Professional Documents

Culture Documents

400 00030930en Engage 8003 Tds

Uploaded by

Manoharan SundaramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

400 00030930en Engage 8003 Tds

Uploaded by

Manoharan SundaramCopyright:

Available Formats

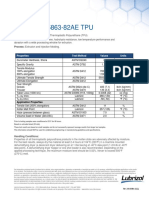

Technical Information

ENGAGE™ 8003

Polyolefin Elastomer

Overview ENGAGE™ 8003 Polyolefin Elastomer is an ethylene-octene copolymer that has excellent flow characteristics and

performs well in a wide variety of general purpose thermoplastic elastomer applications.

ENGAGE 8003 provides superb impact properties in blends with polypropylene (PP) and polyethylene (PE). It also

provides high filler loading capability and outstanding peroxide cure capability. When cross-linked by peroxide, silane,

or irradiation, it gives exceptional heat aging, compression set, and weather resistance properties, and may be used to

produce high performance electrical insulation and jacketing.

Main Characteristics:

• Pellet form

• Excellent flow characteristics

• Improved impact in polypropylene and polyethylene

• High filler loading

• Peroxide, silane, and radiation curable

• Exceptional heat aging, compression set, and weather resistance

Complies with:

• U.S. FDA 21 CFR 177.1520(c)3.2c

• EU, No 10/2011

• Japan Hygienic Olefin and Styrene Plastics Association

• U.S. FDA DMF

Consult the regulations for complete details.

Applications:

• General purpose thermoplastic elastomers

• Wire and cable

• Impact modification

Physical Nominal Value (English) Nominal Value (SI) Test Method

Density 0.885 g/cm³ 0.885 g/cm³ ASTM D792

Melt Index (190°C/2.16 kg) 1.0 g/10 min 1.0 g/10 min ASTM D1238

Mooney Viscosity (ML 1+4, 250°F (121°C)) 22 MU 22 MU ASTM D1646

Mechanical Nominal Value (English) Nominal Value (SI) Test Method

Tensile Modulus - 100% Secant 1

696 psi 4.80 MPa ASTM D638

(Compression Molded)

Tensile Strength 1

2640 psi 18.2 MPa ASTM D638

(Break, Compression Molded)

Tensile Elongation 1 ASTM D638

Break, Compression Molded 640 % 640 %

Flexural Modulus ASTM D790

1% Secant : Compression Molded 4890 psi 33.7 MPa

2% Secant : Compression Molded 4730 psi 32.6 MPa

Elastomers Nominal Value (English) Nominal Value (SI) Test Method

Tear Strength 2 348 lbf/in 61.0 kN/m ASTM D624

Hardness Nominal Value (English) Nominal Value (SI) Test Method

Durometer Hardness ASTM D2240

Shore A, Compression Molded 84 84

Shore D, Compression Molded 31 31

Form No. 400-00030930en

Page: 1 of 4 ® ™ Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow. Rev: 2021-03-10

Thermal Nominal Value (English) Nominal Value (SI) Test Method

Glass Transition Temperature -50.8 °F -46.0 °C Dow Method

Vicat Softening Temperature 145 °F 63.0 °C ASTM D1525

Melting Temperature (DSC) 3 171 °F 77.0 °C Dow Method

Peak Crystallization Temperature (DSC) 140 °F 60.0 °C Dow Method

Notes

These are typical properties only and are not to be construed as specifications. Users should confirm results by their own tests.

1 20 in/min (510 mm/min)

2 Die C

3 10°C/min

Form No. 400-00030930en

Page: 2 of 4 ® ™ Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow. Rev: 2021-03-10

Product Dow has a fundamental concern for all who make, distribute, and use its products, and for the

Stewardship environment in which we live. This concern is the basis for our product stewardship philosophy by which

we assess the safety, health, and environmental information on our products and then take appropriate

steps to protect employee and public health and our environment. The success of our product stewardship

program rests with each and every individual involved with Dow products - from the initial concept and

research, to manufacture, use, sale, disposal, and recycle of each product.

