Professional Documents

Culture Documents

8.misc Cert Pack

8.misc Cert Pack

Uploaded by

ClarkFedele270 ratings0% found this document useful (0 votes)

31 views42 pagesOriginal Title

8.MISC CERT PACK

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views42 pages8.misc Cert Pack

8.misc Cert Pack

Uploaded by

ClarkFedele27Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 42

CAMERON CAMERON, A SCHLUMBERGER COMPANY

s 7200 INTERSTATE 30

Asch LITTLE ROCK, AR 72219

PH (501) 568-6000 FAX (501) 570-5700

CERTIFICATE OF CONFORMANCE i ta]

customern|——S=~S REF P.O. #: N/A

CUSTOMER ORDER #: [——]

MATERIAL DESCRIPTION: PV € RF GV C921 LT-LH-LH DTR 625 GO

yer Compan

QUANTITY: 1

CAMERON 5.0.4 / Line : PRODUCTION ORDER #: 121330018

TAG #: 54-VP-85015 P.O.ITEM #: SERIAL#: 121330018 001

N/A

‘SPECIAL REQUIREMENTS

‘API 6D MONOGRAM PED MONOGRAM

‘THIS CERTIFICATE OF CONFORMANCE STATES THAT SPECIAL REQUIREMENT VALVES LISTED

{BOVE ARE IN EULL COMPLIANCE WITH API 60 LATEST EDITION WHEN MONGRAMMED APL6D,

VALVE TESTING

ViapieD ()APIS98 |] ASMEB16.34 ACTUAL TEST RECORD (ATTACHED) —_[_] CHART TESTS (ATTACHED)

NDE / MATERIAL CERTIFICATIONS (SEE ATTACHED)

! CERTIFICATE OF COMPLIANCE FOR PARTS (EN 10204 2.1)

INDEPENDENT TEST (EN 10204 3.1) “eooy ™ sonnet ¥ LowerPtaTe |i cORE “!STEM

REPRESENTATIVE CERTIFICATION (EN 10204 2.2) || SEAT‘! caPScRews | STEM stemcam (| PLUG

CO TRUNION BUSHING Li corEPINS [Istups = CINUTS

NACE

\v mro475 / 1S015156-200 ™MR0103-201

FIRE SAFE DESIGN OF VALVE (EXCLUDES ACTUATORS)

OIEXXON CLASS 1 Sapico7 1 apirrer |! api era

NONDESTRUCTIVE TESTING (TEST REPORTS ATTACHED)

MAG PARTICLE | LIQUIDPENETRANT (| RADIOGRAPHY “| HARDNESS | | POSITIVE MATERIAL“! VISUAL

OTHER

FUNCTIONAL TEST FOR ROTORK ATTACHED.

|

EN10204 2.2 CERTIFICATES FOR SLIP, STEM, CHESTERTON PACKING, O-RINGS AND GASKETS ATTACHED,

‘Cameron certifies that the products furnished for the order identified above meet the customer's purchase order requirements of the

‘areas marked on this certification. The areas marked indicate either tests that were performed or documentation provided. In certain

situations, any previously agreed upon exceptions between Cameron and the customer order requirements will apply. Latest edition of

applicable specifications apply, except where noted.

cernieoey: [| CERTIFICATION DATE: 9/17/2019

Certification Specialist, Quality Assurance

Form iia Teno 20H7

CAMERON Little Rock, Arkansas

ASeumberge Company

PRESSURE TEST RECORD AND MTR

Customer:

Work Order: 121330018

Product Description: PV 6 RF GV C921 LT-LH-LH DTR 625 GO | Serial Number: 1

JGage(s) Used: 9903/9916 Comments:

MATERIAL TEST RECORD

Part Number Heat Number sn Material Vendor

Body} 84-1-3189-10R past.2 uc Quality Electric

Bonnet| 8A-2-1936-22 811916 AS16 utoo1/a02 D&N

Lower Plate] 8A-3-1931-22 £59236 A516 uTis-004 D&N

PRESSURE TEST RECORD

Mpa Duration (min) Results

7.756605 5 min Accept

Upstream Seat: 5.688177 5 min Accept

Downstream Seat: 5.688177 5 min Accept

Simultaneous Seat: 5.688177 ‘Accept

Low Pressure Air Seat Test Mpa

Upstream Seat: 0.5515808

Downstream Seat: 0.5525808

Inspector Acceptance: Date: 9/11/2019

‘Cameron

700 erste 30

‘Ue Rock AR 72208

[CASTING DATA ¥]

Heat No. Qty

Dag 2

Part No.

BA-1-3189-10-R,

[SPECIFICATION ¥]

'MS-021250-01 Rev. 02

MATERIAL CERTIFICATION

ev:

RvDate 5/8/2019

i

Ser. No. P.O. No.

he 4511750816

Item No.

