Professional Documents

Culture Documents

TDS Infinam ST 6100 L

Uploaded by

KacperOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS Infinam ST 6100 L

Uploaded by

KacperCopyright:

Available Formats

Product Information

INFINAM® ST 6100 L

HIGH STRENGTH AND HEAT RESISTANT PHOTOPOLYMER FOR ADDITIVE MANUFACTURING

INFINAM® ST 6100 L resin is a black-colored easy to process (low viscosity, 1-part system) liquid photopolymer formulation.

The fully cured material exhibits excellent mechanical properties (high strength combined with elongation) and high

temperature resistance.

Storage conditions

INFINAM® ST 6100 L resin is a light-sensitive product protected by its original packaging. Store product in a dry location

with optimum storage temperature of 10-30 °C. Storage beyond this recommended temperature range can adversely affect

both print and product properties. Exposure of the liquid formulation to daylight and especially UV light should be minimized

during storage and handling to ensure consistent print quality.

Statement on reported properties

The values reported in this document are derived from printing various parts with one specific bottom-up DLP machine, and

follow the recommended procedures as detailed in this document. Those values reflect an approximation of the mean value

given as a range of values and are intended for reference and comparison purposes only. Using different printers, post

processing, or not following the material handling recommendations as indicated might lead to different values.

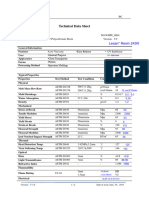

Mechanical Properties Value Unit Test Standard

Tensile Modulus 3200 ± 200 MPa ASTM D638

Ultimate Tensile Strength 90 ± 3 MPa ASTM D638

Elongation at Break 5±2 % ASTM D638

Flexural Modulus 3300 ± 100 MPa ASTM D790

Flexural Stress at 5% Strain 135 ± 5 MPa ASTM D790

Izod Notched Impact 20 ± 5 J/m ASTM D256

Charpy Notched Impact Strength 0.9 ± 0.1 kJ/m 2 ISO 179

Note: Tensile bars were tested with Type V specimen at 1 mm/min

Thermal Properties Value Unit Test Standard

Heat Deflection Temperature, 0.455 MPa/66 psi 120 ± 5 °C ASTM D648

Heat Deflection Temperature, 1.82 MPa/264 psi 93 ± 2 °C ASTM D648

Glass Transition Temperature (tan) 140 ± 3 °C ASTM D4065

Coefficient of Thermal Expansion (CTE) (35-115 °C) 108 µm/(m.K) ISO 11359-2

Evonik Operations GmbH

INFINAM® ST 6100 L ∣ 2023-08-01 ∣ Page: 1/5

Physical Properties Value Unit Test Standard

Liquid Density, 25 °C 1.1 g/cm 3 ASTM D4052

Liquid Viscosity, 25 °C / 1 Hz 450 ± 50 mPa.s ASTM D4287

Shore D Hardness 90 ± 2 - ASTM D2240

Water Absorption (24 h) 0.3 % ASTM D570

Water Absorption (7 d) 0.4 % ASTM D570

Poisson’s Ratio 0.39 - ISO 527

Electrical Properties Value Unit Test Standard

Dielectric Constant @ 100 Hz 3.6 - ASTM D150

Dielectric Constant @ 1 MHz 3.1 - ASTM D150

Dissipation Factor @ 100 Hz 0.012 - ASTM D150

Dissipation Factor @ 1 MHz 0.034 - ASTM D150

Dielectric Strength 30 kV/mm IEC 60243-1

Volume Resistivity 1.8 E16 Ohm.cm ASTM D257

Surface Resistivity > 1.6 E15 Ohm ASTM D257

CTI, test solution A, 50 drops value 600 - IEC 60112

Biocompatibility Result Test Standard

Cytotoxicity Passed ISO 10993-5

Skin Irritation (in-vitro method) Passed ISO 10993-23

Burning Behavior Value Unit Test Standard

Burning Behavior at 3.2 mm HB class UL 94

Burning Behavior at 1.6 mm HB class UL 94

Glow Wire Flammability Index (GWFI) at 1.5 mm 650 °C IEC 60695-2-12

Glow Wire Ignition Temperature (GWIT) at 1.5 mm 675 °C IEC 60695-2-13

Evonik Operations GmbH

INFINAM® ST 6100 L ∣ 2023-08-01 ∣ Page: 2/5

Material handling recommendations

Resin preparation

Shake the bottle of INFINAM® ST 6100 L for ca. 30 sec until the material is homogenous before filling into the printer

The resin needs to be bubble free prior to printing: allow the resin to rest before printing in order to allow air bubbles

to dissipate (prior degassing of the resin can help to expedite this process)

