Professional Documents

Culture Documents

Section 9A - Instrumentation and Controls

Uploaded by

tomasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 9A - Instrumentation and Controls

Uploaded by

tomasCopyright:

Available Formats

Instrumentation and Controls

Instrumentation and Controls

Section 9A - Instrumentation and Controls

Table of Contents

Instrumentation................................................9A-2 Installation...............................................9A-11

Requirements and Recommendations.....9A-2 Dual Station (Helm) Cable Setup............9A-12

Important Installation Information.............9A-2 Cable Attachment Hardware...................9A-13

Accessory Connections............................9A-3 Cable Adjustment...................................9A-15

Dual Station Instrumentation....................9A-3 Motoviewer.....................................................9A-17

Engine Guardian System..........................9A-4 MotoViewer Service Tool........................9A-17

Lanyard Stop Switch Information..............9A-4 Saving Special Functions.......................9A-18

Boat Harness............................................9A-6 Clearing Fault History.............................9A-18

Instrumentation Harness Receptacle........9A-8 Setting Engine Location..........................9A-19

14‑Pin Engine—Analog Gauge Harness AutoSync................................................9A-20

..................................................................9A-9 Trim and Trailer Limit..............................9A-21

14‑Pin Engine Harness Connector.........9A-10 Configuring EZLink Gauges (TachLink)

Remote Control and Cables...........................9A-10 ................................................................9A-25

Requirements and Recommendations. . .9A-10 Other Special Functions.........................9A-26

9

A

90-863758070 APRIL 2008 Page 9A-1

Instrumentation and Controls

Lubricant, Sealant, Adhesives

Tube Ref No. Description Where Used Part No.

25 Liquid Neoprene Electrical connections 92- 25711 3

95 2-4-C with Teflon Cable guides and pivot points 92-802859A 1

Instrumentation

Requirements and Recommendations

IMPORTANT: This section includes information on Quicksilver's standard (non‑digital)

instrumentation and mechanical (cable‑actuated) remote controls. Refer to the Smart Craft

applications manual for information on Mercury's new digital instrumentation and remote

controls.

Mercury MerCruiser inboard and tow sports engines, designed to comply with the ABYC

Standards, use the four basic gauges shown below:

• Tachometer

• Oil pressure

• Water temperature

• Voltmeter (battery charge indicator)

An extensive array of Quicksilver gauges, instrumentation harnesses, extension

harnesses, and related accessories are available through Mercury Precision Parts to

satisfy your instrumentation needs. We recommend the use of Quicksilver instrumentation

because they are specifically designed for compatibility with our engines, and engineered

to the same high quality and performance standards. Refer to the Mercury Precision Parts

Accessories Guide for a complete list. Wiring diagrams of some of the basic instrumentation

configurations are provided at the end of this section.

Important Installation Information

Instrumentation should be installed in accordance with the instructions that accompany

them.

IMPORTANT: When designing and installing the instrumentation, adhere to the applicable

boating industry standards and regulations (NMMA, ABYC, SAE, USCG, EUs, RCD, ISO,

etc.) for the markets where the boat will be sold.

• Ensure that harnesses are routed to avoid getting pinched or chafed.

• Avoid routing the harness in an area where it could be damaged or short circuited later

in the assembly process, such as when a screw is inserted or a hole is drilled.

IMPORTANT: Harness receptacles can be damaged by overtightening clamps.

• The cannon plug connection on the extension harness (at engine and dash) must be

secured with a hose clamp to avoid a loose connection or water entry.

• Support harness every 46 cm (18 in.) using industry approved fasteners. (ABYC

Standard)

• Coat exposed connections on gauges with liquid neoprene to avoid corrosion.

Tube Ref No. Description Where Used Part No.

25 Liquid Neoprene Electrical connections 92- 25711 3

Page 9A-2 90-863758070 APRIL 2008

Instrumentation and Controls

Accessory Connections

! CAUTION

Failure to protect wiring with an appropriate fuse can damage the wiring and start a fire.

When installing any accesories, we recommend using a Mercury accessory kit. Always

use the appropriate fuse to protect wiring.

! CAUTION

Failure to protect wiring with an appropriate fuse can damage the wiring and start a fire.

When installing any accesories, we recommend using a Mercury accessory kit. Always

use the appropriate fuse to protect wiring.

IMPORTANT: The accessory wire in the 14‑pin harness will not support amperage in

excess of 15‑amps. For protection, the main power relay fuse may blow if an excess of

15‑amps is applied. Refer to the Mercury Precision Parts Accessories Guide for an optional

accessory power relay kit that will accommodate higher amperage draw.

A fused accessory panel with up to a 40‑amp current draw can be connected to the helm

harness. On dual station applications, the combined current draw for both stations must

not exceed 40 amps. If optional accessory power relay kits are installed, the combined

current draw for both stations must not exceed 40 amps per kit. Each helm harness may

support up to two accessory power relay kits. The boat manufacturer is responsible for

ensuring that the accessory connections are made in accordance with the industry

standards and regulations. See information under Industry Standards and

Regulations.

Dual Station Instrumentation

Instrumentation and harnesses are available through Mercury Precision Parts and

Accessories to accommodate dual station (helm) applications (see wiring diagram for

typical installation). When oil pressure and water temperature gauges are used at both

stations, dual station oil pressure and temperature senders must be installed on the engine

to obtain the proper gauge readings. Refer to theMercury Precision Parts and Accessories

Guide for part numbers.

