Professional Documents

Culture Documents

Tds Infinam RG 7100 L

Uploaded by

KacperOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tds Infinam RG 7100 L

Uploaded by

KacperCopyright:

Available Formats

RG

Product Information

INFINAM® RG 7100 L

HIGH IMPACT STRENGTH BLACK PHOTOPOLYMER FOR ADDITIVE MANUFACTURING

INFINAM® RG 7100 L resin is a black colored liquid photopolymer formulation, which is easy to process (1-part system).

The fully cured material exhibits excellent mechanical properties (high impact strength).

Directions for use

INFINAM® RG 7100 L resin is a light-sensitive product protected by its original packaging. Exposure of the liquid formulation

to daylight or UV light should be minimized or avoided at all during storage and handling to ensure consistent print quality.

Special light sources shall be used instead. Store product in a dry location with optimum storage temperature of 10-30 °C.

Storage beyond this recommended temperature range can adversely affect both print and product properties.

It is recommended to shake INFINAM® RG 7100 L resin well before use. Degassing can be carried out before any print process.

It is advisable not to store the unused resin in the vat, especially for prolonged period of usage. If the resin is left in the vat

after printing, thoroughly mix and agitate the resin in the vat prior to any print processes. Do not return used resin from the

vat back into the original INFINAM® RG 7100 L container.

Recommended print settings

INFINAM® RG 7100 L is designed to print on bottom-up digital light processing (DLP) machines. When printing with a light

intensity of 11 mW/cm2 at 405 nm, the recommended layer exposure time for 100 µm thick layers is 4 s, with a base layer

exposure time of 7 s. Working curve data for 405 nm wavelength and 11 mW/cm2 intensity: Critical exposure energy

Ec = 7-10 mJ/cm2 and Depth of penetration Dp = 170-250 µm. Setting printing temperature to 35–38 °C is highly

recommended.

Recommended washing procedure

It is recommended to wash printed parts with isopropanol (IPA) to remove uncured resin. Rinse 2 to 3 times, each rinse for

2-5 minutes. Rinse until excess resin have been completely removed. After the IPA washing, allow IPA to drip from the

printed parts for 5 to 10 minutes, afterwards, allow parts to dry for at least 30 minutes after washing to allow IPA to fully

evaporate before the next post-curing process. When support structures are used, they should be removed before post-

curing.

Recommended post-curing procedure

After washing, the parts should be submitted to ultraviolet (UV) light (intensity at ca. 5 mW/cm2) for 120 min at 80 °C,

followed by 180 min at 80 °C without UV light.

Mechanical testing measurements

The mechanical values reported in this document were obtained on specimens printed with a DLP printer at 405 nm

(11 mW/cm2, XY or XZ print with 4 s layer exposure time, 100 µm thick layers). Tensile bars were tested following ASTM

D638, Type V, 10 mm/min using an automated extensometer. Specimens are notched using a manual notching machine.

Statement on reported mechanical and thermal properties

The mechanical and thermal values reported in this document derived from printing various parts with one specific

bottom-up DLP machine and following the above-mentioned procedures. Those values reflect an approximation of the

mean value of a range of values and are intended for reference and comparison purposes only.

Evonik Operations GmbH

INFINAM® RG 7100 L ∣ 2022-11-14 ∣ Page: 1/2

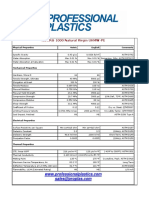

Mechanical Properties Value Unit Test Standard

Tensile Modulus 1450 MPa ASTM D638

Ultimate Tensile Strength 51 MPa ASTM D638

Elongation at Break 48 % ASTM D638

Flexural Modulus 1370 MPa ASTM D790

Flexural Stress at 5% Strain 55 MPa ASTM D790

Izod Notched Impact 80 J/m ASTM D256

Thermal Properties Value Unit Test Standard

Heat Deflection Temperature, 0.455 MPa/66 psi 66 °C ASTM D648

Heat Deflection Temperature, 1.82 MPa/264 psi 52 °C ASTM D648

Glass Transition Temperature (tan) 105 °C ASTM D4065

Physical Properties Value Unit Test Standard

Liquid Density, 25 °C 1.07 g/cm3 ASTM D4052

Liquid Viscosity, 25 °C / 1 Hz 4,870 mPa.s ASTM D4287

Shore D Hardness 81 - ASTM D2240

Water absorption (24 h) 1.1 % ASTM D570

Water absorption (48 h) 1.9 % ASTM D570

Water absorption (72 h) 2.8 % ASTM D570

This information and any recommendations, technical or otherwise, are presented in Evonik Operations GmbH

