Professional Documents

Culture Documents

Valvula Electroneumatica

Uploaded by

Victor Hugo Alvarez CortinezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valvula Electroneumatica

Uploaded by

Victor Hugo Alvarez CortinezCopyright:

Available Formats

FLOW-TEK

SERIES DM7000/DM8000

DIRECT MOUNT 3 PIECE FULL PORT BALL VALVES

DM7000 Stainless Steel | DM8000 Carbon Steel

½" - 2" (15mm - 50mm)

1,000 psi WOG

WWW.BRAY.COM THE HIGH PERFORMANCE COMPANY

DM7000/DM8000 DIRECT MOUNT SERIES BALL VALVES

The Series DM7000/DM8000 design is based on the series 7000/8000

with extensive interchangeability of the majority of the parts between the

two series.

In addition to all the features and options of the Series 7000/8000, the

direct mount valve design reduces the number of parts, the overall enve-

lope dimensions and hysteresis between the ball and actuator. The cast top

flange ensures direct actuator mounting and is designed to the ISO 5211

standard. Actuation equipment can be easily and safely removed while the

valve is under full line pressure. The integrated extension is equipped with

a 1/8” NPT threaded vent hole for pressure relief or for fugitive emissions

monitoring while in service.

Direct Mount valves are offered with the full range of

interchangeable end connections including thread-

ed, socket weld, butt weld, ASME Class 150 flanged

and extended weld in place. These are the same end connections

found in the standard 7000/8000 valves.

Body 3 Piece

Full Port ½” – 2” (15mm - 50mm)

Materials Stainless Steel CF8M*,

Carbon Steel WCB

& Special Alloys

Pressure Ratings 1000 WOG

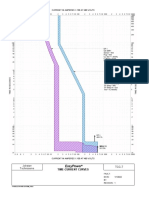

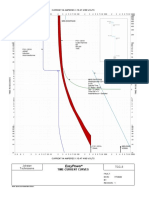

Temperature (°C)

0 50 100 150 200 250 300

1000

900

Temperature (°C) Temperature (°C)

800 0 50 100 150 200 250 300

0 50 100 150 200 250 300 350

Pressure (psi)

700

1000

600 70

1000

900

500

900

60

800

400

800

Pressure (psi)

Pressure (psi)

Pressure (bar)

700

300 50

700

600

200

600

40

500

100

500

400 30

400

Temperature (°C)

300

0

300 100 200 300 400 500 600

0 50 100 150 200 250 300 350 Temperature

20 (°F)

200

200

100 10

100 70

1000

900

1/4" - 4" Valves: UHMWPE 1/4" - 4" Valves: Tek

60 0 100 200 300 400 500 600

0 100 200 300 400 500 600 700

800 Temperature (°F) Temperature (°F)

1/4" - 4" Valves: RPTFE/TFM 6"-12" Butt Weld Va

Pressure (psi)

Pressure (bar)

700 50

1/4" - 4": 50/50 SS Filled TFE ASME Class 150 Flan

600

1/4" - 4" Valves: UHMWPE

40

1/4" -- 4"

1/4" 4" Valves:

Valves: Tek-Fil

UHMWPE 1/4" - 4" Valves: Tek

500

NOTE:

400 1/4" - 4" Valves: RPTFE/TFM

30

1/4"

8000- carbon

Series6"-12" 4" Valves:

Butt steel RPTFE/TFM

Weld valves

Valves:are limited to -20°F.6"-12" Butt Weld Va

RPTFE

300

Series 7000 stainless steel valves are limited to -50°F.

1/4" - 4": 50/50 SS Filled TFE

20 1/4" - Class

ASME 4": 50/50 SS Filled TFE

150 Flanged ASME Class 150 Flan

200

10

100

NOTE: NOTE:

Series 8000 carbon steel valves are limited to -20°F.

Series 8000 carbon steel valves are limited to -20°F.

0 100 200 300 Series

4007000 stainless

500 steel

600valves are Series

700limited to -50°F.7000 stainless steel valves are limited to -50°F.

Temperature (°F)

1/4" - 4" Valves: UHMWPE 1/4" - 4" Valves: Tek-Fil

2| 3 PIECE FULL PORT – DM7000/DM8000

1/4" - 4" Valves: RPTFE/TFM 6"-12" Butt Weld Valves: RPTFE

26

19 AVAILABLE END CAP CONNECTIONS

18 • Threaded End

SPECIAL OPTIONS/SERVICES

• Socket Weld End

Cavity Fillers 15

• Extended Socket Weld End

11

Deadman Handles

• Butt Weld End (Schedule 40)

V Port Balls 14 • Extended Butt Weld End (Schedule 40)

Vented Balls

• Flanged End (ASME Class 150)

Chlorine Service 12

Polished Internals 11

Special Cleaning

Silicone Free

Media Containment Units (MCU's) 5

9

40

6 2

4

4

6

2

7

8

COM P O NE N T S A N D M AT E R I ALS

STAINLESS CARBON STAINLESS CARBON

ITEM/NAME QTY. ITEM/NAME QTY.