15528

a - Typical coolant temperature sender

90-863758070 APRIL 2008 Page 9A-3

Instrumentation and Controls

15529

a - Typical oil pressure sender

Engine Guardian System

The Engine Guardian System monitors the critical sensors on the engine for any early

indications of problems. The system will respond to a problem by emitting a continuous

beep and/or reducing engine power in order to provide engine protection.

If Guardian System has been activated, reduce throttle speed. The horn will turn off when

throttle speed is within the allowable limit. Consult an authorized Mercury MerCruiser

dealer for assistance.

Lanyard Stop Switch Information

! WARNING

Avoid serious injury or death from deceleration forces resulting from accidental or

unintended stop switch activation. The boat operator should never leave the operator's

station without first disconnecting the stop switch lanyard from the operator.

RUN a

b

74608

a - Stop switch c - Clips to operator

b - Lanyard

The purpose of a lanyard stop switch is to turn off the engine when the operator moves

outside the operator's position (as in accidental ejection from the operator's position).

Accidental ejections, such as falling overboard, are more likely to occur in:

• low sided sport boats.

• bass boats.

• high‑performance boats.

Accidental ejections can also occur from:

• following poor operating practices.

• sitting on the seat or gunwale at planing speeds.

Page 9A-4 90-863758070 APRIL 2008

Instrumentation and Controls

• standing at planing speeds.

• operating the boat at planing speeds in shallow or obstacle infested waters.

• releasing your grip on the steering wheel while it is pulling in one direction.

• consuming alcohol or drugs.

• maneuvering the boat at high speeds.

Some remote control units are equipped with a lanyard stop switch. If your remote control

is not equipped with a lanyard stop switch, one can be installed on the dashboard or side

adjacent to the operator's position. The lanyard is a cord usually 1.2–1.5 m (4–5 ft.) long

when stretched out with an element on one end made to be inserted into the switch and a

snap on the other end for attaching to the operator. The lanyard is coiled to make it as short

as possible to minimize the likelihood of entanglement with nearby objects. It stretches to

minimize the likelihood of accidental activation should the operator choose to move around

in an area close to the normal operator's position. If it is desired to have a shorter lanyard,

wrap the lanyard around the operator's wrist or leg or tie a knot in the lanyard.

While activation of the lanyard stop switch will stop the engine immediately, the boat will

continue to coast for some distance depending upon the velocity and degree of any turn

at shut‑down. However, the boat will not complete a full circle. While the boat is coasting,

it can cause injury to anyone in the boat's path as seriously as the boat would when under

power.

We strongly recommend that other occupants be instructed on proper starting and

operating procedures should they be required to operate the engine in an emergency (e.g.

if the operator is ejected).

! WARNING

If the operator falls out of the boat, stop the engine immediately to reduce the possibility

of serious injury or death from being struck by the boat. Always properly connect the

operator to the stop switch using a lanyard.

Accidental or unintended activation of the switch during normal operation is also a

possibility. This could cause any, or all, of the following potentially hazardous situations:

• Occupants could be thrown forward due to unexpected loss of forward motion, a

particular concern for passengers in the front of the boat who could be ejected over the

bow and possibly struck by the gear case or propeller.

• Loss of power and directional control in heavy seas, strong current, or high winds.

• Loss of control when docking.

90-863758070 APRIL 2008 Page 9A-5

Instrumentation and Controls

Boat Harness

DRAWING

2

11

7 10 4

3

1

8

6

5

12340

9

1- 14‑pin Deutsch connector 7 - Warning horn

2- Key switch connector 8 - Accessory relay connection

3- Trim switch (outboard only) (15‑amp)

4- Neutral switch 9 - Gauge connector/CAN connector

5- Lanyard switch (sterndrive) or key for SmartCraft

switch + connection 10 - CAN P (1) with resistor cap

6 - Lanyard (outboard) or E Stop 11 - CAN V (3) with weather cap

connection

Page 9A-6 90-863758070 APRIL 2008

Instrumentation and Controls

DIAGRAM

A B A B

11 A B A B

10

ORG

GRN

DKBLU

WHT

RED

A B C D E F G H J K

BLK

ORG

GRN

PPL 9

GRY

YEL

WHT

DKBLU

PPL_WHT

A B C

BLK

RED

8

PPL

1

7

BRN

5

1

PPL_WHT

1

PPL

BLK

GRN BLK_YEL

1

A B C D E F G H J K L M N P

YEL_RED

GRY 6

BRN BLK BLK

1

YEL

GRN_WHT

1 BLU_WHT

DKBLU

PPL

WHT

YEL_RED

1

ORG

BLK_YEL

PPL 4

BLK YEL_RED

1

RED

RED

3

A B C

BLU_WHT

RED GRN_WHT

RED

A B C D E F

BLK

PPL_WHT

PPL 2

BLK_YEL

YEL_RED

12339

1- 14‑pin Deutsch connector 7 - Warning horn

2- Key switch connector 8 - Accessory relay connection

3- Trim switch (outboard only) (15‑amp)

4- Neutral switch 9 - Gauge connector

5- Lanyard switch (sterndrive) or key 10 - CAN P (1) with resistor cap

switch + connection 11 - CAN V (3) with weather cap

6 - Lanyard (outboard) or E Stop

connection

NOTE: Dual engines are treated as 2 singles in the same boat and are only connected by

a CAN 1 link harness.

NOTE: The lanyard stop switch (PPL and PPL/WHT wires) breaks power to the ECM or

ignition to stop the engine. The switch is normally closed until activated. Therefore the PPL

and PPL/WHT wires must be connected together if Lanyard Stop Switch is not used, or if

the E Stop Switch is used.

