Professional Documents

Culture Documents

Ethane Cargo Handling - Supercooler™

Uploaded by

jenna leeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ethane Cargo Handling - Supercooler™

Uploaded by

jenna leeCopyright:

Available Formats

Ethane cargo handling - SuperCooler™

Providing high methane content cargo handling capability with optimisation of

operational performance.

Babcock has delivered in excess of 300 cargo More ethane is being produced and exported from the

handling systems to the marine liquefied gas USA as a result of the shale gas boom and these ethane

shipping market for more than 50 years, continuously cargoes can have high methane content - up to

pushing the boundaries of plant performance and 1 mol% .

efficiency.

Babcock has developed an innovative solution which

Just as the development of the Vent Gas Cooler (VGC™) provides the capability to handle these higher methane

signalled a step-change in the LPG carrier market, content cargoes, whilst also providing significant OPEX

Babcock has developed the SuperCooler™ to reshape savings.

the ethane market, providing considerable OPEX savings

versus traditional cargo handling systems on Very Large The SuperCooler™ offers significant performance

Ethane Carriers (VLECs). enhancements for ethane carriers, including improved

reliquefaction capacity, as the mol% methane in the

The use of ethane as a petrochemical feedstock and liquid phase increases with lower energy consumption

as both an energy and fuelling solution is growing than conventional systems.

worldwide and, with it, an increasing requirement for its

global transportation in significant quantities.

Marine | Land | Aviation | Cavendish Nuclear babcockinternational.com

Performance at atmospheric suction pressure

Babcock SuperCoolerTM

Refrigeration Capacity (kW)

Conventional system

mol% Methane in Liquid Phase

Greater ability to handle the loading of higher Reduced energy consumption

methane content cargoes

When loading an ethane cargo with 0.8 mol% methane,

The SuperCooler™ provides reduced OPEX when the addition of the SuperCooler™ will result in a

improving Coefficient of Performance for ethane carriers, reduction in energy consumption (kWh) of around 15%

whilst simultaneously reducing environmental footprint. per day compared to a conventional system.

This is achieved through reduced venting of methane to

The SuperCooler™ system provides the ship with

atmosphere in the eventuality of off-spec cargo loading.

significant OPEX savings and, with less running hours

across the cargo handling system, also reduces the

frequency of maintenance.

SuperCooler™ schematic

Cargo Compressor

1 2 3

Condenser

Economiser

Level Control

LC

SuperCoolerTM

Cargo Tanks

Contact us:

Babcock International Group

Rosyth Business Park

Rosyth, Fife, KY11 2YD

Tel: +44 (0)1383 665 586

lge.sales@babcockinternational.com

www.babcockinternational.com/lge

Marine | Land | Aviation | Cavendish Nuclear babcockinternational.com

You might also like

- Pounder's Marine Diesel Engines and Gas TurbinesFrom EverandPounder's Marine Diesel Engines and Gas TurbinesRating: 4 out of 5 stars4/5 (15)

- 3 Winding TransformersDocument11 pages3 Winding TransformersPreethamNo ratings yet

- The SKYLON Space Plane - Progress To IonDocument7 pagesThe SKYLON Space Plane - Progress To Ionhawk303No ratings yet

- Hazardous Area ClassificationsDocument1 pageHazardous Area ClassificationsAndrew Bull100% (2)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Solved Problems and SheetDocument4 pagesSolved Problems and SheetSafaa Hameed Al Nasery50% (6)

- A Guide To Hazardous Locations & Product Certification PDFDocument1 pageA Guide To Hazardous Locations & Product Certification PDFImdad PeshimamNo ratings yet

- Triality VLCCDocument20 pagesTriality VLCCLeo ThomasNo ratings yet

- Catalytic Cracking: P A R T 3Document34 pagesCatalytic Cracking: P A R T 3Bharavi K SNo ratings yet

- GETGs - Tecnologias - EditableDocument60 pagesGETGs - Tecnologias - EditableRicardas Kragnys100% (1)

- Net Metering Reference Guide by by Gaspar Escobar Jr. DOEDocument22 pagesNet Metering Reference Guide by by Gaspar Escobar Jr. DOEKim FernandezNo ratings yet

- Upgrading The Bottom of The BarrelDocument7 pagesUpgrading The Bottom of The BarrelmmintakaNo ratings yet

- Marine Propulsion Systems 2021 en WebDocument32 pagesMarine Propulsion Systems 2021 en Webhumayun121No ratings yet

- Re Liquefaction System EcoRel - Cryostar Magazine 10Document12 pagesRe Liquefaction System EcoRel - Cryostar Magazine 10Narayan Marndi100% (1)