STEEL STEEL STEEL STEEL

ASTM A351 Gr ASTM A216

1 Body 1 10 Anti-Static

(not shown)

Device SS316 2

CF8M Gr WCB

ASTM A351 Gr ASTM A216 Packing/Thrust Washer

2 End Cap• 2 11 PEEK 2•

CF8M• Gr WCB Protector

3 Ball ASTM A351 Gr CF8M 1 12 Thrust Washer TEK-FIL® 1•

4 Seat 15% RPTFE 2• 14 Stem Packing 15% RPTFE 3•

5 Stem ASTM A479 Type 316 1 15 Packing Gland Sleeve SS304 1

6 Body Seal TFM 2• 18 Belleville Washer SS301 2

7 Spring Washer SS304 4 19 Tab Lock Washer SS304 1

8 Body Nut SS304 4 26 Stem Nut SS304 1

9 Body Bolt / Stud SS304 4 40 Plug (optional) SS304 1

•

Weld Ends use CF3M • Recommended spare parts that are available as a packaged repair kit

3 PIECE FULL PORT – DM7000/DM8000 |3

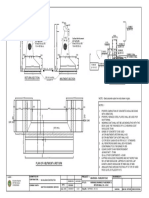

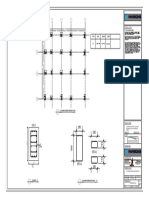

SERIES DM7000 & DM8000 DIMENSIONS øB

1/2" – 2" VALVES (15mm - 50mm)

M For further dimensional data and flow coefficients refer to

the Series 7000/8000 literature available at

L A

www.Flow-Tek.com.

1/8-27 NPT øV1 øV2

C1

ød2

ød1

øB

øP

A

DIMENSIONS – Models DM7000 (SS) / DM8000 (CS)

SIZE C1 M L øP ød1 øV1 ød2 øV2 Weight SPECIFICATIONS

øV1 øV2

1/2 1.92 0.25 0.26 0.37 0.22 1.65 0.28 1.97 1.62 Valve Sizes ½” through 2” (15mm - 50mm)

3/4 1.99 0.25 0.26 0.37 0.22 1.65 0.28 1.97 2.20

Design meets MSS-SP-110. ød2

Threaded End Connections meet

ASME B1.20.1 NPT.

ød1

1 2.41 0.31 0.40 0.43 – – 0.28 1.97 3.00

INCHES

Socket Weld End Connections meet

LBS

11⁄4 2.56 0.31 0.38 0.43 – – 0.28 1.97 4.70 ASME B16.11.

Butt Weld End (sch 40) Connections meet

11⁄2 3.04 0.37 0.43 0.62 – – 0.35 2.76 7.20

MSS SP-72 /ASME B16.25.

2 3.38 0.37 0.43 0.62 – – 0.35 2.76 10.1 Flanged End Connections meet

øPASME Class 150.

15 48.85 6.3 6.7 9.3 5.5 42 7 50 0.734 Valve body and end cap connections are high

quality investment cast and solution annealed/

20 50.55 6.3 6.7 9.3 5.5 42 7 50 1 normalized. Body and end cap wall thickness meets

ASME B16.34.

MILLIMETERS

25 61.1 8 10.1 10.9 – – 7 50 1.342 Valve stems are blow-out proof for maximum safety

and meet ASME B16.34 specification.

KG

32 65.1 8 9.6 10.9 – – 7 50 2.13 All valves are factory tested to MSS SP-72

and API 598.

40 77.2 9.5 11 15.7 – – 9 70 3.275

CERTIFICATION

PE(S)R UKCA S.I. 2016:1105

50 85.95 9.5 11 15.7 – – 9 70 4.975

® All statements, technical information, and recommendations in this bulletin are for general use

only. Consult Flow-Tek representatives or factory for the specific requirements and material

A Subsidiary of BRAY INTERNATIONAL, Inc. selection for your intended application. The right to change or modify product design or