NOTE: E Stop Switch (BLK and BLK/YEL wires) connects ground to ECM to stop engine.

The switch is normally open, the circuit closes when switch is activated. Wires must be

separate unless connected through E Stop Switch.

90-863758070 APRIL 2008 Page 9A-7

Instrumentation and Controls

Instrumentation Harness Receptacle

IMPORTANT: Loose or corroded harness connectors are a common source for engine

malfunctions.

b

d c

12118

Typical 14‑pin DTS harness without Emissions Control

a - Engine harness connector d - DLC/depth transducer connector

b - Transmission harness connector e - Power harness connector/clean

c - Paddle wheel/tank level connector power with 5‑amp fuse (DTS and

PCM09 only)

b c d e 32503

a - Transom harness connector d - Power harness connector

b - Paddle wheel and tank level e - 14‑pin harness connector

connector

c - Diagnostic connector

Page 9A-8 90-863758070 APRIL 2008

Instrumentation and Controls

14‑Pin Engine—Analog Gauge Harness

8

2

9 3

10 4

5

1 6

7

12312

1- Connector to boat harness 6 - Oil

2- Trim 7 - Ground (‑)

3- Tach 8 - Can (+) or spare

4- Key on (+) 9 - Can (‑) or spare

5- Temp 10 - 12V (+)

BRN_WHT

2

GRY

3

PPL

4

DK_BLU

A B C D E F G H J K

WHT

BRN_WHT TAN

5

GRY

PPL

LTBLU

6

TAN

LTBLU

BLK BLK

7

RED

1 WHT

8

DK_BLU

9

RED

10

12318

1- Connector to boat harness 6 - Oil

2- Trim 7 - Ground (‑)

3- Tach 8 - Can (+) or spare

4- Key on (+) 9 - Can (‑) or spare

5- Temp 10 - 12V (+)

Accessory power can be provided up to 15 amps total; on purple wire (switched) and red

wire (continuous power.)

An accessory relay kit can be used for loads up to 40 amps. Refer to MerCruiser Parts and

Accessory Guide or MerCruiser Rigging Guide

90-863758070 APRIL 2008 Page 9A-9

Instrumentation and Controls

14‑Pin Engine Harness Connector

Mechanical 14‑Pin Connector Pin‑Out

Pin Wire Color Function

A PINK + 12 Volt

B BLACK Ground (‑)

C PURPLE Wake

D DK GREEN/YELLOW E‑Stop

E DK BLUE Analog oil pressure

F WHITE CAN 1+

G LT BLUE CAN 1‑

H Open Spare

J Open Spare

K ORANGE/WHITE Analog trim position

L BROWN/DK BLUE Audio warning horn

M GRAY/WHITE Tachometer/Link gauge

N YELLOW/BLACK Crank

P TAN Analog coolant temperature

Remote Control and Cables

Requirements and Recommendations

We recommend using Quicksilver remote controls, which have been specifically designed

for compatibility with our engines, and to the same high quality and performance standards.

An extensive array of Quicksilver remote controls and cables are available through the

Mercury Precision Parts Accessories Guide.

A single lever control (shift and throttle function in same lever) or a two‑lever control

(separate shift and throttle levers) can be used on single station applications. Two‑lever

controls are required on dual station (helm) applications.

• Remote control must provide a cable travel (at engine end).

Remote Control Cable Travel

Function Travel [with 6.8-9 kg (15-20 lb.) load applied]

Shift 70– 80 mm (2‑3/4–3‑1/8 in.)

Throttle 70–80 mm (2‑3/4–3‑1/8 in.)

• The remote control must be set up to retract the shift cable when going into FORWARD

gear on Velvet Drive 71C and 72C in‑line transmissions. On Velvet Drive 5000 and all

Hurth transmissions, shift cable actuation must be set up to achieve the desired

propeller rotation. See information in Section 2 - Transmission and Drive Line.

NOTICE

Incorrect positioning of the transmission shift lever can cause transmission failure. The

spring‑loaded poppet ball helps the transmission shift lever to stay in place. Do not

remove the poppet ball or spring.

• The remote control must be set up to fully extend the throttle cable for idle.

• A neutral start safety switch is included in the transmission. The switch in the remote

control should not be used.

Page 9A-10 90-863758070 APRIL 2008

Instrumentation and Controls

Installation

Install the remote and cables in accordance with the instructions which accompany them

and the instructions in the power package installation manual. To ensure minimal shift and

throttle effort, be sure to observe the following important information:

• Do not fasten the cables to the boat or any other objects within 92 cm (3 ft.) of the

remote control and engine attaching points.

• Keep bends to a minimum.

• Route cables so that they do not have less than an 20 cm (8 in.) radius at all bends.

• Ensure that the cables are not kinked or pinched.

• Lubricate the cable guides and pivot points with 2‑4‑C Marine Lubricant or motor oil.

a

a a

15532

a - Points to lubricate

Tube Ref No. Description Where Used Part No.

95 2-4-C with Teflon Cable guides and pivot points 92-802859A 1

• Tighten cable attaching nuts until they contact, then loosen 1/2 turn (until the washer

under the nut can be turned with your fingers). The attaching points must be free to

pivot.

90-863758070 APRIL 2008 Page 9A-11

Instrumentation and Controls

Dual Station (Helm) Cable Setup

The remote control cables can be connected in series or parallel. When connected in

series, the remote control cables from the secondary station are connected to the remote

control at the primary station. The primary station cables are then connected to the engine,

using the single cable attachment procedure. On some applications, it may be preferable

to connect both sets of cable directly to the engine, using a parallel connection. Mercury

MerCruiser inboard engines come equipped with the necessary hardware for making either

type of connection.

