Professional Documents

Culture Documents

Pelton-And Crane Omniclave OCM Operators Manual PDF

Uploaded by

JuanCarlosRamirezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pelton-And Crane Omniclave OCM Operators Manual PDF

Uploaded by

JuanCarlosRamirezCopyright:

Available Formats

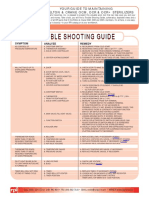

OMNICLAVE STERILIZER

MODELS OCM & OCR SOLID STATE

INSTALLATION

Remove screw holding Omniclave to shipping pallet. Discard shipping washers Thermometer Timer Reservoir Air Valve

and screws. Attach feet using screws supplied. Insert rubber tips. Plug line cord Pressure

into any wall or base receptacle. Ground unit to prevent shock by using three- Gauge Pilot

wire plug. Omniclave is designed for use only on alternating current. Fill reservoir Lights

to within 2-1/2” below opening of reservoir (approximately 2-1/2 quarts for OCM

and approximately 4-1/2 quarts for OCR). Use distilled or demineralized water to

eliminate deposits from collecting inside Omniclave. COUNTER SURFACE MUST

BE LEVEL TO INSURE PROPER OPERATION.

STEAM STERILIZING

FILL - Open safety door by exerting upward and inward pressure on the handle.

Slide bolt to right. Turn lower knob counter-clockwise to FILL. Allow water from

previously filled reservoir to enter chamber until water covers fill plate. Turn

lower knob to STERILIZE position which also stops flow of water.

Temperature

LOAD - Load chamber. See paragraph on preparation of materials and loading of Pressure

chamber. Close and lock door by moving bolt to left and pushing handle down. Safety Control

Door Latch

SET - Turn middle knob to point where indicator is pointing straight up. When Instructions Dry Heat

thermometer reaches desired temperature, rotate middle knob counter- Main Valve

Slide Interlock Reservoir

clockwise slowly until yellow light goes off. Once set, this step may be eliminated Drain

unless it is desired to sterilize at a different pressure and temperature. Turning

middle knob clockwise increases temperature and pressure. Turning knob

counter-clockwise decreases temperature and pressure. Set timer knob to

prescribed time period. See chart for proper temperature-time relationship. DRY HEAT STERILIZATION

VENT - When bell rings, rotate lower knob to VENT position. Allow all steam to be LOAD - Load instruments on trays without cloth or paper coverings. Only two trays

discharged. (CHAMBER PRESS ZERO) may be used. Insert auxiliary thermometer door. Use of dry-heat door is essential

for measuring proper dry-heat temperature.

DRY - Open door about 1/2 inch to permit thorough drying of contents (3-5

minutes). Leave lower knob in VENT position during drying and standby periods.

Omniclave will be ready for immediate reuse by repeating above steps.

SET - Turn lower knob to VENT position. Do not turn through FILL position. Depress

button beneath middle knob and turn knob clockwise to “DRY-STER” section until it

hits stop. This setting will give a temperature of approximately 350˚ (see Helpful

HELPFUL HINTS Hints). Turn counter-clockwise for a lower temperature. Set timer for 60 minutes as

1. Omniclave may be pre-heated for rapid starts by turning lower knob to VENT soon as thermometer reaches 320˚F.

and allowing chamber walls to be heated to temperature before use of Omniclave

is required - approximately 30 minutes before or first thing in the morning.

2. Always rotate upper knob (timer) past 10 minutes before setting time. VENT - When bell rings, remove door and unload. If no additional dry heat

sterilizing is desired, rotate middle knob into steam section. Button will pop out.

3. Always rotate lower knob (valve) counter-clockwise. Lower knob can then be turned to POWER OFF.

4. Standby periods - leave door closed and leave lower knob in VENT position.

5. Add water to reservoir only when lower knob is in VENT or POWER OFF

position. It is advisable to add water as needed to keep reservoir adequately

filled.