ASTM A352 Grade LCC modified. 0.42% CE max. Quality Electric Steel Castings, LP. declares that the products supplied

are in compliance with the requirements of the order, the cited specifications, and EN 10204:2004 Type 3.1

Nb = 0.005

[CHEMICAL DATA ¥|

C Mn Si PS Ni__Mo_vV__cu__W__Al_N__Nb__Ce.

19 |[ 78 || 53 |[-o17 |[ 013 | a2 10 |{ 04 ]f 003 [ 10 ][ 005 ][ 04 ][ 007 |[ 00s ][ 037

[TENSILE DATA ¥| [CHARPY DATA ¥)

Tensile Yield Temp | -50 |r | -46 | °c

1,290 |pst [55,730 |pst [7-41-33 Fe-ub

I96-56-45 Joules

bsShear=55-50-45; Mils Lateral Exp=55-33-28

%EI-2" % Red Area

30, 615

HEW

HEAT TREAT ¥ Hrs AtHeat Coolant

Normalize 1650 °F 5 Air

1650 °F 5 Water

1150 °F 5 Air

[COMMENTS ¥

ssRefer tw 261

tea an

ren

Leb ther 8A)

fate hardness Report Wo.

278 for haxdas

6 values,

uu

03/22/2018

thane ted Ec vial peed ocedace th ME EFAS, Canyon VBA hav caning we maroc ind

joe yun 2 00828

AD , _

ea key Lab Supervisor

ELECTRIC STEEL CASTINGS, L.P.

ASTM E10 - 2012

“Standard Test Method for Brinell Hardness of Metallic Materials”

10mm Tungsten Carbide Ball - 3000 Kilogram Force (HBW 10/3000)

Hardness Tester

Manufacturer Model Serial No. Calibration No. Report No.

Detroit Testing PH 3 813 009240 378

Machine Company

Customer ‘Cameron

Heat Code past

Material ASTM A352 Grade LCC

Part Description Qualification Test Coupon

Test Locations HBW (10/3000)

1 179

2 170

3 170

C20) Klay

Name: Omar W. Khan, Test Date: 02/19/18

Title: Lab Supervisor Report Date: 02/20/18

MISTRAS sores Houslon Lob #563 OliceP:(7131465-4113« F: (713)827-7854

ROUP, ING. brian 10980 Metronomes Houston, Tx. 77043 www.mistrasgroup.com,

‘Submitted To: RT 119454

Quality Electric Stool Casting, 39/2018

252 McCarty Drive. BAI3471-40481726

HOUSTON, TX 7029 49869-78809

‘Quantity Received: 2 Description: 6" Body

Part Number: 8A-1-3189-40-R Heat Number: D491

Serial Number: 1,2 Material: N/A

Customer: Cameron Orbit

PROCEDURE: MT 100-MT-001 Rev. 18

‘SPECIFICATION: MT GVMPS 6001 Rev. K

INSPECTION REPORT ~ MAGNETIC PARTICLE

aty ty ty Date

Scope of Exam Inspected Accepted __Rejected, Completed Inspected By

WT-100% ofall accessible | 2@6" | 2@6" 0 ‘3/16/2018 ‘Abimbola Karun

surface area Body Body

At the time of inspection, no relevant or rejectable indications noted. PID#: 49869-78899, HT#: D491

‘TEST PARAMETERS,

Magnetizing Source:

Mig. & Mode MagnetuxY 6 sm 052464 Calbraton Date sonio017

Magnetic Particle:

Manufacturer ile Systems Te #89 Red Batch No 19037

(coor Red ‘Concentraton| Dry Powder

ght

UY. Lott Utraviolet Light White Light

Seal Number NA Intensty @ surtaco NWA siWion? Intensity @ surface __250 foot cancles

ght Mote Mi. ‘Gould Bass ‘Nedel ___DuM 1000 ‘SIN 14127BAIC_Datoof Cal, _ 11/02/2017

Magnatizing Date:

We O Dy X AX DIC PMO) GrodarAmps NA Longitudinal Ange _Yoke 2.0K. Demag _NA

‘Technician Name and Tile:

‘Abimbola Karunwi ~ MT, PT, VT Level l, HT Approved

Report reviewed on 3/19/2018 - MB

erat nde wba xu wn ob CLIENT Tew fname poral i pt 57 oe loin an nape nd

‘insur sb ogy ope ate Sote ment oes

moves

wmume | “B-Z2-SECI“2Z-AS SEES horsemem

TREES noev = (002s eee

tf] sasaa

sqgpu = tenon oper

at san - nan sone SEES eS | EERE

| seam om en SNe | EER

Corrosion Testing Services

(991) 498-120 PAK (31) 488-4210 855 Ardnoro Hy Tat, TH 30408

Final Report

Hydrogen Induced Cracking (HIC) Resistance Test Results per NACE.

TM0284-2016 of 3.25" Thick; ASTM A516; Grade 70 Plate

Heat Number 811916

Purchase Order 465861

For

A. M. Castle & Co.

By

George M. Waid

Benjamin J. Weid

Walter W. Waid

April 9, 2018

submited by Absoney. tard

BACKGROUND,

Corrosion Testing Services was contracted by A. M. Castle & Co. to conduct Hydrogen-

Induced Cracking (HIC) Resistance Tests per NACE TM0284-2016 Standard on ASTM

A516 Grade70 Plate as described below.

