Professional Documents

Culture Documents

Udc Tyco PDF

Uploaded by

Eder Dax Rodriguez0 ratings0% found this document useful (0 votes)

9 views7 pagesOriginal Title

UDC TYCO.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views7 pagesUdc Tyco PDF

Uploaded by

Eder Dax RodriguezCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

tyco boa 108-37019

Electronics Specification Taian

Universal Distribution Connector , Reinforced

1. SCOPE

14

24

Content

This specification contains performance requirements and qualification tests procedures for

U.D.C. Reinforcad . This connector consists of an “C" member and a Wedge , both stamped.

and formed of copper alloy (ASTM B36) with an adjustable design configuration to act as a

spring . Thay are intended to provide a reliable electrical connection for solid and siranded

‘conductors (aluminum or copper) used on street light and consumer's enter connections .

APPLICABLE DOCUMENTS.

The following documents form a part of this specification to the extent specified herein . In the

‘event of conifict between requirements of this specification and the product drawing , the

product drawing shall take precedance . In the evant of conflict betwaan the raquiremants of

this specification and the referenced documents , this specification shall take precadence .

2.4.1 AMP Documents

+ 109-13009 Thermal Shock , Test Procedure for

= 109-13010 Salt Spray and Elevated Temperature , Test Procedure for

501-289 Test Report

2.4.2 Military Documents

* MIL-C-45662 Calibration of Standards

2.4.3 Commercial Documents

© ANSIC119.4-1991 Amarican National Standard for Connectors for Use

Between Aluminum-to-Aluminum or Aluminum-to-

Copper Conductors.

«NEMA COS - 1973 (R 1978)

3. REQUIREMENTS:

34 Design and Construction

Connectors shall be of the design , construction and physical dimensions specified on the

applicable AMP Product Drawing .

32 Materials

‘The materials used on the construction of these connectors shall be as specified on the

applicable AMP Product Orawing.

Prapared by = Claudio G.Cassall__ | Checked by : Water Balint Je [Apsroved by Joss Ata Sava

‘ye ents te ‘peter escent ae

Loc. AP

Universal Distribution Connector , Reinforced

4108-37019

3.3. Functional Characteristics

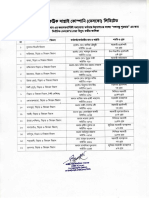

3.3.4 Wire Range

Connectors are designed to accommodate various sizes according to Table |.

UD. Connector Wire Diameter Limits

Part UL Listed ‘Sum Top Groove Bottom Groove

Number cy Wax. Win. Wax. Min. Max. Min

Type | y 552 a7 320 125 292 125;

(PN aarzet-1) con | (a6) | 6.12) (7) 742) 17)

Type ee 440 347 320 125 208 125

(PN 881783-1) ce) | (6,82) 12) em 630) ein

Type il 7 374 2a 258 100 188 050

(PN 881785-1) 50) (740) (655) 54) 65) (27,

Type V Y 302 236 258 100 783 (050

(PN 981787-1) @s7) 6.99) (655) (2,54) 4.65) (27)

Type V 7 a8 180 198 100 783 (050

(PN 881789-1) 620) 4.58) 93) (2.54) (4,65) (1.27)

Type Vi Y 737 661 a7 315 368 257

(PN 444051-1) (72) _| (679) _| (061) | (6,01) 36) (6.54)

Type i N 737 661 ar 3.15 368 257

(PN 444081-2) «.7)_| (679) | (1061 | (8.01) (9,36) (6.54)

Type Vi Y ‘660 552 398 183 ‘327 183

(PN-444083-1) (i678) | 4,03 | (i011) | 66) 630) (4.86)

Type Vil N ‘660 552 398 188 ‘S27 188

(PN 4405-2) (i6.7e)_| 403 | (011) | 66) 630) (4,86)

