Professional Documents

Culture Documents

Anasthesia Machine PM Checklist PDF

Anasthesia Machine PM Checklist PDF

Uploaded by

hem midlandsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anasthesia Machine PM Checklist PDF

Anasthesia Machine PM Checklist PDF

Uploaded by

hem midlandsCopyright:

Available Formats

Anesthesia Machine/Vaporizer Preventive Maintenance Policy

A. Purpose:

The purpose of this document is to provide guidelines regarding recommended

scheduling for anesthesia machine/vaporizer (isoflurane, halothane and methoxyflurane)

preventive maintenance. You are advised to follow the manufacturer recommendations if

they differ from this document.

Policy:

Anesthesia machines and vaporizers must be in good working condition to reduce

anesthetic gas leaks, to have the best performance of scavenging equipment, and ensure

the appropriate percentage of anesthetic is being delivered. Personnel must be trained in

the proper use of anesthetic machines and vaporizers prior to operation.

Each piece of equipment involved in the delivery of inhalant anesthetics should be

evaluated regularly to assure its proper function and integrity.

All anesthetic vaporizers must have preventive maintenance performed a least annually.

Preventive maintenance includes:

Electrical Safety inspection and battery replacement for Desflurane Vaporizers.

Physical inspection for loose or missing screws, sharp edges, or loose

connectors.

Visual inspection for mechanical or electrical damage.

Verify operation of safety interlock if applicable.

Verify operation of handwheel lock and release button.

Verify handwheel turns smoothly through entire range.

Check Fill / Drain system operates properly and that there are no leaks.

Verify concentration delivery accuracy at 0, 1, 3, & 5% settings using room

temperature 100% Oxygen at 5 LPM flow is within manufacturer’s specifications.

References:

OSHA Health Care Workers Guidelines/Chap5b (http://origin.cdc.gov/niosh/hcwold5b.html)

Approved by UCAR: 4/19/06

You might also like

- SOP - Agilent 1260 Infinity HPLC - Regular Operation - 10 - 20 - 16Document5 pagesSOP - Agilent 1260 Infinity HPLC - Regular Operation - 10 - 20 - 16Yousra Zeidan100% (2)

- Maquina de Anestesia Pelon Prima - sp2 - Service - ManualDocument110 pagesMaquina de Anestesia Pelon Prima - sp2 - Service - Manualperla_canto_1No ratings yet

- Penlon Prima SP Anaesthesia Machine - User ManualDocument140 pagesPenlon Prima SP Anaesthesia Machine - User Manualtallraj50% (2)

- FGI Patient Handling and Mobility Assessments 191008Document476 pagesFGI Patient Handling and Mobility Assessments 191008morton1472100% (1)

- Equipment For SurgeryDocument19 pagesEquipment For SurgerysanathNo ratings yet

- Anesthetic GasDocument3 pagesAnesthetic GasJuan PáezNo ratings yet

- SCBA ProgramDocument7 pagesSCBA Programrajakhurshed7185No ratings yet

- Respiratory Protective Equipment (RPE) : Offshore Coshh EssentialsDocument3 pagesRespiratory Protective Equipment (RPE) : Offshore Coshh Essentialsjnacer nacerNo ratings yet

- 490 20081015 01 Major Proc AmbulatoryinfusionpumpDocument5 pages490 20081015 01 Major Proc AmbulatoryinfusionpumpAsmaranto PrajokoNo ratings yet

- RPP SOP Respiratory SummaryDocument5 pagesRPP SOP Respiratory SummaryKimia AsikNo ratings yet

- Are Daily Anesthesia Machine Checks Needed - Courtemanche & AssociatesDocument3 pagesAre Daily Anesthesia Machine Checks Needed - Courtemanche & Associates建榮廖No ratings yet

- AMEREX 05604 Manual For Hand Portable Halon 1211 ExtinguishersDocument6 pagesAMEREX 05604 Manual For Hand Portable Halon 1211 ExtinguishersKamal Jit DhimanNo ratings yet

