Professional Documents

Culture Documents

Astm d2290 12 PDF

Astm d2290 12 PDF

Uploaded by

raja qammar0 ratings0% found this document useful (0 votes)

199 views36 pagesOriginal Title

kupdf.net_astm-d2290-12.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

199 views36 pagesAstm d2290 12 PDF

Astm d2290 12 PDF

Uploaded by

raja qammarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 36

‘Copyrighted mater icensedto Gaus Aramco. No furhar reproduction or bution permite

Printed / viewed by: (husasin drwish@scamco.com) @ 2019-1204

COPYRIGHT NOTICE & TERMS OF USE

‘This document is the copyright of the Publisher. All rights reserved.

The contract allowing you to use this document contains the following terms of use which must be

followed:-

(@) You may view and print a single copy of a document contained in the Subscription for reference

purposes only and only for internal purposes within the site on which such copies are made,

providing such copies are dated and destroyed after the reference usage, typically no more than 60

working days after use, subject to the exception described in clause (b) below. Such copies may not

be filed to form part of any hard copy reference collection.

(b) Where you have a specification or tender requirement to reproduce a document or portions of a

document as part ofits documentation for external submission in response to a tender, the necessary

ages of the document, including the whole document if required, may be reproduced and submitted

Provided @ copyright notice is included. You shall notify SAI Global of any such use. For internal and

archival purposes only, a paper copy may be attached to your documentation and shall be

considered a permanent part of that documentation.

(©) Under no circumstances are you permitted to reproduce all or part of any document for external

Use or for use in any other site or group of sites, except as set forth in (b) above.

(@ You may not remove any proprietary markings or electronic watermarks, including any

‘copyrights and trademarks.

(©) You may copy a maximum of 25% of the content of a document within the Subscription and

paste it to another document for internal use. The copied content in the new document must contain

‘a copyright notice "Copyright [name of publisher] Date where date is the date of copyrighted material

‘Such content is licensed for use only for the duration of the relevant Subscription,

() For ISO standards, the material is reproduced from ISO publications under International

Organization for Standardization (ISO) Copyright License number SAI GLOBAL/MCEA/2008. Not for

resale. No part of these ISO publications may be reproduced in any form, electronic retrieval system

or otherwise, except as allowed under the copyright law in the country of use, or with the prior written

consent of ISO (Case postale 6, 1211 Geneva 20, Switzerland, email: copyright@iso.org) or ISO's

Members.

# SAI GLOBAL

SAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UK

‘B. +44 (0) 1344 636300. Fax: +44 (0)1344 291194, E-mail: standards@saiglobal.com. wwwli.co.uk

SAI GLOBAL, 610 Winters Avenue, Paramus, NJ 07652, USA

‘@ 201-986-1131. Fax: 201-986-7886. E-mail: sales@ili-info.com. wwwili-info.com

SAI GLOBAL, 286 Sussex Street, Sydney NSW 2000, Australia

‘+61 2 8206 6060. Fax: +61 2 8208 6019, E-mail: sales@saiglobal.com, wawsaiglobal.com

Copyiahted matil icons o Saws Aemee, No ther reproduction or detrbuton permit

et cr soa ne ‘ ACSI S A MGSHT AMGEN ERT ORAS rnin tall aes te Sar sane

I Designation: B2290—08 2290

Standard Test Method for

Apparent-Hoop-Tensile Strength of Plastic or Reinforced

I Plastic Pipe-by Split-Disk Method’

This tnd seed unr to fet igation 02250 the name mms flloning the designation ind te year of

vigil gapton oi Ue eee of vison, de year fin evi. A nein prentze nes he en Teepe.