Type Wil 7 796 738 398 316 398 S15

(PN 444965-1) woz) | a7) | cory | won | cory | eon

Type vil i 796 738 398 316 398 318

(PN 444388-2) @oz | cava | corn | eon | corn | eon

Type A ze 431 358 368 220 201 088

(PN 638662-1) (10.95)_| (9,10) 636) 6,60) 6.10) (74)

Type 8. uy 516 431 369 244 201 088)

(PN 638653-1) «39 | oss) | @36) (6.20) 610) 1,74)

Type C Y 81 S16 501 328 201 088

(PN 688664-1) (476) | a3) | 274) | (6.20) 610) (1.74)

Type Y 669 561 ‘502 374 201 068

(PN 688655-1) (v7.0)_| 475) | (274) | (9.50) 6.10) (74)

Type F 7 358 283 328 220 201 068

(PN 638686-1) 0) (720) 633) (6.60) 610)

Type G Y 358 283 328 220 068

(PN 688687-1) 10) (7.20) 33) 6.60) 4.73) (4,96)

Table!

3.3.2 Classification

U.D. Connectors Reinforced are classified electrically as class "A’ and machenically

as class 3 , minimum tension , as described in ANSI Specification C.119.4 - 1991 and

NEMA CC3-1978 (R 1978) .

4. QUALITY ASSURANCE PROVISIONS

44

General Provisions

The quality provisions specified harain shall be employed in the manufacturing and testing of,

this product to insure that normal production units continue to meat the performance

requirements of this specification .

Revision “H™

Zo?

Universal Distribution Connector , Reinforced 4108-37019

42

43

5A,

52

53

Classification of Test

a) Qualification inspection (see §)

b) Quality Conformance inspection (see 6)

Test Conditions

Measurements

Measurements shall be made with instruments that have been calibrated and are

cortiied in accordance with specification MIL-C-45662.,

Laboratory Conditions

Unless otherwise specified herein , normal laboratory temperature , humidity and

atmospheric pressure shall be considered acceptable for test purposas

QUALIFICATION INSPECTION

‘Sample Selection

Connactors selected for test shall be representative of current design and construction .

Preparation of test samples shall be conducted in accordance with AMP Instruction Sheets

govarning assambly techniquas

Test Procedure

Quaification Inspection shall be conducted in accordance with Table I! in sequence specitiod

Sample Preparation

Three or four connectors shall be prepared for each test group in the following manner , as

applicable for their respective tests

5.3.4 Test Group | (Heat Cycle Test)

The exposed length of conductor in the heat cycle loop between the connectors and

equalizers , shall be twelve (12) inches between the connectors and equalizers . For

solid round conductors , the exposed length between connectors shall be twenty-four

(24) inches , es no equalizers are required .

‘The loop shall be connected to the power source using additional lengths (twalve (12)

minimum inches for stranded conductors and twenty-four (24) minimum inches for

solld round conductors) .

Equalizers are installed on stranded conductors to provide equipotential planes for

resistance measurements and to pravent the infiuance of one connector on the othar

in the heat cycle loop . These equalizers may be of any form that assure permanent

contact with all the strands of the conductor between connectors for the duration of,

the heat cycle test : 2.9. , a welded equalizer or a short compression sieeve in the

contor between two connectors , if a continuous conductor is used .

In adaition , for obtaining conductor tamperatura , a control conductor shall be

installed in the heat cycle loop between two equalizers . It shall be the same size and

‘ype as the test conductor that would run at the higher temperatura , and shall be at

least twice the length specified for the test conductor . For temperature measurements

at least one thermocouple shall be permanently attached to each connector , as close

as possible to the midpoint between the two conductors , and one thermocouple

attached at the midpoint of the control conductor .

Test Group Il (Thormal Shock/Corrosion)

Connectors shall be assembled to lengths of conductor as spacitiod in AMP

‘Specitications 109-1309 and 108-13010

Current equalizers shall be installed on strandad conductors twelve inches from the

edgas of the connectors

Revision “H™

3 of7

Universal Distribution Connector , Reinforced 4108-37019

54 Acceptance

‘All samples shall meet the requirements specified in the performance section of this,

specification , paragraph 5.5 .

