Professional Documents

Culture Documents

Part1-Rod12 MM Same Material-2

Uploaded by

koraina2015Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part1-Rod12 MM Same Material-2

Uploaded by

koraina2015Copyright:

Available Formats

Simulation of Part1

Date: Sunday, August 16, 2020

Designer: Solidworks

Study name: rod12 mm same material

Analysis type: Static

Table of Contents

Description...........................................1

Assumptions..........................................2

Model Information..................................2

Study Properties.....................................3

Units..................................................3

Material Properties.................................4

Loads and Fixtures..................................4

Connector Definitions..............................5

Contact Information................................5

Mesh information....................................6

Sensor Details........................................7

Description Resultant Forces....................................7

No Data Beams.................................................7

Study Results........................................8

Conclusion..........................................11

Analyzed with SOLIDWORKS Simulation Simulation of Part1 1

Assumptions

Model Information

Model name: Part1

Current Configuration: Default

Solid Bodies

Document Name and Document Path/Date

Treated As Volumetric Properties

Reference Modified

Mirror1

Mass:725.551 kg

Volume:0.0924268 m^3

Solid Body Density:7,850 kg/m^3

Weight:7,110.4 N

Analyzed with SOLIDWORKS Simulation Simulation of Part1 2

Study Properties

Study name rod12 mm same material

Analysis type Static

Mesh type Solid Mesh

Thermal Effect: On

Thermal option Include temperature loads

Zero strain temperature 298 Kelvin

Include fluid pressure effects from Off

SOLIDWORKS Flow Simulation

Solver type FFEPlus

Inplane Effect: Off

Soft Spring: Off

Inertial Relief: Off

Incompatible bonding options Automatic

Large displacement On

Compute free body forces On

Friction Off

Use Adaptive Method: Off

Result folder SOLIDWORKS document

(C:\Users\user\AppData\Local\Temp\{3D2A8E99-

6175-4256-9755-00540CAD95A1})

Units

Unit system: SI (MKS)

Length/Displacement mm

Temperature Kelvin

Angular velocity Rad/sec

Pressure/Stress N/m^2

Analyzed with SOLIDWORKS Simulation Simulation of Part1 3

Material Properties

Model Reference Properties Components

Name: ASTM A36 Steel SolidBody 1(Mirror1)(Part1)

Model type: Linear Elastic Isotropic

Default failure Max von Mises Stress

criterion:

Yield strength: 2.5e+08 N/m^2

Tensile strength: 4e+08 N/m^2

Elastic modulus: 2e+11 N/m^2

Poisson's ratio: 0.26

Mass density: 7,850 kg/m^3

Shear modulus: 7.93e+10 N/m^2

Curve Data:N/A

Loads and Fixtures

Fixture name Fixture Image Fixture Details

Entities: 2 face(s)

Type: Fixed Geometry

Fixed-1

Resultant Forces

Components X Y Z Resultant

Reaction force(N) 0.00375366 -0.0027771 0.0200958 0.0206312

Reaction Moment(N.m) 0 0 0 0

Load name Load Image Load Details

Entities: 3 face(s)

Type: Normal to selected face

Value: 10.2

Units: kgf/cm^2

Pressure-1 Phase Angle: 0

Units: deg

Analyzed with SOLIDWORKS Simulation Simulation of Part1 4

Connector Definitions

No Data

Contact Information

No Data

Analyzed with SOLIDWORKS Simulation Simulation of Part1 5

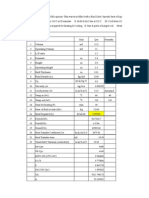

Mesh information

Mesh type Solid Mesh

Mesher Used: Standard mesh

Automatic Transition: Off

Include Mesh Auto Loops: Off

Jacobian points for High quality mesh 16 Points

Element Size 0.0580551 m

Tolerance 0.00290275 m

Mesh Quality High

Mesh information - Details

Total Nodes 33293

Total Elements 16811

Maximum Aspect Ratio 21.918

% of elements with Aspect Ratio < 3 12.4

% of elements with Aspect Ratio > 10 36.5

% of distorted elements(Jacobian) 0

Time to complete mesh(hh;mm;ss): 00:00:06

Computer name:

Analyzed with SOLIDWORKS Simulation Simulation of Part1 6

Sensor Details

No Data

Resultant Forces

Reaction forces

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N 0.00375366 -0.0027771 0.0200958 0.0206312

Reaction Moments

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N.m 0 0 0 0

Free body forces

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N 0 0 0 0

Free body moments

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N.m 0 0 0 0

Beams

No Data

Analyzed with SOLIDWORKS Simulation Simulation of Part1 7

Study Results

Name Type Min Max

Stress1 VON: von Mises Stress 2.220e+05N/m^2 3.960e+08N/m^2

Node: 15209 Node: 4561

Part1-rod12 mm same material-Stress-Stress1

Name Type Min Max

Displacement1 URES: Resultant Displacement 0.000e+00mm 2.159e+00mm

Node: 2455 Node: 22539

Analyzed with SOLIDWORKS Simulation Simulation of Part1 8

Name Type Min Max

Part1-rod12 mm same material-Displacement-Displacement1

Name Type Min Max

Strain1 ESTRN: Equivalent Strain 9.587e-07 1.210e-03

Element: 773 Element: 7579

Part1-rod12 mm same material-Strain-Strain1

Analyzed with SOLIDWORKS Simulation Simulation of Part1 9

Name Type

Displacement1{1} Deformed shape

Part1-rod12 mm same material-Displacement-Displacement1{1}

Analyzed with SOLIDWORKS Simulation Simulation of Part1 10

Image-1

Conclusion

Analyzed with SOLIDWORKS Simulation Simulation of Part1 11

You might also like

- Hand ValvesDocument12 pagesHand Valveskoraina2015No ratings yet

- No Rod1 Material-3Document11 pagesNo Rod1 Material-3koraina2015No ratings yet

- Project NoDocument1 pageProject Nokoraina2015No ratings yet

- Extracted Pages From G.V DSDocument4 pagesExtracted Pages From G.V DSkoraina2015No ratings yet

- What Is NPSHRDocument1 pageWhat Is NPSHRkoraina2015No ratings yet

- Pressure Vessel CalculationsDocument82 pagesPressure Vessel Calculationskoraina2015No ratings yet

- P8I6AH-56 AiDocument1 pageP8I6AH-56 Aikoraina2015No ratings yet

- Offer: Project: Executed By: Contact: Pump Unit:: Operating Data Motor SpecificationDocument3 pagesOffer: Project: Executed By: Contact: Pump Unit:: Operating Data Motor Specificationkoraina2015No ratings yet

- SPC/PNSDP-LPG/1/2012: of 3 Barg Req. When 50% Closed at 6,270 L/min FlowDocument1 pageSPC/PNSDP-LPG/1/2012: of 3 Barg Req. When 50% Closed at 6,270 L/min Flowkoraina2015No ratings yet

- ? @AB C? DE CCF ? GH B C? IB Jakb CL? Mnof C PQLCB RB Akql TU V Y 'GDocument1 page? @AB C? DE CCF ? GH B C? IB Jakb CL? Mnof C PQLCB RB Akql TU V Y 'Gkoraina2015No ratings yet

- Equipement ListDocument28 pagesEquipement Listkoraina2015No ratings yet

- Sand Blasting Clac.Document23 pagesSand Blasting Clac.koraina2015No ratings yet

- UG&AG Tanks Cost BreakdownDocument11 pagesUG&AG Tanks Cost Breakdownkoraina2015No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Modeling and Simulation of Photovoltaic Module Using MATLAB SimulinkDocument6 pagesModeling and Simulation of Photovoltaic Module Using MATLAB SimulinkpraveeneeeNo ratings yet

- Chapter 4 SkoooogDocument20 pagesChapter 4 SkoooogMelissa Suelto100% (1)