- Optimum Transportation Method For Development of Extra Heavy Crude OilDocument21 pagesOptimum Transportation Method For Development of Extra Heavy Crude OilYudi SuwandaNo ratings yet

- Compact LNG C Design Brochure - 110609Document4 pagesCompact LNG C Design Brochure - 110609pal_malayNo ratings yet

- UOP CCR PlatformingDocument3 pagesUOP CCR PlatformingEduardo Carrillo Diaz100% (1)

- LNG - Gas Combustion UnitsDocument13 pagesLNG - Gas Combustion UnitsmorgothsNo ratings yet

- Chevron Catalyst CrackingDocument15 pagesChevron Catalyst CrackingViswanath KapavarapuNo ratings yet

- Concept Design of A Bulk Carrier Retrofit With LNG FUELDocument7 pagesConcept Design of A Bulk Carrier Retrofit With LNG FUELHenrique costa melloNo ratings yet

- Honeywell Uop FCC Related Processes DatasheetDocument4 pagesHoneywell Uop FCC Related Processes Datasheetduraid ahmadNo ratings yet

- INEC 2022 Paper - Vaporise After Reading - Pyrolysis and Waste Management On Queen Elizabeth Class Carriers - Post Comments - 27.09.22Document11 pagesINEC 2022 Paper - Vaporise After Reading - Pyrolysis and Waste Management On Queen Elizabeth Class Carriers - Post Comments - 27.09.22Hayden C100% (1)

- Centrifugal PumpsDocument14 pagesCentrifugal PumpsAshishAgarwalNo ratings yet

- Parsifal 2263Document2 pagesParsifal 2263maritim2k16No ratings yet

- Crouse Hinds Codedigest2020Document130 pagesCrouse Hinds Codedigest2020jenna lee100% (1)

- Regasification HamworthyDocument19 pagesRegasification HamworthyMoustapha Seye100% (1)

- Gravimetric Feeder For Pulvurised FuelDocument2 pagesGravimetric Feeder For Pulvurised FuelVijay KumarNo ratings yet

- Ash ReinjectionDocument22 pagesAsh Reinjectiongaol_bird009No ratings yet

- Uop RFCC UnitDocument4 pagesUop RFCC UnitRobenito Ruben100% (1)

- LGE Brochure ecoVGCDocument2 pagesLGE Brochure ecoVGCIMECCNo ratings yet

- Applied Energy: Maria C. Díaz-de-Baldasano, Francisco J. Mateos, Luis R. Núñez-Rivas, Teresa J. LeoDocument10 pagesApplied Energy: Maria C. Díaz-de-Baldasano, Francisco J. Mateos, Luis R. Núñez-Rivas, Teresa J. LeoYunizar Natanael PragistioNo ratings yet

- Curs 4 Mept - en - Rev 2021Document63 pagesCurs 4 Mept - en - Rev 2021Necula Alexandra Mihaela100% (1)

- Marine: Exhaust Gas Cleaning SolutionsDocument24 pagesMarine: Exhaust Gas Cleaning SolutionsCatalin SevastianNo ratings yet

- WrightBus BrochureDocument11 pagesWrightBus BrochureB7 StudiosNo ratings yet

- Final Seemp PresentationDocument16 pagesFinal Seemp PresentationLyubomir LazarovNo ratings yet

- Becker Mewis DuctDocument4 pagesBecker Mewis Ductjoroma58No ratings yet

- KBR Catalytic Olefins Technology (K PDFDocument2 pagesKBR Catalytic Olefins Technology (K PDFAMANo ratings yet

- LNG Reliquefaction - Ecosmrt: Marine - Land - Aviation - Cavendish NuclearDocument2 pagesLNG Reliquefaction - Ecosmrt: Marine - Land - Aviation - Cavendish Nuclearjenna leeNo ratings yet

- GEN PAPYR 5578 KBR FCC by NICCUM in CH 3 1 BK PP 3 3 3 34 Y 2004Document32 pagesGEN PAPYR 5578 KBR FCC by NICCUM in CH 3 1 BK PP 3 3 3 34 Y 2004Nguyễn ÁnhNo ratings yet

- 2017 Equator P2Document3 pages2017 Equator P2Grizz LyNo ratings yet

- Curs 2 MEPT - EN - Rev 2021 Rev1Document38 pagesCurs 2 MEPT - EN - Rev 2021 Rev1Necula Alexandra MihaelaNo ratings yet

- Alfa Laval Packinox For Catalytic Reforming: Combined Feed/effluent Heat ExchangerDocument3 pagesAlfa Laval Packinox For Catalytic Reforming: Combined Feed/effluent Heat Exchangerrizwan khan100% (1)

