Professional Documents

Culture Documents

MS4 Certification - Verification Procedure

Uploaded by

Brahmananda ChakrabortyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS4 Certification - Verification Procedure

Uploaded by

Brahmananda ChakrabortyCopyright:

Available Formats

Service and Repair Procedures

Certification / Verification Procedure

Certification / Verification Procedure

This Certification/Verification procedure is for the use of the Beckman Coulter Representative or

appropriately trained person to verify the operation of the instrument following a new installation,

at the end of each service visit, or upon certification.

Required Material

r Test Data Sheet

r Two size standards (one size nominally 10 to 20% of the size of the aperture tube, and one that

is any size within the dynamic range of the aperture tube.)

Information to be Recorded in the Test Data Sheet (TDS)

Record the following selected information in the Test Data Sheet (TDS).

r SOM Settings

r Waste Tank Settings

r Sample Delivery Settings

r Fill, Flush, and Drain Settings

r Aperture Resistance Settings

r Noise level and Background.

Maintenance

r Inspect the system for leaks, broken or frayed wiring, or any physical damage to

electromechanical assemblies. Repairs should be made before continuing with this procedure.

r View the Error Log and look for error messages. If you encounter error messages that may

indicate a problem, then the suspected assembly should be tested and inspected. Replace as

necessary.

r Fill the system. Look for error messages that might indicate a problem.

r Inspect tubing. Replace any deteriorating tubing.

r Purge and Adjust the metering pump via the software.

r Enter the Service mode and click on Diagnostic Settings. See Service Mode in Chapter 5,

Troubleshooting Guide (page 5-2) for details.

r Perform the Fixed 15k dummy load test.

r Ensure that the aperture tube, external electrode, and stir rod are free of damage, are clean

and fastened securely.

r Verify that the waste and diluent bottles are clean and free of damage.

r Under Service, select View Voltages . . . and measure all voltages via software.

4-36 MultisizerTM 4 Service Manual (PN A60936AA)

Service and Repair Procedures

Certification / Verification Procedure 4

System Test

r Place a beaker of clean diluent under the aperture tube.

r On the toolbar select Service and then Instrument Schematic. Verify that the following

subassemblies are operating properly:

Valve Operations

r Verify that the system fills correctly and completely when the Fill System command is

activated in the software.

r Repeatedly activate the Flush Aperture Tube command. Verify in the instrument schematic

that the fluid level in the waste tank is incrementing.

Waste Tank

r When the waste tank has been half filled, activate the Empty Waste Tank command and verify

that the emptying cycle completes successfully.

r Verify that the Waste Tank reads 0% in the schematic when emptied. Calibrate the Tank if

needed.

Vacuum Regulator

r Under Run, Troubleshooting, select Sample Delivery Settings and set the vacuum level at Waste

Tank to 2.0” Hg. Verify the progress of this adjustment on the left panel. You might also verify

the vacuum level at the instrument schematic.

r Set the vacuum level at Waste Tank back to 6” Hg (default) and verify.

Door Switches

Verify that an error message is generated when you try to run an analysis with the door open.

Fans

From the instrument schematic, verify that the fans can be turned On and Off. After checking,

ensure that the fans are left on.

Stirrer Motor

Verify that the motor can be turned On and Off by raising and lowering the platform and that the

motor speed adjustment is working.

Aperture Lamp

Verify that the lamp can be turned On and Off in the instrument schematic panel.

MultisizerTM 4 Service Manual (PN A60936AA) 4-37

Service and Repair Procedures

Certification / Verification Procedure

Ground

Verify that the ground terminal of the input filter module is secure and the resistance between the

ground terminal and chassis ground does not exceed 0.1 ohm.

Instrument Performance

r Perform a background count. Record the results on the Test Data Sheet.

r Verify Aperture Calibration on the two different size standards. Ensure that both results pass.

Results pass when the KD change is less than 3%. Record the results on the Test Data Sheet.

r Restore run settings to the customer’s original configuration.

