Professional Documents

Culture Documents

Asynchronous Activities - Quality Control Ii

Uploaded by

Kenny TuanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asynchronous Activities - Quality Control Ii

Uploaded by

Kenny TuanCopyright:

Available Formats

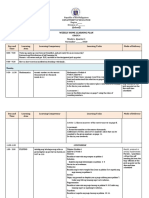

ASYNCHRONOUS ACTIVITIES – QUALITY CONTROL II

(LECTURE AND LABORATORY)

DATE GIVEN: October 27, 2020

DATE OF SUBMISSION: NOVEMBER 5, 2020 (on or before 12 NN)

DISCUSSIONS WILL CONTINUE ON NOVEMBER 5, 2020

JESSA MAE M. LATORRE BSPH IV

RESEARCH AND DISCUSS (in a brief and concise manner and terms) THE

FOLLOWING:

1. Friability Test

a. Tablet Processing Problems

- Capping – Large of fines in the granulation

- Motting – A colored drug used along with colorless excipients;

improper mixing of a colored binder solution.

- Lamination – Oily or waxy materials in granules; too much

hydrophobic lubricant.

- Crackling – Large size of granules; too dry granules; Tablet

expand; Granulation too cold.

- Chipping – Sticking on punch faces; too dry granules; too much

binding causes chipping at bottom.

- Sticking – Granules not dried property; Too little or improper

lubricant; Too much binder; oily or waxy materials.

- Picking – Granules not dried properly; Too little or improper

lubrication; Low melting point substances, may soften from the

heat of compression.

- Binding – Too moist granules; Insufficient or improper lubricant;

Too coarse granules.

- Double Impression – Free rotation of either upper punch or lower

punch during ejection of a tablet

2. Tablet Thickness and Hardness Tests

- Tablet thickness is measured with a vernier caliper, thickness

gauge or automated equipment (Automatic weight, hardness,

thickness, and tablet diameter test instrument). The thickness of a

tablet should be controlled within ±5% variation of a standard

value depending on the size of the tablet.

3. Quality Control Tests for the following:

a. Sterile Products – Leakage Test; Clarity test; Sterility Test; Pyrogen Test

b. Solutions – Appearance; Viscosity; Clarity testing; pH value

c. Suspensions – Appearance; Photo microscopic test; Color, oudour &

taste; pH value; Porability; Viscosity; Redispresibility; Particle size

d. Emulsions – Appearance; Clarity Testing; pH value; Viscosity; Rheology;

Drug content uniformity; Particle size distribution; Densities of phases

4. Spectrometry

a. Range of wavelengths of Radiant energy

- As frequency decreases, radiant energy and wavelength

increase.

b. Branch of Spectrometry

- Spectrophotometry – deals with measurement of the radiant

energy transmitted by a body as a function of the wavelength.

c. Laws of Spectrophotometry

- Bouger’s Law – each layer of equal thickness of the medium

absorbs an equal fraction of the energy traversing it.

- Beer’s Law – the absorptive capacity of a dissolved substance is

directly proportional to its concentration in a solution.

d. Methods of Spectrometry

- Mass spectrometer

- NMR spectrometer

- Optical spectrometer

e. Formulas – Dissolution Analysis

- Can be expressed via the Noyes-Whitney equation:

dm D S

= (Cs−C)

dt h

Where;

Dm/dt= Solute dissolution rate

M= mass of dissolved materials (kg)

t = time (s)

A= surface are of the solute particle (m2)

D= diffusion coefficient (m.s-1)

f. Give one (1) example of Dissolution Analysis problem. Indicate complete

computations

−7 3 −4

dM ( 1,75 x 10 ) ( 2.5 x 10 ) ( 0.35−2.110 )

= =1.22/ se c

dt 1.25 x 10− 4

5. Chromatography

a. Classification of Chromatographic Methods

- Bed Shape – Column chromatography; Planar chromatography

- Physical State of the mobile Phase – Gas chromatography; Liquid

chromatography

- Mechanism of Separation – Ion exchange chromatography; Size

Exclusion chromatography; Expanded Bed absorption

chromatography.

b. Rf or Retention Value Formula

Distan ce travelled by the compound

Rf =

distance travelled by the solvent front

c. Give 2 (two) examples of Rf value problems. Indicate complete

computations.