- Screw CompressorsDocument4 pagesScrew CompressorsGeorge J AlukkalNo ratings yet

- Improved Propulsion With Tuned Rudder Systems: Dirk LehmannDocument2 pagesImproved Propulsion With Tuned Rudder Systems: Dirk LehmannM Z HaiderNo ratings yet

- Alternatives Study For The Technical Improvement of The Campo Arce Crude Oil QualityDocument6 pagesAlternatives Study For The Technical Improvement of The Campo Arce Crude Oil QualityChechotopol12No ratings yet

- 13-02-2019 - WinGD - Article - Volatile Organic Comp As FuelDocument4 pages13-02-2019 - WinGD - Article - Volatile Organic Comp As FuelAVINASH ANAND RAONo ratings yet

- Clean Marine Presentation To Intertanko - Ma 2014Document45 pagesClean Marine Presentation To Intertanko - Ma 2014Yao WeiNo ratings yet

- LGE Brochure LPG Fuel Gas Supply System ecoETHN™Document2 pagesLGE Brochure LPG Fuel Gas Supply System ecoETHN™IMECCNo ratings yet

- MOSS Tank DetailsDocument26 pagesMOSS Tank DetailsRajesh KrishnamoorthyNo ratings yet

- Tech Papers Maximizing PX ProductionDocument8 pagesTech Papers Maximizing PX Productionhml2827No ratings yet

- Experiences in The OperationDocument7 pagesExperiences in The OperationUsama Bin SabirNo ratings yet

- Aalborg XW TGDocument2 pagesAalborg XW TGandy131078No ratings yet

- En Avt 150 02Document32 pagesEn Avt 150 02elebouthillierNo ratings yet

- Contact Cell Info - Gen PDFDocument10 pagesContact Cell Info - Gen PDFsnarf273No ratings yet

- Aalborg XW SuperheaterDocument2 pagesAalborg XW SuperheaterPanagiotisNo ratings yet

- Loading Arm CatalogueDocument18 pagesLoading Arm Catalogue歪西溫No ratings yet

- Aeroderivative Gas Turbine FinalDocument16 pagesAeroderivative Gas Turbine Finaldylan_dearing@hotmail.comNo ratings yet

- Otc19785 OFFSHOE VALUE CHAIN OPTIMIZATIONDocument17 pagesOtc19785 OFFSHOE VALUE CHAIN OPTIMIZATIONflowline2010No ratings yet

- An Experimental Investigation Into The Use of Molten Carbonate Fuel Cells To Capture Co2 From Gas Turbine Exhaust GasesDocument8 pagesAn Experimental Investigation Into The Use of Molten Carbonate Fuel Cells To Capture Co2 From Gas Turbine Exhaust GasesRitesh AgarwalNo ratings yet

- Paper - Chevron Natural Gas Carbon Capture Technology Testing ProjectDocument10 pagesPaper - Chevron Natural Gas Carbon Capture Technology Testing ProjectendosporaNo ratings yet

- Eeoi Eedi SeempDocument31 pagesEeoi Eedi SeempAbhi ChaudhuriNo ratings yet

- Foster Wheeler CfbbrochureDocument20 pagesFoster Wheeler CfbbrochureEdgardo BoieroNo ratings yet

- Method Selection ScreenDocument12 pagesMethod Selection ScreenAnwar SafariNo ratings yet

- 7 Technologies To Reduce Fuel Consumption of ShipsDocument6 pages7 Technologies To Reduce Fuel Consumption of ShipsAVINASH ANAND RAONo ratings yet

- 3.various Units of IOCL Paradip: 3.1. Avu/Srlpg UnitDocument8 pages3.various Units of IOCL Paradip: 3.1. Avu/Srlpg UnitAkankshya MishraNo ratings yet

- D2P3 Dual Fuel Eng With FPP Z PellerDocument8 pagesD2P3 Dual Fuel Eng With FPP Z Pellerguichen wangNo ratings yet

- Compact Flotation UnitDocument3 pagesCompact Flotation Unitzorro21072107No ratings yet

- JR - R 996 - KPCDocument4 pagesJR - R 996 - KPCIgor Tinta FrescaNo ratings yet

- Standards Published: TC5 Ferrous Metal Pipes and Metallic FittingsDocument22 pagesStandards Published: TC5 Ferrous Metal Pipes and Metallic Fittingsjenna leeNo ratings yet

- Elecform PDFDocument1 pageElecform PDFDivya GurukumarNo ratings yet

- Engineer'S Electrical & Instruments: BooksDocument3 pagesEngineer'S Electrical & Instruments: Booksjenna leeNo ratings yet