5.5 Performance Requirements and Test Methods

U.D. Connector Reinforced shall be designed to meet the performance requirements specified

herein. To varify compliance to this specification , production items shall be tested and shall

meet the requirements of this specification

Tasts shall be conducted in order spaeitiad on Table II.

Qualification Inspection

“Test or examination Paragraph ‘Test Group and Sequence

1 1 MW

Examination of Product BBA. 1 1 1

“Termination Resistance (a) B52 3-4 | B46

EET Heat Cycle 553, 3

“Thermal Shock 554, 3

Corosion 555. 5

“Tensile Strengih BSS 2

Table

(@) Test Group I, sequence 4, measurements taken throughout the test as specified

5.8.1 Examination of Product

When examined as specified , all samples shall be free trom any damage or physical

defecis that would affect the electrical or mechanical performance of the connactors

‘After connectors applications , mainly when using solid conductors , they could rotate

over the conductor without any restriction for termination resistance and tensio

strength requirements .

5.5.1.1 Test Method

Test specimens shall be visually examined before and after assembling to assure

proper manufacturing and assembly in accordance with the manufacturar’s drawings.

and instructions .

5.8.2 Termination Resistance

a) Heat Cycle Test

When measured as specified, each connector shall indicate electrical stability

throughout the tast from the 25th to the 500th cycle , by a variation of not

mora than 5% from the average of the measured values in this interval .

b) Thermal Shock and Corrosion

When measured as specified , the voltage drop across connector termination,

shall not deviate more than 250% from the initial measuraments (Stop 2 ,

Tabie Il) fo measurements made after either Thermal Shock or Corrosion

5.5.2.1 Test Method

Measurements shall be taken across each connector , with the probe points

located on the equalizers 1/8 inch back from the edge adjacent to the

connector , of at a similar distance on a solid conductor .

Anonheating magnitude of direct current shall be used for measurements -

Revision “A” aof7

Universal Distribution Connector , Reinforced 4108-37019

5.5.3 Heat Cycle Test

‘Throughout the tast , as specified , the tamperature of connactors shall not exceed

‘hat the control conductor , and the temperature difference batween the control

conductor and each connector shall show a condition of stability from the 25th to the

500th cycle . Stability is indicated by a dectease of this difference of not more than

10°C trom the average of the measured ditferencas in the interval for this connector .

In addition , connectors shall meet the requirements for Termination Resistance

throughout the test as specified in Paragraph 6.5.2.2.

5.5.3.1 Tost Mothod

Connectors shall be subjected to heat cycle tast In accordance with ANSI

€119.4- 1991 , and NEMA CC3-1973 (R 1978) , class "A", as stated herein .

A total of 500 “current on current off" cycles shall be performed . Tasting shall

bbe performed in @ draft-free room at an ambient temperatura of 16°C par

ANSI C119 10 35°C. The tast current shall be adjusted to produce a

temperature rise above ambient of 100°C on the control conductor , the

adjustment to be made during the heating periods of the first 25 cycles

This currant shall be used for tha remainder of the tast , ragardiass of tha

deviation of the control conductor temperatura .

Each heating cycle shall consist of equal “current on” and “currant off*

periods of one (01) hour of duration (the length of these time periods in which

resistance and temperature measuraments are made shall ba extendad for

tha time requited to take the measurements)

a) Mounting

The heat cycle test chain may be installed in the form of a loop , an

“UP, or a “zigzag” configuration in which the connectors shall be

mounted in a horizontal position with at least eight inches distance

between adjacent connectors . The chain shall be a minimum

distance of 12 inches trom any walls and 24 inches from the floor or

ceiling

b) Measurements

Resistance and temperature measurements shall be made at the

beginning of the test and at the following intervals , conforming as.

close as possible to normal working hours :

~ cyolas 25, 50, 75, 100, 125, 165, 205 , 250, 325 , 405 and

500 , plus-or-minus 5 cyclas .

