Professional Documents

Culture Documents

Case Study EM Sept 2020 - F

Uploaded by

ElwasilaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study EM Sept 2020 - F

Uploaded by

ElwasilaCopyright:

Available Formats

C ase Study

of the Month

Er. P.K.Pattanaik, is presently

working with OPTCL as Dy.

General Manager (Elect) in E & MR

Division, Bhubaneswar- Odisha and

associated with the Protection and

Control schemes of Electrical systems.

He is having 25 years of technical

experience in Designing, Testing and Commissioning

of Protection Control and operational Schemes,

project Implementation, co-ordination, operations & VARIOUS CASE STUDIES

maintenance of Electrical Equipments at various LT/ HT/

EHT level Grid Sub- Stations. He has also published ON OPERATION AND CONTROL

around 70 technical papers in different national/ SCHEMES FOR GRID SUB-STATION

international seminars/journals.

Contd….

ele.pkpattanaik@optcl.co.in

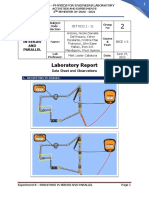

1. Introduction: For the last few months, the response of the readers Sub-station it was found with tripping of one 132 KV outgoing

to the case studies on various incidents is overwhelming. Hence this feeder with fault on R phase.

month we are again choosing the write up on similar kind of studies Observations:

for developing the synchronisation of practical observation to the 1. The disturbance report was found with fault current rise on

theoretical concepts. The analysis of each incident being supported R phase and corresponding voltage dip on its phase.

by actual observations had been described during the situation to 2. The current being found 14.7 KA and tripping on Zone-1.

add awareness amongst the operation, testing and commissioning

3. As it was found with severe sound in the system, the system

engineers to know the cause of problems and be helpful for easy

was not allowed for charging and kept with observations.

rectification of the problems. This can also help to develop economic

schemes for the smooth running of the operation and control system 4. The field visit was done and found with arcing on Y phase

in the Grid Sub-Station. breaker limb as like shown in the figure 2.1.1.

2.1. Arcing on Breaker Limb: At one of the 220/132 Kv Grid 5. The tripping was instant in nature, the reason of Y phase

arcing could not be established.

48 ELECTRICAL MIR ROR || September 2020 || ||www.electricalmirror.net||

6. The Line patrolling engineer was asked to patrol the line Technical Analysis:

for any eventualities, but found with no any abnormality. 1. The bird on touching by the beak has some resistance as

the start current path and again the skin on its leg has

also some resistance path. So the current flow though

high is not like direct conducting path.

w w w. e l e c t r i c a l m i r r o r. n e t

Fig 2.1.1 Arcing of Y phase Limb

7. The Breaker limb and operation of the breaker was Fig 2.2.1 Bird Fault

checked thoroughly and tested before taking into the 2. Moreover this pole on investigation was also found with

system. no dedicated earthing for quick flow of current.

8. On detail investigation and testing the system was charged 3. However the current was sufficient for tripping of the

and stood OK. 33 KV line on Phase to ground fault.

Technical Analysis 4. In some instances, the fault current does not become

1. In this condition R Phase fault with ground had been sufficient for the tripping of the line due to the impedance

resulted causing voltage dip on the respective phase. fault in the system.

2. As per 3 Phase principle, during fault condition and dip 5. However it was advised to the discom wing not to provide

in voltage for any of the pages shall be causing the rise any extra extension for any creature to sit on the arm

of voltage on the healthy phase. Here this might have and to be in contact with the live wire.

been happened. 2.3. Effect of CT terminal opening: In one of the GIS grid and

3. The dust deposition might have tracked this due to due to space constraint and to meet the customer’s requirement,

decrease of Creepage distance. As tripping of the breaker 4 sq.mm wires were in connection to the CT terminal block.

of this limb might have been slight delayed causing the The TBs were found burnt along with cables due to CT opening

re-striking voltage and external arcing as like shown in at one of the terminal.

the figure 2.1.1. Observations:

2.2. 33 KV Bird Fault: one of the 33 KV feeder tripped on R 1. 33 KV GIS blocks are generally provided with combined

phase to ground fault. But the line was nearby to the electrical enclosed with less space area.

collection center. 2. The LCC (Local control Cubicle) panels are usually provided

Observations: as integrated part of the GIS module.