Superscript) ndeates an er change see he ast olson of capa

Ph suns aso pte for ra hy nc of the Deprimet of fone:

I 1. Scope Scope

1.1. This test method covers the determination of the comparative apparent tensile strength of most plastic produets utilizing a

I. split disk or ring segment test fixture, when tested under defined conditions of preteatment, temperature, humidity, and test

machine speed. This test method is applicable to reinforeed-thermoseting resin pipe regardless of fabrication method. This test

method also is applicable to extraded and molded thermoplastic pipe

“A Procedure A is used for reinforced-thermosetingeesin pige; Procedure Bis used for thermoplastic pipe of any size; Procedure

iif Tor thetnoplasOe pipe wiih nominal diameter of 44 i, 110 mum) and greats. Procedure D is used for

polyethylene pipe wth a nominal diameter of 1 in. (380 mm) and greater and preferably having wall thickness | in, GS mm).and

‘reat

1.2 The values stated in inch-pound units are to be regarded as standard, The values given in parentheses are mathematical

conversions to SI units that are provided fr information only and are not considered standard

+13 This standard does not purport to address all ofthe safety concerns, any, associated with ts us. It 18 the responsiblity

of the user of this standard 10 establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior 10 we.

2. Referenced Documents

2.1 ASTM Standards?

D618 Practice for Conditioning Plastics for Testing

11599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

4 Practices for Force Verification of Testing Machines

2 Sipimaer octet ated

1 3:1Grhe For Procedures ADB, and C.the tat specimen is loaded through the suggested selfaligning spit disk test fixture (Fig

1) which applies tensile sess to the testing. An apparent tensile strength rate than a true tensile strength is obtained in this test

because of a bending moment imposed during test at the split between the split dsk test fixture. This moment is induced by the

change in contour of the ring between the two disk sections as they separate. The tet finture is designed to minimize the eet

of this bending moment

3.2 For Procedure D, ring segment test specimen pairs are loaded into the suogested self-aligning test fixtures (Fig, 2) that ere

designed to apply direct tensile stress to the reduced areas of the ring seament (est specimens (Fig. 3) with minimal bending

moment,

4 Significance and Use

[41 Split disk tension-and ring seament tensile tests, properly interpreted, provide reasonably accurate information with regard

to the apparent tensile strenath of plastic pipe when employed under conditions approximating those uncer which the tests are

made.

“A Summary of Changs seston appears at the end ofthis standard

Ceprg@ ASTM itera 100 Bar er Oe, FO Bau TED en Crate FA 198EO.2I6. te et

‘Copyrighted mate cence to Saud Aramco. No further repteduton ar dtrbaton permite

Printed viewed by: (usssn dawieh@aramco com] @ 2013-12-08

lp 02200 - 12

FIG. 4 Tost Fixture: Typical

4.2 Fension-Ring tensile tests may provide data for research and development, engineering design, quality control, acceptance

or rejection under specifications, and for special purposes. The test cannot be considered significant for applications differing

‘widely from the load-time scale of the standard test

‘Nore I—ProcedureC has been used on polyethylene end polybutylene pipe fo produce results equivalent to Quick Burst results (Test Method D199)

for i, 10 8 lps,

5. Apparatus

5.1. Micrometers—Suitable botltype-ball anviltype micrometers, reading to at least 0.001 in., for measuring the width and

thickness of the test specimens.

5.2 Testing Machine—A universal testing machine ofthe constant-ate-of-eross-head-movement type and comprising essentially

the following:

5.2.1 Drive Mechanism—A drive mechanism for imparting to the crosshead 2 uniform controlled velocity with respect to the

‘base, this velocity to be regulated as specified in Section 9.

5.2.2 Load Indicator—A load-indicating mechanism capable of showing the total tensile load carried by the test specimen. This

‘mechanism shall be essentially fre from inertia lag atthe specified rate of testing and shall indicate the load with an accuracy of

61 % of the indicated value, The accuracy of the testing machine shall be verified in accordance with Method E4.

5.3 Procedue A, B. and C Test Fisture—The recommended test fixture Procedures A, B, and C is shown in Fig. 1. The width

othe split isk, for Procedure A and P shall be atleast 0. in, grester than the width of the specimen, The width ofthe

split Procedure C in. The supports for Folding the tension test ixtute shall be selaligning that s,

they shall be attached to the fixed and movable member ofthe test machine, respectively, in such a manner that they move freely

into alignment as soon as any load is applied, so that the direction of the applied pull is directly perpendicular to the split axis of

the test fixture,

5.4 Procedure D Test Fixiure—A tension test fixture for Procedure D is illustrated in Fig, 2. The suppors for holding the tension

test fixture shall be self-aligning thats, they shall be attached to the fixed and movable member ofthe test machine, respectively

n_such a manner that they move fieely into alignment as soon as any load is applied, so thatthe direction of the applied pull is

lirectly perpendicular to the split axis of the test fixture.