Customer Review and Update

Review Preventative Maintenance with the customer. Cover the following subjects.

r Ensure that the aperture tube, external electrode, and stir rod are free of damage, are clean,

and fastened securely.

r Purge and adjust the metering pump via the software.

r Removal, cleaning and care of the aperture tube.

Customer Acceptance

• Have the customer run a sample or control if available, verify that the results are within the

expected range and that the instrument is operational.

NOTE

The customer is ultimately responsible for performing the final instrument calibration.

Certification Reporting

The certification procedure is performed yearly and at the time the service contract is renewed. It is

also performed when a customer requests a certification.

r Under Service select Update Multisizer Certification.

r From the Update Multisizer Certification dialog box, click on Mark as Certified button. Ensure

that the number of days is updated.

4-38 MultisizerTM 4 Service Manual (PN A60936AA)

Service and Repair Procedures

Calibration/Adjustment Procedures 4

Figure 4.39 Update Certification

r Ensure that the correct phone number and Web page are entered.

r Exit the SERVICE mode.

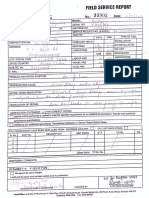

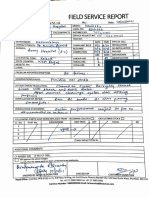

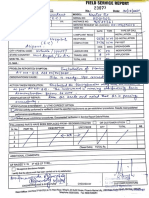

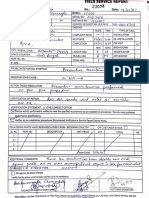

r Fill out and sign the Certification Documents if appropriate. Place the Certification Sticker on

the instrument if appropriate.

r Leave a copy of the Test Data Sheet with the customer.

Calibration/Adjustment Procedures

Stirrer Position Calibration

r Move the Platform to the down position.

r Under Service select Configure Stirrer Position.

r Manually place the stirrer assembly all the way to the left.

r Click on Defaults.

r Click on Calibrate In and let the software perform the calibration routine.

r Once completed, click on Apply and then click on OK.

MultisizerTM 4 Service Manual (PN A60936AA) 4-39

You might also like

- Control Valve Calibration FFDocument3 pagesControl Valve Calibration FFKram Alim VillonNo ratings yet

- Method Statement For Instrument CalibrationDocument14 pagesMethod Statement For Instrument CalibrationFredric Tun100% (2)

- Gen Set Service ReportDocument1 pageGen Set Service ReportReman MarykanNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- DP CalibrationDocument12 pagesDP CalibrationGeorge AsuncionNo ratings yet

- Tata CRMDocument39 pagesTata CRMRoger Brown100% (1)

- Pressure Switch Function TestDocument5 pagesPressure Switch Function Testnjenns100% (1)

- D002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaDocument38 pagesD002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaSurya Darma100% (1)

- DPT Calibration FFDocument4 pagesDPT Calibration FFKram Alim VillonNo ratings yet

- Fresenius 2008HDocument89 pagesFresenius 2008HBIOCARE SERVICE100% (2)

- Ziehm 7000 Compact Main. Pro PDFDocument40 pagesZiehm 7000 Compact Main. Pro PDFLuis Fernando Garcia S100% (1)

- Qdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfDocument16 pagesQdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfLarzon Rodriguez0% (1)

- Sip-Sop04-R0-2017 Sop DPT Level CalibrationDocument2 pagesSip-Sop04-R0-2017 Sop DPT Level CalibrationDwi Mulyanti DwimulyantishopNo ratings yet

- Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDocument4 pagesDensity (Unit Weight), Yield, and Air Content (Gravimetric) of ConcretemickyfelixNo ratings yet

- Basic Principles of Instrument Calibration PDFDocument6 pagesBasic Principles of Instrument Calibration PDFchdiNo ratings yet

- Feeder CalibrationDocument6 pagesFeeder CalibrationPragneshNo ratings yet

- Calibration Certification Procedure Ultra Pro 80 Ultracentrifuge - 2008341445 - 100729 - 4Document3 pagesCalibration Certification Procedure Ultra Pro 80 Ultracentrifuge - 2008341445 - 100729 - 4luroguitaNo ratings yet

