Professional Documents

Culture Documents

Concretepiles PDF

Concretepiles PDF

Uploaded by

bayzura0 ratings0% found this document useful (0 votes)

10 views6 pagesOriginal Title

concretePiles.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views6 pagesConcretepiles PDF

Concretepiles PDF

Uploaded by

bayzuraCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

lune Concrete

Precast Solutions

Applications

Hume RC Piles are used in foundations to increase the bearing capacity and to reduce settlements

at sites with weak compressible soil, which otherwise cannot be used for construction

Hume RC Piles are suitable for supporting,

© Building structures ranging from low-rise to mediumrise and high-rise.

* Infrastructures to be constructed under a wide range of soil conditions.

Features

Quality Assured Production

Hume RC Piles are manufactured under controlled conditions to ensure product quality and

reliability. Hume RC Piles carry the SIRIM Certification under Quality System MS ISO 9001 : 2000.

Wide Selection Of Pile Sizes and Classes

Hume RC Piles are manufactured in sizes ranging from 150mm x 150mm to 400mm x 400mm. To

suit different soil and design conditions, Hume RC Files are available in three classes for each and

every pile size, i.e. Class A, B and C.

High Load Bearing Capacities

With the use of high strength concrete in Grade 45 or Grade 60, Hume RC Piles are engineered to

withstand higher loads during driving and in service. This facilitates the economical design of

foundations to suit varying soil concitions.

Production

Hume RC Piles are manufactured in rigid and dimensionally accurate moulds to facilitate the

accurate fixing of steel reinforcement cages and joint plates.

With proprietary concrete mix design, high strength conorete is produced at our state-of-the-art

conerete batching plant to ensure consistency and homogeneity in concrete mix. Hume RC Piles

are capable of achieving the required strength for driving within 7-14 days.

Specifications

Hume RC Piles are designed to BS 8004 : 1986 - British Standard Code of Practice for Foundation.

(if requested, Hume can supply RC piles designed to other available Standards such as MS 1314

2004 and JKR Standard Specification.]

Constituent Materials : (British Standards are quoted below. Other equivalent Standards, where

appiicable are acceptable)

Cement BS 12: 1996 Ordinary Portland Cement

Aggregates BS 882 : 1992 Sand / 20mm Aggregates

High Tensile Bar BS 4449: 1997 Longitudinal Reinforcement Bars

Cold Drawn Wire BS 4461 : 1978 Lateral Reinforcement

Mild Steel Piate BS EN 10025 : 1993 End Plate (Grade $275)

Admixture BS 5075-3: 1985 Superplasticizer

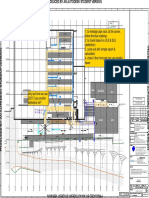

@ Dimensions & Details

_—UFTING HOOK

' -02t - $ soa

owt : = moan

mae IAA AAAAAAARIA AAAI

THWKSATRITCHP)[UNNS ATRITCH ral —____—___UNKS ATTEN z

OO Ts |

‘SECTIONAL VIEW STARTER PILED

_—UFTING HOOK

IIIA AAA ARITA

[IGS AT PITCH PUNKS AT PITCH PZ UNKsatpTonPS

SS LENGTH -

"SECTIONAL VIEW (EXTENSION FILE

Fp main nenronceMeNT

¢ TE carerat REINFORCEMENT

4p LDA f somm won cover

a

ECTION 14

180 x 150 a) 10m)