Nom 2-tn Fig. 2, the 2.00 (50.8 mm) wide by 5.0. (127 mm) long openines ae suitable fr ring seament specimens tha a 1,6 8 in 40.6

1p 457 in) wide ad fom 004.5 (28.40 (143 mm) wal this For rng sepmen specimen wll hikes ereaer than 43 in (1.3 mm)

‘pening size may be adjusted appropriately. Opening size shoul allow 0.10 (23 rm) minimum wich leranes on ish sie. ond ot fast 0.50 (12.7

‘on all hokness clearance, Rig seamen! st spee men securing pins 0,50 2.7 nn) diameter have heen aund sable, Teperng or roading the

‘id ofthe soouring ers pins facliates installation ino ts ing seaments specimens. See a, 2 and Fi, 3

5.5 Conaltioning Apparatus—Apparatus for maintaining the-stenderd-taboratory-atmoepheri-temperstte-of 23-6226 4734-6—

:68F ane S0- She ten ty for conditioning prior to test, ar-defined-in-Procedure-ofin accordance

Copyrighted metal ceased to Saus Aramco, No ‘utes reproduction of cetrbuton permite,

Penta | vwod by: usean darvich@aramoa com] @ 201%-12-04

Ay 02290 - 12

|e 00 ——en| |e— 209- oe]. [+ s 00: |

real

| re —___-| eam el fo

Fire dimension a fo ilustaon only, S28 Note 2

FIG. 2 Proceduro O Test Fixture

6. Test Specimen

6.1. Test specimen for Procedure A.shall be full-diameter,full-wall thickness rings cut from reinforced thermosetting resin pipe

H_ by any suitable means. Specimens shall conform to Fig. 24. Specimens shall have 2 minimum overall width of 0.90 in, and a

as

Copyihted meters cence to Saud Aveo, Nother reprodution ar stbution permite

Pintod/ viewed by: usssn éarvich@aremca.com) @ 2013-12-04

ly 02290 - 12

comet ee

we] ewe

ene 0.280 +1005

1» 0501 + 0005:0.000,

Rose +e0.005

nin, «i tr

Rhee dh Claris)

4a) Second reduced area Is optional.

1 FIG. 24 Reduced-Section Specimone for Procedure A”

_inimumavih inahe reduced section(s) of 0.55 in The nyuber of re

180° apart, Reduced areas must be centered relative tothe sien width to within

62 Test specimens for Procedure B shall be full-diameter, full-thickness rings cut from thermoplastic pipe, by any suitable

smeans, as shown in Fig. 35. The minimum width of the ting, IF per Fi. 35 shall be 0.50-in, The maximum width ofthe ring shal

bbe 200-in, Reduced areas shall be machined as shown in Fig, 33 and shall be located atthe point of minimum wall thickness and

a 180° thereto except when the test is used for specialized purposes (see Note 23). The reduced aeas ofthe specimen must be

free of machining marks ané uniform in eross section.

3s shal ne oF 1p, Ivo, they must be located

‘03 ia

‘Nore 3—The reduced sections for the extuded or molded specimens can be loeated at any points onthe periphery ofthe specimen provided they are

180° spar, thats, even a the weld or “Ini line of the specimen Hf he eng of tess ares fs being investigated.

Nott 4—Spovimen ring width 1, poe Fig, 35 muy be varied be«veen 0.50 in. and 2.00 in, For larger diameter pipes wis ercater wall thickness,

specimen sabliy during testing is improved wien rng width i greater

63 Test specimens for Procedure C shall be cut normal to the pipe axis with parallel sides, The width of the specimen shall be

nominally 1.75 in. 102.00 in, Two areas, one of which includes the minimum pipe wall thickness and the other 180 deg opposite,

shall be wet sanded to remove cutting marks; care must be exercised to retain the rectangular eross-seetion of the prepared areas,

GA Test samples for Procedure D shall be fll rings cut normal to the pipe axis with parallel sides. The width of ring samples

shall Be nominally 2.00 6 0. in, (50.8 6 §.1 mm). One ring sample is used to produce ring sezment Specimens 1 and 2.