- Lifotronic H9 HbA1c Analyzer Installation GuideDocument34 pagesLifotronic H9 HbA1c Analyzer Installation GuideMichael Tanglao100% (2)

- HEMODIALISIS Fresenius 2008H CALIBRATION PROCEDURES PDFDocument89 pagesHEMODIALISIS Fresenius 2008H CALIBRATION PROCEDURES PDFpablo100% (1)

- Ziehm 7000, Compact, Vista C-Arm - Maintenance Procedure PDFDocument40 pagesZiehm 7000, Compact, Vista C-Arm - Maintenance Procedure PDFSergio Montes100% (1)

- Classroom of The Elite Vol. 8Document244 pagesClassroom of The Elite Vol. 8Rahul Lakra85% (13)

- Free Downloads: Type Matters!Document3 pagesFree Downloads: Type Matters!Shinko Art Studio9% (11)

- Illness Narratives - Positioned IdentitiesDocument35 pagesIllness Narratives - Positioned IdentitiesAnaNo ratings yet

- 8.4 Performance Qualification Protocol For Dispensing BoothDocument13 pages8.4 Performance Qualification Protocol For Dispensing BoothArej Ibrahim AbulailNo ratings yet

- Rosemount Pressure Calibration ProcedureDocument6 pagesRosemount Pressure Calibration ProcedureLorenzoNo ratings yet

- Installation Instruction-20200617Document65 pagesInstallation Instruction-20200617Mic GapanNo ratings yet

- Micromass GCT PM ProtocolDocument12 pagesMicromass GCT PM ProtocolOliver MüllerNo ratings yet

- 12.4 Performance Qualification Protocol For Laminar Air Flow UnitDocument13 pages12.4 Performance Qualification Protocol For Laminar Air Flow UnituzairNo ratings yet

- RTP9006S Eng 1Document22 pagesRTP9006S Eng 1Leiden O'SullivanNo ratings yet

- Comissioning ProcedureDocument7 pagesComissioning Procedurekarim karimNo ratings yet

- Coulter Gen-S - AddendumDocument110 pagesCoulter Gen-S - AddendumluisNo ratings yet

- Manual - Filter Oil Test Rig - ISO 1 & 3Document5 pagesManual - Filter Oil Test Rig - ISO 1 & 3Rudra QMS SolutionNo ratings yet

- SunnyDocument32 pagesSunnysunithadurgamNo ratings yet

- Manual XMT A Two Wire Amperometric Hart Transmitter Rosemount en 69036Document118 pagesManual XMT A Two Wire Amperometric Hart Transmitter Rosemount en 69036OmarBleNo ratings yet

- Testing & Commissioning Procedure PRE-Testing Commissioning ProcedureDocument4 pagesTesting & Commissioning Procedure PRE-Testing Commissioning ProcedureanfalapNo ratings yet

- The Instrument Name and DescriptionDocument9 pagesThe Instrument Name and DescriptionMakmal FarmaseutikalNo ratings yet

- 90 Degree Peel Tester: MODEL PA-1000-90 Operating InstructionsDocument14 pages90 Degree Peel Tester: MODEL PA-1000-90 Operating InstructionsSarah LinvilleNo ratings yet

- Quantura 200 300 ManualDocument44 pagesQuantura 200 300 Manualrawiasherif4No ratings yet

- 815 Instruction ManualDocument20 pages815 Instruction ManualSoeAye0% (1)

- Calibration Procedure: 1-PurposeDocument5 pagesCalibration Procedure: 1-PurposeHassan SleemNo ratings yet

- List of Medical Equipment For Laboratory: No. Equipments Unit 1 2Document24 pagesList of Medical Equipment For Laboratory: No. Equipments Unit 1 2An AnneNo ratings yet

- Safety Safety Safety Safety Guide Guide Guide GuideDocument12 pagesSafety Safety Safety Safety Guide Guide Guide GuideMecanica SeguraNo ratings yet