1. The 33 KV pole structure was extended with extra portion 3. In this grid Sub-station, this pattern of combined module

and the disc was connected to the internal part of the system was there with less space.

cross arm as like shown in the figure 2.2.1. 4. The secondary wires of the CT had been terminated to

2. One bird sitting on this extra portion comes in contact the terminal block in the LCC with less space.

to the live wire and electrocuted, resulting with tripping 5. But due to customer’s specific requirement, the internal

of the line. To the surprise, though the bird got burnt, wires had been provided with 4 sq. mm wires with that

but remained sticking to the conductor. limited space. The cables had also been routed in the

3. The construction design of the pole was changed with limited space region. The multi wires had also been run

no extra extension for sitting of any bird or creature. for secondary CTR control at the TBs in the LCC. So the

||www.electricalmirror.net|| || September 2020 || ELECTRICAL MIR ROR 49

Case Study

total system was clumsy. 2. The secondary CTR control should be at CT secondary

6. The TBs as shown in the figure 2.3.1 were also not strong Box, where space is factor to adjust.

enough to accommodate the multi-wire interconnection 2.4.1: Mistake in CT circuit: At one of 63 MVA AUTO transformer,

at on terminal. the facility of TURRET CT was available for developing of any

7. But the executor and supervisor for completion of the protection circuit. Problem developed during stability check

job, attempted the wiring and accommodated all the before commissioning of the transformer.

wires with the TBs. Observations:

8. In due course of service, it was found opening of one 1. This transformer was having two cores as the BCT (Bushing

Case Study of the month

CT terminal of the protection core during in-service CT) in each of the TURRET as like shown in the figure

condition. 2.4.1.

9. It was observed with high voltage and burning of the

particular terminal. Its further effect resulted the burning

of the cables and other adjacent TBs.

10. The root cause of such incident was due to space constraint

and accommodation of more wires in the limited space.

Technical Action:

1. The TBS were changed and 4 sq.mm wires were also

changed with 2.5 Sq.mm.

2. The space and number of TBs were reduced, due to

shifting of CTR control to the CT secondary box.

3. The number of cables were also reduced as CTR control

were shifted.

4. The shorting Link facility was also changed.

5. So the stress upon the TBs was reduced and system was 2. Each core has separate marking of s1 and s2. The wires

allowed to run smooth. connected from terminal finally marked with nomenclature

as 1s1, 1s2, 2s1, 2s2 from each of the secondary core.

Core one as 1s1 and 1s2, core 2 as 2s1 1nd 2s2.

3. The protection engineer as per the marking on the

external terminal developed the wiring connection for

the SEF (Sensitive Earth fault) relay connection as like

shown in fig 2.4.2 from core no-1. Core no 2 as not in

use was kept shorted.

4. But during stability checking, it was observed with some

peculiar behavior of reading as mentioned in the table

A.

5. R phase wire reading came ZERO, Y, B phase and neutral

reading came of same magnitude.

6. So to know the possibility of wrong connection, the joint

reading was taken by the combination wire by clamp

Fig 2.3.1 Clumsy TB Fig 2.3.2 Clean TB on ammeter. The values are mentioned in the table A.

arrangement arrangement The vector diagram, suspecting the possible interchange

Recommendation: of 1s2 and 2s1 were also drawn as shown in fig 2.4.5

1. The CT cables/ wires should be chosen as required. In 7. This was simply confirmed that some problem is there in

present days as we are using low burden numerical the R phase wire coming out of the BCT. It was suspected

relays and indicating meters, it is preferably to use 2.5 about the shorting of the terminals at BCT secondary Box.

sq.mm instead 4 sq.mm. So, BCT box was opened and found with no abnormality.

50 ELECTRICAL MIR ROR || September 2020 || ||www.electricalmirror.net||

Wires had been taken from 1s1, 1s2 and 2s1 and 2s2

were kept short.

8. Now the external wire connections from the R phase

BCT terminals at the secondary box were opened for

resistance checking of the windings.

9. The results were found with OPEN circuit for both the

core. So suspect was on the internal wires regarding

non-connection to the terminals or breakage of wire in

between. But obtaining of same result of OPEN circuit

for both the cores were not thought of impossible.

10. As actual circuit was taken with shorting of the 2nd

core and utilization of the first core, so, it was decided

for measurement of the resistance of the first core in

the same fashion. On doing so, when measurement for

first core was taken, the resistance value came double

as that of the value obtained with Y and B phase BCT

core.

11. So suspect was concentrated on the interchange of the

wires coming from BCT terminals and reporting to the

BCT secondary box.

12. The measurement of the combination wire readings were

also analysed and confirmed as the interchange of 1S2

with 2S1. (Refer fig 2.4.3 (This might have been done

by the electrician due to wrong way reading 1s2 as 2s1 14. Now the rectification in the form of original change of

and 2s1 as 1s2). wire internally was not possible. So with the external

13. The wrong way of reading 1s2 and 2s1 as 2s1 and 1s2 terminal, the shorting was done between 1S2 & 2S2

has been explained in fig 2.4.4. and wires to the relay was taken from 1S1 & 2S1.

15. After rectification, it was found with correct measurement

in the stability check of the transformer.

