Professional Documents

Culture Documents

Understanding Boat Design 97 PDF

Uploaded by

Łukasz ZygielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Understanding Boat Design 97 PDF

Uploaded by

Łukasz ZygielCopyright:

Available Formats

which case these pieces are joined by cleats at the Fastenings

butt ends. With double-sawn frames the parts over-

Electrolysis can be a dangerous problem in boats.

lap and are glued and fastened together so that

Wooden boats, with their many and different kinds

cleats are not necessar}'. Preferable today are lami-

of fastenings, are at risk. Galvanized iron or other fer-

nated frames formed of many layers of veneer glued

rous metals must not be mixed with bronze fasten-

together. If the frames are laminated doubly wide

ings or lead keels. Lead-ballast keels should be fas-

they can be sawn down the middle, making a per-

tened with bronze or monel bolts, never with

fect pair. Large boats may have one or more bent

galvanized iron or stainless steel bolts. Stainless steel

frames fitted between two sawn or lammated

is less noble than lead and subject to crevice corro-

frames, while very large, heaxy craft may use all

sion if fitted below water, and therefore not the ideal

sawn or laminated frames. An example of the latter

material for keel bolts, rudder stocks, or propeller

is our recent 70-foot schooner Tree of Life, which

shafts. Bronze and monel are more costly, so stainless

has 2y2-inch-by-4-inch laminated fir frames fitted

steel keel bolts are common on modem yachts, but

every 14 inches.

they have caused the loss of more than one keel.

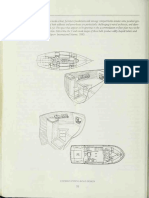

Chine hulls use sawn frames almost exclusively,

Bronze fastenings should never be used with alu-

closely spaced for regular planking and more widely

minum hardware or masts because the two metals

spaced if seam-batten planking is used. On a ply-

form a battery that corrodes the aluminum. Stainless

wood hull longitudinal stringers are fitted. In power-

fastenings, well bedded, are the only choice in that

boats with extreme flare in the forward sections it

case, but even they need to be inspected regularly

may be difficult to avoid cross-grain frames. In such

Even if all fastenings and fittings are of identical

instances, double-sawn frames or even laminated

metal, problems can occur due to stray electncal cur-

frames should be used.

rents that may cause deterioration of the hull metals.

Longitudinal frammg that uses closely spaced lon-

Sacrificial zinc plates should be fitted to the hull at all

gitudinal stringers on widely spaced sawn frames or

major metal points (shafts, through-hulls, mdder fit-

bulkhead framing is excellent for laminated hulls as

tings, etc.) so the zinc is eaten away instead of the

well as for plywood planking. In bulkhead framing,

costly fittings. Many designers and builders recom-

the major hull bulkheads and furniture are reinforced

mend a complete bonding system. In this installation

and supply the necessar)' transverse strength. Strip-

all major metal parts and, in particular, all through-

planked hulls can also use bulkhead framing if the

hull metals are cormected by #8 AWG copper wire to

plank strips are increased in thickness, but if this is

a central copper bonding strip that, in tum, is con-

done It is rare to see longitudinal stringers.

nected to the ballast keel or to a grounding plate on

Composite construction, popular in high-quality

the outside of the hull. Such a bonding system pro-

wood yachts in the 1930s, is rarely seen today In this

vides lightning protection as well as a degree of elec-

form of construction, the wood planking, usually

trolysis protection.

regular caulked planking, is bolted to steel or bronze

angle frames. Steel frames were usually galvanized,

but the very highest quality craft used bronze for its

Decks

durability Composite construction is very strong but

relatively costly With modem glues, laminated The tightest deck for a wooden hull is marine ply-

frames make more sense for today's yachts. wood. It is also the lightest, strongest, and easiest to

CONSTRUCTION

85

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Understanding Boat Design 81 PDFDocument1 pageUnderstanding Boat Design 81 PDFŁukasz ZygielNo ratings yet

- Escrow AgreementDocument3 pagesEscrow Agreementmadelyn sarmientaNo ratings yet

- Personal Grooming PDFDocument8 pagesPersonal Grooming PDFayuNo ratings yet

- Process Pump ControlDocument4 pagesProcess Pump ControlBramJanssen76No ratings yet

- Reading A02wout AnsDocument4 pagesReading A02wout AnsTavi Nicolae67% (3)

- Not A Deck (From Boat Repair Manual, by Marine, 1988) : Areas of or Are Cored. Fiberglass Allan InternationalDocument1 pageNot A Deck (From Boat Repair Manual, by Marine, 1988) : Areas of or Are Cored. Fiberglass Allan InternationalŁukasz ZygielNo ratings yet