- CalibrationDocument25 pagesCalibrationWaqarAhmedButtNo ratings yet

- Software Upgrade Procedure AVEA™ Ventilators Version 4.6 For Coldfire Version 3.10 For ELANDocument11 pagesSoftware Upgrade Procedure AVEA™ Ventilators Version 4.6 For Coldfire Version 3.10 For ELANRoberto ArredondoNo ratings yet

- RWRG0056 - Range Shift Complaints - Fault Code 41: Pre-Authorized Warranty Repair Guideline RWRG0056Document2 pagesRWRG0056 - Range Shift Complaints - Fault Code 41: Pre-Authorized Warranty Repair Guideline RWRG0056Antonio TorresNo ratings yet

- Facilitator: Dr. N. Vishal Kumar Gupta, Asst. Professor, Dept. of Pharmaceutics, Jss Colege of Pharmacy, MYSORE-15Document21 pagesFacilitator: Dr. N. Vishal Kumar Gupta, Asst. Professor, Dept. of Pharmaceutics, Jss Colege of Pharmacy, MYSORE-15kavya nainita0% (1)

- Proceq DY-2 Additional Information Calibration Software Guide - EnglishDocument12 pagesProceq DY-2 Additional Information Calibration Software Guide - EnglishMauricio PiresNo ratings yet

- Engstrom CarestationDocument24 pagesEngstrom CarestationmaruthaiNo ratings yet

- LFXGH Basic SetupDocument2 pagesLFXGH Basic SetupAlvin Garcia PalancaNo ratings yet

- BS-120 Chemistry Analyzer Quick Operation Card: Checking Before StartupDocument2 pagesBS-120 Chemistry Analyzer Quick Operation Card: Checking Before StartupKP ServiceNo ratings yet

- CVHE-F CHILLER COMMISSIONING & STARTUP Checklist - 07102015Document5 pagesCVHE-F CHILLER COMMISSIONING & STARTUP Checklist - 07102015Bernard Bonnin CervantesNo ratings yet

- 915 Instruction ManualDocument18 pages915 Instruction ManualWa TokeNo ratings yet

- 5200 Trivector Analyzer: Machinery Health ManagementDocument4 pages5200 Trivector Analyzer: Machinery Health ManagementJunaid KhurshidNo ratings yet

- Perform Pick Up Drop Off Test of Relay: Prepared By: B.R.PrajapatiDocument4 pagesPerform Pick Up Drop Off Test of Relay: Prepared By: B.R.PrajapatiBhavik PrajapatiNo ratings yet

- CL-1200i (1000P) &2600i&2800i - Operation Card - V1.0 - ENDocument2 pagesCL-1200i (1000P) &2600i&2800i - Operation Card - V1.0 - ENmanal al-hattaliNo ratings yet

- FAT Procedure 12m DoorDocument5 pagesFAT Procedure 12m DoorBjørnar HuseNo ratings yet

- Installation VH20Document21 pagesInstallation VH20Cuong VuNo ratings yet

- Method Statement of Sprinkler System Without LogoDocument9 pagesMethod Statement of Sprinkler System Without LogokiranramNo ratings yet

- Cirris 1100H+: Performance Verification ManualDocument33 pagesCirris 1100H+: Performance Verification ManualJosé MLNo ratings yet

- Information Sheet One Plan and Prepare Commissioning Activities SafetyDocument18 pagesInformation Sheet One Plan and Prepare Commissioning Activities SafetyGizaw TadesseNo ratings yet

- PCM Tally Jet RevA4Document12 pagesPCM Tally Jet RevA4YamenNo ratings yet

- Alaris 7100-7200 Infusion Pump - Service GuidelineDocument4 pagesAlaris 7100-7200 Infusion Pump - Service Guidelinethe7king the7kingNo ratings yet

- Qiacube SopDocument3 pagesQiacube SopNANDA AHSANINo ratings yet

- Operation Manual of Semi Automatic Hydraulic Power Pack Dated 21.03.2017 1Document28 pagesOperation Manual of Semi Automatic Hydraulic Power Pack Dated 21.03.2017 1Fiker Er MarkNo ratings yet

