Professional Documents

Culture Documents

Bearing Temperature

Uploaded by

jakkakirans0 ratings0% found this document useful (0 votes)

8 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageBearing Temperature

Uploaded by

jakkakiransCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

6. Bearing Temperatures,

6.1 Admissible Bearing Temperatures

Considering the operating life of lubricating ols and the heat

resistance of white metals we make the following suggestions

for admissible temperatures of our bearings:

4) measurements with standard thermoprobes in the oll flow or

respectively in the oll bath:

Tin = 80°C

'b) measurement with standard theemoprobes in the loaded

zone of the bearing she

Tan = 90°C

©} measurements with good-quality thermoprobes which are

Carefully bull in and have metalic contact for certain with

the bearing shell in the loaded zone:

Tim = 110°C.

6) precise measurements with resistance thermometers (possl-

bly also with thermocouples or other measuring instruments)

in approx. 1..2 mm distance from the bond compound sur

face steal/whitemetal in the zone of maximum temperature:

Tim = 125°C

If, due to hydrodynamic calculation, the peak temperatures are

10 be expected higher than 125°C bearing metals and lubricat-

ing olls should be carefully selected. In that case for bearings,

with high loadings and high speeds temperatures of up to

Tim = 150°C

‘may be allowed.

{1 Installation of Survey Instructions or specific guidelines state

‘maximum admissibe temperatures the relevant measuring

points have to be considered.

Extremely low admissible bearing temperatures ~ as sometimes

requited ~ often result from measurements in the oll sump of at

the oll outlet and cannot be compared with the temperatures

taken in the loaded zone of the bearing.

6.2 Alarm and Shut-Down Temperatures

Basis forthe intial setting of alarm and shut-down temperatures

's the calculated operating temperature. However this calcula-

tion of operating temperature must take info consideration the

highest possible site ambient, and/or oil inlet temperature, as

well as the maximum spead and relevant loadings.

‘The alarm temperature should be set 10 K higher than the cal-

‘culated bearing temperature and the shut-down-temparature

approx. 20 K higher.

Ut, alter start-up of the machine, the actual bearing temperatures

are considerably higher than those calculated (e.g. by heat

transfer to the bearings),

‘naw basis for setting the alarm and shut-down temperatures,

this however, only after having consulted RENK, The values

should be rounded off to figures ending in 5s or 10s.

6.3 Temperature Measurements

Generally the following types of temperature measurement are

used in engineering:

63.1 Measurements Using Liquid-Filled Thermometers

6.3.1.1. Bar and angle thermometers taciltating direct reading

of thé liquid column along a linear scale.

18

63.1.2 Needle thermometers, where the expansion ofthe liq-

tid pressurises a Bourdon lube and where the expansion is

transmitted to the shaft of the thermometer by means of a pin-

fon.

Where a heat sensor and display unit are fitted separately, they

are linked by means of a capilary tube. This must never be

‘opened up, since it forms an integral part of the system.

632 Measurement using Electrical Thermometers

632.1. Thermocouples, as the name indicates, are elements,

where the soldered junction of two wires made from different

‘materials produces a voltage, the magnitude of which depends

‘on the temperature, whore this voltage can be read using a volt-

‘meter calibrated in temperature units.

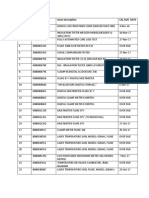

Te unalog tay ya and

Sustraatsmrortaoeteser sy ata!

este reagent cneaeuh nce’

ieomearedis alos teams aoe

Earns Gans we soa ete

ieaeenit ciate setae

Sea seats ireciinener a

Sebeleecias ia Sraecteah on

Soe etecns teak etaersen eens

sea feeettren ea neg tahroa

ial teraen tec onens

Resistance thermometers are frequently used, and for this rea-

‘son they will be dealt with in detall here.

‘Since these are electrical or electronic mathods, the daseription

hich follows ~ which is not intended to be scientifically accu-

tale ~ is meant for easy understanding and relates specifically to

the Pt 100 sensors in usa In Europe.

‘The principle of temperature measuring using resistance ther

_mometors is based on the measurement of the electrical resist-

ance of a measuring resistance in the temperature sensor. The

‘loctrical resistance is a function of temperature i.e. the tem

pperature-dependent change of the electrical resistance of the

‘conductor (measuring resistor is used for the determination of

the temperature,

‘Materials with a large temperature coefficient are used for a

‘measuring resistor. In addition great care is taken to ensure that

the materials do not age in the temperature range in which they.

‘ae used. For this reason platinurn (Pt 100) is mainly used. .100*

‘means that this measuring resistance has a resistance of 100

‘Ohms (0) at a temperature of O°C.

In accordance with DIN 43760 there must be a resistance ratio

(0f Rico/Ry = 1,985, 18, at 100°C the resistance is 198,5 Ohms.

‘The characteristics curve of the measuring resistance Is defined

in accordance with the equation:

B,

100 (1 + 3,90802- 10° T — 0.580195 - 10° T2)

where Ri [0] is the resistance at temperature T [°C].

For the display unit it is also possible to provide a digital display

with LED (llurinated) or LCD (dark)

‘A more elaborate version of the display is the regulator (Ag. 31).

‘A reguiator (generally an electronic unit) can be designed as a

‘ingle, two oF three point regulator. Itis then possible to use

these points as switching points. They actuate a limit switch

‘once the set temperature has been reached. This contact can

bbe used for any signalling and regulating purpose.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1 Min IR Value 10 Min IR Value PIDocument2 pages1 Min IR Value 10 Min IR Value PIjakkakiransNo ratings yet

- Investigationof Effectof Temperature Variationina High Voltage Cableon Electrical InsulationDocument7 pagesInvestigationof Effectof Temperature Variationina High Voltage Cableon Electrical InsulationjakkakiransNo ratings yet

- MT 1128 - Core Loss ReportDocument1 pageMT 1128 - Core Loss ReportjakkakiransNo ratings yet

- MotorDocument16 pagesMotorjakkakiransNo ratings yet

- Assetno. Asset Description Cal Due DateDocument2 pagesAssetno. Asset Description Cal Due DatejakkakiransNo ratings yet

- Bolt Torq 0309Document3 pagesBolt Torq 0309jakkakiransNo ratings yet