HELPFUL HINTS

6. At conclusion of all sterilizing for the day, turn lower knob to POWER OFF.

1. Middle knob cannot be turned to DRY STER section unless button is depressed.

7. As soon as possible after bell rings at end of sterilizing cycle, turn to VENT

Button cannot be depressed unless lower knob is in VENT position.

position. This practice will prevent the autoclave from boiling dry.

8. Never attempt to turn lower knob from STERILIZE to FILL or from VENT to 2. When middle knob is in DRY STER section, lower knob cannot be turned from

STERILIZE. Stops are incorporated to prevent knob from being turned in this VENT position.

manner. 3. The density of the load will determine the time required to reach sterilizing

9. Safety valve is set for 35 PSI. temperature of 320˚. Always distribute load loosely on trays.

39 Western Highway, West Nyack, NY 10994

877-561-0500

(SEE OTHER SIDE)

OMNICLAVE STERILIZER

PREPARATION OF MATERIALS

CARE AND MAINTENANCE

STEAM STERILIZATION

The safety valve should be activated every 2-3 months to insure that mineral

INSTRUMENTS - Clean thoroughly, wrap in muslin and place on trays. deposits or other obstructions are not holding the valve closed. Remove the safety

SYRINGES AND NEEDLES - Take syringe apart, wash thoroughly. Wrap each part valve lid from top of casing and manually operate valve while chamber is under

separately in muslin. Cover entire tray with double thickness muslin cover. pressure.

FABRICS AND DRESSINGS - Fold into convenient packets. Always fold loosely. Avoid When cleaning the sterilizer, be sure to include reservoir, tubing and chamber. All

making many layers and never roll. Never use canvas as a covering. Wrap in muslin parts will be cleaned by running a twenty minute cycle using Pelton & Crane’s

on tray. Do not overload chamber. Original Formula Omni-Cleaner. Do not use this cleaner with descaler while

instruments are being sterilized.

UTENSILS AND GLASSWARE - Lay all jars or vessels on their sides. Fabrics may be

sterilized in enamelware or glass jars; however, cover must fit very loosely, and Pelton’s Original Formula Omni-Cleaner is a mildly acidic concentrate used to clean

container turned on its side. and descale autoclaves. Regular weekly cleaning will promote increased sterilizer

life and trouble-free operation.

SOLUTIONS - Fill flask no more than two-thirds full. Close end of flask with cotton or

paper caps. Notice - Minerals, especially chlorides, are corrosive to any stainless steel. It is

strongly recommended that the autoclave be cleaned at least weekly with Pelton’s

Original Formula Omni-Cleaner. Tap water should not be used where the mineral

content of the water supply is high. The most desirable procedure to follow is to

use distilled or demineralized water. Even with distilled water, the autoclave should

LOADING THE CHAMBER be cleaned weekly. Minerals can be picked up from the load. When sterilizing saline

solutions, it is imperative that the autoclave be cleaned after each use. Unless

1. Never overload or crowd chamber cleaning instructions are followed, long life should not be expected.

2. Do not let material come in contact with door. Draining Reservoir - Reservoir may be drained by sliding Omni-Clave to edge of the

counter so that a container may be placed under the reservoir drain. Unscrew cap

3. Separate thick packs with loosely woven packs. in front of Omni-Clave and allow reservoir to drain. Replace and tighten drain cap

when draining is complete.

Cleaning Chamber

RECOMMENDED PERIODS OF EXPOSURE

STEAM HEAT DRY HEAT 1. Mix three ounces of Original Formula Omni-Cleaner per quart of water.

Material to be Sterilized PSI 15 20 25 ONLY 2. Drain reservoir and fill with cleaning solution. For extremely dirty sterilizers,

solution may be increased to four ounces per quart and may require two cleaning

vs. F˚ 250 260 267 320-355 cycles.

Time in Minutes C˚ 121 127 131 160-180 3. Run one twenty minute cycle in normal manner. Instruments should not be

Fabrics - Loosely woven - sterilized while cleaning sterilizer.

4. Drain cleaning solution from autoclave and reservoir. Rinse thoroughly. Fill

Do not sterilize fabrics, paper, or rubber on these temperatures.

Wrapped in Muslin 30 20 —

sterilizer again and run one rinse cycle for fifteen minutes.

(See ADA Accepted Dental Remedies, Sterilization Section)

Fabrics - Tightly woven 40 30 —

5. Drain rinse solution, remove tray rest and wipe out inside of boiler and tray rest.

MAXMIMUM EXPOSURE PERIOD - 60 MINUTES

Instruments - In Tray - 3 When cleaning chamber, do not damage thermistor located in upper section.

Muslin Cover 15 10 7 6. Add distilled or demineralized water and sterilizer is ready for use.

Instruments - Individually

Wrapped in Muslin 20 15 10 AIR VALVE - The air valve is factory set; however, if debris becomes lodged in valve

Syringes & Needles 15 10 7 it may be necessary to remove large knurled nut at left of opening in rear of

Omni-Clave and clean tip of air valve bellows and seat.

Drums - Loosely woven contents 30 20 —

CLEANING OUTSIDE - All outside parts are either chrome plated or stainless steel.

Drums - Tightly woven contents 40 30 — The chrome may be cleaned with either detergent and water or a non-abrasive

solvent such as glass wax or benzene. It should be polished only with a soft cloth or

Utensils - Loosely woven contents 30 20 10

chamois. DO NOT use metal or lacquer polish on the chrome parts.

Rubber Gloves - In muslin packs 15 — —

Ordinary deposits of dirt are quickly removed from the stainless steel with a deter-

Rubber Covers - In muslin packs 15 — — gent and water. In case of difficult deposits, the stainless may be easily cleaned

Brushes & Miscellaneous Articles - with Bon-Ami. In all cases, rub in direction of pattern or grain of the metal.

Ordinary steel wool or steel brushes should never be used on stainless steel. If for

Wrapped 15 — — any reason the surface becomes contaminated with discoloration, it can be cleaned

with a 5% solution of warm oxalic acid.

Solutions - 1000 cc Flasks 30 25 —

39 Western Highway, West Nyack, NY 10994

877-561-0500

You might also like

- AS3000 Service ManualDocument180 pagesAS3000 Service ManualchibakuNo ratings yet

- Mark 7 Arterion Injection System Training MaterialDocument22 pagesMark 7 Arterion Injection System Training MaterialSyamsul PutraNo ratings yet

- TD Isolette C2000 C2000eDocument212 pagesTD Isolette C2000 C2000eEco Aquiles100% (1)

- 9800 9900 Planned Maintenance Supplement - UM - 5755800-1EN-01 - 2Document14 pages9800 9900 Planned Maintenance Supplement - UM - 5755800-1EN-01 - 2Alexandra JanicNo ratings yet

- Definium 6000Document2,625 pagesDefinium 6000Полина Антонец100% (1)

- Innovet Select ManualDocument91 pagesInnovet Select ManualrosshazlettNo ratings yet

- Procedure Periodic Maint 9600 - SM - 00-880606-02 - CDocument40 pagesProcedure Periodic Maint 9600 - SM - 00-880606-02 - C979104025No ratings yet

- Manual Aloka SSD 1000Document2 pagesManual Aloka SSD 1000ANGEL33% (3)

- AP Standard Data All PDFDocument963 pagesAP Standard Data All PDFSiva Kumar100% (1)

- VS60 VS70 SM 5508160 100 r3 PDFDocument532 pagesVS60 VS70 SM 5508160 100 r3 PDFAnwar DheenNo ratings yet

- Mini Manual EV4543 Rev 6Document24 pagesMini Manual EV4543 Rev 6Nabaes BarraganNo ratings yet

- b40 - b20v1 Technical Reference ManualDocument229 pagesb40 - b20v1 Technical Reference ManualJuan Angel Cerda GuerraNo ratings yet

- Manual de Servicio Bili-TherapyDocument80 pagesManual de Servicio Bili-TherapyDiego DiazNo ratings yet

- Cavitron Bobcat Pro - Manual de Servicio (Ingles)Document33 pagesCavitron Bobcat Pro - Manual de Servicio (Ingles)Betancur AlejandroNo ratings yet

- OEC C-Arm UPS Replacement Kit InstructionsDocument14 pagesOEC C-Arm UPS Replacement Kit InstructionsBrian Hunter100% (1)

- Replacement Medical Batteries GuideDocument32 pagesReplacement Medical Batteries GuideSerdar KartalcıNo ratings yet

- Stryker InTouch Maintenance Manual Rev1 20-10-14 Part1Document145 pagesStryker InTouch Maintenance Manual Rev1 20-10-14 Part1BiomedicoHJMNo ratings yet

- Heinen & Löwenstein Leoni Baby Ventilator - Service ManualDocument16 pagesHeinen & Löwenstein Leoni Baby Ventilator - Service ManualAbraham Segovia MartinezNo ratings yet

- Uni-Vent Eagle 754 Portable Ventilator (Rev. 1.85S 06-07)Document104 pagesUni-Vent Eagle 754 Portable Ventilator (Rev. 1.85S 06-07)Marc LaBarberaNo ratings yet

- 7.1 FRU List: Item Part Number Description Q'ty CommentsDocument5 pages7.1 FRU List: Item Part Number Description Q'ty CommentsKamran ButtNo ratings yet

- CARESCAPE R860 Ventilator Clinical Accessories Guide - JB79010XXDocument16 pagesCARESCAPE R860 Ventilator Clinical Accessories Guide - JB79010XXelcio_sousaNo ratings yet

- Biomerieux BacTAlert 3D 60 - Service ManualDocument332 pagesBiomerieux BacTAlert 3D 60 - Service ManualLeandro Humbert100% (1)

- GE Carescape V100 Monitor - Service ManualDocument178 pagesGE Carescape V100 Monitor - Service ManualGIGNo ratings yet

- Toshiba Xario Model SSA 660A User ManualDocument268 pagesToshiba Xario Model SSA 660A User ManualImágenes Rosendo García100% (1)

- Manual Oti Scan 3000Document93 pagesManual Oti Scan 3000Natalia Lievano MendezNo ratings yet

- Olympus CX31 Biological Microscope Manual PDFDocument24 pagesOlympus CX31 Biological Microscope Manual PDFelnegro300No ratings yet

- Winter's Bracing Approach RevisitedDocument5 pagesWinter's Bracing Approach RevisitedJitendraNo ratings yet

- Atom Incu I Service Manual & Parts List P2Document54 pagesAtom Incu I Service Manual & Parts List P2Diego DiazNo ratings yet

- Autoclave Millennium BDocument285 pagesAutoclave Millennium BJose Tavares67% (3)

- JM 105 SW 120 Ifu 9510905 enDocument124 pagesJM 105 SW 120 Ifu 9510905 enАлекса МирковићNo ratings yet

- Olympus CX - 21 Manual de Usuario PDFDocument28 pagesOlympus CX - 21 Manual de Usuario PDFApocalipsis2072No ratings yet

- Spacelabs Monitor 91369 - Service ManualDocument150 pagesSpacelabs Monitor 91369 - Service ManualBrisa Rios100% (6)

- Giraffe Incubator Service ManualDocument206 pagesGiraffe Incubator Service ManualevanNo ratings yet

- Pelton Crane OCM OCR Sterilizer Service ManualDocument8 pagesPelton Crane OCM OCR Sterilizer Service ManualWilliam Hernandez100% (1)

- LIFEPAK 20 - 20e Service Manual PDFDocument408 pagesLIFEPAK 20 - 20e Service Manual PDFleopa7850% (2)

- Service Manual Im50 EdanDocument59 pagesService Manual Im50 EdanCfim S.A.SNo ratings yet

- User Manual 1692714 PDFDocument66 pagesUser Manual 1692714 PDFAnne Stephany ZambranoNo ratings yet

- Zimmer ATS-2000 Tourniquet System - Service Manual PDFDocument32 pagesZimmer ATS-2000 Tourniquet System - Service Manual PDFcarolus2009100% (2)