6 mm

- Rf = =0.33

18 mm

12mm

- Rf = =0.38

32mm

6. Stability

a. Methods on Stability Testing

- Accelerated stability testing- used to determine the types of

degradation products

- Testing uner less rigorous conditions.

FONT: ARIAL

SIZE: 12

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Semi Final Examination (Ips 1) : EsculentaDocument8 pagesSemi Final Examination (Ips 1) : EsculentaKenny TuanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Phbiosci 7B Experiment 1Document3 pagesPhbiosci 7B Experiment 1Kenny Tuan100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- QC2 Midterm Quiz IDocument2 pagesQC2 Midterm Quiz IKenny TuanNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Seatwork 2Document1 pageSeatwork 2Kenny TuanNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Seatwork 3Document1 pageSeatwork 3Kenny TuanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- PRELIM EXAM IPS 2 Module 4 PharmacologyDocument7 pagesPRELIM EXAM IPS 2 Module 4 PharmacologyKenny TuanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- EXERCISE 5 and 6Document8 pagesEXERCISE 5 and 6Kenny TuanNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- EXERCISE 7 and 8Document9 pagesEXERCISE 7 and 8Kenny TuanNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- PHCARE4BDocument2 pagesPHCARE4BKenny TuanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Phresearch 1 - Activity On Research Methodology For The Semi-Final PeriodDocument2 pagesPhresearch 1 - Activity On Research Methodology For The Semi-Final PeriodKenny TuanNo ratings yet

- Community Pharmacy InternshipDocument8 pagesCommunity Pharmacy InternshipKenny TuanNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- PHCARE4BDocument2 pagesPHCARE4BKenny TuanNo ratings yet

- Tabular Comparative Presentation of The PhilippinenPresident's Profile and AccomplishmentsDocument12 pagesTabular Comparative Presentation of The PhilippinenPresident's Profile and AccomplishmentsKenny Tuan0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Phresearch 1 - Activity On Research StatisticsDocument2 pagesPhresearch 1 - Activity On Research StatisticsKenny TuanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- By C. Kohn Agricultural Sciences, Waterford WIDocument23 pagesBy C. Kohn Agricultural Sciences, Waterford WIKenny TuanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Exercise 11-12Document5 pagesExercise 11-12Kenny TuanNo ratings yet

- EXERCISE 5 and 6Document8 pagesEXERCISE 5 and 6Kenny TuanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Objectives: This Study Was Conducted To Determine TheDocument1 pageObjectives: This Study Was Conducted To Determine TheKenny TuanNo ratings yet

- A Tribute To My TownDocument8 pagesA Tribute To My TownKenny TuanNo ratings yet

- Asynchronous Activities - Quality Control IiDocument1 pageAsynchronous Activities - Quality Control IiKenny TuanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Water Pollution: Presented By: Jessa Mae Latorre BEED3 Jeralyn Orio Beed3Document3 pagesWater Pollution: Presented By: Jessa Mae Latorre BEED3 Jeralyn Orio Beed3Kenny TuanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Intro To Psychology by Charles StangorDocument861 pagesIntro To Psychology by Charles StangorAidan Alexis67% (9)

- A Tribute To My TownDocument8 pagesA Tribute To My TownKenny TuanNo ratings yet

- Polygraph yDocument5 pagesPolygraph yKenny TuanNo ratings yet

- Efficacy of Ayurvedic Interventions in Hypothyroidism: A Comprehensive ReviewDocument7 pagesEfficacy of Ayurvedic Interventions in Hypothyroidism: A Comprehensive ReviewMikel MillerNo ratings yet

- Border-Study/: "Borderless" and Cross-Border EducationDocument10 pagesBorder-Study/: "Borderless" and Cross-Border EducationSan TyNo ratings yet

- Lo1 Obtain and Convey Workplace InformationDocument15 pagesLo1 Obtain and Convey Workplace InformationRamramramManmanmanNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Q4 Week 3 Lesson 4-GenyoDocument55 pagesQ4 Week 3 Lesson 4-GenyoNORIELIE RODRIGUEZNo ratings yet