8323 N. Eldridge Pkwy #100 Houston, Texas 77041 product without prior notice is reserved.

832.912.2300 Fax: 832.912.2301 Flow-Tek® is a registered trademark of Bray International, Inc.

www.flow-tek.com © 2022 Flow-Tek, Inc. F-2808_DM7000_8000 DirectMount_10-17-2022

You might also like

- DES-215B - v3 (Long Time GEH-702) PDFDocument2 pagesDES-215B - v3 (Long Time GEH-702) PDFClaudio DiazNo ratings yet

- Des-215b - v3 (Long Time Geh-702)Document2 pagesDes-215b - v3 (Long Time Geh-702)Claudio DiazNo ratings yet

- DES-092B: Multiple of Long-Time PickupDocument1 pageDES-092B: Multiple of Long-Time PickupBen ClarkNo ratings yet

- Multiples of Current Rating: Molded Case Circuit Breakers Q LineDocument1 pageMultiples of Current Rating: Molded Case Circuit Breakers Q LineMUSIC ELECNo ratings yet

- Multiples of Current Rating: Molded Case Circuit Breakers Q LineDocument1 pageMultiples of Current Rating: Molded Case Circuit Breakers Q LineMUSIC ELECNo ratings yet

- Model 9F54Dfc Series: Current in AmperesDocument1 pageModel 9F54Dfc Series: Current in AmperesPaulo H TavaresNo ratings yet

- Datasheet KPM32F 6A01Document1 pageDatasheet KPM32F 6A01Nurul AzizahNo ratings yet

- Downstream MCCB - TCCDocument1 pageDownstream MCCB - TCCshrikanth5singhNo ratings yet

- Multiples of Current Rating: Molded Case Circuit Breaker K 1000 LINEDocument2 pagesMultiples of Current Rating: Molded Case Circuit Breaker K 1000 LINEAmr AhmedNo ratings yet

- Multiples of Current Rating: Molded Case Circuit BreakersDocument1 pageMultiples of Current Rating: Molded Case Circuit BreakersAmr AhmedNo ratings yet

- Oduct Offering: Multiples of Current RatingDocument1 pageOduct Offering: Multiples of Current RatingAmr AhmedNo ratings yet

- DES-218C: Molded Case Circuit BreakerDocument1 pageDES-218C: Molded Case Circuit BreakerClaudio DiazNo ratings yet

- 4 FlangesDocument52 pages4 FlangesJumanah Al-alshaikhNo ratings yet

- Ges 6231aDocument1 pageGes 6231aAmr AhmedNo ratings yet

- k215-165b (15amp Trip Sel CB)Document1 pagek215-165b (15amp Trip Sel CB)Claudio DiazNo ratings yet

- Ges 6120d Thed GeDocument1 pageGes 6120d Thed GeBolivar MartinezNo ratings yet

- GES-6121C: Multiples of Current RatingDocument1 pageGES-6121C: Multiples of Current RatingAdolfo Sotomayor BurgosNo ratings yet

- GES-6122C: Multiples of Current RatingDocument1 pageGES-6122C: Multiples of Current RatingAdolfo Sotomayor BurgosNo ratings yet

- Ges 6108c Type TQD GeDocument1 pageGes 6108c Type TQD GeBolivar MartinezNo ratings yet

- Cast Bronze 300Document140 pagesCast Bronze 300Adrian GaribNo ratings yet

- Current in Amperes X 100 at 480 Volts: EasypowerDocument1 pageCurrent in Amperes X 100 at 480 Volts: EasypowerHendrix LevaNo ratings yet

- J600 Line TJJ TJK THJK THK2 Ges-6104fDocument1 pageJ600 Line TJJ TJK THJK THK2 Ges-6104fAna Hernández MonterrubioNo ratings yet

- Minimum Operating Envelope 3 Inch 8ppg Trim ChokesDocument1 pageMinimum Operating Envelope 3 Inch 8ppg Trim Chokescarlos angelNo ratings yet

- Current in Amperes X 10 at 4160 Volts: EasypowerDocument1 pageCurrent in Amperes X 10 at 4160 Volts: EasypowerHendrix LevaNo ratings yet

- Trabajo 6 Geologia CorteDocument1 pageTrabajo 6 Geologia Cortejtrinacokhotmail.comNo ratings yet

- Section Aa' PlanDocument7 pagesSection Aa' PlanMayuriNo ratings yet

- Current in Amperes X 100 at 480 Volts: EasypowerDocument1 pageCurrent in Amperes X 100 at 480 Volts: EasypowerHendrix LevaNo ratings yet

- DES-101B: Multiple of Trip Rating PlugDocument1 pageDES-101B: Multiple of Trip Rating Plugjurica_2006No ratings yet

- 26 - Southern Cross - Iso Pump - 100 X 65 - 250 - 1200 - 3000 RPMDocument1 page26 - Southern Cross - Iso Pump - 100 X 65 - 250 - 1200 - 3000 RPMAri sofyanNo ratings yet