- Penlon A-200 SP Circle Absorber - User ManualDocument40 pagesPenlon A-200 SP Circle Absorber - User ManualAnonymous oWnCVtEUQCNo ratings yet

- Wetherford Pump Operations and MaintenanceDocument5 pagesWetherford Pump Operations and MaintenanceRajesh Singh0% (1)

- Calibrating and Testing Direct-Reading Portable Gas MonitorsDocument3 pagesCalibrating and Testing Direct-Reading Portable Gas MonitorsHilari Eckd100% (1)

- Shpa Standards of Practice For The Safe Handling of Cytotoxic DR 2005Document9 pagesShpa Standards of Practice For The Safe Handling of Cytotoxic DR 2005Lan FdzNo ratings yet

- Manual For Hand Portable Halon 1211 ExtinguishersDocument8 pagesManual For Hand Portable Halon 1211 ExtinguishersSerge aswadNo ratings yet

- 456 20110630 01 Major Proc CentrifugesDocument8 pages456 20110630 01 Major Proc CentrifugessantiNo ratings yet

- 07.03.53 Mechanical VentilationDocument3 pages07.03.53 Mechanical VentilationSapna thakurNo ratings yet

- Service Manual A100Document54 pagesService Manual A100erika50% (2)

- Good Laboratories Practice (GLP) in Pharmaceuticals - PharmaguidelineDocument2 pagesGood Laboratories Practice (GLP) in Pharmaceuticals - PharmaguidelineAhmed GasserNo ratings yet

- Anesthesia MachinesDocument4 pagesAnesthesia MachinesEmilio CánepaNo ratings yet

- 2016-11-07 TDB Introduction To Respirator Fit Testing (Europe)Document7 pages2016-11-07 TDB Introduction To Respirator Fit Testing (Europe)Marllory Isaza RuizNo ratings yet

- Mech VentDocument23 pagesMech VentJennille IlagaNo ratings yet

- 450 20081015 01 Major Proc CapnometerDocument8 pages450 20081015 01 Major Proc CapnometersantiNo ratings yet

- Manley Iss3 UserDocument79 pagesManley Iss3 UserJavier CarrascoNo ratings yet

- Manual de Operación Shandon Excelsior ES A78410120Document131 pagesManual de Operación Shandon Excelsior ES A78410120Sacker Daniela GarcíaNo ratings yet

- Anasthesa Unit VentilatorDocument6 pagesAnasthesa Unit VentilatorWidhiatmoko SangjendralNo ratings yet

- For Testing The Fume Hoods Personnel Must Wear at A Minimum Gloves and Goggles Follow "Appendix A" AlgorithmDocument4 pagesFor Testing The Fume Hoods Personnel Must Wear at A Minimum Gloves and Goggles Follow "Appendix A" AlgorithmsandbadbahriNo ratings yet

- Precision Easypulse 5Document16 pagesPrecision Easypulse 5Dale BergerNo ratings yet

- Humdfr ManualDocument4 pagesHumdfr ManualDavid Ronald Chambi AverangaNo ratings yet

- Zfume Hood-Canopy Use and Maintenance Program 2016Document11 pagesZfume Hood-Canopy Use and Maintenance Program 2016hernandezzNo ratings yet

- RDM - Fume Hood Maintenance 10-25-10Document5 pagesRDM - Fume Hood Maintenance 10-25-10Ahlehadith Youth Force AttockNo ratings yet

- Thermo Scientific Excelsior AS Operator Guide A82310100 Issue 5Document201 pagesThermo Scientific Excelsior AS Operator Guide A82310100 Issue 5Yeong Jyh ChinNo ratings yet

- ISPE Good Practice Guide and Compressed AirDocument5 pagesISPE Good Practice Guide and Compressed Airqac gmpNo ratings yet

- Operating Instructions: HTL-PHP Air Torque PumpDocument38 pagesOperating Instructions: HTL-PHP Air Torque PumpvankarpNo ratings yet

