Professional Documents

Culture Documents

Vistamaxx Waterproofing Membrane Factsheet en

Uploaded by

Manoharan SundaramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vistamaxx Waterproofing Membrane Factsheet en

Uploaded by

Manoharan SundaramCopyright:

Available Formats

Vistamaxx™ performance polymers

Enhance the performance of your

waterproofing membranes

Vistamaxx™ performance polymers

allow you to improve the performance

of your waterproofing membranes.

Adding Vistamaxx polymers to your

formulations enables the fabrication

of more flexible membranes that are

easier to install. Seam force and peel

strength can also be enhanced for

more durable membranes.

Easier installation Tailoring TPO membrane solutions for better flexibility

Adding Vistamaxx polymers to your formulation increases and strength

membrane flexibility, making installation easier and faster with Adding Vistamaxx polymers to the formulation enhances the

little maintenance. flexibility of your membranes, making them easier to install.

Vistamaxx polymers can also be used to tailor the tensile

Strength and durability strength and elongation at break for more durable membranes.

When Vistamaxx polymers are added to your formulations,

it broadens the membrane welding window, while TPO membranes typical formulation

simultaneously improving seam force and peel strength. This

stabilizes welding speed for easier membrane installation and Components Weight %

offers excellent welding strength for durability. Polymer: Vistamaxx 6102 and 60

ExxonMobil™ PP7032E3 (30-40)

Cost saving opportunities (PP content: % of total polymer)

Using Vistamaxx polymers allows higher filler loadings and

Magnesium hydroxide masterbatch 30

good filler dispersion, resulting in opportunities to reduce

(flame retardant)

costs and better membrane sheet consistency.

UV stabilizer masterbatch 3

Titanium dioxide (TiO2) masterbatch 7

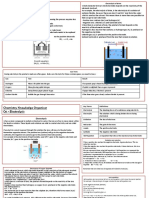

Figure 1: Enhanced compounding flexibility

Variation of flexural modulus with ICP content • Better flexibility versus the market reference leads

400

to easier installation

1% secant modulus in flexure (MPa)

350 • Modulus targets can be attained by varying the PP

300 content in the blend

250

200

150

100

50

0

20 25 30 35 40

PP content: % of total polymer

Vistamaxx + ICP Market reference

Test method: based on ASTM D790

Figure 2: Tailored strength and elongation at break

Variation of tensile strength with ICP content Variation of tensile elongation with ICP content

30.0 900

800

Tensile strength (MPa)

Elongation at break (%)

700

20.0

600

500

10.0

400

300

0.0 20 25 30 35 40

20 25 30 35 40 PP content: % of total polymer

PP content: % of total polymer

Vistamaxx + ICP Market reference Vistamaxx + ICP Market reference

Test method: based on ASTM D638 Test method: based on ASTM D638

• Tensile strength similar to the market reference with better elongation at break

• Properties can be tailored by adjusting the ratio of Vistamaxx™ performance polymers and ICP PP

Enhanced solutions for PE membranes with better flexibility

Adding Vistamaxx polymer as a blend partner to PE-based formulations improves membrane flexibility for easier installation

and provides good tear strength for durability.

Figure 3: Vistamaxx polymers for PE-based membranes

LLDPE based (1 mm thickness) • Adding 10% Vistamaxx 6102 reduces flexure modulus by

300 100

about 33% versus LLDPE

250

80 • Vistamaxx 6102 provides better flexibility and comparable

200

tear strength versus C2-C8 POE

Flexure modulus (MPa)

Tear strength (N/mm)

60

150

40

100

50

20 Formulation used for figure 3

0 0 Components Weight %

0 10 20 30

% of Vistamaxx or C2-C8 POE LLDPE 80-50

Flexure modulus LLDPE C2-C8 POE Vistamaxx 6102

Tear strength LLDPE C2-C8 POE Vistamaxx 6102

Vistamaxx 6102 or C2-C8 POE 0-30

Calcium carbonate powder 20

Test methods: based on TPE0056 for tear strength; based on ASTM D790 for flexure modulus.

Specimens were cut from 1mm thick compression molded plaques.