good faith and believed to be correct as of the date prepared. Recipients of this Smart Materials

information and recommendations must make their own determination as to its High Performance Polymers

suitability for their purposes. In no event shall Evonik assume liability for damages or 45772 Marl / Germany

losses of any kind or nature that result from the use of or reliance upon this information

and recommendations. EVONIK EXPRESSLY DISCLAIMS ANY REPRESENTATIONS AND Tel: +49 2365 49 – 9227

WARRANTIES OF ANY KIND, WHETHER EXPRESS OR IMPLIED, AS TO THE ACCURACY, evonik-hp@evonik.com

COMPLETENESS, NON-INFRINGEMENT, MERCHANTABILITY AND/OR FITNESS FOR A

PARTICULAR PURPOSE (EVEN IF EVONIK IS AWARE OF SUCH PURPOSE) WITH RESPECT TO

ANY INFORMATION AND RECOMMENDATIONS PROVIDED. Reference to any trade names

used by other companies is neither a recommendation nor an endorsement of the

corresponding product and does not imply that similar products could not be used.

Evonik reserves the right to make any changes to the information and/or

recommendations at any time, without prior or subsequent notice.

INFINAM® is registered trademark of Evonik Industries AG or one of its subsidiaries

Evonik Operations GmbH

INFINAM® RG 7100 L ∣ 2022-11-14 ∣ Page: 2/2

You might also like

- Forging Lecture PDFDocument58 pagesForging Lecture PDFJoselo HR100% (1)

- 6 Pushover AnalysisDocument6 pages6 Pushover AnalysisUALU333No ratings yet

- 28 - 2D Seismic Response Analysis of Bridge AbundmentDocument22 pages28 - 2D Seismic Response Analysis of Bridge AbundmentgiselNo ratings yet

- Api 577 3 PDFDocument10 pagesApi 577 3 PDFElankumaran Periakaruppan100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Tds Infinam Ti 3100 LDocument2 pagesTds Infinam Ti 3100 LKacperNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- Ra R120MKDocument1 pageRa R120MKyansyafNo ratings yet

- Exceed™ XP 8346CB: Performance PolymerDocument2 pagesExceed™ XP 8346CB: Performance PolymerMaram YasserNo ratings yet

- Exceed™ XP 8346PA: Performance PolymerDocument2 pagesExceed™ XP 8346PA: Performance PolymerMaram YasserNo ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsDocument1 pageK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsPatricio Bravo CastilloNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- P O L Y P R O P Y L E N E: Reliance Industries LimitedDocument1 pageP O L Y P R O P Y L E N E: Reliance Industries LimitedSiddheshNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- Ficha Tecnica Paxon As55003Document2 pagesFicha Tecnica Paxon As55003Eleannys GarciasNo ratings yet

- Exceed™ XP 6056ML: Performance PolymerDocument2 pagesExceed™ XP 6056ML: Performance PolymerkjmontilNo ratings yet

- Tritan TX1001Document2 pagesTritan TX1001qiongyao cuiNo ratings yet

- SABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)Document2 pagesSABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)yang chinaNo ratings yet

- Solvay - Duradex D3000Document3 pagesSolvay - Duradex D3000Renan GadioliNo ratings yet

- 400 00119895en Infuse 9500 TdsDocument2 pages400 00119895en Infuse 9500 TdsJorge CamargoNo ratings yet

- ImpactDocument3 pagesImpacthyper meshNo ratings yet

- Zytel HTN52 G35 HSLDocument5 pagesZytel HTN52 G35 HSLVisan GheorgheNo ratings yet