- Country Network Power West-EuropeDocument3 pagesCountry Network Power West-Europejenna leeNo ratings yet

- LNG Reliquefaction - Ecosmrt: Marine - Land - Aviation - Cavendish NuclearDocument2 pagesLNG Reliquefaction - Ecosmrt: Marine - Land - Aviation - Cavendish Nuclearjenna leeNo ratings yet

- FGSV0™ - LNG Bunkering SolutionDocument2 pagesFGSV0™ - LNG Bunkering Solutionjenna leeNo ratings yet

- Vent Gas CoolerDocument2 pagesVent Gas Coolerjenna leeNo ratings yet

- NEC Poster e PDFDocument1 pageNEC Poster e PDFRahul PatilNo ratings yet

- Multiple Choice Pre Test Pump - 2Document3 pagesMultiple Choice Pre Test Pump - 2karioke mohaNo ratings yet

- P2104-VD-LEBS-TS-STD-0012 - 0C - RAM Study ReportDocument56 pagesP2104-VD-LEBS-TS-STD-0012 - 0C - RAM Study ReportaddypurnamaNo ratings yet

- First Law of ThermodynamicsDocument5 pagesFirst Law of ThermodynamicsRagh AhmedNo ratings yet

- Water CoolDocument4 pagesWater CoolrkibNo ratings yet

- Neraca Massa AmmoniakDocument10 pagesNeraca Massa AmmoniakMuhammad FadilNo ratings yet

- Filteri EngDocument4 pagesFilteri EngBoskoNo ratings yet

- Hvac BOQDocument10 pagesHvac BOQanwar2masNo ratings yet

- Quenchmaster Class A Foam System PPT - 1Document14 pagesQuenchmaster Class A Foam System PPT - 1Simon BertoliNo ratings yet

- Automotive Servicing NCI: Written TestDocument27 pagesAutomotive Servicing NCI: Written Testjayson platinoNo ratings yet

- 64L - Coffee - Table - Book (1) (1) (1) - 031Document1 page64L - Coffee - Table - Book (1) (1) (1) - 031Nilda Ester RomeroNo ratings yet

- 4.DOING Waste Oil Distillation Project ReportDocument24 pages4.DOING Waste Oil Distillation Project ReportPranav Tubaji100% (1)

- Mech-Engg., Thermal EngineeringDocument8 pagesMech-Engg., Thermal Engineeringnims1964No ratings yet

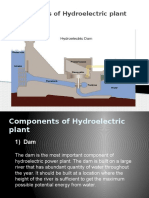

- Components of Hydroelectric PlantDocument13 pagesComponents of Hydroelectric PlantHarun Rasul100% (1)

- How Oil-Injected Rotary Screw Compressors Work - Shenzhen Panrui Mechanical Equipment Co., LTDDocument4 pagesHow Oil-Injected Rotary Screw Compressors Work - Shenzhen Panrui Mechanical Equipment Co., LTDSeyedAli TabatabaeeNo ratings yet

- SIB 121009 E90, E70 M57Y Diesel - Diagnosis For DDE FC 4521 or 4530Document2 pagesSIB 121009 E90, E70 M57Y Diesel - Diagnosis For DDE FC 4521 or 4530Manea DaianaNo ratings yet

- Thermoelectric Energy ConversionDocument4 pagesThermoelectric Energy ConversionMenchie LabadanNo ratings yet

- Solar-Generated Superheated Steam For: Clean, Reliable ElectricityDocument4 pagesSolar-Generated Superheated Steam For: Clean, Reliable Electricityhaitam terribleNo ratings yet

- Specifications: For More Information On This Product and Our Full-Range of Solutions, Contact Ameresco at 1-855-43-SOLARDocument1 pageSpecifications: For More Information On This Product and Our Full-Range of Solutions, Contact Ameresco at 1-855-43-SOLARALdinoNo ratings yet

- Sarasin RSBD Starsteam FlyeDocument2 pagesSarasin RSBD Starsteam Flyepeng chaowenNo ratings yet

- GasTec HydroCut Application BrochureDocument2 pagesGasTec HydroCut Application BrochureDiaa GobranNo ratings yet

- SAMSON Control Valves Type 3213 Type 3214 t5868Document12 pagesSAMSON Control Valves Type 3213 Type 3214 t5868Sai SarihadduNo ratings yet

- Specifications Wall Mounted ON OFFDocument1 pageSpecifications Wall Mounted ON OFFRavi SoondurNo ratings yet

- Sheet 9 (Heat Exchanger)Document3 pagesSheet 9 (Heat Exchanger)Rafi Mahmoud SulaimanNo ratings yet