TABLE 1

Plate Description

Heat# 811916; ASTM A516 Grade 70 Plate (3.25" Thick)

TABLE 2

SUMMARY OF RESULTS

HYDROGEN-INDUCED CRACKING TESTS:

a - Result,

0.04

3.87

- 7 0.82

TABLE 3

HYDROGEN-INDUCED CRACKING TESTS

NACE Standard TM0284-2016

Description of Test Procedures Result

Specimen Size 0.790" x 1.137" x 3.95"

‘Adequacy of Degreasing Per ASTM F21

Solution a «4

‘Test Gas 100 Percent H2S

PH before intraduction of H2S- 2.70

PH at start of test after H2S saturation 3.13

Concentration of H2S saturation at start of 2738 mgiL

test after saturation

PH at finish of test 3.68

‘Concentration of H2S saturation at finish of 2829 mg/L

test

Avg.

Ber Location, GR % CTR %

7 25mm 0.00 0.00

‘somm_ 0.00. 0.00

75mm 0.00 0.00

Section Avg. 0.00. 0,00 0.00.

2 (middie) 25mm. 0.03 5.54 7.38

50mm. 0.20 43.40 2.53

smn, 0.10 13.46 3.42

‘Section Ava. O11 10.70 25

3 25mm | _—-0.00 0.00 0.00

‘umm 0.00 0.00 0.00

75mm. 0.00 0.00 0.00,

‘Section Avg. 0.00 0.00 0.00

Ending O04 3ar 082

‘Specimen

INDUSTRIAL QUALITY SERVICES, LLC

1415 Edison Ave. Benton Ar 72015,

PH 601-704-6670 FAX 501-704-6570

lasnspecton com

emay

OBIAFE

0. No

SPECIFICATION

et

INDUSTRIAL QUALITY SERVICES, LLC

1415 Edison Ave Benton AR 72015

Phone: (504) 7646570 Fax: (501) 7946573

lasspecton com

REBULTS OF INBPECTION

TOTRDICA iE FOUND.

2781

1UPMENT Us [OUR PROBE,

(MODEL #8100

Alans i SIN 10263

Xavian Hansen LVL 11, [4AM Aerosol

: ei

ont 5/5 [20/8 \erons

ON MACHINING

anus

pricaetentat

ASIONTT WAR Longo

‘SOMVNOINY SVIOHOLN- ——

‘warADNOT SEES Yoon 40 SaHOOEY SN LIA, SDAWTICSON NE

S°0 Su AT CEMMIOVANAWN OM CHUTE SMM TUTE

“OBEN WON STALISTE

b/ee/6e (a) RAM aoe

2 la) RADI S050 ss wor ousteoosTs oc! scat (a)

“poerreasen

a ae

OaNT Zsax awe —_SSANELIH AIDKTALS HISENGS EL

‘BUESMAL _@UETA

“SISKTINY TOSI

© 9000'0 e690" ornt'o aro Eero occa'o osge-o osztvo oozt’9 a4govo isgora Ott OFaE

2

siseton ser

-gandowa WaWOISa9 Tess OR TION ‘SEZESE 'ON mH

oS ‘8215, PezyTeuion ‘OL ApEID sTSvs BASW/Y KiSY BOND

kzg09 1r yore 420

oN waMuo asennad ee aayng ‘peo woySeyeuey oZFT

“oN waqNO SETUS rep 3 STRIED “H'Y tOL G1OS

suva BIVTd THAIS 40 SLSBL TWOISAMd GNY TYOIRBHD 40 LOR

jiodoy 3504.12)

‘O71 ‘MSIAONOT TSBs YOON

241 ‘maraguo? 12548 ¥o20N

Senn

La ‘arated to 0 0oran

ULF” P.O; Box 802404 Houston 1X77280-2404 ¢ Telophone (713) 4608685 « FAX(718) 4403696

Roport Date: 3/9/2018

Report No: 81798100

Rev:

Cust Acct: CASOSS

rand Pratie

75063

oO: 463308

ick x 'Square Test Pleoa

2088277

— Charpy Test Results _

Temp__Lacatibn Foot Pounds Shear ills Lat Exe

34-2521 90-25-25 28-22-18

ata obetse sates Chany impact specimens Voth 10% 10 mm. Tsted wih im ste,

Yvonne Reeredindo

Decent

Pevewe

a

‘Beccnhcnen ar

(ur epatsare oe sxe una cr csr an our nar ray be urd ony win pr wien appro. Our epons ept ny othe

‘Sono texed or nspcied aed do nf neoemery erent ne quate apesreny stor ena mle. es opens rd

tacg coniarms io ASTMLASTO ures arise sated Tis erp sol abe repent, exc wane

‘wien approval ol Acne Ted Labs LP.