- Top Sectional Plan ViewDocument1 pageTop Sectional Plan ViewMan ChupingNo ratings yet

- Relacion de Soporte de California (C.B.R.) : MaterialDocument1 pageRelacion de Soporte de California (C.B.R.) : MaterialEdwin Joel Arteaga ChavezNo ratings yet

- 155 - Flow Chart CV .8Document1 page155 - Flow Chart CV .8Mugywara luNo ratings yet

- 22 - Southern Cross - Iso Pump - 100 X 80 - 160 - 1500 - 3500 RPMDocument1 page22 - Southern Cross - Iso Pump - 100 X 80 - 160 - 1500 - 3500 RPMEriz SalmanNo ratings yet

- Dab Evoplus, B 150250.40 MDocument1 pageDab Evoplus, B 150250.40 MNegrea IonutNo ratings yet

- Des-095b - Long TimeDocument1 pageDes-095b - Long Timeshrikanth5singhNo ratings yet

- Strip Plan For Utility Shifting and Tree Cutting (Km.139/Nh-15)Document1 pageStrip Plan For Utility Shifting and Tree Cutting (Km.139/Nh-15)Bilal A BarbhuiyaNo ratings yet

- SK and SK-MK Series With Mechanical Seal or Magnetic Coupling Self-Priming, Delivering GasDocument32 pagesSK and SK-MK Series With Mechanical Seal or Magnetic Coupling Self-Priming, Delivering Gasrene almonacidNo ratings yet

- Antenna Line InfoDocument1 pageAntenna Line InfomosesNo ratings yet

- DES-093B: Multiple of SensorDocument1 pageDES-093B: Multiple of SensorBen ClarkNo ratings yet

- 24 - Southern Cross - Iso Pump - 100 X 65 - 200 - 1500 - 3500 RPMDocument1 page24 - Southern Cross - Iso Pump - 100 X 65 - 200 - 1500 - 3500 RPMHazim HazimNo ratings yet

- Ge SK 1200 TCC K215-178BDocument1 pageGe SK 1200 TCC K215-178BRick DownerNo ratings yet

- Ges 6194 PDFDocument2 pagesGes 6194 PDFjurica_2006No ratings yet

- Minimum Operating Envelope 2 Inch 18ppg Trim ChokesDocument1 pageMinimum Operating Envelope 2 Inch 18ppg Trim Chokescarlos angelNo ratings yet

- Variation of Armature Current and Voltage Against Speed: V (V) I (A)Document4 pagesVariation of Armature Current and Voltage Against Speed: V (V) I (A)Amjasd MasdhashNo ratings yet

- Curvas de BombaDocument1 pageCurvas de BombaDaniel Alejandro García PérezNo ratings yet

- Godwin UHH250Document1 pageGodwin UHH250hendrynNo ratings yet

- MTP CAD 1-Layout3Document1 pageMTP CAD 1-Layout3Laurence Emmanuel BenedictosNo ratings yet

- Pump Hm250 FHC-S C5 Performance Curve: 600mm 600mm Full Closed 73mm High Chrome High ChromeDocument1 pagePump Hm250 FHC-S C5 Performance Curve: 600mm 600mm Full Closed 73mm High Chrome High ChromeJoão Paulo Augusto MacedoNo ratings yet

- A005 DOORS Old Drawing FOR SPOT DETAIL ONLYDocument13 pagesA005 DOORS Old Drawing FOR SPOT DETAIL ONLYJessica PerezNo ratings yet

- GAD FINAL 4+541 No. 2Document1 pageGAD FINAL 4+541 No. 2popemiNo ratings yet

- PDFDocument28 pagesPDFLutfi FaisalNo ratings yet

- Speck Pumpenside - Channel - Pumps - NPSH - Suction - Stage - Ask - Ask-Mk-SeriesDocument28 pagesSpeck Pumpenside - Channel - Pumps - NPSH - Suction - Stage - Ask - Ask-Mk-SeriesdtbukNo ratings yet

- Lateral Load Vs Deflection & Max. Moment: Civiltech SoftwareDocument1 pageLateral Load Vs Deflection & Max. Moment: Civiltech SoftwareEdan EdanNo ratings yet

- 8X8X3M (H) Layout2Document1 page8X8X3M (H) Layout2Erick YuseNo ratings yet

- DES-095B: Approximately (0.784-Actual Pickup)Document1 pageDES-095B: Approximately (0.784-Actual Pickup)shrikanth5singhNo ratings yet