©2018 ExxonMobil. ExxonMobil, the ExxonMobil logo, the interlocking “X” device and other product or service names used herein are trademarks of ExxonMobil, unless indicated otherwise. This document may not be distributed, displayed, copied or altered

without ExxonMobil’s prior written authorization. To the extent ExxonMobil authorizes distributing, displaying and/or copying of this document, the user may do so only if the document is unaltered and complete, including all of its headers, footers, disclaimers

and other information. You may not copy this document to or reproduce it in whole or in part on a website. ExxonMobil does not guarantee the typical (or other) values. Any data included herein is based upon analysis of representative samples and not the actual

product shipped. The information in this document relates only to the named product or materials when not in combination with any other product or materials. We based the information on data believed to be reliable on the date compiled, but we do not

represent, warrant, or otherwise guarantee, expressly or impliedly, the merchantability, fitness for a particular purpose, freedom from patent infringement, suitability, accuracy, reliability, or completeness of this information or the products, materials or processes

described. The user is solely responsible for all determinations regarding any use of material or product and any process in its territories of interest. We expressly disclaim liability for any loss, damage or injury directly or indirectly suffered or incurred as a result of

or related to anyone using or relying on any of the information in this document. This document is not an endorsement of any non-ExxonMobil product or process, and we expressly disclaim any contrary implication. The terms “we,” “our,” “ExxonMobil Chemical”

and “ExxonMobil” are each used for convenience, and may include any one or more of ExxonMobil Chemical Company, Exxon Mobil Corporation, or any affiliate either directly or indirectly stewarded.

To find out more about Vistamaxx performance polymers, visit:

exxonmobilchemical.com

V0118-078E49

You might also like

- Influence of Water Absorption On Creep Behaviour of Carbon Fiber Epoxy Laminates (L)Document6 pagesInfluence of Water Absorption On Creep Behaviour of Carbon Fiber Epoxy Laminates (L)Navid HoseiniNo ratings yet

- Peerless Pump Brochures and Flyers - 8196Document2 pagesPeerless Pump Brochures and Flyers - 8196Gaudencio Rodriguez RomeroNo ratings yet

- Pavement PerformanceDocument70 pagesPavement PerformanceAnonymous J9OnNRNo ratings yet

- Multiples of Current Rating: Molded Case Circuit Breaker K 1000 LINEDocument2 pagesMultiples of Current Rating: Molded Case Circuit Breaker K 1000 LINEAmr AhmedNo ratings yet

- BR CycloneDocument8 pagesBR CycloneRiegos Veracruz100% (1)

- Excavation NoticeDocument1 pageExcavation NoticeEslam EsamNo ratings yet

- Challenges: Case Study No.03 DN005-P01 Road & Infrastructure in Umm Slal Mohammed 30-May-21Document1 pageChallenges: Case Study No.03 DN005-P01 Road & Infrastructure in Umm Slal Mohammed 30-May-21Eslam EsamNo ratings yet

- Tr-43 Design Service Life Corugated Polyethlene PipeDocument11 pagesTr-43 Design Service Life Corugated Polyethlene PipeErSoravNo ratings yet

- Self-Compacting Concrete and Its Application in Hong KongDocument23 pagesSelf-Compacting Concrete and Its Application in Hong KongKris dNo ratings yet

- Low-Voltage Power Circuit Breakers: Multiples of Current Setting (C) Multiples of Breaker Short-Time Rating (H)Document1 pageLow-Voltage Power Circuit Breakers: Multiples of Current Setting (C) Multiples of Breaker Short-Time Rating (H)James Albeiro Sánchez NarváezNo ratings yet

- FW - 3M Technical PaperDMRDocument4 pagesFW - 3M Technical PaperDMRSergioNo ratings yet

- SCE L High Head Low Flow Process Pump Brochure Apr20Document8 pagesSCE L High Head Low Flow Process Pump Brochure Apr20Aymen BabourNo ratings yet

- Bamboo Materials in Cement, Geopolymer and Reinforced Concrete AsDocument18 pagesBamboo Materials in Cement, Geopolymer and Reinforced Concrete AsabebechNo ratings yet

- Diesel or LPG Engine Pneumatic Tires: CMP20 CMP25 CMP30Document7 pagesDiesel or LPG Engine Pneumatic Tires: CMP20 CMP25 CMP30Corjuc StefanNo ratings yet

- KSB MDXDocument3 pagesKSB MDXLuis VelazcoNo ratings yet

- DES-218C: Molded Case Circuit BreakerDocument1 pageDES-218C: Molded Case Circuit BreakerClaudio DiazNo ratings yet

- OSC Business Case For Robi, Bangladesh: 14 Sept, 2012Document24 pagesOSC Business Case For Robi, Bangladesh: 14 Sept, 2012Kr RavindraNo ratings yet