- Berchtold Operon B-810 Operating Table - Service ManualDocument120 pagesBerchtold Operon B-810 Operating Table - Service ManualJHON ALEXANDER QuinteroNo ratings yet

- AHTOIrrigation Pump Service ManualDocument24 pagesAHTOIrrigation Pump Service Manualchad100% (1)

- DCARE Series Dental Autoclave: Operation ManualDocument14 pagesDCARE Series Dental Autoclave: Operation ManualPolyclinique MahdiaNo ratings yet

- Service Manual OPX Mobilis Operating TableDocument68 pagesService Manual OPX Mobilis Operating Tableimansantoso23100% (1)

- Philips Heartstart XL Plus Defibrillator ManualDocument235 pagesPhilips Heartstart XL Plus Defibrillator ManualvikasNo ratings yet

- Smith Medical - Hotline Fluid Warmer - HL-90Document54 pagesSmith Medical - Hotline Fluid Warmer - HL-90Victor ȘchiopuNo ratings yet

- Matachana Miniclave 21e - User ManualDocument24 pagesMatachana Miniclave 21e - User Manualcarolus2009100% (1)

- Actalyke Mini Op Man D6500091JDocument29 pagesActalyke Mini Op Man D6500091Jjyoti ranjanNo ratings yet

- GE Vivid 7 - User Manual Rev 11Document858 pagesGE Vivid 7 - User Manual Rev 11Albert Risolo100% (1)

- Cardico306 - Operation Manual (ENG) - (1048)Document62 pagesCardico306 - Operation Manual (ENG) - (1048)Kuni KazeNo ratings yet

- Stryker Vision Monitor ManualDocument40 pagesStryker Vision Monitor ManualGeorge VlNo ratings yet

- Contec CMS800G - User Manual PDFDocument31 pagesContec CMS800G - User Manual PDFDea GarNo ratings yet

- HEYER VizOR 6 - Manual 1.0 EN PDFDocument128 pagesHEYER VizOR 6 - Manual 1.0 EN PDFkalandorka92No ratings yet

- Manual Servicio Oximetro Mindray Pm50Document35 pagesManual Servicio Oximetro Mindray Pm50Franz David Bastidas MayaNo ratings yet

- Phoenix Infant Radiant Warmer NWS 101Document2 pagesPhoenix Infant Radiant Warmer NWS 101Chandan ChinnaNo ratings yet

- Vio 3 ServiceDocument84 pagesVio 3 ServiceAngeloNo ratings yet

- 2492E en AGFA CR Plates and CassettesDocument54 pages2492E en AGFA CR Plates and CassettesKampus Atro Bali100% (1)

- Congelador Horizontal DometicDocument71 pagesCongelador Horizontal DometicMarcial Choquehuayta CcamaNo ratings yet

- 10L Evaporative Cooler Instruction ManualDocument10 pages10L Evaporative Cooler Instruction ManualNickNo ratings yet

- Cabinet Model Instructions PDFDocument6 pagesCabinet Model Instructions PDFMenders FieldmaintenancesquadronNo ratings yet

- Instructions Top Hatch With Humidity PumpDocument17 pagesInstructions Top Hatch With Humidity Pumppaul jezreel bondadNo ratings yet

- Steam Press Instruction Manual: Please Read This Manual Carefully Before Using and Keep It For Future ReferenceDocument77 pagesSteam Press Instruction Manual: Please Read This Manual Carefully Before Using and Keep It For Future ReferenceKishan SthankiyaNo ratings yet

- 1 PSP990manualpdfDocument18 pages1 PSP990manualpdfDino DrmicNo ratings yet

- Hoover Fridge HVBF5172Document2 pagesHoover Fridge HVBF5172colincharles682710No ratings yet

- Application of Gis in Electrical Distribution Network SystemDocument16 pagesApplication of Gis in Electrical Distribution Network SystemMelese Sefiw100% (1)

- Community HelpersDocument3 pagesCommunity Helpersapi-252790280100% (1)

- CHM131 Presentation - Oxidation of MetalsDocument11 pagesCHM131 Presentation - Oxidation of MetalsNazrul ShahNo ratings yet

