Professional Documents

Culture Documents

CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 Basf

Uploaded by

AngererOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 Basf

Uploaded by

AngererCopyright:

Available Formats

CAMPUS® Datasheet

Ultradur® B 4330 G6 HR - PBT-I-GF30

BASF

Product Texts

Injection-moulding grade containing 30% glass-fibres, for rigid,tough and dimensionally stable technical parts, used in applications with

highest demands on hydrolysis resistance such es automotive connectors and housings for electronic units under the hood.

Abbreviated designation according to ISO 1043-1: PBT-I-GF30

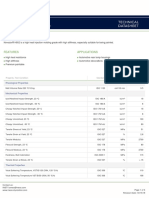

Rheological properties Value Unit Test Standard

Melt volume-flow rate, MVR 40 cm³/10min ISO 1133

Temperature 250 °C ISO 1133

Load 10 kg ISO 1133

Molding shrinkage, parallel 0.5 % ISO 294-4, 2577

Molding shrinkage, normal 1.1 % ISO 294-4, 2577

Mechanical properties Value Unit Test Standard

Tensile Modulus 8500 MPa ISO 527-1/-2

Stress at break 120 MPa ISO 527-1/-2

Strain at break 3.4 % ISO 527-1/-2

Charpy impact strength, +23°C 74 kJ/m² ISO 179/1eU

Charpy impact strength, -30°C 65 kJ/m² ISO 179/1eU

Charpy notched impact strength, +23°C 14 kJ/m² ISO 179/1eA

Thermal properties Value Unit Test Standard

Melting temperature, 10°C/min 223 °C ISO 11357-1/-3

Temp. of deflection under load, 1.80 MPa 205 °C ISO 75-1/-2

Temp. of deflection under load, 0.45 MPa 220 °C ISO 75-1/-2

Coeff. of linear therm. expansion, parallel 27.5 E-6/K ISO 11359-1/-2

Burning Behav. at 1.5 mm nom. thickn. HB class IEC 60695-11-10

Burning Behav. at thickness h HB class IEC 60695-11-10

Thickness tested 0.8 mm IEC 60695-11-10

Electrical properties Value Unit Test Standard

Volume resistivity >1E13 Ohm*m IEC 60093

Surface resistivity 1E15 Ohm IEC 60093

Comparative tracking index 400 - IEC 60112

Other properties Value Unit Test Standard

Water absorption 0.4 % Sim. to ISO 62

Humidity absorption 0.2 % Sim. to ISO 62

Density 1490 kg/m³ ISO 1183

Material specific properties Value Unit Test Standard

Viscosity number 108 cm³/g ISO 307, 1157, 1628

Last update: 2014-04-23 Source: http://www.campusplastics.com Page: 1/4

Ultradur® B 4330 G6 HR - PBT-I-GF30

BASF

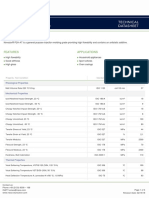

Diagrams

Stress-strain Secant modulus-strain

Stress-strain Secant modulus-strain

Ultradur® B 4330 G6 HR Ultradur® B 4330 G6 HR

200 12000

B -40 °C -40 °C

-20 °C -20 °C

0 °C 0 °C

23 °C 23 °C

B 40 °C 10000 40 °C

60 °C 60 °C

150 80 °C 80 °C

Y

Secant modulus in MPa

100 °C 100 °C

120 °C 8000 120 °C

140 °C 140 °C

Stress in MPa

Y B

B - Break B B - Break

100 Y - Yield 6000 Y - Yield

Y Y

Y Y

Y 4000

Y

B B

50

Y

2000

Y

Y Y

B B

0 0

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

Strain in % Strain in %

Tensile modulus-temperature

Tensile modulus-temperature

Ultradur® B 4330 G6 HR

1E5

Tensile modulus in MPa

1E4

1E3

-50 0 50 100 150

Temperature in °C

Characteristics

Processing Regional Availability

Injection Molding North America, Europe, Asia Pacific, South and Central America,

Near East/Africa

Other text information

Injection molding

PREPROCESSING

Pre/Post-processing, max. allowed water content: .04 %

Pre/Post-processing, Pre-drying, Temperature: 80 - 120 °C

Last update: 2014-04-23 Source: http://www.campusplastics.com Page: 2/4

Ultradur® B 4330 G6 HR - PBT-I-GF30

BASF

Pre/Post-processing, Pre-drying, Time: 4 h

PROCESSING

injection molding, Melt temperature, range: 250 - 280 °C

injection molding, Melt temperature, recommended: 260 °C

injection molding, Mold temperature, range: 60 - 100 °C

injection molding, Mold temperature, recommended: 80 °C

Chemical Media Resistance

Acids

Acetic Acid (5% by mass) (23°C)

Citric Acid solution (10% by mass) (23°C)

Lactic Acid (10% by mass) (23°C)

Bases

Sodium Hydroxide solution (35% by mass) (23°C)