Resistance measurements shall be made In accordance with

paragraph 6.6.2.1. at the end of the specified “current off periods .

‘The ambient temperature shall be recorded along which each sel of

resistance measurements , and the resistance values corrected to

20°C . Temperatura measurements shall be taken on connaciors and

the control conductors at the ond of the spacified “currant on" heating

periods

5.8.4 Thermal Shock

After five cycles of Thermal Shock as specified , connectors shall meet the

requirements for Termination Resistance . paragraph 6.5.2.0

Revision “H™ 5 of7

Universal Distribution Connector , Reinforced 4108-37019

64.

62

5.5.5

5.86

554,

Test Method

Connectors shall be subjected to five cycles of Thermal Shock in accordance

with AMP Specification 109-13009 , each consisting of :

= 2¥ehours at 150°

= 15 minutes at 0°C (meting ice water) , immediataly from the previous

environment

= 30 minutes at 150°C

= 20% hours at room temperature.

Corrosion

Upon completion of the 30-day Salt Spray test as specified , connectors shall meet

the requirements for Termination Resistance , Paragraph 5.5.2.0

5.5.5.1 Test Method

Connectors shall be subjected to a 30-day Salt Spray Corrosion Test in

accordance with AMP Specification 109-13010 , each daily exposure

consisting of :

- 18 hours in a 6% salt spray atmosphare

= Thour In a drying oven at 100°C

- Shouts at room temperature.

Tensile Strength (Test Group Ill)

When tested as spocified . the taps shall not break or bacome separated from the

cable until attaining a tensile force of 200 pounds or §% of the rated cable strength of

‘the weaker conductor , whichaver is larger , for conductors larger than 6 AWG .

For conductor sizes 6 AWG and smaller , tha force value shall ba 100 pounds ..

5.5.6.1 Test Method

Test specimens shall be placed in a tonsil testing machine and an axial force

applied to the conduciors at a rate of %4 Inch per minute per 12 Inches of

length between jaws until the connector breaks or becomes separated from

the conductor . When tasting connectors assembled to stranded conductors

suitable deadening procedure shall be performed on the cable ends to

assure simultaneous loading of all strands

QUALITY CONFORMANCE INSPECTION

‘Sample Selection

Unless otherwise spet

cd, sampling procedures shall be in accordance with MIL-STD-105

‘Sampling and Acceptable Quality Levels shall be as specified in the applicable AMP Quality

Inspection Plan .

Dimer

Test

Conn:

;nsional raquiramants shall bo in accordance with the applicable AMP Product Drawing .

Procedure

actors supplied in accordance with this specification shall meet the requirements for

Quality Conformance Inspection , Tabla Ill.

Examination and test shall be conducted in the sequence specified

Quality Conformance Inspection

Testor Examination [Test Method

Examination of Product [Quality Inspection Plan

Tensile Strength Paragraph 6.5.6

Table itt

Revision “H™

6 of7

Universal Distribution Connector , Reinforced

4108-37019

Revision Record

Revision Date Description:

o : | Reteased

A 06-Jan-1993 | 3393

5 (O1-Sep-1993 | L800-0259-98

c 25-Api-1994 | LBOO-0186-94

o “13-Jul-4984 | LB00-0854-94

E (02-Jun-1995 | LB00-0256-95,

F 15-Deo-1995 | LB00-0587-95.

c 27-Aug-1999 | L800-0381-99

H 27-Nov-2001 | L800-0505-01

Revision “H™ 7 of7

You might also like

- Duet Seal No For DDP, Lot-1 - 2Document1 pageDuet Seal No For DDP, Lot-1 - 2Shahriar AhmedNo ratings yet

- Limitei) : BRB Cable IndustriesDocument10 pagesLimitei) : BRB Cable IndustriesShahriar AhmedNo ratings yet