- The Correlation of Social Anxiety Towards The Behaviour of Grade 12 Students in SJDM Cornerstone College Inc.Document47 pagesThe Correlation of Social Anxiety Towards The Behaviour of Grade 12 Students in SJDM Cornerstone College Inc.Mark The PainterNo ratings yet

- Lesson From Seveso ItalyDocument48 pagesLesson From Seveso ItalyBilal ZamanNo ratings yet

- Ten Tips Baum Perspectives Fall 2001Document3 pagesTen Tips Baum Perspectives Fall 2001HienngoNo ratings yet

- QI-WEEK 4-ADM BasedDocument10 pagesQI-WEEK 4-ADM BasedMarloCris ToqueroNo ratings yet

- 2223 S3 Longman Edge U4 SuppWSDocument9 pages2223 S3 Longman Edge U4 SuppWShexu wangNo ratings yet

- Thesis FieldworkDocument5 pagesThesis FieldworkPaySomeoneToWriteAPaperUK100% (1)

- Agathias The HistoriesDocument101 pagesAgathias The HistoriesFrançois88% (24)

- Sports Aerodynamics - One Credit CourseDocument12 pagesSports Aerodynamics - One Credit CourserajkalamaeroNo ratings yet

- Structural Analysis of Steel Structures Under Fire Loading: Acta Polytechnica Hungarica January 2009Document9 pagesStructural Analysis of Steel Structures Under Fire Loading: Acta Polytechnica Hungarica January 2009Nenad GajicNo ratings yet

- CAPILLAN, SHAIRA - Semi-Detailed-Lesson-PlanDocument7 pagesCAPILLAN, SHAIRA - Semi-Detailed-Lesson-PlanShai Ra CapillanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Block 7Document113 pagesBlock 7KK ArticlesNo ratings yet

- Psychological Contracts Assignment Template 1Document4 pagesPsychological Contracts Assignment Template 1api-651039702No ratings yet

- Slope SitabiltyDocument13 pagesSlope SitabiltyZELALEMNo ratings yet

- Theories On Human DevelopmentDocument42 pagesTheories On Human DevelopmentHANS CHRISTIAN DELOS REYESNo ratings yet

- (Phase-04) Test Planner-Repeater Course - 2022-23 - FTDocument1 page(Phase-04) Test Planner-Repeater Course - 2022-23 - FTDonvito CannoliNo ratings yet

- Industrial Accidents in Cement Industries of Nepal: Submitted ToDocument58 pagesIndustrial Accidents in Cement Industries of Nepal: Submitted ToSushma Karn100% (1)

- Maximizing Productivity, Physical & Mental Health With Daily Tools - Huberman Lab Podcast #28Document44 pagesMaximizing Productivity, Physical & Mental Health With Daily Tools - Huberman Lab Podcast #28wnd cNo ratings yet

- Heating and Cooling With Ground-Source Heat Pumps in Moderate and Cold Climates, Two-Volume Set 1Document397 pagesHeating and Cooling With Ground-Source Heat Pumps in Moderate and Cold Climates, Two-Volume Set 1Pavan Kalyan0% (1)

- SÔ 1 de Thi HSG Tieng Anh Tinh Phu Tho 20162017Document8 pagesSÔ 1 de Thi HSG Tieng Anh Tinh Phu Tho 20162017Huỳnh Minh ĐứcNo ratings yet

- Civil Engineering Laws and Ethics in The PhilippinesDocument16 pagesCivil Engineering Laws and Ethics in The PhilippinesMonde Nuylan90% (48)

- Unesco 5 Pillars For EsdDocument6 pagesUnesco 5 Pillars For EsdMary Lois Dianne TinaNo ratings yet

- Book - 1914 - Mathematical Recreations and EssaysDocument505 pagesBook - 1914 - Mathematical Recreations and Essaysankit madanNo ratings yet

- Mock Exam - MathDocument4 pagesMock Exam - MathFati FleurNo ratings yet

- TT For All Classes-2Document4 pagesTT For All Classes-2RatheeshNo ratings yet

- Sefirot - The GuidebookDocument28 pagesSefirot - The GuidebookOscarC2No ratings yet

- Material Specification For Preformed Plastic Pavement Marking TapeDocument10 pagesMaterial Specification For Preformed Plastic Pavement Marking TapeTony ParkNo ratings yet

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactFrom EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactRating: 5 out of 5 stars5/5 (5)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet