Professional Documents

Culture Documents

Mytech LTD.: Type Din Iso en 61212 Din 7735

Uploaded by

WidyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mytech LTD.: Type Din Iso en 61212 Din 7735

Uploaded by

WidyaCopyright:

Available Formats

Tubes made of cotton-fabric are mainly used in machine construction but also in the electronic

industry as construction material. Another main field of usage are the hydraulic and the bearing

production.Because of the fabric-strength in combination with the phenolic resin you can put much weight on

it, and so is used as substitute to metallic materials many areas.

Structure: Tubes made of type 100 or type 102 consists of with phenolic resin impregnated cott on-fabric-

sheets. The quality type 100-M has additional MOS as gliding

2 substance They are parallel winded on winding

machines, where the resin and fabric glues together under the influence of heat and pressure. At the following

hardening process the layers get indissoluble. The finished tubes then get grinded and mechanically worked as

the customer wishes.

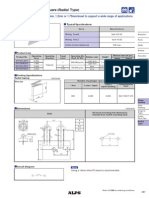

Type DIN ISO EN 61212 DIN 7735

100 PF CC 22 Hgw 2085

100-M PF CC 22 Hgw 2085

102 PF CC 21 Hgw 2086

Normal sizes and tolerances:

Inside diameter: from ø 5 mm to ca. ø 850 mm, Special sizes on request

Wall thickness: from 1,0 mm, depending on the diameter

Lenght: from 500 mm to ca. 1500 mm depending on type and diameter

Tolerances: according to EN 61212-3-1 bzw. or after agreement

Technical terms Unit Type 100 Type 100-M Type 102

Compression, axial MPa 100 100 120

Flexural strenght MPa 80 80 90

Tensile strenght MPa 90 90 90

Flexural Modulus N/mm² 6.000 6.000 6.000

Friction against steel µ 0,25 0,15 0,25

Density g/cm³ 1,15-1,35 1,2-1,3 1,15-1,35

Water absorbtion Mg/cm³ 10 10 5

Temperature restistance °C 120 120 120

Ball pressure hardness, vertical N/mm² 130 130 130

Ball pressure hardness, parallel N/mm² 115 120 120

Voltage, vertical kV/3mm 10 10 10

The above called specifications were made to the best of our knowledge. It is recommended to prove the

material in case of doubt for special applications. All values are the minimum requirement!

MyTech Ltd.

www.gteek.com

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Leser API 520 LiquidDocument6 pagesLeser API 520 LiquidWidyaNo ratings yet

- Fleet ManagementDocument20 pagesFleet ManagementMarco Antônio Claret TeixeiraNo ratings yet

- Is 15652Document3 pagesIs 15652IshanNo ratings yet

- Key Topics in PSM by DR Vivek JainDocument5 pagesKey Topics in PSM by DR Vivek Jaindocvivekjain100% (4)

- Aluminum Alloy Specification'Document12 pagesAluminum Alloy Specification'ArjunNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Nuclear Reactor Fuel ElementsDocument761 pagesNuclear Reactor Fuel ElementsMuhammad Riaz, 0092-3138432432No ratings yet

- Mobile Management SystemDocument9 pagesMobile Management SystemNaga Sai Anitha NidumoluNo ratings yet

- ASTM A-967-13 Pasivado Inoxidable PDFDocument7 pagesASTM A-967-13 Pasivado Inoxidable PDFmagierezNo ratings yet

- Dorna AC Servo ManualDocument189 pagesDorna AC Servo ManualShazib Shaukat SroyaNo ratings yet

- M T Ch16 Innate Immunity SDocument30 pagesM T Ch16 Innate Immunity SAnonymous STRYVGKNo ratings yet

- Material PropertiesDocument16 pagesMaterial PropertiesMadan Kulkarni100% (1)

- Compound Plamar GanglionDocument4 pagesCompound Plamar Ganglionchinmayghaisas100% (2)

- NGL Extraction TechnologiesDocument7 pagesNGL Extraction Technologiescbba2310% (1)

- Yahagi Siren S-283Document1 pageYahagi Siren S-283WidyaNo ratings yet

- Vanishing TieDocument14 pagesVanishing TieIchwalsyah SyNo ratings yet

- Datasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Document5 pagesDatasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Kashish100% (2)

- DIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- MediaDocument9 pagesMediaxtdrifttxNo ratings yet

- Gb8417domex500mc PDFDocument2 pagesGb8417domex500mc PDFMario MereniNo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- M/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsDocument8 pagesM/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsBahador YazdiNo ratings yet

- Gaskets - Graphite PDFDocument4 pagesGaskets - Graphite PDFSH1961No ratings yet

- SKEGDocument4 pagesSKEGshyhuNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Two-Way Pressure Balanced Plug Valve, Flanged, PN16: Field Devices EuropeDocument4 pagesTwo-Way Pressure Balanced Plug Valve, Flanged, PN16: Field Devices EuropeGourav SharmaNo ratings yet

- CuAg0,1P PDFDocument8 pagesCuAg0,1P PDFirajfarji2481No ratings yet

- A 897 - A 897M - 02 Qtg5ny9bodk3ts1sruqDocument11 pagesA 897 - A 897M - 02 Qtg5ny9bodk3ts1sruqrolando cuadro blancoNo ratings yet

- NAK Product Overview 2 PDFDocument48 pagesNAK Product Overview 2 PDFSoumyajit BoseNo ratings yet

- Voltis HGW 2082 TDSDocument1 pageVoltis HGW 2082 TDSAndra ManuNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- VG221 - 2 Port Control ValveDocument4 pagesVG221 - 2 Port Control ValveNoah MusundiNo ratings yet

- LEXAN 9030 and Lexan 9030 TG Datasheet PDFDocument2 pagesLEXAN 9030 and Lexan 9030 TG Datasheet PDFIbrahim Levent AkkoyunluNo ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- Policarbonato Macizo Polygal Plazit PDFDocument4 pagesPolicarbonato Macizo Polygal Plazit PDFnicolas peraltaNo ratings yet

- DIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

- Airmaster HVAC Ducting BrochureDocument12 pagesAirmaster HVAC Ducting BrochureWaseem NaamoNo ratings yet

- Ausschreibungstexte Engl ExtractDocument12 pagesAusschreibungstexte Engl Extractqsdpfyb2c5No ratings yet

- Rubber Mastic and Sealant Tapes PDFDocument18 pagesRubber Mastic and Sealant Tapes PDFNikhil MathewNo ratings yet

- Shin Nan Catalogue PDFDocument38 pagesShin Nan Catalogue PDFElan ChezhiyanNo ratings yet

- Datasheet-Sandvik-13rm19-En-V2020-12-10 07 - 47 Version 1Document6 pagesDatasheet-Sandvik-13rm19-En-V2020-12-10 07 - 47 Version 1aceinsteinNo ratings yet

- Technical Data Sheet - Nylon X: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylon X: 3D Printing FilamentSteven DonosoNo ratings yet

- Technical Data Sheet - Nylon X: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylon X: 3D Printing FilamentwidyarahmahNo ratings yet

- Aq-Differential Pressure GaugeDocument4 pagesAq-Differential Pressure Gaugepankaj doshiNo ratings yet

- DS - TW9512 - GB - 724 - Poço de Proteção FLG Materiais EspeciaisDocument4 pagesDS - TW9512 - GB - 724 - Poço de Proteção FLG Materiais EspeciaisThomasFrenchNo ratings yet

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- MST 33Document2 pagesMST 33Imawan WastNo ratings yet

- 01.03.03.101 Spesifikasi-BPM HDPE SmoothDocument1 page01.03.03.101 Spesifikasi-BPM HDPE SmoothRezky BaskoroNo ratings yet

- Materialdatasheet 80 NBR 709 6Document3 pagesMaterialdatasheet 80 NBR 709 6Miguel ContrerasNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- 1.4057 Aisi 431 Data Sheet PDFDocument2 pages1.4057 Aisi 431 Data Sheet PDFGagat GongatNo ratings yet

- Adding A New Dimension To Impact Resistant Glazing and CladdingDocument1 pageAdding A New Dimension To Impact Resistant Glazing and CladdingOmer TahaNo ratings yet

- Bondstrand 2400Document17 pagesBondstrand 2400Pinakin PatelNo ratings yet

- Worm Gear Sets enDocument29 pagesWorm Gear Sets enmohammad khoraminiaNo ratings yet

- Catalogue Worm Gear Sets and Customised Worm Gear SetsDocument30 pagesCatalogue Worm Gear Sets and Customised Worm Gear Setsfog900No ratings yet

- Preserv 1 300 K2DDocument4 pagesPreserv 1 300 K2DamitabhsrivastavaNo ratings yet

- 2a Annexure - II-IMTECH-NEW ITEMS Draft-16.01.2016Document12 pages2a Annexure - II-IMTECH-NEW ITEMS Draft-16.01.2016Amit SinghNo ratings yet

- MFS BrochureDocument5 pagesMFS BrochurePhan Đức NgọcNo ratings yet

- Eurocw617n ST enDocument4 pagesEurocw617n ST endrgilleNo ratings yet

- Datasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1Document5 pagesDatasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1aceinsteinNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- Đông Hô Nhiêt Suku PDFDocument2 pagesĐông Hô Nhiêt Suku PDFTháiSơnTrầnNo ratings yet

- Preserv 1 TF - 150, 300Document4 pagesPreserv 1 TF - 150, 300amitabhsrivastavaNo ratings yet

- Datasheet PDFDocument5 pagesDatasheet PDFgbaetaNo ratings yet

- Creusabro MDocument4 pagesCreusabro MhealgoseNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- Low Lift Safety Relief Valve: Model: S3S-A / S34-A / S36-A Without Lever S3S-Lr / S34-Lr / S36-Lr With LeverDocument1 pageLow Lift Safety Relief Valve: Model: S3S-A / S34-A / S36-A Without Lever S3S-Lr / S34-Lr / S36-Lr With LeverWidyaNo ratings yet

- Yoshitake AL-140Document2 pagesYoshitake AL-140WidyaNo ratings yet

- Intercrystalline CorrosionDocument24 pagesIntercrystalline Corrosionlu190765No ratings yet

- RS PRO Digital, Bench Power Supply, 217W, 3 Output, 0 32V 3 A, 5 ADocument5 pagesRS PRO Digital, Bench Power Supply, 217W, 3 Output, 0 32V 3 A, 5 AGuillaume FoubertNo ratings yet

- Essays of Mice and MenDocument7 pagesEssays of Mice and Menafibzfwdkaesyf100% (2)

- Escherichia Coli O157:H7 Issues and Ramifications: Executive SummaryDocument12 pagesEscherichia Coli O157:H7 Issues and Ramifications: Executive SummaryTinnysumardiNo ratings yet

- Forces and Moments Transmitted by Slender Members: ME231: Solid Mechanics-IDocument7 pagesForces and Moments Transmitted by Slender Members: ME231: Solid Mechanics-IRohan sharmaNo ratings yet

- Tenda Catalogo 2020 PDFDocument24 pagesTenda Catalogo 2020 PDFTenda Región AndinaNo ratings yet

- 2.SLTC Proposals For Bridges - Booklet 01.08.2022Document9 pages2.SLTC Proposals For Bridges - Booklet 01.08.2022harsha vardhanNo ratings yet

- Unit Homework Momentum Its Conservation Ans KeyDocument6 pagesUnit Homework Momentum Its Conservation Ans KeyKristyne Olicia100% (1)

- Nutritional Impact On Performance in Student-Athletes - Reality AnDocument36 pagesNutritional Impact On Performance in Student-Athletes - Reality AnAbbygail WasilNo ratings yet

- Sheet 2 of 2: Turn TurnDocument2 pagesSheet 2 of 2: Turn TurnJesùs AlfaroNo ratings yet

- Activity Sheet EnglishDocument17 pagesActivity Sheet EnglishELAINE ARCANGELNo ratings yet

- NNDL Assignment AnsDocument15 pagesNNDL Assignment AnsCS50 BootcampNo ratings yet

- The Said and The UnsaidDocument19 pagesThe Said and The UnsaidOzana BudauNo ratings yet

- Airports 14 EndDocument9 pagesAirports 14 EndMeedenken en Doen BVNo ratings yet

- Persuasive Speech OutlineDocument4 pagesPersuasive Speech Outlineapi-311196068No ratings yet

- Farm and Home Visits Are An Essential Part ofDocument16 pagesFarm and Home Visits Are An Essential Part ofChariss VerdidaNo ratings yet

- Works) : SABS 1200Document10 pagesWorks) : SABS 1200Palesa TshetlanyaneNo ratings yet

- Vibration Analysis of An Automotive Silencer For Reduced Incidence of FailureDocument6 pagesVibration Analysis of An Automotive Silencer For Reduced Incidence of FailureerpublicationNo ratings yet

- Marine Accident in IndonesiaDocument3 pagesMarine Accident in IndonesiananangNo ratings yet

- Hanson PDFDocument10 pagesHanson PDFAlberto Caceres ValenciaNo ratings yet