Ammonium Hydroxide solution (10% by mass) (23°C)

Alcohols

Isopropyl alcohol (23°C)

Methanol (23°C)

Ethanol (23°C)

Hydrocarbons

n-Hexane (23°C)

Toluene (23°C)

iso-Octane (23°C)

Ketones

Acetone (23°C)

Ethers

Diethyl ether (23°C)

Mineral oils

SAE 10W40 multigrade motor oil (23°C)

SAE 10W40 multigrade motor oil (130°C)

Standard Fuels

Diesel fuel (pref. ISO 1817 Liquid F) (23°C)

Salt solutions

Sodium Carbonate solution (2% by mass) (23°C)

Other

Ethyl Acetate (23°C)

Water (23°C)

The data contained in this publication are based on our current

knowledge and experience. In view of the many factors that may affect

processing and application of our product, these data do not relieve

processors from carrying out their own investigations and tests. Any

descriptions, drawings, photographs, data, proportions, weights etc.

given herein may change without prior information and do not constitute

Last update: 2014-04-23 Source: http://www.campusplastics.com Page: 3/4

Ultradur® B 4330 G6 HR - PBT-I-GF30

BASF

the agreed contractual quality of the product. It is the responsibility

of the recipient of our products to ensure that any proprietary rights

and existing laws and legislation are observed. NO WARRANTIES OF ANY

KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OFMERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE, ARE MADE REGARDING PRODUCTS

DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH, OR THAT THE

PRODUCTS, DESIGNS, DATA OR INFORMATION MAY BE USED WITHOUT INFRINGING

THEINTELLECTUAL PROPERTY RIGHTS OF OTHERS.

In order to check the availability of products please contact us or our

sales agency.

For more information about our products contact your local BASF

representative or

BASF SE

Dept. PM/K

Fax: 0621-60-49497

e-mail: e-mail

CAMPUS® is a registered trademark of CWFG (Chemie

Wirtschaftsfoerderungsgesellschaft GmbH, Frankfurt)

Last update: 2014-04-23 Source: http://www.campusplastics.com Page: 4/4

You might also like

- Challenges Faced by Irregular StudentsDocument13 pagesChallenges Faced by Irregular StudentsTicag Teo80% (5)

- Filipino Nationalism LessonDocument24 pagesFilipino Nationalism LessonIan Jay TumulakNo ratings yet

- Enscape Tutorial GuideDocument27 pagesEnscape Tutorial GuideDoroty CastroNo ratings yet

- Chakra System of Animals FACT SHEETDocument4 pagesChakra System of Animals FACT SHEETNiko Diamesis75% (4)

- DS-RTCD905 H6W4Document2 pagesDS-RTCD905 H6W4david fonsecaNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- Luran S757 GDocument5 pagesLuran S757 GPeter EvansNo ratings yet

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 pagesCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNo ratings yet

- TerluranGP-22Document5 pagesTerluranGP-22Chu ChuNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Bayer Makrolon 2407Document3 pagesBayer Makrolon 2407DiegoTierradentro100% (1)

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 pagesAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobNo ratings yet

- Dupont Delrin 527UV BK701Document4 pagesDupont Delrin 527UV BK701Phung LucNo ratings yet

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 pagesR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiNo ratings yet

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinDocument6 pagesDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarNo ratings yet

- TerluranGP35Document5 pagesTerluranGP35cristinamss33No ratings yet

- Makrolon® 2805Document8 pagesMakrolon® 2805Dridi BadredineNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- 2024 03 06 TDS Elastollan1185ADocument4 pages2024 03 06 TDS Elastollan1185AChaker AbdellatifNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Kynar Flex® 2800-20 ResinDocument5 pagesKynar Flex® 2800-20 ResinmohammedNo ratings yet

- ABS - Novodur P2HGVDocument2 pagesABS - Novodur P2HGVarmandoNo ratings yet

- ASA Styrolution: Luran® S 778 TDocument2 pagesASA Styrolution: Luran® S 778 TayyappanNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Styrolution PS 454N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 454N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Bakelite PF6507Document4 pagesBakelite PF6507dioguitomsolhaNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Luran 368 RDocument5 pagesLuran 368 RmucahitkaraballNo ratings yet

- TDS MakrolonET3113Document3 pagesTDS MakrolonET3113It WittayaNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- Styro Lution Tds 401200140448Document3 pagesStyro Lution Tds 401200140448scribdNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- CELANEX® 2000-K-EnDocument3 pagesCELANEX® 2000-K-EnCarlos AgianiNo ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- ABS Data Sheet with Heat Resistance and Impact StrengthDocument1 pageABS Data Sheet with Heat Resistance and Impact StrengthDanielNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- CELCON® M90-EnDocument8 pagesCELCON® M90-EnJosue OrtizNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Delrin® 100 NC010-enDocument14 pagesDelrin® 100 NC010-enshahin_723No ratings yet

- Dupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinDocument11 pagesDupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinTomGaliciaNo ratings yet