16. The transformer was successfully commissioned with the

system.

Table-A

Phase / Wire Current in m Ref. from Remarks

No. Amp. Vector Diagram

R ph. A111 0 Doubt?

Y ph. A131 18 OC O.K

B ph. A151 19 OE O.K

Neutral A71 18 OD=OC Doubt?

A111+ A131 18 OC O.K

A131+ A151 19 OD O.K

A111+ A151 18 OE O.K

A171+ A111 19 OD Doubt?

A171+ A131 32 OG=√3OC Doubt?

A171+ A151 31 OH=√3OE Doubt?

||www.electricalmirror.net|| || September 2020 || ELECTRICAL MIR ROR 51

Case Study

1 year to study the evolution of any objectionable gas

in the transformer.

5. The commissioning DGA value was kept for reference.

But surprisingly it was found with rise of CO2 gas in

the oil for all the testing conditions in drastic increasing

trend.

6. The result after one month was found more and again

at 3 month and 6 month.

Case Study of the month

7. As normal practices, the diverter switch oil is required

to be changed after every 6 months.

8. So in this case also, after 6 months of operation, the

diverter switch oil was planned for replacement.

9. The planned shutdown was availed. But when the operator

climbed top of the transformer for closing of the equalizing

2.5. Development of more CO2 in Main Tank Oil: One of the pipe valve, to his surprise he found the valve was closed

new 20 MVA 132/11KV transformer in the process plant was from the day of commissioning.

found with development more carbon dioxide content during

10. Now the valve was closed for the replacement of the

DGA testing of the oil.

OLTC tank oil.

Observations:

11. As Carbon dioxide content was also found dissolved with

1. This transformer had been commissioned for the last 8 the main tank, the main tank oil was also decided for

months. the total filtration with few days.

2. The transformer was used for the process plant and 12. After filtration, the transformer was charged and taken

provided with AVR (Automatic Voltage Controller Relay) into service. But this time, the closure of the equalization

to maintain the output voltage within the allowable limit, was done before allowing for taking the transformer into

by changing of the tap position by the OLTC provided. service.

3. In an average, the OLTC used to run for 5 to 6 times 13. The mistake of non-closure of the equalization valve,

daily. caused the mixing of diverter switch oil with main tank.

( The interconnecting pipe between Main Tank and OLTC

tank is called equalization pipe as shown in the figure

2.5.1)

14. Then due to frequent operation of OLTC to maintain

output voltage constant, the CO2 was getting generated

and getting mixed to the main tank oil.

15. This transformer was having OLTC conservator at the

same level of main tank conservator being partition of

the main conservator tank.

16. If it could have been taken with separate tank at low

level position, then it would have caused overflowing

of oil from the OLTC breather, indicating about the

interconnection of both main and OLTC oil tank.

17. So the status of equalization valve could not be known.

Only it was confirmed during time of attempt for

Fig 2.5.1 Equalization pipe with valve replacement of OLTC tank Oil.

4. As per the normal practice, DGA of the transformer had Recommendations:

been prescribed to do with time span of 1. Commissioning The equalization pipe need to be kept in CLOSED condition

time, after 1 Month, after 3 Months and 6 months and during the service of the transformer.

52 ELECTRICAL MIR ROR || September 2020 || ||www.electricalmirror.net||

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Losses Reduction and Voltage Profile ImprovementDocument28 pagesLosses Reduction and Voltage Profile ImprovementElwasilaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 2020 Paper PSSE Tuning Tool RGDocument7 pages2020 Paper PSSE Tuning Tool RGElwasilaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Welcome To A Presentation On: "Transmission-An Over View" BY A.Sai Prasad Sarma Retd. Ce/AptranscoDocument189 pagesWelcome To A Presentation On: "Transmission-An Over View" BY A.Sai Prasad Sarma Retd. Ce/AptranscoElwasila100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Establishing The Working DirectoryDocument30 pagesEstablishing The Working DirectoryElwasila100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Unit 1, 160 Ealing RD, Wembley HA0 4PY, United Kingdom. Tel: +44 118 3100 856, +44 7429-186 058 - WebsiteDocument2 pagesUnit 1, 160 Ealing RD, Wembley HA0 4PY, United Kingdom. Tel: +44 118 3100 856, +44 7429-186 058 - WebsiteElwasilaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Table 8: Electric Power Supply and Consumption in Base Year 2014Document1 pageTable 8: Electric Power Supply and Consumption in Base Year 2014ElwasilaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Table 7: Solar Radiation and Sunshine Duration in Sudan (: Create PDF in Your Applications With The PdfcrowdDocument1 pageTable 7: Solar Radiation and Sunshine Duration in Sudan (: Create PDF in Your Applications With The PdfcrowdElwasilaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Table 2: Hydroelectric Power Plant (Operational, Under Construction, and Planned)Document2 pagesTable 2: Hydroelectric Power Plant (Operational, Under Construction, and Planned)ElwasilaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Pec CodesDocument10 pagesPec CodesMujeeb AbdullahNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Primitrve Machine of Kron: by C. S. PDocument17 pagesThe Primitrve Machine of Kron: by C. S. Pni60No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Valeenonline: Name: City: Department: Time: 90 Min Examiner: Ahmed OsamaDocument7 pagesValeenonline: Name: City: Department: Time: 90 Min Examiner: Ahmed OsamaHussein K. AliNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Using IR Remote Controls With Arduino - Drone Bot WorkshopDocument26 pagesUsing IR Remote Controls With Arduino - Drone Bot WorkshopAhmed ShadeedNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ECM-MH-240.21 NEC Requirements For 10 FT Tap RulesDocument4 pagesECM-MH-240.21 NEC Requirements For 10 FT Tap RulesJosé Luis FalconNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Report GSM Based Remote Monitoring of 3 Parameters On TransformersDocument16 pagesReport GSM Based Remote Monitoring of 3 Parameters On TransformersJilly ArasuNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- EATON2 Electrical Distribution in Residential and Commercial Price ListDocument28 pagesEATON2 Electrical Distribution in Residential and Commercial Price ListLokendra SinghNo ratings yet

