Professional Documents

Culture Documents

TECAFINE PMP Natural - Stock Shapes (Rods, Plates, Tubes)

Uploaded by

yatheendravarmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TECAFINE PMP Natural - Stock Shapes (Rods, Plates, Tubes)

Uploaded by

yatheendravarmaCopyright:

Available Formats

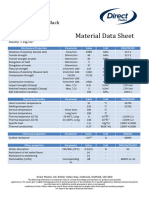

TECAFINE PMP natural - Stock Shapes (rods, plates, tubes)

Chem ical Designation Main features Target Industries

PMP (Polymethylpentene) good chemical resistance food technology

electrically insulating mechanical engineering

Colour

good machinability automotive industry

light yellow transparent

easy to polish

Density high creep resistance

0.83 g/cm 3 low density

high toughness

Mechanical properties parameter value unit norm comment

Tensile strength 50mm/min 26 MPa DIN EN ISO 527-2 (1) For tensile test: specimen

type 1b

Modulus of elasticity 1mm/min 1000 MPa DIN EN ISO 527-2 1) (2) For flexural test: support

(tensile test) span 64mm, norm specimen.

Tensile strength at yield 50mm/min 26 MPa DIN EN ISO 527-2 (3) Specimen 10x10x10mm

(4) Specimen 10x10x50mm,

Elongation at yield 50mm/min 6 % DIN EN ISO 527-2 modulus range between 0.5

and 1% compression.

Elongation at break 50mm/min 67 % DIN EN ISO 527-2 (5) For Charpy test: support

Flexural strength 2mm/min, 10 N 31 MPa DIN EN ISO 178 2) span 64mm, norm specimen.

(6) Specimen in 4mm

Modulus of elasticity 2mm/min, 10 N 800 MPa DIN EN ISO 178 thickness

(flexural test)

Compression strength 1% / 2% 11 / 19 MPa EN ISO 604 3)

5mm/min, 10 N

Compression modulus 5mm/min, 10 N 1000 MPa EN ISO 604 4)

Impact strength (Charpy) max. 7,5J 17 kJ/m2 DIN EN ISO 179-1eU 5)

Ball indentation hardness 58 MPa ISO 2039-1 6)

T hermal properties parameter value unit norm comment

Service temperature short term 170 °C 1) (1) Found in public sources.

Individual testing regarding

Service temperature long term 120 °C application conditions is

mandatory.

Electrical properties parameter value unit norm comment

Other properties parameter value unit norm comment

Water absorption 24h / 96h (23°C) <0.01 / % DIN EN ISO 62 1) (1) Ø ca. 50mm, h=13mm

<0.01 (2) (+) limited resistance

(3) - poor resistance

Resistance to hot water/ bases (+) - 2) (4) Corresponding means no

Resistance to weathering - - 3) listing at UL (yellow card). The

information might be taken

Flammability (UL94) corresponding to HB DIN IEC 60695-11-10; 4) from resin, stock shape or

estimation. Individual testing

regarding application

conditions is mandatory.

Our information and statements reflect the current state of our knowledge and shall inform about our products and their applications. They do not assure or guarantee chemical

resistance, quality of products and their merchantability in a legally binding way. Our products are not defined for use in medical or dental implants. Existing commercial patents

have to be observed. The corresponding values and information are no minimum or maximum values, but guideline values that can be used primarily for comparison purposes

for material selection. These values are within the normal tolerance range of product properties and do not represent guaranteed property values. Therefore they shall not be

used for specification purposes. Unless otherwise noted, these values were determined by tests at reference dimensions (typically rods with diameter 40-60 mm according to

DIN EN 15860) on extruded and machined specimen. As the properties depend on the dimensions of the semi-finished products and the orientation in the component (esp. in

reinforced grades), the material may not be used without a separate testing under individual circumstances. The customer is solely responsible for the quality and suitability of

products for the application and has to test usage and processing prior to use. Data sheet values are subject to periodic review, the most recent update can be found at

www.ensingerplastics.com. Technical changes reserved.

E ns inger GmbH Tel +49 7032 819 0 Date: 2020/05/13 V ers ion: A C

Rudolf-Dies el S t r. 8 Fax +49 7032 819 100

71154 Nufringen - Deut s c hland ensingerplastics.com

You might also like

- HZ Tecafine PMP Natural in de 201604Document1 pageHZ Tecafine PMP Natural in de 201604Luis Alberto Silva NavarroNo ratings yet

- TECAPEEK PVX Black 7 PDFDocument1 pageTECAPEEK PVX Black 7 PDFHARSHANo ratings yet

- TECAMID 66 GF30 Black 0Document1 pageTECAMID 66 GF30 Black 0VTHafnergmx.deNo ratings yet

- Material Data Sheet PA 6 GF30 Black: Main FeaturesDocument2 pagesMaterial Data Sheet PA 6 GF30 Black: Main FeaturesmohanNo ratings yet

- Pa6 BlackDocument2 pagesPa6 BlackworkatarNo ratings yet

- Tecatron Gf40 Black en All 201711Document2 pagesTecatron Gf40 Black en All 201711JorgeMariscalNo ratings yet

- HZ Tecaflon PVDF Natural Se de 201709Document1 pageHZ Tecaflon PVDF Natural Se de 201709Ha Tran KhiemNo ratings yet

- TECAPEEK CF30 Black 7 PDFDocument1 pageTECAPEEK CF30 Black 7 PDFHARSHANo ratings yet

- TECAPEEK GF30 Natural - Stock ShapesDocument1 pageTECAPEEK GF30 Natural - Stock ShapesHARSHANo ratings yet

- Tecasint 1011 Natural 0Document1 pageTecasint 1011 Natural 0Suraj_73No ratings yet

- TDS Nylon v3.011-enDocument3 pagesTDS Nylon v3.011-enmartinf090574No ratings yet

- TDS CPE V3.010-EnDocument3 pagesTDS CPE V3.010-EnspicefooNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Ficha Técnica Nylon MolyDocument1 pageFicha Técnica Nylon MolyHector ArciniegasNo ratings yet

- TECASINT_2011_natural_14Document1 pageTECASINT_2011_natural_14e.montgomeryNo ratings yet

- HDPE Physical PropertiesDocument7 pagesHDPE Physical PropertiesshaffetiNo ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- Acetal Natural Data SheetDocument1 pageAcetal Natural Data SheetvijayNo ratings yet

- Propertie NilonDocument3 pagesPropertie Nilonmuhammad daffaNo ratings yet

- PA6EDocument1 pagePA6EDiego ReggianiniNo ratings yet

- Nylon 6Document1 pageNylon 6luuiissNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- Original Material "S" Green: Technical InformationDocument1 pageOriginal Material "S" Green: Technical InformationPedro Henriques RamosNo ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- VASITESA MEXICO Datasheet - Polystone - P - Homopolymer - Grey - ENDocument1 pageVASITESA MEXICO Datasheet - Polystone - P - Homopolymer - Grey - ENIsrael AristaNo ratings yet

- High-Temp PI Stock ShapesDocument2 pagesHigh-Temp PI Stock ShapesGreeshmaNo ratings yet

- Technical specifications and test results for Panlite AD-5503 polycarbonate sheetDocument1 pageTechnical specifications and test results for Panlite AD-5503 polycarbonate sheetmarioNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- PET Glide DatabladDocument1 pagePET Glide DatabladMuhammad IrfanNo ratings yet

- Technical Data Sheet: Perspex CCDocument2 pagesTechnical Data Sheet: Perspex CCResist IkatNo ratings yet

- LNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetDocument2 pagesLNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetcoroNo ratings yet

- Murtfeldt Material S Group Material-S-1000-Green Technical Data enDocument1 pageMurtfeldt Material S Group Material-S-1000-Green Technical Data enPedro Henriques RamosNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- PA66 Nylon Properties SheetDocument2 pagesPA66 Nylon Properties SheetAshish Mohurle100% (1)

- Material Data Sheet: Urban@plastum - CZ WWW - Plastum.czDocument1 pageMaterial Data Sheet: Urban@plastum - CZ WWW - Plastum.czDavis GNo ratings yet

- Perspex Cell Cast Acrylic: Technical Data SheetDocument1 pagePerspex Cell Cast Acrylic: Technical Data Sheetarun manchekarNo ratings yet

- Datasheet Maywosol ABSPMMA Mat ENDocument1 pageDatasheet Maywosol ABSPMMA Mat ENtrippNo ratings yet

- Sustatron Pps GF 40: Technical Data SheetDocument1 pageSustatron Pps GF 40: Technical Data SheetyatheendravarmaNo ratings yet

- Datasheet Saphir HCE 2021 EN v1Document2 pagesDatasheet Saphir HCE 2021 EN v1André CardosoNo ratings yet

- PA6G MoSDocument1 pagePA6G MoSjhax90No ratings yet

- Datasheet SustaPEEK ENDocument1 pageDatasheet SustaPEEK ENazwar1105No ratings yet

- Polystone P Homopolymer: Technical Data SheetDocument1 pagePolystone P Homopolymer: Technical Data Sheetmuchamad yasinNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Impact Modified PS Clear for Sneeze Guards and Face ShieldsDocument1 pageImpact Modified PS Clear for Sneeze Guards and Face ShieldsIceMan3No ratings yet

- Datasheet Cast Acrylic Sheet enDocument1 pageDatasheet Cast Acrylic Sheet entrippNo ratings yet

- Datasheet Matrox ENDocument1 pageDatasheet Matrox ENrajanarenderNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Green Cast Setacryl UKDocument4 pagesGreen Cast Setacryl UKgillestalbotNo ratings yet

- 1120192 Technical Data SheetDocument1 page1120192 Technical Data SheetSilversnape00No ratings yet

- Pe-Uhmw Technical Data SheetDocument1 pagePe-Uhmw Technical Data SheetPrashant MalikNo ratings yet

- 06 HPS6 DatasheetDocument2 pages06 HPS6 Datasheet张浩No ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- Achieve™ Advanced PP8285E1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP8285E1: Polypropylene Impact CopolymermosesNo ratings yet

- Noise and Signal Interference in Optical Fiber Transmission Systems: An Optimum Design ApproachFrom EverandNoise and Signal Interference in Optical Fiber Transmission Systems: An Optimum Design ApproachNo ratings yet

- PTFE MythsDocument4 pagesPTFE MythsyatheendravarmaNo ratings yet

- Extrusion Honing PDFDocument6 pagesExtrusion Honing PDFyatheendravarmaNo ratings yet

- How Do We Measure Surface TextureDocument4 pagesHow Do We Measure Surface TextureyatheendravarmaNo ratings yet

- DOT 3AL cylinder specification summaryDocument5 pagesDOT 3AL cylinder specification summaryyatheendravarmaNo ratings yet

- Effects of Alloying Elements in SteelDocument12 pagesEffects of Alloying Elements in SteelyatheendravarmaNo ratings yet

- Measuring Total Runout for Circularity, Cylindricity & MoreDocument1 pageMeasuring Total Runout for Circularity, Cylindricity & MoreyatheendravarmaNo ratings yet

- Guide To Hot Work Loss PreventionDocument8 pagesGuide To Hot Work Loss PreventionyatheendravarmaNo ratings yet

- Asbury Carbons Safety Data Sheet for Synthetic GraphiteDocument7 pagesAsbury Carbons Safety Data Sheet for Synthetic GraphiteyatheendravarmaNo ratings yet

- Introduction To Eddy Current TestingDocument4 pagesIntroduction To Eddy Current TestingyatheendravarmaNo ratings yet

- MS Teams - Interactive Step by Step Guide - PPSXDocument24 pagesMS Teams - Interactive Step by Step Guide - PPSXyatheendravarmaNo ratings yet

- Chemours Prop 65 Response 1-25-2019Document1 pageChemours Prop 65 Response 1-25-2019yatheendravarmaNo ratings yet

- CHAPTER 1 - Introduction To CNC MachinesDocument35 pagesCHAPTER 1 - Introduction To CNC Machinesswami061009No ratings yet

- MRBDocument12 pagesMRByatheendravarmaNo ratings yet

- Applicability of Test Methods For Material Characterization PDFDocument18 pagesApplicability of Test Methods For Material Characterization PDFyatheendravarmaNo ratings yet

- Sustatron Pps GF 40: Technical Data SheetDocument1 pageSustatron Pps GF 40: Technical Data SheetyatheendravarmaNo ratings yet

- ASQR 4.6 A220 Suppliers Quality RequirementsDocument40 pagesASQR 4.6 A220 Suppliers Quality RequirementsyatheendravarmaNo ratings yet

- Fomblin Y45: Perfl UoropolyetherDocument1 pageFomblin Y45: Perfl UoropolyetheryatheendravarmaNo ratings yet

- IATF 16949 - 2016: Presented by - Kuldeep TanwarDocument193 pagesIATF 16949 - 2016: Presented by - Kuldeep Tanwarsololips100% (2)

- Revision 2: International Automotive Task ForceDocument21 pagesRevision 2: International Automotive Task ForceSelvaraj SimiyonNo ratings yet

- FOD Overview For Supplier ForumDocument22 pagesFOD Overview For Supplier ForumyatheendravarmaNo ratings yet

- Sai CharithamDocument910 pagesSai CharithamBinuNo ratings yet

- As 9103 o ReviewDocument28 pagesAs 9103 o ReviewAnonymous Wi2Pd2UgPINo ratings yet

- MDS Report for PTFE TubeDocument3 pagesMDS Report for PTFE TubeyatheendravarmaNo ratings yet

- What Is A CleanroomDocument3 pagesWhat Is A CleanroomyatheendravarmaNo ratings yet

- India MP Salary Benchmark 2019 ALL WebDocument21 pagesIndia MP Salary Benchmark 2019 ALL Webbonika08No ratings yet

- Annex A Step by Step Guide For ISO 9001 2015 NG FG AGDocument39 pagesAnnex A Step by Step Guide For ISO 9001 2015 NG FG AGRt Saragih100% (1)

- Sample Size and Method in Statistical SamplingDocument3 pagesSample Size and Method in Statistical SamplingyatheendravarmaNo ratings yet

- GUR 022 BroucherDocument4 pagesGUR 022 BroucheryatheendravarmaNo ratings yet

- Recycling of PTFEDocument36 pagesRecycling of PTFEyatheendravarmaNo ratings yet

- Y12 - Hand - Book - 2019 2Document22 pagesY12 - Hand - Book - 2019 2tiagoNo ratings yet

- PBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Document45 pagesPBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Ramdas KambleNo ratings yet

- DL1 Dragons of DespairDocument38 pagesDL1 Dragons of DespairHeath Page100% (1)

- Registered Unregistered Land EssayDocument3 pagesRegistered Unregistered Land Essayzamrank91No ratings yet

- Update ResumeDocument3 pagesUpdate ResumeSubbareddy NvNo ratings yet

- CALCULATE TRADE AND CASH DISCOUNTSDocument13 pagesCALCULATE TRADE AND CASH DISCOUNTSrommel legaspi71% (7)

- GSAA HET 2005-15, Tranche M2 - JPMorgan Investment Funds / Income Oppt'y FundDocument192 pagesGSAA HET 2005-15, Tranche M2 - JPMorgan Investment Funds / Income Oppt'y FundTim BryantNo ratings yet

- Learner's Module in Grade 7 Mathematics Pages 1 - 4 Global Mathematics, Page 2 - 18 Synergy For Success in Mathematics, Pages 2 - 13Document12 pagesLearner's Module in Grade 7 Mathematics Pages 1 - 4 Global Mathematics, Page 2 - 18 Synergy For Success in Mathematics, Pages 2 - 13Maricel Tarenio MacalinoNo ratings yet

- STDM Course OutlineDocument11 pagesSTDM Course OutlineTp RayNo ratings yet

- Mercruiser 4.3L Mpi SpecsDocument2 pagesMercruiser 4.3L Mpi Specssalvatore dalessandro100% (1)

- Nick Bradbeer Thesis Master v11 Corrections REDACTEDDocument276 pagesNick Bradbeer Thesis Master v11 Corrections REDACTEDbatra_763079313No ratings yet

- EVCC Product Specifications-2.1.2Document11 pagesEVCC Product Specifications-2.1.2Windya SaputraNo ratings yet

- Safety Budget PlannerDocument12 pagesSafety Budget Plannersidhant nayakNo ratings yet

- Year 12 - Chemistry PDFDocument108 pagesYear 12 - Chemistry PDFWill Nguyen100% (2)

- Readings in Philippine History: Tanza, Boac, MarinduqueDocument16 pagesReadings in Philippine History: Tanza, Boac, MarinduqueLucy SyNo ratings yet

- Individualized Education PlanDocument7 pagesIndividualized Education Planapi-337934829No ratings yet

- Lovacka Kamera UputstvoDocument24 pagesLovacka Kamera UputstvoEmir MusijaNo ratings yet

- Logical Ability QuestionsDocument23 pagesLogical Ability Questionsjaya pavanNo ratings yet

- Understanding Social Problems - PPTDocument21 pagesUnderstanding Social Problems - PPTaneri patel100% (1)

- Mestrado Hang GlidingDocument82 pagesMestrado Hang GlidingJuliana Silveira100% (2)

- Campus Event ReflectionDocument2 pagesCampus Event ReflectiondntbenfordNo ratings yet

- Lesson 2.1Document16 pagesLesson 2.1Jeremie Manimbao OrdinarioNo ratings yet

- Insulation Coordination in Power System - Electrical4UDocument13 pagesInsulation Coordination in Power System - Electrical4UR.SivachandranNo ratings yet

- Dual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch GebruikershandleidingDocument21 pagesDual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch Gebruikershandleidingminerva_manNo ratings yet

- Astm d5580Document9 pagesAstm d5580Nhu SuongNo ratings yet

- Chem 101 Fall17 Worksheet 2Document2 pagesChem 101 Fall17 Worksheet 2mikayla sirovatkaNo ratings yet

- Designing An LLC ResonantDocument30 pagesDesigning An LLC Resonant劉品賢No ratings yet

- E'Lyn Joyce Taylor: EducationDocument1 pageE'Lyn Joyce Taylor: EducationE'Lyn TaylorNo ratings yet

- Criminal Law 2 - TreasonDocument408 pagesCriminal Law 2 - TreasonInna SalongaNo ratings yet

- Creating and Using Virtual DPUsDocument20 pagesCreating and Using Virtual DPUsDeepak Gupta100% (1)