- Top-Down DesignDocument18 pagesTop-Down DesignNguyễn Duy ThôngNo ratings yet

- Ce Brochure 20july16Document76 pagesCe Brochure 20july16Yogesh SharmaNo ratings yet

- Bài Tập Phần Project ManagementDocument11 pagesBài Tập Phần Project ManagementhunfgNo ratings yet

- Factory Test Report For OPzS 800 EED-20041724 2VDocument3 pagesFactory Test Report For OPzS 800 EED-20041724 2VmaherNo ratings yet

- Unit 1Document50 pagesUnit 1vaniphd3No ratings yet

- The Beggar's Opera by Gay, John, 1685-1732Document50 pagesThe Beggar's Opera by Gay, John, 1685-1732Gutenberg.orgNo ratings yet

- Manual PDFDocument9 pagesManual PDFRuth ResuelloNo ratings yet

- A New Aftercooler Is Used On Certain C9 Marine Engines (1063)Document3 pagesA New Aftercooler Is Used On Certain C9 Marine Engines (1063)TASHKEELNo ratings yet

- Mercury Poisoning Symptoms and TreatmentsDocument1 pageMercury Poisoning Symptoms and TreatmentsRakheeb BashaNo ratings yet

- Analects of A.T. Still-Nature Quotes-UnboundedDocument8 pagesAnalects of A.T. Still-Nature Quotes-UnboundedBruno OliveiraNo ratings yet

- Optical Fiber Communication Case Study on Material DispersionDocument5 pagesOptical Fiber Communication Case Study on Material DispersionAyush SharmaNo ratings yet

- Design and Analysis of Buck ConverterDocument18 pagesDesign and Analysis of Buck Converterk rajendraNo ratings yet

- Frequently Asked Questions About Ailunce HD1: Where Can Find HD1 Software & Firmware?Document5 pagesFrequently Asked Questions About Ailunce HD1: Where Can Find HD1 Software & Firmware?Eric Contra Color0% (1)

- FacebookH Cking 1 3 (SFILEDocument10 pagesFacebookH Cking 1 3 (SFILEFitra AkbarNo ratings yet

- DaburDocument3 pagesDaburchiru94No ratings yet

- 01 A Brief Introduction To Cloud ComputingDocument25 pages01 A Brief Introduction To Cloud ComputingfirasibraheemNo ratings yet

- Tugas Bahasa Inggris Analytical Exposition Text: Disusun Oleh: Nama:Hansel Hendrawan Effendy Kelas:XI IPA 1Document4 pagesTugas Bahasa Inggris Analytical Exposition Text: Disusun Oleh: Nama:Hansel Hendrawan Effendy Kelas:XI IPA 1Hansel HendrawanNo ratings yet

- 4) April 2023 Current AffairsDocument24 pages4) April 2023 Current AffairsPicturesque vibrant shadesNo ratings yet

- INSYS - EBW Serie EbookDocument4 pagesINSYS - EBW Serie EbookJorge_Andril_5370No ratings yet

- MNCs-consider-career-development-policyDocument2 pagesMNCs-consider-career-development-policySubhro MukherjeeNo ratings yet

- Addressable Fire Detection and Control Miniplex TranspondersDocument8 pagesAddressable Fire Detection and Control Miniplex TranspondersAfdhal SyahrullahNo ratings yet

- Assessmentof Safety Cultureand Maturityin Mining Environments Caseof Njuli QuarryDocument12 pagesAssessmentof Safety Cultureand Maturityin Mining Environments Caseof Njuli QuarryAbdurrohman AabNo ratings yet

- Concurrent AuditorDocument67 pagesConcurrent AuditorAjoydeep DasNo ratings yet

- Unit 2 - Chapter 04 - Working With FormsDocument24 pagesUnit 2 - Chapter 04 - Working With FormsSnr Berel ShepherdNo ratings yet

- Deviser TV Analyser S7000: Bagian 1: Fungsi AnalyzerDocument15 pagesDeviser TV Analyser S7000: Bagian 1: Fungsi AnalyzerAlexander WieseNo ratings yet