- Johnson Electric Tech Brief 3 Pull Vs Push SolenoidsDocument12 pagesJohnson Electric Tech Brief 3 Pull Vs Push Solenoidsfahad pirzadaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Floor Plan Floor Plan: Schedule of Loads PB1Document1 pageFloor Plan Floor Plan: Schedule of Loads PB1Lady Mae BrigoliNo ratings yet

- How To Derive The Instrumentation Amplifier Transfer FunctionDocument1 pageHow To Derive The Instrumentation Amplifier Transfer FunctionHelioBernardoNo ratings yet

- EEE 35 ProblemSet 3Document3 pagesEEE 35 ProblemSet 3Pao YapNo ratings yet

- Mechatronics 2.3Document2 pagesMechatronics 2.3Rohan YadavNo ratings yet

- K FactorDocument3 pagesK FactorsagarNo ratings yet

- Data Sheet 1500kw 6.6kv Pa Fan MotorDocument4 pagesData Sheet 1500kw 6.6kv Pa Fan MotorRamesh CuppuNo ratings yet

- Group 2 - Experiment 7 - Resistors in Series and ParallelDocument10 pagesGroup 2 - Experiment 7 - Resistors in Series and ParallelJohn Eazer FranciscoNo ratings yet

- Troubleshooting: Troubleshooting The 604 (41TE) The 604 (41TE)Document4 pagesTroubleshooting: Troubleshooting The 604 (41TE) The 604 (41TE)Autof FerreiraNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- DAS APM Catalogue v1.0 ENDocument5 pagesDAS APM Catalogue v1.0 ENJan SebastianNo ratings yet

- Oscilloscope User ManualDocument254 pagesOscilloscope User ManualFrancisco Martinez AlemanNo ratings yet

- Jameco Part Number 894542: Distributed byDocument22 pagesJameco Part Number 894542: Distributed byVeGiNo ratings yet

- ADS Tutorial: A Beginners Tutorial: Modes of OperationDocument23 pagesADS Tutorial: A Beginners Tutorial: Modes of OperationShakil Ahmed ChowdhuryNo ratings yet

- ServiceDocument3 pagesServiceJustin WilliamsNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- MCQ On Unit 3 EC20Document9 pagesMCQ On Unit 3 EC20zohaib100% (2)

- Panasonic Th-42pz85u CH Gpf11du PDFDocument126 pagesPanasonic Th-42pz85u CH Gpf11du PDFRadu BriaNo ratings yet

- Operation Manual of NPFC Series Li-Ion Batteries - 0423 (V8.1)Document22 pagesOperation Manual of NPFC Series Li-Ion Batteries - 0423 (V8.1)hariesha5722No ratings yet

- 01 Properties of Electric Charges PDFDocument28 pages01 Properties of Electric Charges PDFSeroKeretaMasaroWidiarNo ratings yet

- Modicon Quantum 140DDI35310Document5 pagesModicon Quantum 140DDI35310Samdan NamhaisurenNo ratings yet

- Day 1 08 SE PDFDocument98 pagesDay 1 08 SE PDFnova hilangNo ratings yet

- IP6000Document2 pagesIP6000IAMATMANo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DF107 E2Document2 pagesDF107 E2Kaushik SinghaNo ratings yet

- Shure Sm81-Specification-Sheet-English PDFDocument1 pageShure Sm81-Specification-Sheet-English PDFVicent Adsuara MoraNo ratings yet