Professional Documents

Culture Documents

HOSTAFORM® C 27021 - POM - Unfilled: Description

Uploaded by

rahul vermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HOSTAFORM® C 27021 - POM - Unfilled: Description

Uploaded by

rahul vermaCopyright:

Available Formats

HOSTAFORM® C 27021 | POM | Unfilled

Description

Chemical abbreviation according to ISO 1043-1: POM

Molding compound ISO 9988- POM-K, M-GNR, 05-002

POM copolymer

Very easy flowing Injection molding type with high rigidity and

hardness; good chemical resistance to solvents, fuel and strong

alkalis as well as good hydrolysis resistance; high resistance to

thermal and oxidative degradation.

Fulfils EG-directive 2002/72/EU as well as the recommendation

XXXIII for consumer goods of the BgVV, corresponding to

FDA-regulation for food contact.

UL-registration for all colours and a thickness more than 1.5 mm as

UL 94 HB, temperature index UL 746 B electrical 110°C, mechanical

90°C.

Burning rate ISO 3795 and FMVSS 302 < 75 mm/min for a thickness more

than 1 mm.

Ranges of applications: thin-walled molded parts with unfavourite

flow-path-wallthickness relation; multicavity moulds; complicated

precision molded parts; short cycle time.

FDA = Food and Drug Administration (USA)

BgVV = Bundesinstitut f•r gesundheitlichen Verbraucherschutz und

Veterin rmedizin

FMVSS = Federal Motor Vehicle Safety Standard (USA)

UL = Underwriters Laboratories (USA)

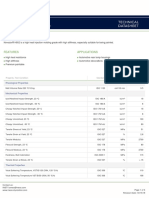

Physical properties Value Unit Test Standard

Density 1410 kg/m³ ISO 1183

Melt volume rate (MVR) 24 cm³/10min ISO 1133

MVR test temperature 190 °C ISO 1133

MVR test load 2.16 kg ISO 1133

Mold shrinkage - parallel 1.9 % ISO 294-4

Mold shrinkage - normal 1.8 % ISO 294-4

Water absorption (23°C-sat) 0.65 % ISO 62

Humidity absorption (23°C/50%RH) 0.2 % ISO 62

Mechanical properties Value Unit Test Standard

Tensile modulus (1mm/min) 2900 MPa ISO 527-2/1A

Tensile stress at yield (50mm/min) 65 MPa ISO 527-2/1A

Tensile strain at yield (50mm/min) 7.5 % ISO 527-2/1A

Nominal strain at break (50mm/min) 17 % ISO 527-2/1A

Tensile creep modulus (1h) 2500 MPa ISO 899-1

Tensile creep modulus (1000h) 1300 MPa ISO 899-1

Charpy impact strength @ 23°C 120 kJ/m² ISO 179/1eU

Charpy impact strength @ -30°C 120 kJ/m² ISO 179/1eU

Charpy notched impact strength @ 23°C 6 kJ/m² ISO 179/1eA

Charpy notched impact strength @ -30°C 4.5 kJ/m² ISO 179/1eA

Printed: 12. January 2007 Page: 1

Ticona - A business of Celanese

HOSTAFORM® C 27021 | POM | Unfilled

Thermal properties Value Unit Test Standard

Melting temperature (10°C/min) 166 °C ISO 11357-1,-2,-3

DTUL @ 1.8 MPa 106 °C ISO 75-1/-2

Vicat softening temperature B50 (50°C/h 50N) 151 °C ISO 306

Coeff.of linear therm. expansion (parallel) 1.1 E-4/°C ISO 11359-2

Flammability @1.6mm nom. thickn. HB class UL94

thickness tested (1.6) 1.5 mm UL94

UL recognition (1.6) UL - UL94

Flammability at thickness h HB class UL94

thickness tested (h) 3 mm UL94

UL recognition (h) UL - UL94

Electrical properties Value Unit Test Standard

Relative permittivity - 100 Hz 4 - IEC 60250

Relative permittivity - 1 MHz 4 - IEC 60250

Dissipation factor - 100 Hz 25 E-4 IEC 60250

Dissipation factor - 1 MHz 50 E-4 IEC 60250

Volume resistivity 1E12 Ohm*m IEC 60093

Surface resistivity 1E14 Ohm IEC 60093

Electric strength 35 kV/mm IEC 60243-1

Comparative tracking index CTI 600 - IEC 60112

Test specimen production Value Unit Test Standard

Processing conditions acc. ISO 9988 - Internal

Injection molding melt temperature 195 °C ISO 294

Injection molding mold temperature 85 °C ISO 294

Injection molding flow front velocity 200 mm/s ISO 294

Injection molding hold pressure 90 MPa ISO 294

Rheological Calculation properties Value Unit Test Standard

Density of melt 1200 kg/m³ Internal

Thermal conductivity of melt 0.155 W/(m K) Internal

Specific heat capacity of melt 2210 J/(kg K) Internal

Ejection temperature 165 °C Internal

Printed: 12. January 2007 Page: 2

Ticona - A business of Celanese

HOSTAFORM® C 27021 | POM | Unfilled

Dynamic Shear modulus-temperature

Typical injection moulding processing conditions

Maximum residual moisture content: 0.1500%

Processing Temperatures:

Cavity Melt Hot Runner Die 4 3 2 1 Feeding Hopper

min (°C) 80 190 190 190 190 190 180 170 60 20

max (°C) 120 210 210 210 210 200 190 180 80 30

Processing Pressures:

Injection Pressure Holding Pressure Back Pressure

min (bar) 600 600 0

max (bar) 1200 1200 40

Injection speed: slow - medium

Screw speed:

Printed: 12. January 2007 Page: 3

Ticona - A business of Celanese

HOSTAFORM® C 27021 | POM | Unfilled

Screw diameter (mm) 25 40 55

Screw speed (rpm) 120 100 70

Pre-drying conditions:

It is normally not necessary to dry HOSTAFORM. However, should there be surface moisture (condensate) on the molding

compound as a result of incorrect storage, drying is required. A circulating air drying cabinet can be used for this purpose if

the granul

The product can then be stored in standard conditions until processed.

Drying time: 3 - 4 h

Drying temperature: 120 - 140 °C

Special information:

No special information available.

Injection Molding

Standard injection moulding machines with three phase (15 to 25 D)

plasticating screws will fit.

Melt temperature 190-230 °C

Mould temperature 60-120 °C

Contact Information

Americas Europe

Ticona Ticona GmbH

Product Information Service Information Service

8040 Dixie Highway Tel.: +49 (0) 180-5842662 (Germany)*

Florence, KY 41042 +49 (0) 69-30516299 (Europe)

USA Fax: +49 (0) 180-2021202 (Germany & Europe)**

Tel.: +1-800-833-4882 email: infoservice@ticona.de

Tel.: +1-859-372-3244 Internet: www.ticona.com

email: prodinfo@ticona.com

Ticona on the web: www.ticona.com *starting 01.01.2007 0,14€/minute + local landline rates

**0,06€/Call + local landline rates

Customer Service

Tel.: +1-800-526-4960

Tel.: +1-859-372-3214

Fax: +1-859-372-3125

Printed: 12. January 2007 Page: 4

Ticona - A business of Celanese

HOSTAFORM® C 27021 | POM | Unfilled

General Disclaimer

NOTICE TO USERS: Values shown are based on testing of laboratory test specimens and represent data that fall within the standard range

of properties for natural material. These values alone do not represent a sufficient basis for any part design and are not intended for use in

establishing maximum, minimum, or ranges of values for specification purposes. Colorants or other additives may cause significant variations

in data values.

Properties of molded parts can be influenced by a wide variety of factors including, but not limited to, material selection, additives, part

design, processing conditions and environmental exposure. Any determination of the suitability of a particular material and part design for any

use contemplated by the users and the manner of such use is the sole responsibility of the users, who must assure themselves that the

material as subsequently processed meets the needs of their particular product or use.

To the best of our knowledge, the information contained in this publication is accurate; however, we do not assume any liability whatsoever for

the accuracy and completeness of such information. The information contained in this publication should not be construed as a promise or

guarantee of specific properties of our products. It is the sole responsibility of the users to investigate whether any existing patents are

infringed by the use of the materials mentioned in this publication.

Moreover, there is a need to reduce human exposure to many materials to the lowest practical limits in view of possible adverse effects. To

the extent that any hazards may have been mentioned in this publication, we neither suggest nor guarantee that such hazards are the only

ones that exist. We recommend that persons intending to rely on any recommendation or to use any equipment, processing technique or

material mentioned in this publication should satisfy themselves that they can meet all applicable safety and health standards.

We strongly recommend that users seek and adhere to the manufacturer’s current instructions for handling each material they use, and

entrust the handling of such material to adequately trained personnel only. Please call the telephone numbers listed (+49 (0) 69 30516299 for

Europe and +1 859-372-3244 for the Americas) for additional technical information. Call Customer Services for the appropriate Materials

Safety Data Sheets (MSDS) before attempting to process our products.

The products mentioned herein are not intended for use in medical or dental implants.