- Enable™ 4002MC Blown: Performance PolymerDocument2 pagesEnable™ 4002MC Blown: Performance PolymerCristian RodriguezNo ratings yet

- Exceed™ XP 8656MK: Performance PolymerDocument2 pagesExceed™ XP 8656MK: Performance PolymerCristian RodriguezNo ratings yet

- PDS M365Document2 pagesPDS M365prabhunmayNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- LLDPE-218BJ_edit (1)Document3 pagesLLDPE-218BJ_edit (1)Chu ChuNo ratings yet

- Ficha Tecnica Polipropileno Moplen Ep300l (J440)Document1 pageFicha Tecnica Polipropileno Moplen Ep300l (J440)Carlos SiuNo ratings yet

- 400 00030953en Engage 8180 TdsDocument3 pages400 00030953en Engage 8180 TdsSIDDHARTH BHASNEYNo ratings yet

- Exceed XP 8784 SeriesDocument2 pagesExceed XP 8784 SeriesAli RazuNo ratings yet

- 400 00285217en Hdpe 6200 TdsDocument2 pages400 00285217en Hdpe 6200 TdsOriana Gudiño GaliñoNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- Upp Tds Ep548s EnglishDocument1 pageUpp Tds Ep548s EnglishRula SiuNo ratings yet

- Exceed™ XP 8358 Series: Performance PolymerDocument2 pagesExceed™ XP 8358 Series: Performance PolymerMaram YasserNo ratings yet

- TIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsDocument2 pagesTIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsVictor AguirreNo ratings yet

- Exceed 3518PA Cast PDFDocument2 pagesExceed 3518PA Cast PDFchinchotarngNo ratings yet

- Exceed 3518Document2 pagesExceed 3518Amin PanNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Enable™ 4009MC Blown: Performance PolymerDocument2 pagesEnable™ 4009MC Blown: Performance PolymerCristian RodriguezNo ratings yet

- TDS_PP-5705PR-SabicDocument1 pageTDS_PP-5705PR-SabicChu ChuNo ratings yet

- Product PDF 210710Document1 pageProduct PDF 210710vaibhav ShindeNo ratings yet

- Escorene Ultra LD728.61Document2 pagesEscorene Ultra LD728.61José Roberto LazoNo ratings yet

- Exceed™ XP 6026 Series: Performance PolymerDocument2 pagesExceed™ XP 6026 Series: Performance PolymerMaram YasserNo ratings yet

- PP RANDOM Lotte - Ranpelen - J590K MI 44Document1 pagePP RANDOM Lotte - Ranpelen - J590K MI 44Luis LOZANONo ratings yet

- Driscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetDocument2 pagesDriscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetmariannyNo ratings yet

- RB02CR PP Random Copolymer Technical DataDocument1 pageRB02CR PP Random Copolymer Technical DataPiyush A JoshiNo ratings yet

- PP Homopolymer for Housewares and ToysDocument1 pagePP Homopolymer for Housewares and ToysAdonis BasilioNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Im B120MADocument1 pageIm B120MAPrashant MalikNo ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- 400 00030930en Engage 8003 TdsDocument4 pages400 00030930en Engage 8003 TdsManoharan SundaramNo ratings yet

- High Stiffness, Fluidity PP HomopolymerDocument1 pageHigh Stiffness, Fluidity PP HomopolymerMohit MohataNo ratings yet

- Exxon MobilDocument2 pagesExxon MobilVictor SilvestreNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Exceed 3518Document2 pagesExceed 3518Jimmys GothiqueNo ratings yet

- ExxonMobil Enable 20-05HHDocument2 pagesExxonMobil Enable 20-05HHHung TranNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- TPU 95A Technical Data SheetDocument3 pagesTPU 95A Technical Data SheetSteven DonosoNo ratings yet

- Engage 7467Document2 pagesEngage 7467RomDipaNo ratings yet

- Latent Heat of Phase ChangesDocument18 pagesLatent Heat of Phase ChangesHarsh TripathiNo ratings yet