- Baoli: Dry-Cut Strand Pelletizer For Compounding and RecyclingDocument2 pagesBaoli: Dry-Cut Strand Pelletizer For Compounding and Recyclingrong duNo ratings yet

- Aluminum Wire Harness: New ProductsDocument3 pagesAluminum Wire Harness: New ProductsAliNo ratings yet

- Mill Circuit Solutions: GIW Hard Rock Mining PumpsDocument8 pagesMill Circuit Solutions: GIW Hard Rock Mining PumpsbabarNo ratings yet

- Valvula ElectroneumaticaDocument4 pagesValvula ElectroneumaticaVictor Hugo Alvarez CortinezNo ratings yet

- Data Sheet BISALLOY 500-STEELDocument1 pageData Sheet BISALLOY 500-STEELFery FebryantoNo ratings yet

- Marketing of Broadband ServicesDocument32 pagesMarketing of Broadband ServicesRajesh KumarNo ratings yet

- Maximize The Efficiency of Your AdditiveDocument2 pagesMaximize The Efficiency of Your Additivesriatul2006No ratings yet

- Mitsubishi IC Pneumatic Forklift PDFDocument5 pagesMitsubishi IC Pneumatic Forklift PDFfdpc1987No ratings yet

- E SpecCMP15 18 20sDocument6 pagesE SpecCMP15 18 20sJan HendriksNo ratings yet

- Astralloy 600 Pipe: A 600 BHN Abrasion Resistant PipeDocument4 pagesAstralloy 600 Pipe: A 600 BHN Abrasion Resistant Pipesarsan nedumkuzhiNo ratings yet

- Pressure Switch Bellow Type (Industrial) : Special FeaturesDocument1 pagePressure Switch Bellow Type (Industrial) : Special Featuresajinkya deshmukhNo ratings yet

- 8X8X3M (H) Layout2Document1 page8X8X3M (H) Layout2Erick YuseNo ratings yet

- The Filter Mat A 3 / 300 SDocument12 pagesThe Filter Mat A 3 / 300 SEdy WijayaNo ratings yet

- Top Sectional Plan ViewDocument1 pageTop Sectional Plan ViewMan ChupingNo ratings yet

- Modeling The Static Force of A Festo Pneumatic Muscle Actuator: A New Approach and A Comparison To Existing ModelsDocument12 pagesModeling The Static Force of A Festo Pneumatic Muscle Actuator: A New Approach and A Comparison To Existing Modelsقاسم رافع عمران المواليNo ratings yet

- General: A Minimum of 250-mm Wide Reinforcing Strip of Is Recommended Over The Corners Followed by The Full MembraneDocument2 pagesGeneral: A Minimum of 250-mm Wide Reinforcing Strip of Is Recommended Over The Corners Followed by The Full MembraneEngr KamalNo ratings yet

- Effect of Strain Rate On Bake Hardening Response of BH220 SteelDocument5 pagesEffect of Strain Rate On Bake Hardening Response of BH220 SteelTC Tugay DoğanNo ratings yet

- Water District - Specification-PR No. 13-0431 PDFDocument43 pagesWater District - Specification-PR No. 13-0431 PDFAnna Maree100% (1)

- Slide PresentationDocument17 pagesSlide PresentationCt Izzatul AisyahNo ratings yet

- Exhaust Fan Exhaust Fan Add Window Depend On Sink Area: E D S DDocument1 pageExhaust Fan Exhaust Fan Add Window Depend On Sink Area: E D S DFALAKNo ratings yet

- Cherry PDFDocument1 pageCherry PDFFALAKNo ratings yet

- Downstream MCCB - TCCDocument1 pageDownstream MCCB - TCCshrikanth5singhNo ratings yet

- k215-165b (15amp Trip Sel CB)Document1 pagek215-165b (15amp Trip Sel CB)Claudio DiazNo ratings yet

- Final Portfolio For Print 2 FULLDocument29 pagesFinal Portfolio For Print 2 FULLJim NohNo ratings yet

- Tensile and Compression TestDocument17 pagesTensile and Compression TestAnonymous 0Frw5LxNo ratings yet

- Haris 2Document1 pageHaris 2Abdul HameedNo ratings yet

- HARIS Led HOLDING STRUCTURE-ModelDocument1 pageHARIS Led HOLDING STRUCTURE-ModelAbdul HameedNo ratings yet

- PT Communication Cable Systems Indonesia TBK Company and Industry UpdatesDocument17 pagesPT Communication Cable Systems Indonesia TBK Company and Industry Updatesprayogi abyNo ratings yet

- 1350 ESSAR - FLUE - GAS - FAN - SPEED - AER - OPTION - CurveDocument1 page1350 ESSAR - FLUE - GAS - FAN - SPEED - AER - OPTION - CurveAhmed ElhusseinyNo ratings yet

- Lateral Load Vs Deflection & Max. Moment: Civiltech SoftwareDocument1 pageLateral Load Vs Deflection & Max. Moment: Civiltech SoftwareEdan EdanNo ratings yet

- Design: Data 12MDocument7 pagesDesign: Data 12Moz_1990No ratings yet

- Enviromix: Environment - Performance - ProfitDocument4 pagesEnviromix: Environment - Performance - ProfitDileepa DissanayakeNo ratings yet

- BHR 35 - 30 4 Stg.Document3 pagesBHR 35 - 30 4 Stg.Maknan SteelNo ratings yet

- Product Information SWEDAC Damping CassettesDocument8 pagesProduct Information SWEDAC Damping CassettesJay JayNo ratings yet

- 730Sn, 730un, 730dun, 730Bpn, 730us, 730dus and 730enn PumpsDocument4 pages730Sn, 730un, 730dun, 730Bpn, 730us, 730dus and 730enn PumpsalexingmNo ratings yet

- Improved Polysilicon Surface-Micromachined Micromirror Devices Using Chemical-Mechanical PolishingDocument6 pagesImproved Polysilicon Surface-Micromachined Micromirror Devices Using Chemical-Mechanical PolishingharidasmaNo ratings yet

- Natural Convection in Geothermal Resources Containing Near-Critical WaterDocument22 pagesNatural Convection in Geothermal Resources Containing Near-Critical WaterWillianNo ratings yet

- 2018-1-Impact of GIC On Noise Performance of Large Power TransformersDocument7 pages2018-1-Impact of GIC On Noise Performance of Large Power TransformersArief BudiantoNo ratings yet

- Concrete A2Document1 pageConcrete A2Darshan ShahNo ratings yet

- Loctite 620: Product Description Technology Cure Speed vs. Bond GapDocument3 pagesLoctite 620: Product Description Technology Cure Speed vs. Bond GapKamrange100% (1)

- Lowara NSC PompeDocument204 pagesLowara NSC PompePaul Daniel100% (1)

- HMCP400X5 Data SheetDocument7 pagesHMCP400X5 Data SheetClaudio DiazNo ratings yet

- Next Generation Optical Wireless Communication Systems: A Systems ApproachFrom EverandNext Generation Optical Wireless Communication Systems: A Systems ApproachNo ratings yet

- Vistamaxx Performance Polymer in Tpo Roofing FRDocument2 pagesVistamaxx Performance Polymer in Tpo Roofing FRManoharan SundaramNo ratings yet

- Silicone InsulatorsDocument4 pagesSilicone InsulatorsManoharan SundaramNo ratings yet

- Declaration Sec 54Document1 pageDeclaration Sec 54Manoharan SundaramNo ratings yet

- Chemlok 205 - 220 영문Document5 pagesChemlok 205 - 220 영문Ardiansyah Andry100% (1)

- AOAC 2020.08 Lactose Concentration in Milk, Milk Products and Dairy Ingredients by Megazyme Test KitDocument7 pagesAOAC 2020.08 Lactose Concentration in Milk, Milk Products and Dairy Ingredients by Megazyme Test KitdcardonasterNo ratings yet

- Test Bank For Biochemistry 1st Edition Roger L Miesfeld Megan M McevoyDocument36 pagesTest Bank For Biochemistry 1st Edition Roger L Miesfeld Megan M Mcevoyempericetagragyj6f8100% (31)

- Alkyl Halides - Memory Map - Nucleophilic Substitution: Kno /agno NahsDocument1 pageAlkyl Halides - Memory Map - Nucleophilic Substitution: Kno /agno NahsAryan GuptaNo ratings yet

- Safety Hiblack 30LDocument3 pagesSafety Hiblack 30Lalfa twoNo ratings yet

- Flame TestDocument2 pagesFlame Testfreedom5345No ratings yet

- High Density Polyethylene - HdpeDocument2 pagesHigh Density Polyethylene - HdpeVENKATESAN JNo ratings yet