Pogotie tot 1 ‘isrepe cons 1 panes)

CASTLE METALS

2602 Pinewood Or. Grand Pralie, TX 75052

Certificate of Compliance

‘Matera Type: AS16670 carbon pate

‘Sine: 5,0" thick

Heat Number: £59236

Quantity: 2s

‘This letters to certiy

with the requirentents o

x the matertal supplied to DN Machining Inc on POW 18436/s in Conformance

this purchase order.

ve aun

Sty

IQs

neato | PaRT#

2130-01 [GAS 105

21630-02|aA5 10.

© wmaaparnce | pexernam [PATE] 6/24/2010

INDUSTRIAL QUALITY SERVICES, LLC Memioo—[- BMULSIFIER

I ORY Wer

19921 MannRoad Mebetale, AR, 72103 | ~ FLOURESANT | soLvENT

PH 801.455.2030 FAX 501.458.3320 ‘CURRENT

lsnapetoncom

Ly PLATE, ABI, 0

DESCRIPTION RESULTS OF INSPECTION

PERFOR PARTICLE INSPECTION OW. RELEVANT INDICATIONS, ACCEPTABLE.

[WR PLATE, 6° ABI6, 50

‘PERFORMED MAGHECTIC PARTI [ON_—_| NO RELEVANT INDICATIONS, ACCEPTABLE.

Corrosion Testing Services

(931) 438-4224 FAK (931) 438-1210 895 Ardmore llny Taft. TY. 38488

Final Report

Hydrogen Induced Cracking (HIC) Resistance Test Results per NACE

TM0284-2016 of 5.00" Thick; ASTM A516; Grade 70 Plate

Heat Number 59236

Purchase Order 473203

For

A. M. Castle & Co.

By

George M. Waid

Benjamin J. Waid

Walter W. Waid

June 5, 2018

Submitted by Stans. vrs atl

BACKGROUND

Corrosion Testing Services was contracted by A. M. Castle & Co. under their purchase

order 473203 to conduct Hydrogen-Induced Cracking (HIC) Resistance Tests per NACE

‘TM0284-2016 Standard on ASTM A516 Grade70 Plate as described below.

TABLE 1

Desoriptio

Heati# £59236; ASTM A516 Grade 70 Plate (5.00" Thick)

TABLE 2

SUMMARY OF RESULTS.

HYDROGEN-INDUCED CRACKING TESTS

Ratio

CSR, %

CLR, %

CTR, %

TABLE 3

HYDROGEN-INDUCED CRACKING TESTS

NACE Standard TM0284-2016

of Test Procedures Result

~ 0.785" x 1.065" x 4.00° |

[ Per ASTM F21

Solution RY

Test Gas 100 Percent H2S.

pH before introduction of H2S 2.66

~ —pHatstartoftestafterH2S saturation | == 8.04. —_

Concentration of H2S saturation at start of 2815 mg/L

test after saturation

PH at finish of test 3.68

Concentration of H2S saturation at finish of 2844 mg/L

test

Location

CLR, %

25mm

50mm

75mm

Section Avg.

0.00 —

50mm, 0.00

75mm 0.00

Section Avg. — 0.00

4 25mm. 0.00 0.00 | 0.00

50mm __ 0.00 0.00 0.00

pect 75mm 0.00 0.00 0.00

| Section Avg. - —0.00 |

8 25mm 0.00

_ 50mm. ___0.00

1 75mm. 0.00

Section Avg. — 0.00 0.00

Ending 0.00 0.00 0.00

‘Specimen

> INDUSTRIAL QUALITY SERVICES, LLC

Conan

27) kee

IQs ‘entiaoncon

in ae

Lower Plates

DESCRIPTION OF SERVICE

[Performed UTI

ee

fener

[ewe PLATE, 6a, 30

[no RELEVANT NDIEATIONS FOUND

favavoz

[owe PLATE, Aste 30

furseooe

[Wo RELEVANT RDICATIONS FOUND

RANA ANSE

AUSTIN McGLURE

2. _5/3°/ Za)