7670

Typical series cable installation

a - Shift cable

c

g

b

e

a

f

d

e

b 7675

Typical parallel cable installation

a- Cable end guide e - Cable barrel location

b- Locknut and washer f - Cable barrel stud

c- Spacer (fits over bushings) g - Cable end guide stud

d- Bushing

Page 9A-12 90-863758070 APRIL 2008

Instrumentation and Controls

Cable Attachment Hardware

INBOARD MODELS

Inboard models can accommodate forward or aft shift cable entry and single or dual cable

attachment. Hardware must be installed as shown.

d g

e c

b

e

h

a

f

b 7672

Typical single cable: forward entry

a- Cable end guide e - Cable barrel location

b- Locknut and washer f - Spacer (fits over stud)

c- Spacer (fits over bushings) g - Cable barrel stud

d- Bushings h - Cable end guide stud

a

f h

e b

d

g

e

c

b 7673

Typical single cable: rear entry

a- Cable end guide e- Cable barrel location

b- Locknut and washer f- Spacers (fits over stud)

c- Spacer (fits over bushings) g- Cable barrel stud

d- Bushings h- Cable end guide stud

90-863758070 APRIL 2008 Page 9A-13

Instrumentation and Controls

f

e b

c g

a

7674

b

Typical dual cable: forward entry

a- Cable end guides e - Cable barrel locations

b- Locknut and washer f - Cable barrel stud

c- Spacer (fits over stud) g - Cable end guide stud

d- Bushings

c

g

b

e

a

f

d

e

b 7675

Typical dual cable: rear entry

a- Cable end guides e - Cable barrel locations

b- Locknut and washer f - Cable barrel stud

c- Spacer (fits over stud) g - Cable end guide stud

d- Bushings

Page 9A-14 90-863758070 APRIL 2008

Instrumentation and Controls

TOW SPORTS MODELS

Tow sports models accommodate single cable forward entry only. Attaching hardware is

provided for a Morse cable.

c

b

a

15535

a - Throttle lever stud c - Locknut

b - Cable end

Cable Adjustment

NOTICE

Incorrect positioning of the transmission shift lever can cause transmission failure. The

spring‑loaded poppet ball helps the transmission shift lever to stay in place. Do not

remove the poppet ball or spring.

The shift and throttle cable must be installed and adjusted exactly as stated in the

installation instructions to achieve proper operation and avoid transmission problems. The

following items are of particular importance.

• The throttle cable must be adjusted to fully close the engine throttle plates when the

remote control is in the neutral, idle position. Failure to do this will result in a high idle,

erratic idle, or both.

• Transmission shift lever must be positioned fully in the FORWARD, NEUTRAL and

REVERSE selector positions (see Section 2 -- Propeller Rotation).

90-863758070 APRIL 2008 Page 9A-15

Instrumentation and Controls

• On Velvet Drive models, the shift lever must be in the designated detent position for

each gear.

a

e

b c

7665

Velvet Drive 5000 series (8 degree down angle shown, V‑drive similar)

a - Transmission shift lever d - Poppet ball must be centered in this

b - Poppet ball must be centered in detent hole for neutral position

this detent hole when left‑hand e - Install shift lever stud in this hole

propeller shaft rotation is desired when using quicksilver shift cables

c - Poppet ball must be centered in

this detent hole when right‑hand

propeller shaft rotation is desired

• On ZF Marine (Hurth) transmissions, the shift lever must be against the stops for

forward and reverse, and in the centered detent position for neutral.

a

8297

Typical ZF Marine (Hurth) transmission shown

a - Shift lever b - Shift cable bracket

Page 9A-16 90-863758070 APRIL 2008

Instrumentation and Controls

• Velvet Drive In‑line 71C and 72C transmissions must be operated with the shift lever

in the FORWARD gear selector position when propelling the boat forward. Damage to

transmission will result if it is operated in REVERSE (with the wrong rotation propeller)

under full power.

F - N - R

a

d

e

b F

R

c 7653

Velvet Drive 71C and 72C Transmission

a - Transmission shift lever d - Poppet ball must be centered in

b - Shift lever must be over this letter detent hole for each F‑N‑R position

when propelling boat FORWARD (FORWARD gear shown)

c - Shift lever must be over this letter e - Install shift lever stud in this hole, to

when propelling boat in REVERSE center poppet ball in FORWARD

and REVERSE detent holes

Motoviewer

MotoViewer Service Tool

At this time, the Computer Diagnostic System (CDS) software does not communicate with

products using the PCM 09 controller through the RS‑485 connection. However, all engine

and vessel set up, information, and fault codes are available using a new software package

from MotoTron called MotoViewer. All communications to MotoViewer travel over the

existing RS‑485 connection using the CDS laptop and SmartComms. You must install a

special SmartComms software update (CDS 8.2x) to the CDS laptop to use MotoTron

software. Contact your Product Integration Engineer (PIE) or Technical Account Manager

(TAM) for assistance.

To connect MotoViewer to an engine using PCM 09, obtain the following:

Description Part Number

System contact:

SPX Corporation

28635 Mound Rd.

Warren, MI 48092

SmartComms Interface Box or call:

USA ‑ 1‑800‑345‑2233

Canada ‑ 800‑345‑2233

Europe ‑ 49 6182 959 149

Australia ‑ (03) 9544‑6222

Diagnostic Tester Harness Assembly for PCM 555 models 84‑822560A13

NOTE: If the Diagnostic Tester Harness Assembly (84‑822560A13) is unavailable, you can

order harness 84‑822560T12 and adapter 84‑822560A5.