Customer Dow strongly encourages its customers to review both their manufacturing processes and their

Notice applications of Dow products from the standpoint of human health and environmental quality to ensure

that Dow products are not used in ways for which they are not intended or tested. Dow personnel are

available to answer your questions and to provide reasonable technical support. Dow product literature,

including safety data sheets, should be consulted prior to use of Dow products. Current safety data sheets

are available from Dow.

Medical Any and all medical application use of Dow materials, whether a device, a component, or any type of

Applications primary or secondary packaging of a medically related object or substance, needs to be reviewed and

approved by Dow before any Dow material can be tested in such application.

Policy

Dow requests that customers considering use of Dow products in medical applications notify Dow so that

appropriate assessments may be conducted. Dow does not endorse or claim suitability of its products for

specific medical applications. It is the responsibility of the medical device or pharmaceutical manufacturer

to determine that the Dow product is safe, lawful, and technically suitable for the intended use. DOW

MAKES NO WARRANTIES, EXPRESS OR IMPLIED, CONCERNING THE SUITABILITY OF ANY DOW

PRODUCT FOR USE IN MEDICAL APPLICATIONS.

For further information contact your Dow sales or technical representative to request a Medical Application

Review Request Form.

Additional details of Dow’s Medical Applications Policy are available at: https://www.dow.com/en-us/

support/product-safety.html

Tobacco and Dow does not support or intend for its products to be used, directly or indirectly, in the production of

Marijuana Policy tobacco, the manufacture of tobacco products, the manufacture and use of electronic cigarettes (including

vaping devices), the production of marijuana, or the manufacture of marijuana products intended for

human consumption, where the Dow product (or its residues) may be present in the finished product or be

alleged to facilitate the delivery of nicotine, other tobacco components, marijuana, or marijuana

components.

Harmful Dow does not intend for its products to be used in applications specifically intended to harm humans.

Applications

Policy

Disclaimer NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because

use conditions and applicable laws may differ from one location to another and may change with time, the

Customer is responsible for determining whether products and the information in this document are

appropriate for the Customer’s use and for ensuring that the Customer’s workplace and disposal practices

are in compliance with applicable laws and other governmental enactments. Dow assumes no obligation

or liability for the information in this document. NO WARRANTIES ARE GIVEN; ALL IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE

EXPRESSLY EXCLUDED.

NOTICE: If products are described as “experimental” or “developmental”: (1) product specifications may not be fully determined;

(2) analysis of hazards and caution in handling and use are required; (3) there is greater potential for Dow to change specifications

and/or discontinue production; and (4) although Dow may from time to time provide samples of such products, Dow is not obligated

to supply or otherwise commercialize such products for any use or application whatsoever.

NOTICE: This data is based on information Dow believes to be reliable, as demonstrated in controlled

laboratory testing. They are offered in good faith, but without guarantee, as conditions and method of use

of Dow products are beyond Dow’s control. Dow recommends that the prospective user determine the

suitability of these materials and suggestions before adopting them on a commercial scale.

To the best of our knowledge, the information contained herein is accurate and reliable as of the date of

publication, however we do not assume any liability for the accuracy and completeness of such

information.

For additional information, not covered by the content of this document, contact us via our web site http://

www.dow.com/products_services/.

Form No. 400-00030930en

Page: 3 of 4 ® ™ Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow. Rev: 2021-03-10

Additional North America Europe/Middle East +800-3694-6367

Information U.S. & Canada: 1-800-441-4369 +31-11567-2626

1-989-832-1426 Italy: +800-783-825

Mexico: +1-800-441-4369

Latin America South Africa +800-99-5078

Argentina: +54-11-4319-0100

Brazil: +55-11-5188-9000

Colombia: +57-1-219-6000 Asia Pacific +800-7776-7776

Mexico: +52-55-5201-4700 +603-7965-5392

www.dow.com This document is intended for use within Asia Pacific, Europe, Latin America, North America

Published: 2000-11-30

© 2022 The Dow Chemical Company

Form No. 400-00030930en

Page: 4 of 4 ® ™ Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow. Rev: 2021-03-10