reetametacnmenycteraiicctn niet eaeteninenttebeatal

Acerian, S.A. do c.v MATRIX MEPALS ACERLAN LLC

Canine & San Pedro Amuncacian 3 20643 WEST AIRPORT BLVD / Suriz2 100

Zona Industrial Velle d= Ore, C.F. 76602 STAFFORD, TX 77477

San Juan del Rio, Oro. Phone: (381) 633-4200, Fax: (291) 623-4290

el. (427) 2726600 Fax (427) 2720601

CERTIFIED MATERIAL TES? REGORT

HEAT MR@ER : 1ecsc HEAT DATE : 03/01/2018 CUSTOMER ; CAMERON 12-K

onpen Mo. : 4521742607 guawrre 2

PART Wo. @A-4-1326-10-R PLUS 6-300

CUSTOMER SPECIEZCATTONS : AST A3S2

HEAT Cones : A001,a002

sR LCC CeeMo<.32

CHEMICAL CoMPOSrTION, w2. 4

165 | .0170 1

DELTA FERRITE § BY

MECHANICAL PROPERTIES

TENSILE STRENGTH : 84705 PSE CKARBY V INPACT AT 45 ceustus

YIELD STRENGTH 66203 PSE ENERGY + 37-45-45 Foor-pouND

ELONGATION a8 avg 42 Foor-PoUND

REDUCTION OF AREA oy ERTERAL EXP. 01s mce

saRDNESS 179 WBN PERCENT OF SHEAR 62-64-61

austerrrze austenrere

HEAT TREATIGNT TO NORMALIZE ceusrus To QUENCH : 930 ceLsius

rEMEER 650 censrus © aEALIWG. census

REMARKS : THIS CEREIPICATION COMPLIES WITH SPECIFICATION EN 10204, TYPE 3.1

o2:4ipm 04/03/2018 pepro X. jaARties Ressxor2|

TABORMORY SUPERVISOR

2701 W Roosevelt

PO Box 2803,

Little Rock AR 72203-2803

PHONE 501-375-(244

NATIONAL WATS:

800-727-BOLT (2658)

FAX 501-375-6028

ABC Cover Sheet for Material Certification

ABC Cert Number 53401

Customer ~ Cameron Process Valves (Little Rock, AR)

Customer PO Number ~ 4511936055

Date Shipped ~ 6/20/2018

Part Number—8A-71-928 STUDS

Quantity - 48

Heat Number ~ 10532950

Heat Code —NA

Lot Number ~ 121209-B-2

Special Specification - NA

Prepared by - PEGGY STONE

Title - QUALITY ASSURANCE ASSISTANT

Material Test Report 5 USA

Customer ai

‘ABC Logistics [BA-71-317° ee

PO BOX 2603 BA-71-425 FASTENER

lea-71-701 ‘GROUP. INC.

ENG ROEK M2208 IBA-71-928 USA Fastener Grup, Ine:

Fax. na a teeeien ko ie Texas 77020

Rt (866)546-SB7: *: (713)64 1-4555

lary 48 Siesta can

Speciiication Year Description PO Number Lot Number

A320 2014 Threaded Rod 053116-105 121298-8-2

Heat Number Grade Se pl Length Anish

10532950 W/B7M 3/410 Plain

a te Se Ron: | Me ber (NE A Sipe) th cu

0.4) 0.27 0.025 0.008 0.89 0.21 0.92 0,06 0,025..0.003 Oo 0.002 017

Yield Scale. Tensile Seale.

95 0 ksi 17 o kel

Elong % RA% Hardness Scale.

2 0 69 0 99) 98 HRB

Charpy Set 2 Scale Temp Macro Etch Wedge Tensile Proof Load

185 131 134 Ft Lbs oor R Mc F

Charpy Set 2 5.) Bale

o 0 0

Quenched , Stress Relieved

@ 0° ih 0°

Remarks:

Nb=.001; Sn=.006; N=.007; B=.000._

Conforms to ASTM A193°57M Revi14

100% Hardness Tested . ‘

Memo: © z

3/4-10 X 3-1/2 AT STUD A320-L7m PLAIN":

3.1/4" bst-Ast erse [QUALITY SYSTEM APPROVED

MFG FROM ABOVE =

IDATE: 6/27/18 _ INITIAL: PS

EN 10204:2004,3,

above described product was manufactured, sampled, tested and inspected \n accordance Desay

Ih the reauired specication, incuaing any supplementary requirements Or other requirements

Uesigneted i the purchase order or contract enc were faurd to meet those requiremenss. awe pt

2701 W Roosevelt FEC PHONE 501-375-0244

PO Box 2803 NATIONAL WATS

Little Rock AR. 72203-2803 I 800-727-BOLT (2658)

FAX 501-375-6028

ABC Cover Sheet for Material Certification,

ABC Cert Number ~ 53403

Customer ~ Cameron Process Valves (Little Rock, AR)

Customer PO Number ~ 4511936055

Date Shipped ~ 6/20/2018

Part Number ~8A-75-781 NS

Quantity ~ 48

Heat Number ~ JU0361-02

Heat Code - NA

Lot Number ~ 119626-1

Special Specification - NA.

Prepared by ~ PEGGY STONE

Title - QUALITY ASSURANCE ASSISTANT

Customer Material Test Report

‘ABC Logistics

PO BOX 2803 BA-75-729,

UttleRock 72203 BA-75-74, GROUP,

Fox. BA-75-781 USA Fastener Group, {rc.