450 | 75 | 4200

76x17 [178 172/175) 4 | THO

525 | 8 | 3900

200x200 | 204 196 | 200) 4 | 112° 600 | 100 | 3600 | 8

235x235, | 239 | 231 235 8 | TIO 705 115 | 10 | 8

250x260 | 264 | 246 250 4 | T16 750 | 110 | 9000 8

278x275 | 279 | 27 | 275 | 4 5 825 | 135 8700 | g

300x900 | 305 | 295 | 300 | @ von | us | ecco) 12

320x320 | 325 | 315 | 320 | 4 960 | 140 | 8160 2

350x360 | 365 | 345 | 360 | 4 4080 | 130 | 7800 | Cc al

"381x381 | 386 | 376 | 381 | 4 [1145] 120 [7420 [12

400x400 405 | 365 | 400 [| Tie | 60 | 40 | 1200 40-115 1200/ 116 [aan 12

ii ese A Fn eee

Pile Dimensions and Details

Sy a

om) STG mena Dia. (mm) (mm) | (mm) | (mm) (mm) CC

150x150 | 183 | 147 1604] T9 | | s2_| 450 32-75 | 450 | 75 | 4200, 6

175x175 178 | 172 | 175 | 4 | _T9 35 525 35.86 | 525 | 85 | 3900 | 6

200x200 | 204 | 196 | 200 | 4 | rio | 3_| 600 | 35-100 600 | 100 | 3600 | 8

2isx208 |[zi0 2st | a6 [4 | Tia | me ens oe |e [ero o |

250x250 | 254 | 246 250 8 | T10 40 | 750 40-110 750 | 110 | 9000 9

| 275x275 | 279 | 2 | 275 | 8 | Tio | | 50_| 26 60-195 | 925 | 195 | e700 | 9

300x300 905 | 295 | 300 | 4) TI6 50 | 900 | 50-145 | 900 | 145 | 8400 2

sort eelse [is | Me | ail = fie [amie] eal cel eal ae

350x350 | 355 | [30s (30/8 | Tz | 45 | 1050 45-130 1050 | 130 | 7800 12 |

Sibel on VR cor cron za [| elie Po [es PA

400x400 | 405 | 395 | 400 | 4 120 6.0 | 40 | 1200 40-115 | 1200 | 115 | 7200 | 12

* For maximum pile length only

Pile Dimensions and Detai

150% 150 | 153 | 147 | 150° 450 eo

"178x178 | 178 | 172 | 175 Ta om 3 | 525 | 3585 a 3900 6 |

200x200 | 204| 198 | 200 4| T10 | 45 35 | 600 35-100 600 100 | 2600 6

235x235 | 239 | 231 | 235 Tiz_ | 50 | 40 | 705 40115 | 705 | 115 | 6180 | 8

250x260 | 264 | 246 | 260 Tio | 50 | 40 | 760 | 40110| 760 | 110 | 9000 ~ 1

~ 275x275 | 279 | 271 | 275 T10 | 60 | 80 | 026 [50-195 | 25 | 195 | e700| eC

300x300 | 305/295 300/ 4| Tie | 60 | 60 | 000 60145 | 900 | 145 | 8400 9 |

320x320 | 325 | 315 | 320 Tie | 60 | 45 | 960 45140 960 140 8160 9 |

t 950x950 | 965 | 345 | 350] 8 T12 | 60 | 45 1050 45-190 | 1050| 190 | 7800, 9

381x381 | 386 | 376 | 381 T20 60 | 40 | 1145 | 40-120 | 1145 | 120 | 7420 om |

400x400 | 405 | 395 | 400 | 4| T20 | 60 | 40 | 1200/40115| 1200| 115 | 720 | 9 |

For maximum pile length only

© Working Loads of Piles

Maximum axial working loads on Hume RC Square Piles are calculated to BS 8004 : 1986 and CP 116 : 1989

Maximum Axial Working load = % Ag+ fec Ase

385

Where fey = ~—oharacteristic cube strength of concrete at 28 days

60 N/mm? {Class A)

= 45.N/mm? (Class B/C)