- Program: Medical Evaluation of SCBA UsersDocument6 pagesProgram: Medical Evaluation of SCBA UsersBenaoumeur FertasNo ratings yet

- Enviro-Flo, Inc. Enviro-Chlor Tablet Chlorinator: Installation & Owner'S ManualDocument7 pagesEnviro-Flo, Inc. Enviro-Chlor Tablet Chlorinator: Installation & Owner'S ManualSteve DennisNo ratings yet

- HC 11-Control of Smoke From LaserElectric Surgical ProceduresDocument2 pagesHC 11-Control of Smoke From LaserElectric Surgical Proceduresseguridadyambiente641No ratings yet

- Anesthetic Gases: Guidelines For Workplace ExposuresDocument40 pagesAnesthetic Gases: Guidelines For Workplace ExposuresTejinder SinghNo ratings yet

- SpecificationsDocument1 pageSpecificationsAnshul GuptaNo ratings yet

- Cholinesterase TestDocument5 pagesCholinesterase TestFariha FirdausNo ratings yet

- OPPI Guidelines On Good Laboratory Practices (GLP)Document31 pagesOPPI Guidelines On Good Laboratory Practices (GLP)Vitalis MbuyaNo ratings yet

- Labotary Safety Guidence: 1.1 Elements of The Laboratory StandardDocument21 pagesLabotary Safety Guidence: 1.1 Elements of The Laboratory Standardroyroy0093No ratings yet

- ASA Publications Anesthesia Machine Obsolescence 20041Document7 pagesASA Publications Anesthesia Machine Obsolescence 20041Julio Corona100% (1)

- Ellsworth Respiratory Protection PlanDocument17 pagesEllsworth Respiratory Protection PlanidahssNo ratings yet

- Anesthetic Gases: Guidelines For Workplace Exposures: General Information Health EffectsDocument44 pagesAnesthetic Gases: Guidelines For Workplace Exposures: General Information Health EffectsReza KhajeNo ratings yet

- Foam Mix Fire Sup TM HP0296 v2Document126 pagesFoam Mix Fire Sup TM HP0296 v2Rachel Flores100% (1)

- Respiratory Protection Toolbox TalkDocument4 pagesRespiratory Protection Toolbox TalkJomy JohnyNo ratings yet

- Affirmagen Affirmagen 4: OrthoDocument6 pagesAffirmagen Affirmagen 4: OrthoDominic EmerencianaNo ratings yet

- Condicones Test Toxicidad PeneidosDocument18 pagesCondicones Test Toxicidad PeneidosroraysideblancoNo ratings yet

- Compressor Maintenance IH Survey 240A1Document11 pagesCompressor Maintenance IH Survey 240A1Kar LikeNo ratings yet

- SB04 4Document4 pagesSB04 4hugomalespinNo ratings yet

- Alinity H-Series Control 29P NoticeDocument3 pagesAlinity H-Series Control 29P NoticePopovNo ratings yet

- Environmental Monitoring GuidelinesDocument36 pagesEnvironmental Monitoring Guidelinesmadosb5133No ratings yet

- Environmental Monitoring For Aseptic Dispensing FacilitiesDocument36 pagesEnvironmental Monitoring For Aseptic Dispensing FacilitiesGuna Babu100% (2)

- Hybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesFrom EverandHybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesNo ratings yet

- Don't Drink It But Fix It: An Alternative Safe Histology Fixative For Eliminating FormaldehydeFrom EverandDon't Drink It But Fix It: An Alternative Safe Histology Fixative For Eliminating FormaldehydeNo ratings yet

- Policy Themes For Higher Education in Sudan Higher Education Access and EquityDocument4 pagesPolicy Themes For Higher Education in Sudan Higher Education Access and Equitymorton1472No ratings yet

- Mechanical Ventilator: Design and Implementation: Professor Yasser Mostafa KadahDocument19 pagesMechanical Ventilator: Design and Implementation: Professor Yasser Mostafa Kadahmorton1472No ratings yet