Print settings

INFINAM® ST 6100 L is designed to print optimally on digital light processing (DLP) and LCD machines at 385 or 405 nm

(see table below for exposure time) and is also compatible with stereolithography (SLA) printers

At 405 nm: Critical exposure energy Ec = 8 mJ/cm2 - Depth of penetration Dp = 170 µm

It is advisable to use standard separation speed (e.g. peeling and separation speed of 2–3 mm/s)

Wavelength (nm) Intensity (mW/cm2) Layer thickness (µm) Burn-in exposure time (s) Layer exposure time (s)

385 9 100 10 5

385 9 50 3 2

405 11 100 9 4

405 11 50 3 2

Support structures settings

INFINAM® ST 6100 L is designed to be printed with support contact size of 0.2–0.5 mm for easy support removal from

printed parts

For complex geometries, lattice support structure is recommended to ensure high print success rate

Washing procedure

Wash printed parts with isopropanol (IPA) to remove uncured resin and use compressed air to accelerate the removal of

residual solvent from the surface of the parts

Recommended wash cycles: rinse 2-3 times (each rinse for 1-2 min) until excess resin has been completely removed

Let the parts dry for at least 30 min before the next post-processing step

Contact with washing fluids like IPA should be minimized, as prolonged immersion or sonication of the uncured parts

may result in loss in the mechanical properties: do not exceed more than 10 min total exposure to IPA

When support structures are used, they should typically be removed before post-curing

Post-curing procedures

After washing, the parts should be post-cured in order to achieve specified properties

Below are two recommended procedures (it is recommended to flip printed parts once during UV-curing):

Method UV-curing Thermal-curing

Option 1 405 nm lamp (LED, 40 W) at 80 °C for 120 min 80 °C for 120 min

Option 2 Broad-spectrum lamp (metal-halide, 400 W) for 20 min -

Note: TDS values with their ranges, as reported in this document, were obtained following Option 1 with minimal exposure

to IPA (using wipes wetted with IPA). In order to achieve a HDT of 120 °C, it is recommended, for the thermal-curing, to use

a higher temperature (110 °C instead of 80 °C). In Option 2, thermal-curing is induced in the post-curing apparatus due to

the high intensity of the lamp, although temperature control is not possible.

Evonik Operations GmbH

INFINAM® ST 6100 L ∣ 2023-08-01 ∣ Page: 3/5

Chemical resistance

INFINAM® ST 6100 L was tested for solvent compatibility following standard ASTM D543. Tensile specimens were immersed

in various liquid media for either 24 hours or 7 days (see charts below) and tested following ASTM D638.

Retained tensile properties in % after 24 h immersion in test liquids

100

Relative Change (%)

80

60

100 100 100 102 100

96 99 97 98 95 93 89 93 95 89 94 95 95 97 95 93 97

40

60

50

20

0

Control Water IPA Acetone Motor Oil 10% HCl 10% NaOH 5% NaClO

Tensile Modulus Ultimate Tensile Strength Elongation at Break

Retained tensile properties in % after 7 days immersion in test liquids

100

Relative Change (%)

80

60

108 111 111

100 100 100 95 98 95 99

102 100 100 105 101

93 98 92 90 91

40 85 82

64

57

20

0

Control Water IPA Acetone Motor Oil 10% HCl 10% NaOH 5% NaClO

Tensile Modulus Ultimate Tensile Strength Elongation at Break

Evonik Operations GmbH

INFINAM® ST 6100 L ∣ 2023-08-01 ∣ Page: 4/5

Long term environmental stability

INFINAM® ST 6100 L was tested for its stability towards indoor and outdoor weathering conditions. The method is intended

to reproduce the weathering effects that occur when the material is exposed to either solar radiation through glass (indoor

conditions, ASTM D4459, Q-Sun) or to sunlight and moisture as rain or dew (outdoor conditions, ASTM G154, Cycle 1, QUV).

Accelerated indoor weathering Accelerated outdoor weathering

108

95 92 96 98 100 92 95

100 90

85 86

Relative Change (%)

Relative Change (%)

75 96

80 80 86

70 87 80

66 66

73 60

60 53 60 51

40 40

20 20

0 0

0 200 400 600 800 0 400 800 1200

Time (hours) Time (hours)

Tensile Modulus Ultimate Tensile Strength Elongation at Break

Note: For the indoor method, it is possible to infer that accelerated weathering times of 400 and 800 hours correspond to

ca. 5 and 10 years of ageing in normal conditions, respectively. For the outdoor method, it is possible to infer that accelerated

weathering times of 600 and 1200 hours correspond to ca. 12 and 24 months of ageing in normal conditions, respectively.