Lapo eae st, Houston, texas 77020

‘ Ps (866)546°S872 | Fs (713)641-4055

ory: 4s He alo 3th

‘Specification Year Description Po Number LotNumber

Asa M4 Heavy Hex Nuts: 053118-405 119626-1

Grade Ske | TPL Finish Heat Number Heat Code Markings

1M 34 10 0361-02

G St iS | aR tn, Mo Rea, er) cu

0.410 0.230 0.008 | 0,017 0,800 0.210 0.970 0.170 0.120

Hardness Scale ‘Tempered Hardness. Tempered Hardness Scale

20 22 HRC 86 8B HRB

First Charpy Set. Charpy Scale Charpy Temp Macro Etch Proofload

22 22 22 Ft Lbs +73 °C TSC R 226 KN

‘Second Charpy Set 2 ts. 2

o oO 0

Quenching Tempering a

@o°* in @ 750 ©

Remarks

Ny [QUALITY SYSTEMTAPPROVED

Memos: DATE: 6/27/18 INITIAL: PS

3/4-10 HVY HEX NUT A19@°GR 7M PLAIN

100% HARDNESS TESTED ©

EN 10204:2004 311, ©

* Quality ance j

‘he nove sesereed proaiet was uta, sample, sed ad npece ih acorns ee

wilh the requred specication, meuling any supplementary vequlersects or cher requirements =F

designated nthe purchase order of conrect nd mere folnd to meet those requements

)

Ia]

Za

6

CERTIFICATE OF TEST

Page 01 of 02

Certification pate

25-MAR-2019

CUSTOMER ORDER NUMBER EARLE M. JORGENSEN COMPANY Invoice Number

4512252522/10 $654945

3167 CYPRESS RIDGE DR

CUSTOMER PART NUMBER EADS “IN 38088

0001 8A-16-187 \y Sw

CAMERON PROCESS VALVES uIP To: CAMERON PROCESS VALVES

ATTN:ACCOUNTS PAYABLE ATTN KEISER MFG

PO BOX 3101 3501 N HWY 123 BYBASS

HOUSTON TX 77253 SEGUIN TX 78155

Description: ETD 150 CF BAR AMS 6378

1-7/8 RD X 12' R/L Line Total: 144 IN

HEAT: 027036 ITEM: 505738

Specifications:

AMS 6378 G ASTM A108 13 ASTM A29 15

ASTM A331 00

CHEMICAL ANALYSIS

P 8 st NI cR MO

0.45 0.90 0.01 0.032 0.24 0.02 0.99 0.197

AL v N TE PB SE NB

0.025 0.003 0.007 0.005 0.004 0.0470 0.003

263790

NIAGARA LASALLE CORPORATION COUNTRY OF ORIGIN : FRANCE

MECHANICAL PROPERTIES

YD STR ULT TEN %ELONG | $RED HARDNESS.

DESCRIPTION PSI PST IN 02 IN IN AREA ‘BEN

158424.0 159137.0 9.8 38.6 321

‘Vinal Edt come notre wihrasny wile

‘The above data were nied fot the mtfoclur’s Cette of Teale verison ar pmiedon,

Drolet tn pctesonurenensstae ascnnoetn arin Af TIM ROUSH

realeremsin on la ster o exams, Ft AD

Weherey ceri heme ever by hirer wil mesttheaptaberemiements tw foe al

ested heen, into ny speci forming opr othe desapion

‘The wlll ecorting of se, tous or fauduleatsatmens in commecton with st wale iy Asse

maybe punitablea lon unr federal aatuten,

)

Ia)

a

0

CERTIFICATE OF TEST

Page 02 of 02

certification Date

25-MAR-2019

CUSTOMER ORDER NUMBER

EARLE M. JORGENSEN COMPANY Invoice Number

4512252522/10 8654945

3167 CYPRESS RIDGE DR

CUSTOMER PART NUMBER EADS IN. 38028

0001. 8A~16-187

SOLDTO: CAMERON PROCESS VALVES — gyip To: CAMERON PROCESS VALVES

ATTN:ACCOUNTS PAYABLE ATTN KEISSR MFG

P © BOX 3101 3501 N HWY 123 BYBASS

HOUSTON TX 77253 SEGUIN TX 78155

Description: ETD 150 CF BAR AMS 6378

1.7/8 RD X 12" R/L Line Total: 144 IN

HEAT: 027036 ITEM: 505738

END-QUENCH HARDENABILITY (JOMINY - RC)

1203 4 5 6 8 10 12 14 16 20 24 28 32

59 59 59 59 59 59 57 54 50 50 47 45 44 41 39

STRAND CAST REDUCTION RATIO 53.6 TO 1

MATERIAL IS FREE FROM MERCURY CONTAMINATION

NO WELD REPALR PERFORMED ON MATERIAL

MACRO; OK

Viral dd ot come cosas wT ey we

cour posession

‘The above date were tanseibed fm the manaficiue'sCatiente of Teale wefcation

for completeness and span reqiremerts ofthe information onthe cerifont. All est

reniltsremsinon he sibjet examen

‘We herchy cei thatthe materi eovered by this tepor wil met the aplcale equrerente

500

Compressibility, % 40

Recovery, % 14

Creep Relaxation, % 4

Ash content, % <2.0

Carbon content, % > 98.0

Moisture content, % <05

Total Sulfur content, PPM 500

Leachable Halogen content, PPM <50

Oxidation Inhibitor, PPM > 800

Oxidation rate in air at 670°C (TGA), <4.0

%alhour

Note: All properties except thickness are for the flexible graphite portion only. Values

are nominal unless otherwise specified.