- CPRI Report-15KVADocument34 pagesCPRI Report-15KVAShahriar AhmedNo ratings yet

- Substation - NoaraiDocument575 pagesSubstation - NoaraiShahriar AhmedNo ratings yet

- Change Management As Context For Capacity Development - Cesar UmaliDocument31 pagesChange Management As Context For Capacity Development - Cesar UmaliShahriar AhmedNo ratings yet

- AGM Tranning 07 07 2015Document8 pagesAGM Tranning 07 07 2015Shahriar AhmedNo ratings yet

- 1877Document1 page1877Shahriar AhmedNo ratings yet

- Duet Seal No For DDP, Lot-1Document1 pageDuet Seal No For DDP, Lot-1Shahriar AhmedNo ratings yet

- BERC Electricity Tariff Order (NESCO) - 2017Document29 pagesBERC Electricity Tariff Order (NESCO) - 2017Shahriar AhmedNo ratings yet

- BERC - Tariff Order - 2017 - PDB (Retail) - 2Document30 pagesBERC - Tariff Order - 2017 - PDB (Retail) - 2Shahriar AhmedNo ratings yet

- Effiffirwqqfrb-Rr: I' Ii' of Iii' NRDocument1 pageEffiffirwqqfrb-Rr: I' Ii' of Iii' NRShahriar AhmedNo ratings yet

- Electricity Tariff 2015Document17 pagesElectricity Tariff 2015Shahriar AhmedNo ratings yet

- BERC Electricity Tariff Order (WZPDCL) - 2017Document30 pagesBERC Electricity Tariff Order (WZPDCL) - 2017Shahriar AhmedNo ratings yet

- BERC Electricity Tariff Order (DPDC) - 2017Document30 pagesBERC Electricity Tariff Order (DPDC) - 2017Shahriar AhmedNo ratings yet

- Seniority List Pay Grade-07Document5 pagesSeniority List Pay Grade-07Shahriar AhmedNo ratings yet

- Criscop (Kallyan)Document2 pagesCriscop (Kallyan)Shahriar AhmedNo ratings yet

- RPGCL CircularDocument3 pagesRPGCL CircularShahriar AhmedNo ratings yet

- Organizational Set-Up of Bangladesh Rural Electrification BoardDocument1 pageOrganizational Set-Up of Bangladesh Rural Electrification BoardShahriar AhmedNo ratings yet

- Full Suggestion - Senior Officer WrittenDocument16 pagesFull Suggestion - Senior Officer WrittenShahriar AhmedNo ratings yet

- RM Elqfffi Re C5Tffi (C5Rty Ffifre: Rfuffca in A Ae ReatanDocument1 pageRM Elqfffi Re C5Tffi (C5Rty Ffifre: Rfuffca in A Ae ReatanShahriar AhmedNo ratings yet

- Durham A Catalog - New2019Document100 pagesDurham A Catalog - New2019Shahriar AhmedNo ratings yet

- Material Standard: 21 KV Heavy Duty Distribution Class, Polymer, Metal-Oxide Surge ArrestersDocument3 pagesMaterial Standard: 21 KV Heavy Duty Distribution Class, Polymer, Metal-Oxide Surge ArrestersShahriar AhmedNo ratings yet

- Evsjv 'K E VSK: (Wi Zu G U Gû Avdu MVWM©S DBS)Document1 pageEvsjv 'K E VSK: (Wi Zu G U Gû Avdu MVWM©S DBS)Shahriar AhmedNo ratings yet

- Watson ThesisDocument224 pagesWatson ThesisShahriar AhmedNo ratings yet

- High Density Apitong Cross Arm BracesDocument4 pagesHigh Density Apitong Cross Arm BracesShahriar AhmedNo ratings yet

- Frequency Control Concerns in The North American Electric Power SystemDocument32 pagesFrequency Control Concerns in The North American Electric Power SystemShahriar AhmedNo ratings yet

- Admission-21 AdDocument2 pagesAdmission-21 AdShahriar AhmedNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)