This information and any recommendations, technical or otherwise, are presented in Evonik Operations GmbH

good faith and believed to be correct as of the date prepared. Recipients of this Smart Materials

information and recommendations must make their own determination as to its High Performance Polymers

suitability for their purposes. In no event shall Evonik assume liability for damages or 45772 Marl / Germany

losses of any kind or nature that result from the use of or reliance upon this information

and recommendations. EVONIK EXPRESSLY DISCLAIMS ANY REPRESENTATIONS AND Tel: +49 2365 49–9878

WARRANTIES OF ANY KIND, WHETHER EXPRESS OR IMPLIED, AS TO THE ACCURACY, evonik-hp@evonik.com

COMPLETENESS, NON-INFRINGEMENT, MERCHANTABILITY AND/OR FITNESS FOR A

PARTICULAR PURPOSE (EVEN IF EVONIK IS AWARE OF SUCH PURPOSE) WITH RESPECT TO

ANY INFORMATION AND RECOMMENDATIONS PROVIDED. Reference to any trade names

used by other companies is neither a recommendation nor an endorsement of the

corresponding product and does not imply that similar products could not be used.

Evonik reserves the right to make any changes to the information and/or

recommendations at any time, without prior or subsequent notice.

INFINAM® is registered trademark of Evonik Industries AG or one of its subsidiaries

Evonik Operations GmbH

INFINAM® ST 6100 L ∣ 2023-08-01 ∣ Page: 5/5

You might also like

- Policarbonato Macizo Polygal Plazit PDFDocument4 pagesPolicarbonato Macizo Polygal Plazit PDFnicolas peraltaNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- TDS Nylon V3.011-EnDocument3 pagesTDS Nylon V3.011-Enmartinf090574No ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Abs (Basf Terluran Gp22)Document1 pageAbs (Basf Terluran Gp22)hakangokceNo ratings yet

- Um180821 TDS Tpu 95a RB V11Document3 pagesUm180821 TDS Tpu 95a RB V11Steven DonosoNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- Product Texts: P:Partial BreakDocument8 pagesProduct Texts: P:Partial BreakDridi BadredineNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- Techtron PPSDocument5 pagesTechtron PPSSenthil Kumar GanesanNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- ULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersDocument3 pagesULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersRui MatiasNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Tds Infinam RG 7100 LDocument2 pagesTds Infinam RG 7100 LKacperNo ratings yet

- Tds Infinam Ti 3100 LDocument2 pagesTds Infinam Ti 3100 LKacperNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Durafide 6165A6 TDSDocument6 pagesDurafide 6165A6 TDSCassianNo ratings yet

- SABIC® PPcompound - H1030 - Global - Technical - Data - SheetDocument2 pagesSABIC® PPcompound - H1030 - Global - Technical - Data - SheetRobertoNo ratings yet

- HOSTAPHAN® Polyester films..PETDocument10 pagesHOSTAPHAN® Polyester films..PETsreeeragNo ratings yet

- Stratasys - MSS FDM ABSplusP430Document2 pagesStratasys - MSS FDM ABSplusP430feltofsnakeNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- Policarbonato Teijin Panlite Ad-5503Document1 pagePolicarbonato Teijin Panlite Ad-5503marioNo ratings yet

- LEXAN 9030 and Lexan 9030 TG Datasheet PDFDocument2 pagesLEXAN 9030 and Lexan 9030 TG Datasheet PDFIbrahim Levent AkkoyunluNo ratings yet

- Absplus-P430: Production-Grade Thermoplastic For 3D PrintersDocument2 pagesAbsplus-P430: Production-Grade Thermoplastic For 3D PrinterscontrolorNo ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- ProductFile 131206155656Document1 pageProductFile 131206155656Michael HajzerNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Epofine 556 FR/ FInehard 951Document3 pagesEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- TIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsDocument2 pagesTIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsVictor AguirreNo ratings yet

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDocument5 pagesHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaNo ratings yet

- PBT Data SheetDocument2 pagesPBT Data Sheetabhishek chaudharyNo ratings yet

- Pe-Uhmw Technical Data SheetDocument1 pagePe-Uhmw Technical Data SheetPrashant MalikNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNo ratings yet

- Green Cast Setacryl UKDocument4 pagesGreen Cast Setacryl UKgillestalbotNo ratings yet

- Makrolon® 2805Document8 pagesMakrolon® 2805Dridi BadredineNo ratings yet

- Custom Made Movement Joint ProfileDocument2 pagesCustom Made Movement Joint Profileemrah turerNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- 3m VHB Tape 5958frDocument9 pages3m VHB Tape 5958frDonald A HuntNo ratings yet