- Crastin S600 F40 NC010Document11 pagesCrastin S600 F40 NC010TomGaliciaNo ratings yet

- Styrolution TDS401600170785Document3 pagesStyrolution TDS401600170785shahin_723No ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Styrolution PS 158N/L Heat Resistant GPPSDocument3 pagesStyrolution PS 158N/L Heat Resistant GPPSscribdichigoNo ratings yet

- PD Arnite t06 204 SN (En)Document2 pagesPD Arnite t06 204 SN (En)MuthuswamyNo ratings yet

- HOSTAFORM® C 9021 TF-enDocument4 pagesHOSTAFORM® C 9021 TF-enshahin_723No ratings yet

- VESTAMID® L1670 - EvonikDocument5 pagesVESTAMID® L1670 - EvonikShikha MishraNo ratings yet

- Technical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticDocument1 pageTechnical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticarmandoNo ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- LANXESS Durethan A30SFN31 000000 ISO ENDocument3 pagesLANXESS Durethan A30SFN31 000000 ISO ENNguyen Dinh VinhNo ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- TDS PBT 5829F-105Document2 pagesTDS PBT 5829F-105TRUONGNo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- PP Copolimero - Lloyndellbasell Adstif Ea648pDocument1 pagePP Copolimero - Lloyndellbasell Adstif Ea648parmandoNo ratings yet

- Durethan B30S 000000 ISO enDocument3 pagesDurethan B30S 000000 ISO enjujuplasticNo ratings yet

- Actor analysis explores decision-making in environmental governanceDocument48 pagesActor analysis explores decision-making in environmental governancerizkyNo ratings yet

- Modigliani MillerDocument12 pagesModigliani MillerAlvaro CamañoNo ratings yet

- Economics Principles and Policy 13th Edition Baumol Solutions ManualDocument2 pagesEconomics Principles and Policy 13th Edition Baumol Solutions ManualCraigGonzalezaxzgd100% (17)

- CNC Instructables PDFDocument13 pagesCNC Instructables PDFNadim AhmedNo ratings yet

- Ceftriaxone R Salmonella Typhi 02Document8 pagesCeftriaxone R Salmonella Typhi 02docsumitraiNo ratings yet

- Cell Organelles 11Document32 pagesCell Organelles 11Mamalumpong NnekaNo ratings yet

- Examining The Structural Relationships of Destination Image, Tourist Satisfaction PDFDocument13 pagesExamining The Structural Relationships of Destination Image, Tourist Satisfaction PDFAndreea JecuNo ratings yet

- Allison WallaceDocument3 pagesAllison WallaceOskar KarvajalNo ratings yet

- Chapter 22A - Sound WavesDocument24 pagesChapter 22A - Sound Wavesqwivy.comNo ratings yet

- 2011 Mena Annual Reportv1Document73 pages2011 Mena Annual Reportv1Yasmeen LayallieNo ratings yet

- S7 - Q2 - Answer KeyDocument11 pagesS7 - Q2 - Answer KeyRaniel LacuarinNo ratings yet

- 5.test Report - RFU-C-7Ghz IP10 Extract VersionDocument42 pages5.test Report - RFU-C-7Ghz IP10 Extract Versionminhdung.pham4713No ratings yet

- 5G Antenna Talk TWDocument48 pages5G Antenna Talk TWRohit MathurNo ratings yet

- Research 10 Mod2Document28 pagesResearch 10 Mod2Fernadez RodisonNo ratings yet

- Object Detection mAP ExplainedDocument18 pagesObject Detection mAP ExplainedMai MinhNo ratings yet

- New Translation and Deciphering of ChineDocument14 pagesNew Translation and Deciphering of ChineRémyNo ratings yet

- How To Critique A Photograph - Facebook PDFDocument1 pageHow To Critique A Photograph - Facebook PDFpeterNo ratings yet

- 2006fileaveo MTDocument63 pages2006fileaveo MTeurospeed2100% (1)

- SD Series Digital AC Servo System User Manual GuideDocument66 pagesSD Series Digital AC Servo System User Manual GuideAdnene SaanounNo ratings yet

- The Control of Building Motion by Friction Dampers: Cedric MARSHDocument6 pagesThe Control of Building Motion by Friction Dampers: Cedric MARSHAlam Mohammad Parvez SaifiNo ratings yet

- 1 Catalyst FundamentalsDocument17 pages1 Catalyst FundamentalsSam AnuNo ratings yet

- Rubric Poetry Pyramid 4th GradeDocument2 pagesRubric Poetry Pyramid 4th Gradeapi-302020585No ratings yet

- 6.4 Permutations and CombinationsDocument14 pages6.4 Permutations and CombinationsAns SembiringNo ratings yet

- Strawberry GenerationDocument2 pagesStrawberry GenerationImat12No ratings yet

- wizBRAINeng20 2Document4 pageswizBRAINeng20 2Deepika AgrawalNo ratings yet