- Ab STR 101 B124Document1 pageAb STR 101 B124arainzada807No ratings yet

- Detail Pembuangan Septic TankDocument1 pageDetail Pembuangan Septic TankMuhammad DjuandaNo ratings yet

- Description: 0529EN March 2016Document2 pagesDescription: 0529EN March 2016Cristian NicolescuNo ratings yet

- En1456-001 TC8 AnsiDocument1 pageEn1456-001 TC8 AnsiJesus CasasNo ratings yet

- Water Sampling Equipment EPB0023BDocument1 pageWater Sampling Equipment EPB0023Bdennis rio perdanaNo ratings yet

- FLANSZE DO SPALIN - flanges-DIN-86044Document2 pagesFLANSZE DO SPALIN - flanges-DIN-86044PawelNo ratings yet

- How It Works - 3565 KPHDocument1 pageHow It Works - 3565 KPHorqh007No ratings yet

- Kiln Float and Hydraulic Thrust DeviceDocument21 pagesKiln Float and Hydraulic Thrust DevicehaiderNo ratings yet

- S Curve Instrument CepuDocument1 pageS Curve Instrument CepuRicardo NapitupuluNo ratings yet

- 5 EvacOnlineMax-TechnicalDetailsDocument1 page5 EvacOnlineMax-TechnicalDetailsJose LiraNo ratings yet

- ExcelDocument65 pagesExcelrendalop ujtaNo ratings yet

- NewLecture8 Centrifugal CompressorsDocument126 pagesNewLecture8 Centrifugal CompressorsKhalid Mahmood100% (1)

- Fluid Mechanics Lab 1Document7 pagesFluid Mechanics Lab 1Esra BelhajNo ratings yet

- Solar Turbine Surge ControlDocument10 pagesSolar Turbine Surge ControlMinZartar100% (1)

- 2 Stage Ammonia Refrigeration System For 2 Sisters Food Group Designed and Built by C&L RefrigerationDocument2 pages2 Stage Ammonia Refrigeration System For 2 Sisters Food Group Designed and Built by C&L RefrigerationzhyhhNo ratings yet

- Moody Diagram: Darcy Friction FactorDocument6 pagesMoody Diagram: Darcy Friction FactorNikka Briones DomingoNo ratings yet

- DesuperheatersDocument8 pagesDesuperheatersmuhdrijasmNo ratings yet

- Applying NPSH To Metering PumpsDocument3 pagesApplying NPSH To Metering PumpsJoce88888100% (1)

- Hydraulic TrainingDocument128 pagesHydraulic TrainingRaj100% (1)

- CN Valve Sizing Tech Spec GEA31796C EnglishDocument28 pagesCN Valve Sizing Tech Spec GEA31796C EnglishphostyNo ratings yet

- Boiler Feed PumpDocument22 pagesBoiler Feed PumpnksatnamiNo ratings yet

- Pipe Schedules PDFDocument2 pagesPipe Schedules PDFEngineering KaizenNo ratings yet

- General Piping and ValvesDocument184 pagesGeneral Piping and Valvesfacebookshop100% (2)

- IMG - 0026 PSME Code 2012 24Document1 pageIMG - 0026 PSME Code 2012 24Bugoy2023No ratings yet

- b16 24Document24 pagesb16 24Gustavo FamaNo ratings yet

- Semi-Internal "Pop-Action" Pressure Relief Valves For ASME ContainersDocument1 pageSemi-Internal "Pop-Action" Pressure Relief Valves For ASME ContainersshuzaoNo ratings yet

- ME 203 Mechanics of FluidsDocument3 pagesME 203 Mechanics of FluidsSherwinNo ratings yet

- Esquema Electrico SilanosDocument1 pageEsquema Electrico SilanosDoruNo ratings yet

- General Abbreviations & AcronymsDocument11 pagesGeneral Abbreviations & AcronymsAslamsherkhan Ibn Hussain KandamangalamNo ratings yet

- Astm E190 - 97 - Procedimiento de Doblez (Traducción)Document7 pagesAstm E190 - 97 - Procedimiento de Doblez (Traducción)Ivan D100% (1)

- What Is A Flushing RingDocument6 pagesWhat Is A Flushing RingFarooqNo ratings yet

- Rexroth PGH 2X Internal Gear Pump, Fixed Displacement Re10223 - 2005-10Document28 pagesRexroth PGH 2X Internal Gear Pump, Fixed Displacement Re10223 - 2005-10Adit AdriyantoNo ratings yet

- Hovercraft DesignDocument73 pagesHovercraft Designakash shindeNo ratings yet

- CV Trim eDocument1 pageCV Trim eAnonymous Wu6FDjbNo ratings yet