- MS4 Error MessagesDocument5 pagesMS4 Error MessagesBrahmananda ChakrabortyNo ratings yet

- Teachers Day CardDocument1 pageTeachers Day CardBrahmananda ChakrabortyNo ratings yet

- Yenepoya De-Installation ReportDocument1 pageYenepoya De-Installation ReportBrahmananda ChakrabortyNo ratings yet

- MS3-MS4 Small and Large Aperture Additional TechniquesDocument5 pagesMS3-MS4 Small and Large Aperture Additional TechniquesBrahmananda ChakrabortyNo ratings yet

- B23942ab Ms4e V-Check Review OnlyDocument78 pagesB23942ab Ms4e V-Check Review OnlyBrahmananda ChakrabortyNo ratings yet

- TOPICDocument1 pageTOPICBrahmananda ChakrabortyNo ratings yet

- Digha Is The Most Popular Sea Beach in West BengalDocument2 pagesDigha Is The Most Popular Sea Beach in West BengalBrahmananda ChakrabortyNo ratings yet

- Case 4 Workbook and DiscussionDocument9 pagesCase 4 Workbook and DiscussionBrahmananda ChakrabortyNo ratings yet

- Panel Rule Presentation and QCDocument11 pagesPanel Rule Presentation and QCBrahmananda ChakrabortyNo ratings yet

- Agenda CME KolkataDocument1 pageAgenda CME KolkataBrahmananda ChakrabortyNo ratings yet

- Case 5 Workbook and DiscussionDocument14 pagesCase 5 Workbook and DiscussionBrahmananda ChakrabortyNo ratings yet

- Craig Chronic Lymphoid Disorders Useful Information CCEN India 2018 FinalDocument9 pagesCraig Chronic Lymphoid Disorders Useful Information CCEN India 2018 FinalBrahmananda ChakrabortyNo ratings yet

- Case 7 Workbook and DiscussionDocument17 pagesCase 7 Workbook and DiscussionBrahmananda ChakrabortyNo ratings yet

- Craig Mature B-Cell Neoplasms CCEN India 2018 FinalDocument24 pagesCraig Mature B-Cell Neoplasms CCEN India 2018 FinalBrahmananda ChakrabortyNo ratings yet

- 5 Challenge Case Workbook and DiscussionDocument17 pages5 Challenge Case Workbook and DiscussionBrahmananda ChakrabortyNo ratings yet

- SOP For Membrane & Cytoplasmic StainingDocument2 pagesSOP For Membrane & Cytoplasmic StainingBrahmananda ChakrabortyNo ratings yet

- CLPD SopDocument9 pagesCLPD SopBrahmananda ChakrabortyNo ratings yet

- Navios Start UpDocument4 pagesNavios Start UpBrahmananda ChakrabortyNo ratings yet

- Reticulocyte Platlett j.1939-165X.2008.00086Document9 pagesReticulocyte Platlett j.1939-165X.2008.00086Brahmananda ChakrabortyNo ratings yet

- DGFMS PanelDocument1 pageDGFMS PanelBrahmananda ChakrabortyNo ratings yet

- Cytoplasmic Staining Kappa LambdaDocument2 pagesCytoplasmic Staining Kappa LambdaBrahmananda ChakrabortyNo ratings yet

- Leukemia SOPDocument8 pagesLeukemia SOPBrahmananda ChakrabortyNo ratings yet

- B Booruah BD Call 151221Document1 pageB Booruah BD Call 151221Brahmananda ChakrabortyNo ratings yet

- SOP For Surface StainingDocument1 pageSOP For Surface StainingBrahmananda ChakrabortyNo ratings yet

- Water PPT For SavioDocument6 pagesWater PPT For SavioBrahmananda ChakrabortyNo ratings yet

- B Booruah PM 151222Document1 pageB Booruah PM 151222Brahmananda ChakrabortyNo ratings yet

- Army BD Call 170321Document1 pageArmy BD Call 170321Brahmananda ChakrabortyNo ratings yet