You might also like

- 400 00030953en Engage 8180 TdsDocument3 pages400 00030953en Engage 8180 TdsSIDDHARTH BHASNEYNo ratings yet

- Engage 7467Document2 pagesEngage 7467RomDipaNo ratings yet

- Dow KT 10000 UeDocument2 pagesDow KT 10000 UeLuca GuadagnoNo ratings yet

- 400 00119895en Infuse 9500 TdsDocument2 pages400 00119895en Infuse 9500 TdsJorge CamargoNo ratings yet

- Dow KS 10100 UeDocument2 pagesDow KS 10100 UeLuca GuadagnoNo ratings yet

- 400 00285217en Hdpe 6200 TdsDocument2 pages400 00285217en Hdpe 6200 TdsOriana Gudiño GaliñoNo ratings yet

- DOW_KT10000UEDocument2 pagesDOW_KT10000UEChu ChuNo ratings yet

- 400 00119894en Infuse 9107 Lower Density Higher Performance Olefin Block Copolymer TdsDocument3 pages400 00119894en Infuse 9107 Lower Density Higher Performance Olefin Block Copolymer TdsKanagarajan VijayakumarNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- Hdpe Dmda-8920 NT 7 DowDocument2 pagesHdpe Dmda-8920 NT 7 DowEric Mahonri PereidaNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- Dow™ Ldpe 450E: Low Density Polyethylene ResinDocument2 pagesDow™ Ldpe 450E: Low Density Polyethylene ResinñeNo ratings yet

- Solvay - Duradex D3000Document3 pagesSolvay - Duradex D3000Renan GadioliNo ratings yet

- Elite 5538GDocument2 pagesElite 5538GHafiani HichamNo ratings yet

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsDocument1 pageK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsPatricio Bravo CastilloNo ratings yet

- 1613 11 PDFDocument2 pages1613 11 PDFGabriel DapuettoNo ratings yet

- DOWLEX™ 2038.68G: Polyethylene ResinDocument3 pagesDOWLEX™ 2038.68G: Polyethylene ResinJosé PalmaNo ratings yet

- Blown Film Resin - ELITE 5400G Enhanced PolyethyleneDocument2 pagesBlown Film Resin - ELITE 5400G Enhanced PolyethyleneEndayenew MollaNo ratings yet

- ELITE 5401G: Blown Film ResinDocument2 pagesELITE 5401G: Blown Film ResinEndayenew MollaNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- Product PDF 4956Document2 pagesProduct PDF 4956Mohammad PoostforushNo ratings yet

- LLDPE Dowlex 2645G TDSDocument3 pagesLLDPE Dowlex 2645G TDSAli RazuNo ratings yet

- High Performance Stretch Film ResinDocument3 pagesHigh Performance Stretch Film Resinujang sukartaNo ratings yet

- DOW™ LLDPE 1613: Linear Low Density Polyethylene ResinDocument2 pagesDOW™ LLDPE 1613: Linear Low Density Polyethylene ResinPilar CarmenNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- Ficha Tecnica Paxon As55003Document2 pagesFicha Tecnica Paxon As55003Eleannys GarciasNo ratings yet

- ELITE™ AT 6111: Enhanced Polyethylene ResinDocument3 pagesELITE™ AT 6111: Enhanced Polyethylene ResinRoberto De Mesa PNo ratings yet

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsDocument1 pageK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationssumherilNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Hdpe HD 7845.30Document2 pagesHdpe HD 7845.30Cristian RodriguezNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- Dowlex 2006GDocument2 pagesDowlex 2006GVõ HạnhNo ratings yet

- ExxonMobil Enable 20-05HHDocument2 pagesExxonMobil Enable 20-05HHHung TranNo ratings yet

- Repol® C015Eg: Reliance Industries LimitedDocument2 pagesRepol® C015Eg: Reliance Industries LimitedCamilo ObandoNo ratings yet

- H030SGDocument2 pagesH030SGLaxman AhirNo ratings yet

- DOW™ Butene 1221P: Linear Low Density Polyethylene ResinDocument3 pagesDOW™ Butene 1221P: Linear Low Density Polyethylene ResinMinh TranNo ratings yet

- Geogrid Standard Material SpecificationDocument2 pagesGeogrid Standard Material SpecificationBriccioNo ratings yet

- Exxonmobil™ Hdpe Hta 108: High Density Polyethylene ResinDocument2 pagesExxonmobil™ Hdpe Hta 108: High Density Polyethylene ResinCristian RodriguezNo ratings yet

- Yuplene™ H360F: SK Global ChemicalDocument2 pagesYuplene™ H360F: SK Global ChemicalNguyễn Hồng NamNo ratings yet

- Tritan TX1001Document2 pagesTritan TX1001qiongyao cuiNo ratings yet

- Exxon MobilDocument2 pagesExxon MobilVictor SilvestreNo ratings yet

- Zytel HTN52 G35 HSLDocument5 pagesZytel HTN52 G35 HSLVisan GheorgheNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

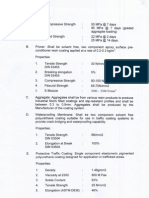

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- Exceed™ S 9333 Series: Performance PolymerDocument2 pagesExceed™ S 9333 Series: Performance PolymerMaram YasserNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- DMDH6400Document2 pagesDMDH6400JUAN SEBASTIAN BUSTOS GARNICANo ratings yet

- ELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinDocument2 pagesELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinLeductoan LeNo ratings yet

- TDS Pe 100 Ub5206h 02 PDFDocument2 pagesTDS Pe 100 Ub5206h 02 PDFOktaviandri SaputraNo ratings yet

- Product 301485Document1 pageProduct 301485Geovani Daniel Gonzalez LopezNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Ra R120MKDocument1 pageRa R120MKyansyafNo ratings yet

- AmplifyDocument2 pagesAmplifyİsmail YakinNo ratings yet

- ImpactDocument3 pagesImpacthyper meshNo ratings yet

- Exceed 1012MK PDFDocument2 pagesExceed 1012MK PDFEdgar CascoNo ratings yet

- Exceed 1012HA PDFDocument2 pagesExceed 1012HA PDFEdgar CascoNo ratings yet

- Exceed™ XP 6026 Series: Performance PolymerDocument2 pagesExceed™ XP 6026 Series: Performance PolymerMaram YasserNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- Vistamaxx Performance Polymer in Tpo Roofing FRDocument2 pagesVistamaxx Performance Polymer in Tpo Roofing FRManoharan SundaramNo ratings yet

- Vistamaxx Waterproofing Membrane Factsheet enDocument2 pagesVistamaxx Waterproofing Membrane Factsheet enManoharan SundaramNo ratings yet

- Silicone InsulatorsDocument4 pagesSilicone InsulatorsManoharan SundaramNo ratings yet

- Silicon Rubber For Electrical Insulation PDFDocument4 pagesSilicon Rubber For Electrical Insulation PDFPushkar NathNo ratings yet

- Declaration Sec 54Document1 pageDeclaration Sec 54Manoharan SundaramNo ratings yet

- Project SpecDocument4 pagesProject SpecManoharan SundaramNo ratings yet

- Chemlok 205 - 220 영문Document5 pagesChemlok 205 - 220 영문Ardiansyah Andry100% (1)

- Analytical and Bioanalytical Methods Conference AbstractsDocument56 pagesAnalytical and Bioanalytical Methods Conference AbstractsbebbbNo ratings yet

- PREN Value (Duplex)Document4 pagesPREN Value (Duplex)onkarNo ratings yet

- DDS Laboratory Activities - Prep 1-4Document20 pagesDDS Laboratory Activities - Prep 1-4ja_QuinineNo ratings yet

- Organic Chemistry Chapter 4Document58 pagesOrganic Chemistry Chapter 4Laiba KhanNo ratings yet

- 05 Notes On Nitriles IR SpectraDocument5 pages05 Notes On Nitriles IR SpectraMarcoNo ratings yet

- Topic: Autotroph: HistoryDocument5 pagesTopic: Autotroph: Historyvindhya shankerNo ratings yet