- Measurement of Fabric Abrasion Resistance FOR LABDocument5 pagesMeasurement of Fabric Abrasion Resistance FOR LABSudip TalukdarNo ratings yet

- Experiments and Theory in Strain Gradient PDFDocument32 pagesExperiments and Theory in Strain Gradient PDFAnonymous 17ihTauS5No ratings yet

- IWPSD 2015 International Workshop on Physics of Semiconductor DevicesDocument49 pagesIWPSD 2015 International Workshop on Physics of Semiconductor DevicesHardik KalasuaNo ratings yet

- Bonding & Properties WorksheetDocument4 pagesBonding & Properties WorksheetCraig KingNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- Compressible Flow ProjectDocument2 pagesCompressible Flow Projectizzehhhh0% (1)

- GOLDI - 072GN1 (390-400) .CDR MonoDocument2 pagesGOLDI - 072GN1 (390-400) .CDR Monomk gandhiNo ratings yet

- 4 - Rotary DryerDocument24 pages4 - Rotary DryerkhawarNo ratings yet

- Idosr JST 41 81 105 2019. PuDocument25 pagesIdosr JST 41 81 105 2019. Pujamiu1175No ratings yet

- Results in Physics: SciencedirectDocument11 pagesResults in Physics: SciencedirectbharatNo ratings yet

- AFFRI Catalogo Gral 2010Document95 pagesAFFRI Catalogo Gral 2010Oscar Fabian MayorgaNo ratings yet

- International Journal of Fatigue: Urbi Pal, Goutam Mukhopadhyay, Ankush Sharma, Sandip BhattacharyaDocument7 pagesInternational Journal of Fatigue: Urbi Pal, Goutam Mukhopadhyay, Ankush Sharma, Sandip BhattacharyaRodrigo Alejandro Flores ZuñigaNo ratings yet

- Ceramics Manufacturing Processes SeminarDocument44 pagesCeramics Manufacturing Processes SeminarSajjadNo ratings yet

- Lecture 2 Version 1 EEE 471 Switchgear and Protection - NMKHANDocument12 pagesLecture 2 Version 1 EEE 471 Switchgear and Protection - NMKHANMortuzaNo ratings yet

- Finite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Document6 pagesFinite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Aswaja313No ratings yet

- Effect of Fire in ConcreteDocument6 pagesEffect of Fire in ConcreteS PraveenkumarNo ratings yet

- Liebherr Telescopic Grease 9613 PlusDocument1 pageLiebherr Telescopic Grease 9613 PlusUmar TauniNo ratings yet

- Comparative Analysis of Transmittance For Different Types of Commercially Available Zirconia and Lithium Disilicate MaterialsDocument6 pagesComparative Analysis of Transmittance For Different Types of Commercially Available Zirconia and Lithium Disilicate MaterialsNaoki MezarinaNo ratings yet

- Lesson 11 Activity 1 Thermal ExpansionDocument18 pagesLesson 11 Activity 1 Thermal ExpansionEthel WenceslaoNo ratings yet

- GME Online Test and Interview SyllabusDocument3 pagesGME Online Test and Interview SyllabusNimish Singh100% (1)

- Yamaha Bbg4aii Bbg4sii GuitarDocument6 pagesYamaha Bbg4aii Bbg4sii GuitarMiguel pazNo ratings yet

- Objective:: σ and hasDocument9 pagesObjective:: σ and hasfareeha saeedNo ratings yet

- Processing Strategies in BionanocompositesDocument47 pagesProcessing Strategies in BionanocompositesEDILENE DE CÁSSIA DUTRA NUNESNo ratings yet

- Heat Conduction Equation: Aguk Zuhdi M FathallahDocument62 pagesHeat Conduction Equation: Aguk Zuhdi M FathallahWahyuRidhaPratamaNo ratings yet

- Comparing Strengths and Moduli of Fiber Composites and Metal AlloysDocument13 pagesComparing Strengths and Moduli of Fiber Composites and Metal AlloysBilim KapsülüNo ratings yet