90-863758070 APRIL 2008 Page 9A-17

Instrumentation and Controls

Saving Special Functions

IMPORTANT: You must cycle the key switch after performing some special functions to

store the calibration values in the propulsion control module (PCM). If you are saving a

special function on a DTS engine, you must also place the remote control in reverse, wide

open throttle (RWOT).

Access special functions from the Special menu.

35003

Special functions that require a key cycle include:

• Set Engine Location

• Turn AutoSync Off

• Alter Trim Limit

• Alter Trailer Limit

• Configure Easy‑Link Gauges

To save a special function calibration to the PCM:

1. Perform the special function as described in this manual and the on‑screen prompts.

2. Turn the key switch to "OFF" to retain settings.

3. If the engine is equipped with DTS, turn the key switch to "OFF" and place the remote

control handle in reverse, wide‑open throttle (RWOT) to retain settings.

NOTE: The Cylinder Misfire, Output Device Control, Start, and Emergency Stop! features

are disabled.

Clearing Fault History

1. From the Special menu, select Clear Fault History.

35006

Page 9A-18 90-863758070 APRIL 2008

Instrumentation and Controls

2. Click OK to clear the fault history or Cancel to abort.

35007

Setting Engine Location

1. Turn the key switch to the "ON" position.

2. From the Special menu, select Set Engine Location.

35008

3. From the Transom Configuration drop‑down list, choose the configuration that matches

the vessel: Single, Twin, Triple, or Quad.

90-863758070 APRIL 2008 Page 9A-19

Instrumentation and Controls

4. Select the option that matches the engine location and click OK to save or Cancel to

abort. The default values of each selection are shown below.

35009

5. Turn the key switch to "OFF" to retain settings.

6. If the engine is equipped with DTS, turn the key switch to "OFF" and place the remote

control handle in reverse, wide‑open throttle (RWOT) to retain settings.

AutoSync

The AutoSync feature synchronizes RPM for engines in a multiple‑engine application.

When engine speed exceeds 900 RPM, or when the two ERC handles are within 5° (10%)

of each other, AutoSync engages for two seconds. In a multiple‑engine application, the

starboard engine is the master engine. The other engines then match the master engine

RPM. Use MotoViewer to disable or enable AutoSync.

1. Turn the key switch to the "ON" position.

Page 9A-20 90-863758070 APRIL 2008

Instrumentation and Controls

2. From the Special menu, select Turn AutoSync Off.

35010

3. Click OK to turn off AutoSync or Cancel to abort.

35011

4. Turn the key switch to "OFF" to retain settings.

5. If the engine is equipped with DTS, turn the key switch to "OFF" and place the remote

control handle in reverse, wide‑open throttle (RWOT) to retain settings.

Trim and Trailer Limit

ALTER TRAILER LIMIT

1. Turn the key switch to the "ON" position.

2. From the Special menu, select Alter Trailer Limit.

35012

90-863758070 APRIL 2008 Page 9A-21

Instrumentation and Controls

3. Trim the drive down using the electronic remote control (ERC) until the drive reaches

its full, down position and squeaks for 3 seconds. The PCM records this as the full,

down position.

4. Trailer the drive up using the ERC or other switch to the highest position possible

without contacting the vessel or damaging components. The PCM records this location

as the upper trailer limit (100%).

5. Trim the drive to any desired position.

6. From the Limit DFM window's drop‑down menu, select Current Position.

35013

7. Click Next to continue or Cancel to abort.

8. Turn the key switch to "OFF" to retain settings.

9. If the engine is equipped with DTS, turn the key switch to "OFF" and place the remote

control handle in reverse, wide‑open throttle (RWOT) to retain settings.

10. Click Finish to save the calibration settings or Cancel to abort.

35014

11. Set the trim limit as detailed below.

ALTER TRIM LIMIT

IMPORTANT: Always set the trailer limit before setting the trim limit.

1. Turn the key switch to the "ON" position.

Page 9A-22 90-863758070 APRIL 2008

Instrumentation and Controls

2. From the Special menu, select Alter Trim Limit.

35097

3. Trim the drive down using the electronic remote control (ERC), until the drive reaches

its full, down position and squeaks for 3 seconds. The PCM records this as the full,

down position.

4. Trim the drive up using the ERC or other switch to the desired position for the trim limit

while monitoring the trim position counts on MotoViewer. The PCM records this location

as the upper trim limit.

b 35091

a - Trim sensor data b - Trim position counts

IMPORTANT: Trim position counts must not exceed 180 counts past the original trim in

position. If you exceed this, it will fail the trim setting. You will have to start over. For

example, if your original trim in position count is 135, you cannot exceed 315 counts, or

the trailer setting will not calibrate correctly (135 + 180 = 315).

90-863758070 APRIL 2008 Page 9A-23

Instrumentation and Controls

5. Measure from anchor pin centers. The distance between both front and rear pins must

not exceed 55.25 cm (21.75 in.).

55.25 cm

(21.75 in.)

35087

6. Trim the drive to any desired position.

7. From the Limit DFM window's drop‑down menu, select Current Position.

8. Click Next to continue or Cancel to abort.

35014

9. Turn the key switch to "OFF" to retain settings.

10. If the engine is equipped with DTS, turn the key switch to "OFF" and place the remote

control handle in reverse, wide‑open throttle (RWOT) to retain settings.