- Medtronic Shares Ventilation Design Specifications To Accelerate Efforts To Increase Global Ventilator ProductionDocument1 pageMedtronic Shares Ventilation Design Specifications To Accelerate Efforts To Increase Global Ventilator Productionmorton1472No ratings yet

- Syringe Selection Guide: Common Syringe Data - Diameter and Plunger Surface AreaDocument2 pagesSyringe Selection Guide: Common Syringe Data - Diameter and Plunger Surface Areamorton1472No ratings yet

- MPS - HY - 60 ML BD Syringe Now 50 ML - Customer Letter - CL - ENDocument3 pagesMPS - HY - 60 ML BD Syringe Now 50 ML - Customer Letter - CL - ENmorton1472No ratings yet

- General Water Baths 1Document4 pagesGeneral Water Baths 1morton1472No ratings yet

- Engineering Specifications OS Vent1.3Document2 pagesEngineering Specifications OS Vent1.3morton1472No ratings yet

- FGI BF HealthCareFutures SummaryDocument11 pagesFGI BF HealthCareFutures Summarymorton1472No ratings yet

- 2019 10 03 SudanStakeholderDialogues 0Document18 pages2019 10 03 SudanStakeholderDialogues 0morton1472No ratings yet

- A A A A: Gspublisherversion 0.65.100.100Document1 pageA A A A: Gspublisherversion 0.65.100.100morton1472No ratings yet

- Wa0018Document1 pageWa0018morton1472No ratings yet

- Quality of Lifecheck ListDocument4 pagesQuality of Lifecheck Listmorton1472No ratings yet

- Wa0019Document1 pageWa0019morton1472No ratings yet

- Isolation Rooms Final Version V3 Publication 2Document14 pagesIsolation Rooms Final Version V3 Publication 2morton1472No ratings yet

- CRC Handbook of Ayurvedic Medicinal Plants: L. D. Ka Oor, PH.D., F.I.A.C, F.A.S.PDocument2 pagesCRC Handbook of Ayurvedic Medicinal Plants: L. D. Ka Oor, PH.D., F.I.A.C, F.A.S.Pmorton1472No ratings yet

- Cas Balances Service ManualDocument51 pagesCas Balances Service Manualmorton1472No ratings yet

- For Guidance For Guidance For Guidance For Guidance: Australasian HFG Standard Components WTPL Water Treatment Plant RoomDocument1 pageFor Guidance For Guidance For Guidance For Guidance: Australasian HFG Standard Components WTPL Water Treatment Plant Roommorton1472No ratings yet

- Patient Monitoring Smart Wheelchair: September 2015Document5 pagesPatient Monitoring Smart Wheelchair: September 2015morton1472No ratings yet

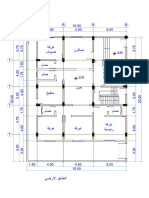

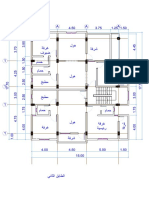

- Archive - RLS Complete Sets Batch 2 - 5 April 2018 PDFDocument143 pagesArchive - RLS Complete Sets Batch 2 - 5 April 2018 PDFmorton1472No ratings yet

- IHFG Part B Renal Dialysis UnitDocument18 pagesIHFG Part B Renal Dialysis Unitmorton1472No ratings yet

- How Reliable Is Your Diagnosis - Really - Medical Design BriefsDocument10 pagesHow Reliable Is Your Diagnosis - Really - Medical Design Briefsmorton1472No ratings yet

- Whole Blood Coagulation Analyzer PDFDocument1 pageWhole Blood Coagulation Analyzer PDFmorton1472No ratings yet

- Evaluation of Operating Room Units Within The Context of Green Design Criteria (#303368) - 290212Document15 pagesEvaluation of Operating Room Units Within The Context of Green Design Criteria (#303368) - 290212morton1472No ratings yet

- Microfluidics Device Can Detect Cancer Cells in Blood - Medical Design BriefsDocument7 pagesMicrofluidics Device Can Detect Cancer Cells in Blood - Medical Design Briefsmorton1472No ratings yet