- Practical ElectronicsDocument107 pagesPractical ElectronicsSaeed Ali Shahani100% (2)

- PKL 2023-112-01 Rev. 21 SettembreDocument8 pagesPKL 2023-112-01 Rev. 21 Settembreprakash majjiNo ratings yet

- EMS Lab Manual-2Document68 pagesEMS Lab Manual-2M SamarNo ratings yet

- 19.06-01-2017 J (A) Score - 1Document64 pages19.06-01-2017 J (A) Score - 1iitd080No ratings yet

- DiodoDocument6 pagesDiodoDante_84No ratings yet

- SMP1012X Series - Installation Guide: OverviewDocument4 pagesSMP1012X Series - Installation Guide: OverviewenriquealugovNo ratings yet

- Self Excitation of Induction MotorsDocument5 pagesSelf Excitation of Induction MotorsDiego Nicolás López-RamírezNo ratings yet

- Group II HandoutDocument22 pagesGroup II HandoutJazer Mike RamosNo ratings yet

- 25-36-22 Oven PN 8201-01-0000& PDFDocument181 pages25-36-22 Oven PN 8201-01-0000& PDFMUHANDES UKRAINE100% (2)

- Omron Relay MKI S D500Document12 pagesOmron Relay MKI S D500Khairi JahaparNo ratings yet

- Raman Nath Study MaterialDocument24 pagesRaman Nath Study MaterialNitish KumarNo ratings yet

- KelvionKDC 2018 Factsheet ENDocument2 pagesKelvionKDC 2018 Factsheet ENАндрій РомNo ratings yet

- LG Multi Split AC Catalogue 2019Document5 pagesLG Multi Split AC Catalogue 2019Ravi SankarNo ratings yet

- Convert Ion of Galvanometer Into VoltmeterDocument3 pagesConvert Ion of Galvanometer Into Voltmeterhrpatel31No ratings yet

- William Gilbert Robert HookeDocument3 pagesWilliam Gilbert Robert HookeJan Alan RosimoNo ratings yet

- Design and Simulation of A Linear LVDT Sensor For Precise Measurement-Based ApplicationsDocument3 pagesDesign and Simulation of A Linear LVDT Sensor For Precise Measurement-Based ApplicationsamitpandaNo ratings yet

- Klim Ovzek lp7 - Topic ReviewDocument2 pagesKlim Ovzek lp7 - Topic Reviewapi-463570013No ratings yet

- Essay On Renewable EnergyDocument2 pagesEssay On Renewable EnergyLavanyaNo ratings yet

- The Energy Car Project - I.E. Mousetrap CarDocument8 pagesThe Energy Car Project - I.E. Mousetrap CarblueberryNo ratings yet

- Fluid Tank & Ship MotionDocument30 pagesFluid Tank & Ship Motionsalman GtrNo ratings yet

- Data Sheet Stamford AltenatorDocument8 pagesData Sheet Stamford AltenatorsupriNo ratings yet

- Manuel García Pérez, Esa Vakkilainen, Timo Hyppänen: Full Length ArticleDocument14 pagesManuel García Pérez, Esa Vakkilainen, Timo Hyppänen: Full Length ArticleMarcos DuarteNo ratings yet

- Steam TurbinesDocument64 pagesSteam TurbinesGIRIPRASAD T GNo ratings yet

- EXPERIMENT 4 Equivalent ResistanceDocument7 pagesEXPERIMENT 4 Equivalent ResistanceqwertyNo ratings yet

- UG - Physics (Introduction To Mechanics) - EnglishDocument20 pagesUG - Physics (Introduction To Mechanics) - EnglishAMV SenpaiNo ratings yet

- Reguladora de Voltaje MarathonDocument4 pagesReguladora de Voltaje MarathonFercho SanchezNo ratings yet

- CEB Training Report 3Document26 pagesCEB Training Report 3Lakshan Walpita100% (2)

- Limpet Coil Reactor - 28-05Document3 pagesLimpet Coil Reactor - 28-05AJAY138150% (2)