11. Click Finish to save the calibration settings or Cancel to abort.

RESET TRAILER LIMIT

If you cannot reach your desired trailer limit, you may need to reset the system. To reset

the trailer limit after the PCM has accepted a limit calibration:

1. Turn the key switch to the "ON" position.

Page 9A-24 90-863758070 APRIL 2008

Instrumentation and Controls

2. From the Special menu, select Alter Trailer Limit.

35012

3. Trim the drive down using the ERC until the drive reaches its full, down position and

squeaks for 3 seconds. The PCM records this as the full, down position.

4. Using a remote switch on the trim pump, trailer the drive to the highest trailer position

desired.

5. From the helm (ERC) trim switch, press the trim up button for 3 seconds. The trim pump

will not operate at this time. The PCM records this location as the upper trailer limit

(100%).

6. Turn the key switch to "OFF" to retain settings.

7. If the engine is equipped with DTS, turn the key switch to "OFF" and place the remote

control handle in reverse, wide‑open throttle (RWOT) to retain settings.

Configuring EZLink Gauges (TachLink)

1. Turn the key switch to the "ON" position.

2. From the Special menu, select Configuring EZLink Gauges.

35028

3. In the pop‑up window, choose:

90-863758070 APRIL 2008 Page 9A-25

Instrumentation and Controls

• Yes to enable easy‑link to change the tachometer signal to a communication

signal and turn on an AGI or run SC100 gauges without an SC1000 series or

VesselView display.

• No to enable easy‑link to return the tachometer output lead to its normal

tachometer signal.

• Cancel to abort.

35029

4. Turn the key switch to "OFF" to retain settings.

5. If the engine is equipped with DTS, turn the key switch to "OFF" and place the remote

control handle in reverse, wide‑open throttle (RWOT) to retain settings.

Other Special Functions

The Cylinder Misfire Test, Output Device Control, Starting, and Emergency Stop features

are currently disabled for products equipped with PCM09.

Page 9A-26 90-863758070 APRIL 2008

You might also like

- tp99124 PDFDocument20 pagestp99124 PDFDieselkNo ratings yet

- Constant Running Hydraulic Pump (E12171, E12172) Installation Instructions 87039-3-ENDocument28 pagesConstant Running Hydraulic Pump (E12171, E12172) Installation Instructions 87039-3-ENPanificados MarielaNo ratings yet

- S DV99Document43 pagesS DV99beexoNo ratings yet

- Pioneer 1722Document61 pagesPioneer 1722telkonNo ratings yet

- KEWO AD Sereis AC Drive Operation Manual 1 - 3V20150921 PDFDocument193 pagesKEWO AD Sereis AC Drive Operation Manual 1 - 3V20150921 PDFUsman Shah100% (4)

- Hardware Manual: Simple Application ControllerDocument182 pagesHardware Manual: Simple Application ControllerYogyBear43No ratings yet

- Manual Markon NAC160 NAC190Document23 pagesManual Markon NAC160 NAC190Sajjad HussainNo ratings yet

- Grove Rt-880e-Service ManualDocument346 pagesGrove Rt-880e-Service Manualramiro serrano olliscoNo ratings yet

- Torsional Vibration Monitoring System - AWM M30-B2, DWG 1142957-2.0Document21 pagesTorsional Vibration Monitoring System - AWM M30-B2, DWG 1142957-2.0cengiz kutukcu100% (1)

- 200 Through To 275HP VeradoDocument833 pages200 Through To 275HP VeradoAbdoulah Abdoulah100% (24)

- Sharp Lc-43cuf8472es 43,55cug8461ks 43,49,55cug8462ks 49,55,65cug8052e 49,55,65cug8062e 49cug8362ks 49,55cuf8372es 49,55cuf8472es SMDocument90 pagesSharp Lc-43cuf8472es 43,55cug8461ks 43,49,55cug8462ks 49,55,65cug8052e 49,55,65cug8062e 49cug8362ks 49,55cuf8372es 49,55cuf8472es SMMarko MatićNo ratings yet

- Mercruiser Service Manual Merc-Marine 4 Cyl 1985 To 1989Document274 pagesMercruiser Service Manual Merc-Marine 4 Cyl 1985 To 1989Osw Galati100% (3)

- SV 9000 UserDocument81 pagesSV 9000 UservickersNo ratings yet

- CENTROID Fanuc Retrofit Installation ManualDocument80 pagesCENTROID Fanuc Retrofit Installation ManualsunhuynhNo ratings yet

- CENTROID Fanuc Retrofit Manual 4-21-14Document80 pagesCENTROID Fanuc Retrofit Manual 4-21-14samacda1000No ratings yet

- Invt Servo Drive ManualDocument296 pagesInvt Servo Drive ManualAbdul HameedNo ratings yet

- Acs800 17 0170 5b055c129 - UmDocument124 pagesAcs800 17 0170 5b055c129 - Ummarcelek80No ratings yet

- VFD F User Manual PDFDocument190 pagesVFD F User Manual PDFVictor Raziel ReaverNo ratings yet

- DA200 Series AC Servo Drive Operation Manual - V2.2Document300 pagesDA200 Series AC Servo Drive Operation Manual - V2.2Ivan CardenasNo ratings yet

- DA200 Operation Manual - V1.2 20171020Document286 pagesDA200 Operation Manual - V1.2 20171020wilson rodriguez100% (1)

- P50a202 SM Hitachi enDocument92 pagesP50a202 SM Hitachi enluis perdigonNo ratings yet