‘While information on this data sheet is typical, it may be subject to change and does not

constitute a product warranty or a specification value.

70-DS-0069 REV. H February 2019

28176 Avenue Stanford

Valencia, CA 91358 USA

1) 257-0500

Salo Fax (661) 257-7742

90-FRO31C DCO public - (BURNETTT!)

&* CHESTERTON.

Global Solutions, Local Service.

CERTIFICATE OF COMPLIANCE

PART NUMBER 8A-63-422

Pastry,

CAM PROCESS VALVES-LITTLE ROCK CAMERO

7200 INTERSTATE 30

Little Rock, AR 72209

United States

‘A.W. CHESTERTON ORDER NUMBER: 000768874

CUSTOMER PURCHASE ORDER NUMBER: 4511865416

uNEs ary ITEM NUMBER DESCRIPTION

a 50 394232N 1622 NOF 2.950x 3.950X9.500

We certify that, the products identified in this order, are in accordance with A.W. Chesterton's

Groveland Business Management System Manual GRO GMGM 0001, Revision J, dated June 15, 2017

and conforms with all applicable Chesterton Engineering Specifications and requirements of this

order.

Sincerely,

Thevabng Gum 6/12/2018

avalon rum Date

Quality Assurance Representative

AW. Chesterton Company

860 Salem Street, Groveland, MA(1834-1563 USA Tel: 978-469-6629 Fax: 781-484-7773

'$0 9001:2015 Registered Visits at: www.chesterton.com 1S014001:2015 Registered

OIL Crry Iron Works, Ino.

Crgincored Qralty Castings

nae nos - Duct Inox - Piametivs - Machen Soe

14. nan Sacer cozyeraesrs

coset To 1530 rns obser

April 17,2018

Schlumberger

Attn: Accts Payable

P.O. Box 3101

Houston, TX 77253-3101

‘TYPE If MATERIAL CERTIFICATION

ATTN: QUALITY CONTROL DEPT.

REFERENCE: P.O. No. 4511785833.

Heat No. — 180326

Pattern No. 8A-5-747-24-R_, Slip

No. Shipped 6 pes).

We certify the ab6ve castings shipped were produced from material thet will satisfy your

Specificat ashe 395, Gr. 60-40-18 Ductile Iron. This certificate has been prepared in

accordafice with EN 10204, 3.1. The following properties were determined from our standard test

report typical of the heat involved:

Tensile Vield Elongation BHN

74,500 psi 51,800 psi 18.5% 143-187

Total Carbon Silicon Manganese Phosphorus

3.64% 2.67% .2%

rely,

OIL CITY IRON WORKS, INC.

@ cameron

LITTLE ROCK

DIMENSIONAL RECORD

‘The valves on this order have been dimensionally checked and found to be within acceptable

‘tolerance ranges as identified below.

Serial No. EndtoEnd BoreDia. O.A.Height Flange Dia. H.W. Open Torque Close Wall Thick.

121330018 1 022.125 6 42 125 92

CAMERON S.0, Number:

Customer / Order Number:

Referenc

Production Order #: 121330018 Quantity: 1.

Material Description: PV 6 RF GV C921 LT-LH-LH DTR 625 GO

Line Item 135 Tag Numb: 54-VP-85015,

Signed: Glenn Fuller Date: 9/26/2019

Title Inspector / Tester

Form No. 1114 Page Loft Revised: 10/24/2015

Certificate of Conformance

1301 Georgia St

South Houston, TX 77587

Phone: (713) 946-8920

Houston Plating & Coatings, LLC. Fax: (113) 946-8487

Houston Plating & Coatings, LLC. wav oustonpating com

Etectoloss Nickel Plating Spray Coatings

Customer: P.O. Number Order Ni

CAM PROCESS VALVES - LITTLE ROCK 4512054272, 592329

‘We certify that all the parts listed were prepared and processed to conform 100% to drawing.

specifications, applicable standards, Engineering Specifications, and QA Procedures. Any

deviations are reported in detail below:

Part or Drawing No: Customer Ref Qua

BA-4-1326-10 LINE ITEM 00010 2

Process Date 9/17/2018 Expiration Date: NA

Process Require Elecroless Nickel Plating

To Spec: 8A-GVMPS-7021 Rev 02

Manufacture Coventya Batch No: 091718

(Cure TimerTemp: NA DFT: NA

ENPMils: .001/.0015

Notes:

‘VISUAL INSPECTION PRE-PLATE/POST-PLATE: PASS

Quality, Assurance Manual Rev: 16 Date: 06/2018

DATE: 912772019 SIGNATURE:

Country of Orgin: U.S.A. Alberto Landois

Page | of 1 Onder Number 592329

Specification #: 8A-GVMPS-7021 Rev 02

AAN-EZE

a PLATING "ING.

