digimatic Indicator - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- Calculation-Type Digital Indicator Calculation-Type Digital IndicatorDocument4 pagesCalculation-Type Digital Indicator Calculation-Type Digital IndicatorMariangel Rodríguez GómezNo ratings yet

- ROUNDTEST RA-2100 SERIES - Mitutoyo America CorporationDocument12 pagesROUNDTEST RA-2100 SERIES - Mitutoyo America CorporationMariangel Rodríguez Gómez100% (1)

- Mitutoyo New Products Guide - Mitutoyo America CorporationDocument20 pagesMitutoyo New Products Guide - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- QV APex SeRieS - Mitutoyo America CorporationDocument19 pagesQV APex SeRieS - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- 99MBA092A2 MF-U Microscope Hardware GuideDocument98 pages99MBA092A2 MF-U Microscope Hardware GuideMariangel Rodríguez GómezNo ratings yet

- CNC Vision Measuring System - Precision Tool DistributorsDocument24 pagesCNC Vision Measuring System - Precision Tool DistributorsMariangel Rodríguez GómezNo ratings yet

- SERIES 500 Digimatic Caliper - Mitutoyo America CorporationDocument2 pagesSERIES 500 Digimatic Caliper - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- HILO Takes The Guesswork Out of Setting Adjustable Ring GagesDocument2 pagesHILO Takes The Guesswork Out of Setting Adjustable Ring GagesMariangel Rodríguez GómezNo ratings yet

- Metric Thread Gages - PMC Lone StarDocument26 pagesMetric Thread Gages - PMC Lone StarMariangel Rodríguez GómezNo ratings yet

- BX-1000 BXG-1000 Operation Manual0 PDFDocument36 pagesBX-1000 BXG-1000 Operation Manual0 PDFMariangel Rodríguez GómezNo ratings yet

- CA-9001 Coupling Alignment Gage: Operation ManualDocument12 pagesCA-9001 Coupling Alignment Gage: Operation ManualMariangel Rodríguez GómezNo ratings yet

- TF-DG CALPAK New DRODocument20 pagesTF-DG CALPAK New DROMariangel Rodríguez GómezNo ratings yet

- Cal-Pak TF-VBDocument12 pagesCal-Pak TF-VBMariangel Rodríguez GómezNo ratings yet

- Fuel Temperature SensorDocument12 pagesFuel Temperature SensorAakarsh Verma100% (2)

- SparqugDocument48 pagesSparqugIan BagleyNo ratings yet

- Gen - Importance of Welding in L & T PDFDocument30 pagesGen - Importance of Welding in L & T PDFSivaNo ratings yet

- LG 23MT77V LW50A Schematic Diagram and Service ManualDocument34 pagesLG 23MT77V LW50A Schematic Diagram and Service Manualaze1959No ratings yet

- Desktop F0ecjd0 20230613 0007Document8 pagesDesktop F0ecjd0 20230613 0007Mican HoriaNo ratings yet

- Grade 9: Tle - Ict Computer Systems Servicing Quarter 2 - Module 1 Install Network CablesDocument6 pagesGrade 9: Tle - Ict Computer Systems Servicing Quarter 2 - Module 1 Install Network CablesSharmaine Paragas FaustinoNo ratings yet

- Cryptocurrency System Using Body Activity Data Wo2020060606 2 of 6Document1 pageCryptocurrency System Using Body Activity Data Wo2020060606 2 of 6Nemo NemoNo ratings yet

- 5 HANDGREPEN 1 Horizon - Eng - 0Document28 pages5 HANDGREPEN 1 Horizon - Eng - 0FORLINE nuiNo ratings yet

- Platform General Vxworks Migration Guide 3.6Document124 pagesPlatform General Vxworks Migration Guide 3.6Ding YueNo ratings yet

- The Power of Social MediaDocument3 pagesThe Power of Social MediaTIGER CHEETANo ratings yet

- Common Hydraulic Problems - Symptoms and Causes - Hydraproducts - Hydraulic Systems - Hydraulic Power Packs - BlogDocument3 pagesCommon Hydraulic Problems - Symptoms and Causes - Hydraproducts - Hydraulic Systems - Hydraulic Power Packs - BlogLacatusu MirceaNo ratings yet

- Forensic Ballistics Reviewer - ScribdDocument589 pagesForensic Ballistics Reviewer - ScribdMelcon S. Lapina96% (25)

- G95me c10 5Document4 pagesG95me c10 5KyinaNo ratings yet

- SGV Series: Storage Filling PumpDocument2 pagesSGV Series: Storage Filling PumpAnupam MehraNo ratings yet

- DC BASIC GAS at Ravi Ranjan KumarDocument1 pageDC BASIC GAS at Ravi Ranjan KumarRAVI RANJAN KUMARNo ratings yet

- HTML Project On Shopping WebsiteDocument2 pagesHTML Project On Shopping WebsiteSunitha ManamNo ratings yet

- About GoogleDocument7 pagesAbout GoogleMeera Gayathri DNo ratings yet

- ITIL® 4 Drive Stakeholder Value (DSV)Document2 pagesITIL® 4 Drive Stakeholder Value (DSV)Eugene ArkadievNo ratings yet

- Indian Institute of Technology: Delhi Summary Sheet Consumable StoresDocument2 pagesIndian Institute of Technology: Delhi Summary Sheet Consumable StoresSumit SinghNo ratings yet

- ITC LAB 4 - FlowchartsDocument7 pagesITC LAB 4 - FlowchartspathwayNo ratings yet

- M2 Pre-Task: Application Software - System Software Driver Software Programming SoftwareDocument2 pagesM2 Pre-Task: Application Software - System Software Driver Software Programming SoftwareBee Anne BiñasNo ratings yet

- Update Penjualan 2019 1Document941 pagesUpdate Penjualan 2019 1Viar TimikaNo ratings yet

- Basic Passport Checks: Cyan Magenta BlackDocument23 pagesBasic Passport Checks: Cyan Magenta BlackRakesh KanniNo ratings yet

- U19EC416 DSP Lab SyllabusDocument2 pagesU19EC416 DSP Lab SyllabusRamesh MallaiNo ratings yet

- Activity 6Document29 pagesActivity 6Kenneth Puguon0% (1)

- MS Word Basics GuideDocument36 pagesMS Word Basics GuideCarmen NelNo ratings yet

- Accounting and Finance: NTQF Level Ii-IvDocument143 pagesAccounting and Finance: NTQF Level Ii-Ivteshome neguse100% (3)

- Facial RecognitionDocument5 pagesFacial RecognitionPeterNo ratings yet

- Bomag BF 300 C2Document4 pagesBomag BF 300 C2Vishwdeep VaidNo ratings yet

- Advance Adgressor 3220D Parts ManualDocument52 pagesAdvance Adgressor 3220D Parts Manualerik49No ratings yet