- Traverse SurveyingDocument2 pagesTraverse Surveyingchaudharylucky1818.sNo ratings yet

- Moc3052 PDFDocument9 pagesMoc3052 PDFHernan JavierNo ratings yet

- In Praise of LongchenpaDocument3 pagesIn Praise of LongchenpaJigdrel77No ratings yet

- IELTS Reading Skills & StrategiesDocument4 pagesIELTS Reading Skills & StrategiesThinn Thinn Oo100% (1)

- Et3491 Esiot LabDocument95 pagesEt3491 Esiot LabfreefireyomaNo ratings yet

- Short Physical Performance Battery Protocol and Score Sheet: 1. Balance TestsDocument8 pagesShort Physical Performance Battery Protocol and Score Sheet: 1. Balance Testsruth lopezNo ratings yet

- Combined Cycle Power Plant - Summary StudyDocument3 pagesCombined Cycle Power Plant - Summary StudydndudcNo ratings yet

- Seidel's TestDocument13 pagesSeidel's TestFahcrezaNo ratings yet

- Introduction To Energy & Society: Importance of Energy in Our Daily LifeDocument12 pagesIntroduction To Energy & Society: Importance of Energy in Our Daily LifeArun SaiNo ratings yet

- Advanced Training Course On FPGA Design and VHDL For Hardware Simulation and SynthesisDocument17 pagesAdvanced Training Course On FPGA Design and VHDL For Hardware Simulation and SynthesisMD RockyNo ratings yet

- Tenda Catalogo 2020 PDFDocument24 pagesTenda Catalogo 2020 PDFTenda Región AndinaNo ratings yet

- Airports 14 EndDocument9 pagesAirports 14 EndMeedenken en Doen BVNo ratings yet

- Arieso - GEO 6 1 1 Rel GuideDocument73 pagesArieso - GEO 6 1 1 Rel GuidemanuelNo ratings yet

- P 51 DonalddDocument20 pagesP 51 DonalddNitu Iulian100% (3)

- 09 Husserl - The Encyclopaedia Britannica Article - Draft EDocument19 pages09 Husserl - The Encyclopaedia Britannica Article - Draft EAleksandra VeljkovicNo ratings yet

- Vibration Analysis of An Automotive Silencer For Reduced Incidence of FailureDocument6 pagesVibration Analysis of An Automotive Silencer For Reduced Incidence of FailureerpublicationNo ratings yet

- Notes:: Grate IDocument1 pageNotes:: Grate IAfuye Oluyemi IbiyinkaNo ratings yet

- Earth Pressure CalculationsDocument5 pagesEarth Pressure Calculationsnazeer_mohdNo ratings yet

- EY Making India Brick by Brick PDFDocument96 pagesEY Making India Brick by Brick PDFRKVSK1No ratings yet

- Lecture 1Document46 pagesLecture 1Imtiyaaz MalickNo ratings yet

- Module 4Document5 pagesModule 4Ivan PaulinoNo ratings yet

- Type Abz PDFDocument15 pagesType Abz PDFle khánhNo ratings yet

- Lecture 1 TF BiomechanicsDocument63 pagesLecture 1 TF BiomechanicsAlfred JacksonNo ratings yet

- Ebook Physics of Cryogenics An Ultralow Temperature Phenomenon PDF Full Chapter PDFDocument67 pagesEbook Physics of Cryogenics An Ultralow Temperature Phenomenon PDF Full Chapter PDFlouise.fleming716100% (25)

- Atomic Structure Short Notes 7 PageDocument7 pagesAtomic Structure Short Notes 7 PageSubhajit GoraiNo ratings yet

- Green Airports Recognition 2022 - Carbon ManagementDocument61 pagesGreen Airports Recognition 2022 - Carbon ManagementSurendra DarpelluNo ratings yet

- Body Parts Remove & Refit Labor Schedule - Tier 4Document4 pagesBody Parts Remove & Refit Labor Schedule - Tier 4ADHAR SHARMANo ratings yet

- Advanced IC Engines: Prof. R. Devaraj Dr. S. Ramachandran Dr. A. AndersonDocument61 pagesAdvanced IC Engines: Prof. R. Devaraj Dr. S. Ramachandran Dr. A. AndersonGopi KrishnanNo ratings yet

- Escherichia Coli O157:H7 Issues and Ramifications: Executive SummaryDocument12 pagesEscherichia Coli O157:H7 Issues and Ramifications: Executive SummaryTinnysumardiNo ratings yet