100 Mission Drive » Nashville, Arkansas 71852 + (870) 645-5134 » Fax (870) 845-5168

e-mail:’ ghughes@janezeplating.com

TO: Cameron - Little Rock

This is to cortify the item(s) listed below are plated by the Hard Chromium Plating

Process and mect the requirements of GVMPS 7005 minimum 3 mils per side.

Date 9-26-79

Cameron PO ASUIIEEIE

Cameron Part Number _& A -/~ 3/E9-.

Jan-Eze Invoice # _ @ 2 #@S

Quantity

Post Inspection

Pre-Plate Inspection

Arkansas Painting & Specialties

Le Rook AR 72202

onte: fuay 17,2018 CUSTOMER, Camaron international om:

PROUECT,

Customer WO oP # 4512520600 APS WIDE

atast | 225 28 vets

fost seMay | 15itoy | s6aty | seatay | 17 240

[time 00 | +00 | 200 [100 200

fettiv mii s |e | » | 6 8

[ambien Temperature re | se | 75 | so

foewPoine ea [nls | 6

face Temperature u | | 2 | 7 eo

tent Grade aluminum oxide | A006

pase

Ste s01016 ‘ni

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 9.1 Corporate Profile: SchlumbergerDocument5 pages9.1 Corporate Profile: SchlumbergerClarkFedele27No ratings yet

- Technical Submittal - PF-K & Er-VDocument50 pagesTechnical Submittal - PF-K & Er-VClarkFedele27No ratings yet

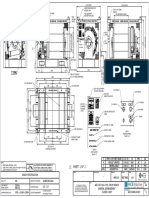

- Valve GADDocument2 pagesValve GADClarkFedele27No ratings yet

- Non Destructive Testing FacilityDocument158 pagesNon Destructive Testing FacilityClarkFedele27No ratings yet

- Valve Inspection and Test PlanDocument1 pageValve Inspection and Test PlanClarkFedele27100% (1)

- Product Data: Carboguard 190 HDocument2 pagesProduct Data: Carboguard 190 HClarkFedele27100% (1)

- Wedding Song ChordsDocument13 pagesWedding Song ChordsClarkFedele27No ratings yet

- APS - New Capability StatementDocument12 pagesAPS - New Capability StatementClarkFedele27No ratings yet

- Carbozinc 11: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11: Selection & Specification Data Substrates & Surface PreparationClarkFedele27No ratings yet

- APS Business ReferencesDocument3 pagesAPS Business ReferencesClarkFedele27No ratings yet

- Sutech Valves - Product RangeDocument5 pagesSutech Valves - Product RangeClarkFedele27No ratings yet

- Copon EA 4-2217 Data SheetDocument2 pagesCopon EA 4-2217 Data SheetClarkFedele27No ratings yet

- 18B. Protegol UR 32.55R Data SheetDocument3 pages18B. Protegol UR 32.55R Data SheetClarkFedele27No ratings yet

- Carbothane 134Document2 pagesCarbothane 134ClarkFedele27No ratings yet

- Venting Requirement - API 2000 5th EditionDocument1 pageVenting Requirement - API 2000 5th EditionClarkFedele27No ratings yet

- Avery Hardoll Whittaker Controls 4 Inch Self Sealing Ind CouplingsDocument2 pagesAvery Hardoll Whittaker Controls 4 Inch Self Sealing Ind CouplingsClarkFedele27No ratings yet

- CatalogueDocument2 pagesCatalogueClarkFedele27No ratings yet

- 24 150 8811 DTR.L Go.aDocument1 page24 150 8811 DTR.L Go.aClarkFedele27No ratings yet

- 24 150 8811 DTR.L Ma.g Fa14Document1 page24 150 8811 DTR.L Ma.g Fa14ClarkFedele27No ratings yet

- 20 150 8811 DTR.L Ma.g Fa14Document1 page20 150 8811 DTR.L Ma.g Fa14ClarkFedele27No ratings yet

- 04 150 211 DTR.L Mat Fa10Document1 page04 150 211 DTR.L Mat Fa10ClarkFedele27No ratings yet

- Cameron: Valves & Measurement General Arrangement 4"-150 CL, MODEL 211, 201 HO Safety Bleed/DtrDocument1 pageCameron: Valves & Measurement General Arrangement 4"-150 CL, MODEL 211, 201 HO Safety Bleed/DtrClarkFedele27No ratings yet

- Ace 00480 01001 R5Document2 pagesAce 00480 01001 R5ClarkFedele27No ratings yet

- 16 150 8811 DTR.L Ma.g Fa14 - Rev02Document1 page16 150 8811 DTR.L Ma.g Fa14 - Rev02ClarkFedele27No ratings yet

- Orbit Facility ProfileDocument23 pagesOrbit Facility ProfileClarkFedele27No ratings yet

- Ace 02380 001 R8 PDFDocument1 pageAce 02380 001 R8 PDFClarkFedele27No ratings yet