- Industrial Pharmacy Particle-Size Reduction: Faculty of Pharmacy, Philadelphia University, Amman, JordanDocument58 pagesIndustrial Pharmacy Particle-Size Reduction: Faculty of Pharmacy, Philadelphia University, Amman, JordanMohammad IsmaeelNo ratings yet

- Training Module: AnalysersDocument28 pagesTraining Module: Analysersmilton1987No ratings yet

- Group 7BDocument5 pagesGroup 7BKate Ashley HugoNo ratings yet

- Hyprox 500 MSDSDocument16 pagesHyprox 500 MSDSkurniawanNo ratings yet

- Base Oil Manufacturing Hydroprocessing (Amy Claxton, ICIS)Document36 pagesBase Oil Manufacturing Hydroprocessing (Amy Claxton, ICIS)die_1No ratings yet

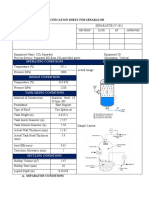

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Antistic Flyer - New2Document2 pagesAntistic Flyer - New2hanihiNo ratings yet

- EnviroPeel StripperDocument3 pagesEnviroPeel StripperAhmed ElghmatiNo ratings yet

- Risk AssesmentDEFERMENT FOR MAIN ENGINE UNIT NO 5 DECARBDocument8 pagesRisk AssesmentDEFERMENT FOR MAIN ENGINE UNIT NO 5 DECARBNUTALAPATI HARIPRASADNo ratings yet

- Paint Failures Library - PPT (Read-Only)Document75 pagesPaint Failures Library - PPT (Read-Only)Elhusseiny FoudaNo ratings yet

- Nano KeywordsDocument2 pagesNano KeywordsTika SeptiaNo ratings yet

- C6 - ElectrolysisDocument2 pagesC6 - ElectrolysisDarlene BellesiaNo ratings yet

- Ncert Solutions Class 10 Science Chapter 15Document3 pagesNcert Solutions Class 10 Science Chapter 15Pujara PujaraNo ratings yet

- Basic Well Logging (Pet 407) : (Section 3) Dr. OhiaDocument61 pagesBasic Well Logging (Pet 407) : (Section 3) Dr. OhiamsvaletNo ratings yet

- SNDHANOI - ASI - 00 - BOQ - Unit Price PDFDocument2 pagesSNDHANOI - ASI - 00 - BOQ - Unit Price PDFDo BuiNo ratings yet

- Tutorial 5Document4 pagesTutorial 5Eqieyn JerrNo ratings yet

- Department of Defense Standard Practice Chromium Plating, Low Embrittlement, Electro-DepositionDocument14 pagesDepartment of Defense Standard Practice Chromium Plating, Low Embrittlement, Electro-DepositionAbed samadsureyft7vewyrNo ratings yet

- Chemistry Project:: Metal Coupling Effect On Rusting of IronDocument10 pagesChemistry Project:: Metal Coupling Effect On Rusting of IronDaksh GudwaniNo ratings yet

- D.K.T.E.S Textile & Engineering Institute, Ichalkaranji-416115 (M.H), India, February 1, 2014Document10 pagesD.K.T.E.S Textile & Engineering Institute, Ichalkaranji-416115 (M.H), India, February 1, 2014shreeket3953No ratings yet

- Earth's Early History - 19-3Document4 pagesEarth's Early History - 19-3alex rodriguezNo ratings yet

- Mid-Term Dev 1Document5 pagesMid-Term Dev 1Hong Nhung DamNo ratings yet

- Dehydrative Etherification of Carbohydrates To 5-Ethoxymethylfurfural Over SBA-15-supported Sn-Modified Heteropolysilicate CatalystsDocument12 pagesDehydrative Etherification of Carbohydrates To 5-Ethoxymethylfurfural Over SBA-15-supported Sn-Modified Heteropolysilicate Catalystsbruno barrosNo ratings yet

- Changes in Vapour Pressure. (Vapour Pressure Lowering) : V - P Depends Only On The SolventDocument5 pagesChanges in Vapour Pressure. (Vapour Pressure Lowering) : V - P Depends Only On The SolventMarthy DayagNo ratings yet

- Alphaplus® 1-Octene (C8 H16) : Safety Data SheetDocument13 pagesAlphaplus® 1-Octene (C8 H16) : Safety Data SheetlyesNo ratings yet