Re net grea of concrete

fee 175 N/mm? for high yield reinforcement

Asc = ofoss sectional area of longitudinal steel

50 x 15: 3,6

175x175, 3.6

200 x 200 3.6 452 fea

[235x235 | 3.6.9 628 i

| 280x260 |3,6,9,12 804 17 > a

a“ 275x275 |3,6,9,12 804, 139

300x300 | 3,6,9,12 905 | 1

| 320x320 13.6.9, 12 | 1287 [ 191 -

360x350 | 3,6,9,12 1257 ae Ze

381x381 /3,6,9,12) 1521 207 ie

400x400 3.6.9, 12 1608 294

f 180 at 54 “i

| 17 | 254

es | 314 5

2 45 6

6 89 6

75, E 1 5 |

300, + 126 10

q 320 . 130

x3 6. ie 14

31 x 3 26, 178

400% 6 7 19%

‘+ Maximum and recommended axial working loads shown are only theoretical structural capacities of piles.

‘* Actual working capacities are dependent on soil conditions end other considerations, but shall not exceed maximum

axial working loads shown,

© Types Of Pile Shoes

Five types of pile shoes are available to suit various driving and soil concitions.

ye al

Type 2 : Plain Shoe ‘Type 3 : Fabricated Pointed Shoo

(Sizes From 160 - 200) (Sizes From 235 - 400)

+ Standard Pile Shoes

* Pile Shoes For Special Application

4 AI

45, 4655 3

Type 1: Cast Iron Shoo Type 4: X-Pointed Shoo Type 6: Rock Shoe

Piling work in progress

HUME CONCRETE MARKETING SDN. BHD. «1»

[A Member 0! tho Hong Leong Group Malaysia

Level 2, Bangunan PanGloba', 14, Jalan Tandang, 46050 Petaling Jay

PO. Box 21, $6700 Petaling Jaya, Selangor Deru) Ehsan, Melayai

“Tl: 03-7783 3068 (General Line) / 03.7785 5282 Hotline)

Fax: 03-1785 1823 (Marketing) / 03-7782 7220 |Special Projects Unit)

E-mail: hom@humeconerete.commy Homepage: hitp:/www.humeconcrete.com.my

Hume Concrote Factories :

Beranang Keontan ‘Gudarg Pal

Lot, Berorang inure Estate, Lo 46, Semambu hdustal Estate, Pht 248, Jalan Emas, Lo. 230-239,Lorong Peruianaan8,

5700 BoranongKojona, 25350 Kuanton, (1700Pair Gudong, Pra Inurl Eta,

Selangor Dara Eheon Penang Gar Raku ‘oho: Darul Tata ‘9800? Penang.

Teko3s7es rssv2ci4 “Tot 09566 1427/1482 ‘Tavor 261 26000 ‘To: 01300 6166458,

Fax 0387567890, Fax: 8-556 3688, Fox 07512677 Fac 063093421,

Seah

5th Milo, Turan oad,

88200 Kota Kinabalu, Sabah,

“Tes 0682892526

Fw: 088422473,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Creep & Degree of ConsolDocument9 pagesCreep & Degree of ConsolTOM YEENo ratings yet

- 600mm PIT ModelDocument1 page600mm PIT ModelTOM YEENo ratings yet

- ATB TLB DrawingsDocument20 pagesATB TLB DrawingsTOM YEENo ratings yet

- Design Calculation For Truck Loading StationDocument55 pagesDesign Calculation For Truck Loading StationTOM YEENo ratings yet

- 37.ON-MECH-PR-LAY-001A - GCU 20201128-ModelDocument1 page37.ON-MECH-PR-LAY-001A - GCU 20201128-ModelTOM YEENo ratings yet

- Comment On The Grand Staircase Shop DrawingDocument14 pagesComment On The Grand Staircase Shop DrawingTOM YEENo ratings yet

- Calculation Sheet: Design of Splice For BeamDocument6 pagesCalculation Sheet: Design of Splice For BeamTOM YEENo ratings yet

- Staircase Canopy Calculation ReportDocument70 pagesStaircase Canopy Calculation ReportTOM YEENo ratings yet

- Axis 6 Axis 4: References Document No. TitleDocument1 pageAxis 6 Axis 4: References Document No. TitleTOM YEENo ratings yet