- Army Install ReportDocument1 pageArmy Install ReportBrahmananda ChakrabortyNo ratings yet

- Apollo PM Report 040121Document1 pageApollo PM Report 040121Brahmananda ChakrabortyNo ratings yet

- Chapter 2 PDFDocument21 pagesChapter 2 PDFMahdi BanjakNo ratings yet

- DCS - VI Sem SchemeDocument2 pagesDCS - VI Sem SchemePriya UpadhyayNo ratings yet

- Study of PomeloDocument30 pagesStudy of PomeloKyle Cabusbusan75% (4)

- Experiment 5: Resistors in Series and Parallel CircuitsDocument2 pagesExperiment 5: Resistors in Series and Parallel CircuitsVictoria De GuzmanNo ratings yet

- Multifocal AntennaDocument5 pagesMultifocal AntennaLazni NalogNo ratings yet

- An Exploration of The Concept of Identity Crisis in Salman Rushdie's GrimusDocument3 pagesAn Exploration of The Concept of Identity Crisis in Salman Rushdie's GrimusIJELS Research JournalNo ratings yet

- Practice For Group Work Week 2 Case 2.1 - Assigning Plants To Products (Better Products Company)Document2 pagesPractice For Group Work Week 2 Case 2.1 - Assigning Plants To Products (Better Products Company)Thu TrangNo ratings yet

- Bump Grade Force On Wire Student-1Document3 pagesBump Grade Force On Wire Student-1Benjamin WatsonNo ratings yet

- 302 Decision Science Question - PaperDocument3 pages302 Decision Science Question - Paperajay taleNo ratings yet

- Employee Engagement - Korn - Ferry InternationalDocument2 pagesEmployee Engagement - Korn - Ferry InternationalЯрослава ЛояничNo ratings yet

- Foundations For Low Loss GRIN Fiber CouplingDocument16 pagesFoundations For Low Loss GRIN Fiber CouplingpsylabsNo ratings yet

- OG19 RC 新题解析Document14 pagesOG19 RC 新题解析Chi JianNo ratings yet

- Đề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Document8 pagesĐề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Chi Vũ LinhNo ratings yet

- Astm D2777 Determinacion de La Precision y El Sesgo PDFDocument21 pagesAstm D2777 Determinacion de La Precision y El Sesgo PDFAlvaro Pérez PérezNo ratings yet

- Lesson - 03 - Focus On Plastic FootprintsDocument59 pagesLesson - 03 - Focus On Plastic FootprintsMariaNo ratings yet

- Sciencedirect: Development of Battery Monitoring System in Smart Microgrid Based On Internet of Things (Iot)Document6 pagesSciencedirect: Development of Battery Monitoring System in Smart Microgrid Based On Internet of Things (Iot)KiranNo ratings yet

- Compare and ContrastDocument9 pagesCompare and Contrastmai mohamedNo ratings yet

- MRR1Document3 pagesMRR1Shaena LarezaNo ratings yet

- Sheree Hendersonresume 2Document3 pagesSheree Hendersonresume 2api-265774249No ratings yet

- Filtergehà Use - Beutel Und - Kerzen - enDocument5 pagesFiltergehà Use - Beutel Und - Kerzen - ennabila OktavianiNo ratings yet

- Session Nos. 26 - 31: Cities of Mandaluyong and PasigDocument25 pagesSession Nos. 26 - 31: Cities of Mandaluyong and PasigLego AlbertNo ratings yet

- LEPTOSPIRADocument31 pagesLEPTOSPIRADinar NastitiNo ratings yet

- We Exist As Molecular Structures.: Have You Found Your Path?Document9 pagesWe Exist As Molecular Structures.: Have You Found Your Path?Stephen KingNo ratings yet

- The Hornbook Method and The Conflict of LawsDocument16 pagesThe Hornbook Method and The Conflict of LawslanglangNo ratings yet

- DLL-All Subjects - Week 7 Day 1Document5 pagesDLL-All Subjects - Week 7 Day 1Windel Beth Quimat ZafraNo ratings yet