© Copyright 2007, Ticona, all rights reserved. (Pub. 02-Jan-2007)

Printed: 12. January 2007 Page: 5

Ticona - A business of Celanese

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Product Texts: P:Partial BreakDocument8 pagesProduct Texts: P:Partial BreakDridi BadredineNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Makrolon® 2805Document8 pagesMakrolon® 2805Dridi BadredineNo ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 pagesCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Zytel® 45HSB NC010-gbDocument14 pagesZytel® 45HSB NC010-gbJuan Fernando CampuzanoNo ratings yet

- Zytel® 101 NC010-gbDocument11 pagesZytel® 101 NC010-gbalejandrocharlescollNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- POM Celcon M270Document3 pagesPOM Celcon M270Er Shashi SinghNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Abs (Basf Terluran Gp22)Document1 pageAbs (Basf Terluran Gp22)hakangokceNo ratings yet

- Zytel® 103HSL NC010-gbDocument15 pagesZytel® 103HSL NC010-gbFaustoNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- PP Gf30 - Suplen v30 LCDocument2 pagesPP Gf30 - Suplen v30 LCarmandoNo ratings yet

- TITLE Fast Molding Polyamide for Thin Wall PartsDocument3 pagesTITLE Fast Molding Polyamide for Thin Wall PartsSATHISH KUMAR SNo ratings yet

- Styrolution PS 158N/L Heat Resistant GPPSDocument3 pagesStyrolution PS 158N/L Heat Resistant GPPSscribdichigoNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- HOSTAFORM® C 9021 TF-enDocument4 pagesHOSTAFORM® C 9021 TF-enshahin_723No ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Styrolution PS 454N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 454N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Bakelite PF6507Document4 pagesBakelite PF6507dioguitomsolhaNo ratings yet

- ProductFile 131206155656Document1 pageProductFile 131206155656Michael HajzerNo ratings yet

- Datasheet-Ultra Hh-4115-Hi-IsoDocument3 pagesDatasheet-Ultra Hh-4115-Hi-IsoDiegoTierradentroNo ratings yet

- Zytel® 101L NC010-gbDocument21 pagesZytel® 101L NC010-gbRamiro PredassiNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Styrolution PS 495N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 495N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- ABS Data Sheet with Heat Resistance and Impact StrengthDocument1 pageABS Data Sheet with Heat Resistance and Impact StrengthDanielNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- Delrin® 100 NC010-enDocument14 pagesDelrin® 100 NC010-enshahin_723No ratings yet

- Bayer Makrolon 2407Document3 pagesBayer Makrolon 2407DiegoTierradentro100% (1)

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 pagesR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiNo ratings yet

- Propertie NilonDocument3 pagesPropertie Nilonmuhammad daffaNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Styrolution PS 485N: High Impact Polystyrene (HIPS)Document2 pagesStyrolution PS 485N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Styrolution PS 147F: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 147F: General Purpose Polystyrene (GPPS)Ayaan Anowar100% (1)

- POM_KEPITAL_F30-03_EnDocument2 pagesPOM_KEPITAL_F30-03_EnAthonioMourinhoNo ratings yet

- Durethan BKV240H2.0XCP properties guideDocument3 pagesDurethan BKV240H2.0XCP properties guideshahin_723No ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Plating Specification ListDocument11 pagesPlating Specification Listsursh60% (5)

- IS 8856 1991 - Hexagon Weld Nuts PDFDocument12 pagesIS 8856 1991 - Hexagon Weld Nuts PDFDheeraj Chavan100% (1)

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDocument5 pagesHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- Surface RoughnessDocument9 pagesSurface RoughnessKarthick DuraiNo ratings yet

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Document1 pageAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNo ratings yet

- Wrought aluminium alloys specificationDocument2 pagesWrought aluminium alloys specificationrahul vermaNo ratings yet

- Purchasing Department Roles Duties and ResponsibilitiesDocument8 pagesPurchasing Department Roles Duties and Responsibilitiesrahul vermaNo ratings yet

- Wrought aluminium alloys specificationDocument2 pagesWrought aluminium alloys specificationrahul vermaNo ratings yet

- Hardness Conversion ChartDocument1 pageHardness Conversion ChartFresly JayaNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationRishith Ellath Meethal VadakaraNo ratings yet

- Is - 2062.2011 PDFDocument17 pagesIs - 2062.2011 PDFN GANESAMOORTHYNo ratings yet

- Design & Construction of An Experimental Setup For Measuring Thermal Conductivity of Versatile Range of Solid MaterialsDocument6 pagesDesign & Construction of An Experimental Setup For Measuring Thermal Conductivity of Versatile Range of Solid MaterialsBobby YilmazNo ratings yet