- E-Content - Metal Nitrosyls, Metal-Dinitrogen and Metal-Dioxygen ComplexesDocument3 pagesE-Content - Metal Nitrosyls, Metal-Dinitrogen and Metal-Dioxygen ComplexesAdnan BukhariNo ratings yet

- Salt Salt Analysis - 6 ZN (CO3) 2Document2 pagesSalt Salt Analysis - 6 ZN (CO3) 2mystical moonbeamNo ratings yet

- Heat Effect & ThermochemistryDocument29 pagesHeat Effect & ThermochemistryRani TriwrdhNo ratings yet

- Laporan Praktikum Biofarmasetika 1 Percobaan 1: Optimasi Metode Analisa ObatDocument9 pagesLaporan Praktikum Biofarmasetika 1 Percobaan 1: Optimasi Metode Analisa ObatRizky Bachrul AlamNo ratings yet

- Plan and Prepare HVAC Troubleshooting RepairsDocument41 pagesPlan and Prepare HVAC Troubleshooting Repairsjan tio100% (1)

- 01 Celanex®PBT Short-Term Properties GuideDocument12 pages01 Celanex®PBT Short-Term Properties Guide张彦海No ratings yet

- Two-Component Polysulphide Sealant Technical Data SheetDocument2 pagesTwo-Component Polysulphide Sealant Technical Data Sheetali alimNo ratings yet

- Characterising the Influence of p-p Interactions in Reversed-Phase Liquid ChromatographyDocument8 pagesCharacterising the Influence of p-p Interactions in Reversed-Phase Liquid ChromatographyKitmanul AsroriNo ratings yet

- Bio Inorganic 1 PPT ChemistryDocument57 pagesBio Inorganic 1 PPT ChemistryShantanu MawaskarNo ratings yet

- My TestDocument6 pagesMy TestMarin PesicNo ratings yet

- HL Paper3Document18 pagesHL Paper3charlesma123No ratings yet

- Basic Molecular Biology: Gene StructureDocument36 pagesBasic Molecular Biology: Gene StructureLutfil HadiNo ratings yet

- Commercial Kitchen VentilationDocument157 pagesCommercial Kitchen Ventilationarour.mokraneNo ratings yet

- A Review On Application of Natural Dyes On Textile Fabrics and Its Revival StrategyDocument25 pagesA Review On Application of Natural Dyes On Textile Fabrics and Its Revival StrategyNathalia MerizaldeNo ratings yet

- Astm F467Document6 pagesAstm F467MuhammadYusronAlfanyNo ratings yet

- Day1 CompiledDocument39 pagesDay1 CompiledWinsletJoyDauagNo ratings yet

- Phan Tich Bang Cong Cu PTBCC Chapter 10 Gas Chromatography (Cuuduongthancong - Com)Document86 pagesPhan Tich Bang Cong Cu PTBCC Chapter 10 Gas Chromatography (Cuuduongthancong - Com)Phong VõNo ratings yet

- Surface Vehicle Standard: Rev. SEP2004Document13 pagesSurface Vehicle Standard: Rev. SEP2004wilian_coelho3309No ratings yet

- Erosion Control / Re-Vegetation Mesh GREENAX: Technical Data SheetDocument1 pageErosion Control / Re-Vegetation Mesh GREENAX: Technical Data SheetHassan ZAFFA CISNEROSNo ratings yet

- Symbols and Charges for Monoatomic IonsDocument3 pagesSymbols and Charges for Monoatomic IonsKelvin Mark KaabayNo ratings yet

- MSDS Unioleo Fa C1299Document5 pagesMSDS Unioleo Fa C1299Phirate DorindNo ratings yet

- Cancer Poster 840x552Document1 pageCancer Poster 840x552Sreeharsha GurrapuNo ratings yet

- Formulae For: Alcohol, Phenols and EthersDocument10 pagesFormulae For: Alcohol, Phenols and EthersSâmïr Kumar MundariNo ratings yet

- Request Bearing Pad Test UrgentlyDocument1 pageRequest Bearing Pad Test UrgentlyShoyeeb AhmedNo ratings yet