Professional Documents

Culture Documents

Quality Control For Aluminium Alloy Ingots

Uploaded by

ankit kumar0 ratings0% found this document useful (0 votes)

128 views1 pageQC Chart for Al Alloy Ingots

Original Title

Quality Control for Aluminium Alloy Ingots

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentQC Chart for Al Alloy Ingots

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

128 views1 pageQuality Control For Aluminium Alloy Ingots

Uploaded by

ankit kumarQC Chart for Al Alloy Ingots

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

Quality Control for Aluminium Alloy Ingots

Incoming Material

1. Visual Check

2. Scraps of one quality are purchased & segregated separately

3. Scraps generally bought are baled wires, baled/loose sheets, turnings etc.

4. Spectrometer test for chemical composition.

5. Testing of Secondary ingots for quality.

6. Raw materials are kept in an enclosure free of moisture.

Inprocess Inspection { Most Important }

1. Temperature Control using pyrometer

2. Degassing & Fluxing

3. Grain refinement where required

4. Onlilne chemical Composition check {If NG, re-melting & grain refining}

Finished Goods

1. Every heat is marked with batch number, which ensure

complete back traceability upto raw material stage.

2. Every heat is re-tested for its chemical composition.

3. Each Batch test samples retention for 60 days.

4. Each batch is color coded after the ingots have cooled.

5. All manufactured goods are kept in an enclosure free of moisture.

Dispatch of Goods

1. Each batch of ingots is dispatched with its own test certificate.

2. If required strapping is done of 500Kg lots.

3. Each Batch test samples retention for 60 days.

You might also like

- Samples Inspection ReportDocument5 pagesSamples Inspection ReportArun GuptaNo ratings yet

- Melt Flow IndexDocument3 pagesMelt Flow Indexshubhendra mishraaNo ratings yet

- 2013-11-030M PT AHUDocument11 pages2013-11-030M PT AHUEdison WalitNo ratings yet

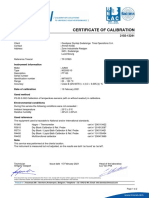

- Calibration CertificateDocument2 pagesCalibration CertificatemangengueyNo ratings yet

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Document5 pagesStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- Demagnatization Demagnatization Demagnatization Demagnatization Downhole Tools Downhole Tools Downhole Tools Downhole ToolsDocument10 pagesDemagnatization Demagnatization Demagnatization Demagnatization Downhole Tools Downhole Tools Downhole Tools Downhole ToolsMehdi SoltaniNo ratings yet

- Sample Report 3Document23 pagesSample Report 3raulNo ratings yet

- Magnetic Particle Testing ProcedureDocument18 pagesMagnetic Particle Testing ProcedureTĩnh Hồ TrungNo ratings yet

- LGT - WHD - QP03-Material Handling and Storage Control ProcedureDocument7 pagesLGT - WHD - QP03-Material Handling and Storage Control ProcedureGregorNo ratings yet

- Approval of MPI ProcedureDocument17 pagesApproval of MPI ProcedureimranNo ratings yet

- 05 MDCC Scogen DiffusersDocument1 page05 MDCC Scogen DiffusersGarimaSinghNo ratings yet

- Stumpp Schuele & Somappa Springs Pvt. LTD.: Internal Particulate Cleanliness Analysis ReportDocument1 pageStumpp Schuele & Somappa Springs Pvt. LTD.: Internal Particulate Cleanliness Analysis ReportRajkumar KantiwalNo ratings yet

- Checklist for WPS-PQR certification requirementsDocument1 pageChecklist for WPS-PQR certification requirementsssNo ratings yet

- High Performance Epoxy Coating SpecificationDocument12 pagesHigh Performance Epoxy Coating SpecificationDanny SeeNo ratings yet

- Visual Check List For Control Valve: Rock Payvand Sanat ArvandDocument1 pageVisual Check List For Control Valve: Rock Payvand Sanat Arvandarmin heidariNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- FINAL Inspection Report PO#KL-3448 PDFDocument21 pagesFINAL Inspection Report PO#KL-3448 PDFArslan HaiderNo ratings yet

- STD-InSP-0007 (Fitting Inspection Report)Document3 pagesSTD-InSP-0007 (Fitting Inspection Report)airbroomNo ratings yet

- Windals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportDocument2 pagesWindals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportMurtza ArzaiNo ratings yet

- Viscosity Measurement So Easy, Yet So Difficult by Janet L. Lane and Kenneth O. HendersonDocument7 pagesViscosity Measurement So Easy, Yet So Difficult by Janet L. Lane and Kenneth O. HendersonLuis VilchezNo ratings yet

- Attachment D (SAEP 316)Document1 pageAttachment D (SAEP 316)imtiazNo ratings yet

- Cutting Procedure GuideDocument3 pagesCutting Procedure Guiderial100% (1)

- Ocp For Oil Handling-ModiDocument3 pagesOcp For Oil Handling-ModiRaja RamNo ratings yet

- Title: Process Validation Report of Stress Relieving: 1. AbstractDocument3 pagesTitle: Process Validation Report of Stress Relieving: 1. AbstractCorrosion FactoryNo ratings yet

- Procedure For Liquid Penetrant ExaminationDocument12 pagesProcedure For Liquid Penetrant ExaminationShashank ParmarNo ratings yet

- LPT Written ProcedureDocument8 pagesLPT Written ProcedureManikantaSumanthNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Calibration Certificate for PT100 Temperature SensorDocument2 pagesCalibration Certificate for PT100 Temperature SensorSazzath HossainNo ratings yet

- PTDocument7 pagesPTMohdHuzairiRusliNo ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Inspection Report: CPP-RM-PO-0180Document4 pagesInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- Ioc ApiDocument3 pagesIoc ApiGobinderSinghSidhuNo ratings yet

- Duro Drive Installation PDFDocument14 pagesDuro Drive Installation PDFmagantiramuduNo ratings yet

- Metallography Kit PDFDocument3 pagesMetallography Kit PDFKashif Zaheer AlviNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- 18.in House Calibration ProcedureDocument1 page18.in House Calibration ProcedureSAKTHIVEL ANo ratings yet

- WIKA Calibration Certificate for Process CalibratorDocument3 pagesWIKA Calibration Certificate for Process CalibratorBalaji BobadeNo ratings yet

- EX - 12.7MM - PLATE 01 PAUT Report TrainingDocument4 pagesEX - 12.7MM - PLATE 01 PAUT Report Trainingagung akbarNo ratings yet

- Astm G85Document6 pagesAstm G85Abdul MunirNo ratings yet

- WI-INSP-11 R0 Work Instruction-Fastener InspDocument3 pagesWI-INSP-11 R0 Work Instruction-Fastener InspRakesh MishraNo ratings yet

- QMS Trackerv1Document2 pagesQMS Trackerv1ukhlaqNo ratings yet

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- Forging PresentationDocument17 pagesForging PresentationRakesh PuriNo ratings yet

- Gloss Meter Operating ProcedureDocument2 pagesGloss Meter Operating ProcedureM Jawad Ali100% (1)

- Patrol Inspection Report Check List UpdatedDocument2 pagesPatrol Inspection Report Check List Updatedanbusaravanan4No ratings yet

- Nabl Electrical TestingDocument104 pagesNabl Electrical Testingram27_rajiNo ratings yet

- INPEC Welding Consumables Handling ProcedureDocument5 pagesINPEC Welding Consumables Handling ProcedureAnilNo ratings yet

- Aban Constructions Pvt. LTD: Procedure For PaintingDocument4 pagesAban Constructions Pvt. LTD: Procedure For PaintingAkhilesh KumarNo ratings yet

- Ferrovanadium: Standard Specification ForDocument3 pagesFerrovanadium: Standard Specification ForIsabel Christina Gonzalez MoralesNo ratings yet

- 6063 Aluminum Alloy PropertiesDocument1 page6063 Aluminum Alloy Propertiestrieu vy phamNo ratings yet

- Material Inspection ReportDocument2 pagesMaterial Inspection ReportReza AchmalyadiNo ratings yet

- As 1816.1-2007 Metallic Materials - Brinell Hardness Test Test Method (ISO 6506-1-2005 MOD)Document3 pagesAs 1816.1-2007 Metallic Materials - Brinell Hardness Test Test Method (ISO 6506-1-2005 MOD)SAI Global - APACNo ratings yet

- Form 18 NABL 163Document2 pagesForm 18 NABL 163asr labNo ratings yet

- Determining Flash & Fire Points of BitumenDocument11 pagesDetermining Flash & Fire Points of BitumenWily RustamNo ratings yet

- Recycling WPS OfficeDocument23 pagesRecycling WPS Officeprakash sNo ratings yet

- Institutional Foodservice Facility - Ground Beef Patties: HACCP Plan ForDocument6 pagesInstitutional Foodservice Facility - Ground Beef Patties: HACCP Plan Forapi-287569720No ratings yet

- Organic Walnut Process FlowDocument2 pagesOrganic Walnut Process FlowЕвгения ЕвгенияNo ratings yet

- Evaluation of Sustainable Waste Management PracticesDocument4 pagesEvaluation of Sustainable Waste Management Practiceskeshav kumarNo ratings yet

- Internal Training on Record Keeping and Monitoring Critical Control Points at Platinium Marine ProductsDocument23 pagesInternal Training on Record Keeping and Monitoring Critical Control Points at Platinium Marine ProductsHas platiniumNo ratings yet

- Global Spice Summit & Excellence Awards - 2019Document248 pagesGlobal Spice Summit & Excellence Awards - 2019ankit kumarNo ratings yet

- Adversity to opportunity: How Tata Nirman utilizes LD slagDocument33 pagesAdversity to opportunity: How Tata Nirman utilizes LD slagJay ShuklaNo ratings yet

- JCB 2DXL Super Loader Versatility and PerformanceDocument2 pagesJCB 2DXL Super Loader Versatility and PerformanceHemmenth Raj JagannathanNo ratings yet

- DGFT Approved PsicDocument29 pagesDGFT Approved Psicankit kumar100% (1)

- Agra Urban Directory EstablishmentsDocument1,203 pagesAgra Urban Directory Establishmentssudhanshu kumarNo ratings yet

- Full Members List 2017Document6 pagesFull Members List 2017SurajPandey100% (1)

- PR - November 1, 2018Document47 pagesPR - November 1, 2018ankit kumarNo ratings yet

- Projects / Tenders: India's Project DatabaseDocument54 pagesProjects / Tenders: India's Project Databaseankit kumarNo ratings yet

- Aluminium production technology: Hall-Heroult process and raw materialsDocument16 pagesAluminium production technology: Hall-Heroult process and raw materialsSandeep MozumdarNo ratings yet

- ISMW August 20 PDFDocument255 pagesISMW August 20 PDFankit kumarNo ratings yet