- Understanding Boat Design 102 PDFDocument1 pageUnderstanding Boat Design 102 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 92 PDFDocument1 pageUnderstanding Boat Design 92 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 95 PDFDocument1 pageUnderstanding Boat Design 95 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 98 PDFDocument1 pageUnderstanding Boat Design 98 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 101 PDFDocument1 pageUnderstanding Boat Design 101 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 93 PDFDocument1 pageUnderstanding Boat Design 93 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 104 PDFDocument1 pageUnderstanding Boat Design 104 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 103 PDFDocument1 pageUnderstanding Boat Design 103 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 90 PDFDocument1 pageUnderstanding Boat Design 90 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 87 PDFDocument1 pageUnderstanding Boat Design 87 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 75 PDFDocument1 pageUnderstanding Boat Design 75 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 88 PDFDocument1 pageUnderstanding Boat Design 88 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 80 PDFDocument1 pageUnderstanding Boat Design 80 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 78 PDFDocument1 pageUnderstanding Boat Design 78 PDFŁukasz ZygielNo ratings yet

- Seward Stomacher 400Document2 pagesSeward Stomacher 400ugomiesterNo ratings yet

- Ellena's Book of Birds in SingaporeDocument38 pagesEllena's Book of Birds in SingaporeEllena GabrielleNo ratings yet

- AlbertEinstein PDFDocument3 pagesAlbertEinstein PDFABDUL ALEEMNo ratings yet

- GRP 1Document2 pagesGRP 1Yuva RaniNo ratings yet

- FTL20.pdf Ultrasonic SondeDocument20 pagesFTL20.pdf Ultrasonic SondeJaroslav BiresNo ratings yet

- Neopuff Brochure 31.05.2013 PDFDocument4 pagesNeopuff Brochure 31.05.2013 PDFfika_khayan7489No ratings yet

- Help Utf8Document8 pagesHelp Utf8Jorge Diaz LastraNo ratings yet

- TErmination Letter-ContractorDocument1 pageTErmination Letter-ContractorBojoNo ratings yet

- Top Tips For Marriage Habits For A Happy Marriage 2019Document2 pagesTop Tips For Marriage Habits For A Happy Marriage 2019Marcel Henri Pascal Patrice Moudiki KingueNo ratings yet

- Problems - Tax and BSDocument5 pagesProblems - Tax and BSNguyễn Thùy LinhNo ratings yet

- Dif Conrete Tension (Malvar)Document5 pagesDif Conrete Tension (Malvar)mohamed_gmal22No ratings yet

- OpenScapeBusiness V1 R2.1.0 Release Note V1.2.10 ExternDocument14 pagesOpenScapeBusiness V1 R2.1.0 Release Note V1.2.10 Externjan2No ratings yet

- Smart School EseiDocument15 pagesSmart School Eseiz89100% (1)

- Fon Iv Ass1Document2 pagesFon Iv Ass1HemanthNo ratings yet

- MineralsDocument40 pagesMineralsGhillian Mae GuiangNo ratings yet

- 2.2 Crime Scene Investigation andDocument1 page2.2 Crime Scene Investigation andFatima Sarpina HinayNo ratings yet

- Supermarket Price List - With Price DiscrepanciesDocument12 pagesSupermarket Price List - With Price DiscrepanciesEj GanocNo ratings yet

- Lab CPD-2Document35 pagesLab CPD-2Phu nguyen doanNo ratings yet

- An Introduction To Mount EverestDocument4 pagesAn Introduction To Mount EverestJihad HasanNo ratings yet

- Money and BankingDocument20 pagesMoney and BankingFAH EEMNo ratings yet

- Vmware Esx Server 3.5 Installation Guide: Devoloped By: KalamDocument24 pagesVmware Esx Server 3.5 Installation Guide: Devoloped By: KalamKarimulla KolimiNo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster PumpsDocument14 pagesSTOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster PumpsAHMED AMIRANo ratings yet

- Lab Report Literature Review ExampleDocument5 pagesLab Report Literature Review ExampleafmzmqwdglhzexNo ratings yet

- Effect of Pitting Corrosion On The Mechanical Properties of 316 Grade Stainless SteelDocument6 pagesEffect of Pitting Corrosion On The Mechanical Properties of 316 Grade Stainless SteelAnilNo ratings yet

- 3.1 Mitosis Ans PDFDocument7 pages3.1 Mitosis Ans PDFtess_15No ratings yet

- Independent Contractor Agreement For Accountant & BookkeeperDocument7 pagesIndependent Contractor Agreement For Accountant & BookkeeperWen' George BeyNo ratings yet