- LC 90le760xDocument77 pagesLC 90le760xبوند بوندNo ratings yet

- UENR87840001Document14 pagesUENR87840001Brian RomanoNo ratings yet

- Installation, Maintenance and Service Manual: Winch DivisionDocument27 pagesInstallation, Maintenance and Service Manual: Winch DivisionWesly ChavezNo ratings yet

- PA No. 0196: Service ManualDocument80 pagesPA No. 0196: Service ManualricardoNo ratings yet

- Q7999A Controlinks™ Universal Wiring Subbase: FeaturesDocument4 pagesQ7999A Controlinks™ Universal Wiring Subbase: FeaturesAndrey VegaNo ratings yet

- Console Remote Control Installation InstructionsDocument18 pagesConsole Remote Control Installation InstructionsJoswyn LopesNo ratings yet

- Solcon USA HRVS DN MV 10 13pt8kV Spec Guide 2011Document10 pagesSolcon USA HRVS DN MV 10 13pt8kV Spec Guide 2011harmlesdragonNo ratings yet

- Installation and Maintenance: R2 Droop R1 Q2 Q1 F2 F1 N WVDocument16 pagesInstallation and Maintenance: R2 Droop R1 Q2 Q1 F2 F1 N WVMuhamad Ilham Fatchu RezaNo ratings yet

- Hitachi P50H401 Service Manual PDFDocument123 pagesHitachi P50H401 Service Manual PDFCharles Albert67% (3)

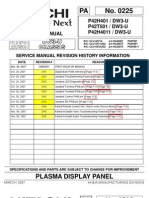

- PA No. 0224: Plasma Display PanelDocument123 pagesPA No. 0224: Plasma Display PanelJoe NovogradacNo ratings yet

- Precision Autocal 36585-Series Automatic Vna Calibrator: Reference ManualDocument18 pagesPrecision Autocal 36585-Series Automatic Vna Calibrator: Reference ManualenticoNo ratings yet

- P42A202Document84 pagesP42A202Rex Banks0% (2)

- Balmar Sup 0276 Rev ADocument24 pagesBalmar Sup 0276 Rev AartemNo ratings yet

- Edwards Rv8 Vacuum Pump ManualDocument58 pagesEdwards Rv8 Vacuum Pump Manualterryphi100% (1)

- A06B 6093 H101 β SERIES SERVO AMPLIFIER UNIT FANUC MANUAL PDFDocument74 pagesA06B 6093 H101 β SERIES SERVO AMPLIFIER UNIT FANUC MANUAL PDFNiteshNo ratings yet

- Altenador de Tensão PDFDocument51 pagesAltenador de Tensão PDFFrancisco MesquitaNo ratings yet

- P50a202 PDFDocument97 pagesP50a202 PDFUzziel MagueNo ratings yet

- 87xB ManualDocument142 pages87xB Manualtsehay asratNo ratings yet

- P42H401Document124 pagesP42H401jangel332045No ratings yet

- Hitachi 50HDT50Document128 pagesHitachi 50HDT50ricardo_MassisNo ratings yet

- Dual Display LCR Meter: ModelDocument142 pagesDual Display LCR Meter: ModelNurrochim IndraNo ratings yet

- AVR Features AGN023 - B PDFDocument6 pagesAVR Features AGN023 - B PDFAnonymous BBX2E87aHNo ratings yet

- RLC Svu006a E4 0414Document32 pagesRLC Svu006a E4 0414Emerson PenaforteNo ratings yet

- Mercury Service Manual 40-50-55-60-90Document566 pagesMercury Service Manual 40-50-55-60-90Will Gates86% (208)

- Edwards Pump Manual EdpDocument58 pagesEdwards Pump Manual EdpVoletiram BabuNo ratings yet

- Manual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveDocument100 pagesManual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveWallace Ferlim100% (6)

- Retrofit Nulec PDFDocument40 pagesRetrofit Nulec PDFNhat Nguyen VanNo ratings yet

- ProNet Plus User S Manual V1 03Document216 pagesProNet Plus User S Manual V1 03Cesar Sn Juan100% (1)

- Pioneer VSX-108Document39 pagesPioneer VSX-108Eduardo RossettoNo ratings yet

- Pioneer cmx-3000Document85 pagesPioneer cmx-3000videosonNo ratings yet

- LC 32L50m BK - LC 32L50m RD - LC 32L50m WH PDFDocument82 pagesLC 32L50m BK - LC 32L50m RD - LC 32L50m WH PDFSk Wong50% (2)

- Instruction Manual For AC Generators English: Downloaded From Manuals Search EngineDocument114 pagesInstruction Manual For AC Generators English: Downloaded From Manuals Search EngineEzaz ahamed ImranNo ratings yet

- Abs Wabco HabsDocument20 pagesAbs Wabco HabsBom_Jovi_681No ratings yet

- SDA2 High Performance Type V1.4bDocument201 pagesSDA2 High Performance Type V1.4bSamir TahaNo ratings yet

- Minarik Manual 250-0362Document64 pagesMinarik Manual 250-0362Amarillo PerezNo ratings yet

- BA-5 CDocument123 pagesBA-5 CLuis Arturo Leiva Monjaras100% (1)

- Stainlesslite Plus: Design, Installation & ServicingDocument19 pagesStainlesslite Plus: Design, Installation & ServicingtomasNo ratings yet

- Compressed Air Management SystemDocument11 pagesCompressed Air Management SystemtomasNo ratings yet

- Internal Compressor Controller: WWW - Hpccompressors.co - UkDocument8 pagesInternal Compressor Controller: WWW - Hpccompressors.co - UktomasNo ratings yet