- Importance of Proper Grounding Systems in Homes and BuildingsDocument4 pagesImportance of Proper Grounding Systems in Homes and BuildingsCod Ry-angelNo ratings yet

- 730 WavesDocument4 pages730 WavesMuhtar LathiefNo ratings yet

- Orbital Physics in Transition-Metal Oxides From First-PrinciplesDocument8 pagesOrbital Physics in Transition-Metal Oxides From First-PrinciplesalfonsoNo ratings yet

- Weekly Science Learning PlanDocument6 pagesWeekly Science Learning PlanRonelyn SobrianoNo ratings yet

- Surface Charge PosterDocument1 pageSurface Charge PosterParekkat MKNo ratings yet

- 2021-USAPhO PlusDocument10 pages2021-USAPhO PluscrmzNo ratings yet

- Underwater Communications: Recent Advances (2019)Document7 pagesUnderwater Communications: Recent Advances (2019)Sam RubinNo ratings yet

- IR Drop PDFDocument3 pagesIR Drop PDFarammartNo ratings yet

- Calculating Formation Water Resistivity From The Spontaneous PotentialDocument18 pagesCalculating Formation Water Resistivity From The Spontaneous PotentiallakhanmukhtiarNo ratings yet

- Strong Correlation Between Membrane Charge and Proton ConductivityDocument10 pagesStrong Correlation Between Membrane Charge and Proton ConductivityArdiansyah BataraNo ratings yet

- Low-Cost Resistivity Meter For Groundwater Exploration Using High Voltage ExperimentationsDocument5 pagesLow-Cost Resistivity Meter For Groundwater Exploration Using High Voltage ExperimentationsjaimemanNo ratings yet

- Ground Grid SizingDocument65 pagesGround Grid SizingMohan SaravanaNo ratings yet

- EC8252: Electronic DevicesDocument23 pagesEC8252: Electronic DevicesjehovavijayNo ratings yet

- Electric Circuits A Primer by JC OlivierDocument263 pagesElectric Circuits A Primer by JC Olivierretrueke1170No ratings yet

- Cell Filled PavementDocument11 pagesCell Filled PavementAparna PANo ratings yet

- Chapter - 18 Electrical QuantitiesDocument98 pagesChapter - 18 Electrical QuantitiesNayeem HakimNo ratings yet

- SSPC AB1 Standard For Mineral and Slag Abrasives PDFDocument5 pagesSSPC AB1 Standard For Mineral and Slag Abrasives PDFDeepak YadavNo ratings yet

- NEET Crash Course: 650 NEET 2020 Questions SolvedDocument88 pagesNEET Crash Course: 650 NEET 2020 Questions SolvedAlokNo ratings yet

- MCQ's Chap 17Document4 pagesMCQ's Chap 17Arham MunirNo ratings yet

- Exercise 2 (2nd Sem)Document17 pagesExercise 2 (2nd Sem)Jan VegaNo ratings yet

- Module 1 Electrical Engineering PDFDocument4 pagesModule 1 Electrical Engineering PDFKeith Tanaka Magaka84% (37)

- Frank J. Owens, Charles P. Poole Jr. Electromagnetic Absorption in The Copper Oxide Superconductors 1999Document212 pagesFrank J. Owens, Charles P. Poole Jr. Electromagnetic Absorption in The Copper Oxide Superconductors 1999edward floresNo ratings yet

- Cusidó Et Al. - 2015 - Incorporation of Paper Sludge in Clay Brick Formulation Ten Years of Industrial ExperienceDocument8 pagesCusidó Et Al. - 2015 - Incorporation of Paper Sludge in Clay Brick Formulation Ten Years of Industrial ExperienceJuan EstebanNo ratings yet

- Astm C449Document3 pagesAstm C449DilaFirizqinaNo ratings yet

- Din 8075Document11 pagesDin 8075Marco Jorquera AguilarNo ratings yet

- Item 2 - Coke Breeze Loresco SC3Document2 pagesItem 2 - Coke Breeze Loresco SC3Noor A QasimNo ratings yet

- 1 s2.0 S0304389400003526 Main PDFDocument24 pages1 s2.0 S0304389400003526 Main PDFAnonymous NxpnI6jCNo ratings yet

- Chapter 3 Current ElectricityDocument31 pagesChapter 3 Current ElectricitySajjan BalasubramanyanNo ratings yet

- Draft Syllabus: Engineering PhysicsDocument4 pagesDraft Syllabus: Engineering PhysicsMartin Luther JrNo ratings yet