- Owner'S Manual: 6BG-9-39-1E0.book 1 ページ 2013年4月29日 月曜日 午前9時41分Document112 pagesOwner'S Manual: 6BG-9-39-1E0.book 1 ページ 2013年4月29日 月曜日 午前9時41分tomasNo ratings yet

- Electrical: Section 2D - Wiring DiagramsDocument29 pagesElectrical: Section 2D - Wiring DiagramstomasNo ratings yet

- Servise Manual f40 YAMAHADocument285 pagesServise Manual f40 YAMAHAZauf Satrapicus100% (1)

- rqiljxudwlrq HQH Udo 6xemhfwvDocument7 pagesrqiljxudwlrq HQH Udo 6xemhfwvtomasNo ratings yet

- Owner's Manual: Outboard Motor Bf8ADocument88 pagesOwner's Manual: Outboard Motor Bf8Atomas100% (1)

- Hotpoint FDUD 43133 X Ultima Dishwasher PDFDocument20 pagesHotpoint FDUD 43133 X Ultima Dishwasher PDFtomasNo ratings yet

- Technical DataDocument1 pageTechnical DatatomasNo ratings yet

- WinCC Configuration Manual Vol 1Document320 pagesWinCC Configuration Manual Vol 1andtibNo ratings yet

- TestDocument1 pageTesttomasNo ratings yet

- WinCC Configuration Manual Vol 1Document320 pagesWinCC Configuration Manual Vol 1andtibNo ratings yet

- TurDocument1 pageTurtomasNo ratings yet

- Interpreting PLCDocument30 pagesInterpreting PLCpraveenNo ratings yet

- Book of Abstract CSSR 2017Document70 pagesBook of Abstract CSSR 2017Syǝd KhairiNo ratings yet

- List of QP - IASC SSCDocument6 pagesList of QP - IASC SSCMaruti PatilNo ratings yet

- Gas Compression Control SystemsDocument45 pagesGas Compression Control SystemsarielNo ratings yet

- Process Control System SpecificationDocument11 pagesProcess Control System Specificationabdkha8644100% (1)

- Dale 3100Document2 pagesDale 3100Flores Juan Carlos100% (1)

- ISA-RP77.60.05-2001 (R2007) - Fossil Fuel Power Plant Human-Machine Interface - Task AnalysisDocument24 pagesISA-RP77.60.05-2001 (R2007) - Fossil Fuel Power Plant Human-Machine Interface - Task Analysislionking1No ratings yet

- Paccar Multi-Plex 2010Document195 pagesPaccar Multi-Plex 2010Luis Tepezano100% (4)

- Robotics AutomationDocument55 pagesRobotics AutomationchandyNo ratings yet

- DeltaV System Overview - v12Document40 pagesDeltaV System Overview - v12Josue RomeroNo ratings yet

- Offline SPI TrainingDocument2 pagesOffline SPI Trainingsmartravi222No ratings yet

- Instrumentation and Control SystemDocument14 pagesInstrumentation and Control Systemkhushoo pandeyNo ratings yet

- National Apprenticeship Training Scheme (NATS) EstablishmentDocument2 pagesNational Apprenticeship Training Scheme (NATS) EstablishmentSunny SonawaneNo ratings yet

- Work Smarter. Work Faster.: Fluke 750 Series Documenting Process CalibratorsDocument12 pagesWork Smarter. Work Faster.: Fluke 750 Series Documenting Process CalibratorsFraz AhmadNo ratings yet

- Commissioning Plan For Pipeline Construction PDFDocument5 pagesCommissioning Plan For Pipeline Construction PDFservignafNo ratings yet

- Ml18331a073 PDFDocument184 pagesMl18331a073 PDFNathan BlockNo ratings yet

- Safety Measures For Employees PROJECT REPORT MBA HRDocument66 pagesSafety Measures For Employees PROJECT REPORT MBA HRBabasab Patil (Karrisatte)67% (3)

- Ethyl Acetate Kinetics 2011Document9 pagesEthyl Acetate Kinetics 2011Paola moreno100% (1)

- JERES-J-801 Control BuildingsDocument16 pagesJERES-J-801 Control BuildingsMahi IndraNo ratings yet

- Airshields C100Document6 pagesAirshields C100Marlon DeteraNo ratings yet

- Syllabus BISC 586 Biological Oceanographic Instrumentation 2018Document3 pagesSyllabus BISC 586 Biological Oceanographic Instrumentation 2018uscbiscgradNo ratings yet

- Typical ScheduleDocument14 pagesTypical ScheduleNitekNo ratings yet

- Torsional Vibration - Measurement and Analysis PDFDocument14 pagesTorsional Vibration - Measurement and Analysis PDFCrystal FrazierNo ratings yet

- Monitoring Solutions For Large Rotating Machines: P /L P P P M FDocument3 pagesMonitoring Solutions For Large Rotating Machines: P /L P P P M FJavier CasteloNo ratings yet

- CVDocument6 pagesCVvk yvNo ratings yet

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument5 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNo ratings yet

- Calibration of Displacer Level Transmitter Instrumentation ToolsDocument2 pagesCalibration of Displacer Level Transmitter Instrumentation Toolskali bangonNo ratings yet

- Intelligent InstrumentationDocument1 pageIntelligent InstrumentationAshish Arora25% (4)

- Myrkos BrochureDocument4 pagesMyrkos Brochurewinston11No ratings yet

- Advt - No. 29 - 2020Document6 pagesAdvt - No. 29 - 2020Rabbani ShaikNo ratings yet