4

Copyihted mater oense to Sau Aramco, No ure rapraticton or tution permite,

Printed! vewod by: [hussain dawish@acamoo com] @ 2013-12-06

fly v2280 - 12

—-| fos

sath | 0.125 +1-0.005in,

{|= | 0250+7-0.005in

sLoT

— R0.125 +4. 0.005 in

FIG. a§ Reduced Section Specimen for Procedure 8

6.4.1 Ring sample wall thickness shall be measured, and the minimum wall thickness and the point 180 degrees opposite shall

be located and marked.

6.4.2 Ring segment Specimens 1 and 2 shall be eut ftom the ring sample. Ring segment specimen cuts shall be made not less

than 2.0 in (50 mm) above and below the minimum wall thickness point (Specimen 1) and the point 180 degrees opposite

‘Specimen 2). Ring sezment Specimens | and 2 shall be machined smooth on both sides to width W (1.70 6 0.10 in (43.2 6 2.5

‘mm)) per Fis. 3. Care shall be taken to retain a rectangular cross seetion. After machining, Specimens | and 2 shall be conditioned

per Practice DOI8 Procedure A at 73.4 6 3.6°F (23 6 2°C) and SO 6 50 pereentwithout regard to relative humidity for not less

than 24 b,

6.43 After conditioning per 6.4.2, reduced cross section areas shall be machined into rine segment Specimens | and 2, and two

holes for cross pins shall be drilled parallel to and centered equidistant above and below the Specimen | and 2 reduced eross

seotion areas. See Fig. 3.

6.5 Number of Test Specimens—The number of ring test speetmenssamples is optional; however, a minimum of five specimens

issamples are needed to obtain a reliable average for-e-sample-test value. For quality control purposes, the sample quantity shall

be one, and in cases of disagreement, five specimens-ting samples shall be tested and the average test value shall be recorded.

7. Conditioni

7.1. Conaltoning~Condition the Procedure A, B. and C test specimens at 73.4 6 3.6°F (23 6 2°C) and 50 6 5 940 % relative

humidity for not less than 24 h prior to test in accordance with Procedure A of MethodsPractice D618-forthose-estewhere Afler

reparation per 6.4 through 6.4.3is-req

s2eelateehemity-eondn Procedure D tet specinens at 72.4 6 36°F 23 6 2°C) without regard to relative humidity _

{for not less than 24 h in accordance dure A of Practice DGIS prior fo test specimen

7.2 Test Conditions Conduct Procedure A, B, and C tests in tho standard laboratory atmosphere of 73.4 6 3.6°F (23 6 2°C)

and 50 6 54%10% relative humidity, unless otherwise specified in the test methods or in this specification. In-cases-of-

Hoe ELBF-{GHC}-and-62- relative humidity Conduct Procedure B,C, and D tests in a

laboratory atmosphere of 73.4 6 3.6°F (23 6 2°C) without regard to relative humidity, unless otherwise specified in the test

methods or in this specification,

73 Specisl-In case of disagreement, special conditioning procedures may be used by agreement between cooperating

laboratories

8))Speed of Testing

Covwighled material Soensed to Sauti Aramco, No rer reproduction or esivton perme,

Pred viawed by: hussain cervieh@arrnco cam) @ 2012-12-04

Aly p2290 - 12

9. Procedure

9.1. Procedure std 3 1:

9.1.1 Measure the minimum width and thickness of the reduced area(s) to the nearest 0.001 in., using a suitable micrometer

9.1.2 Mount the specimen on the lubricated periphery of the test fixture, with the reduced area(s) centered 2.0 6 0.2 in. away

from the split in the disk,

9.1.3 Run the test at a constant speed between 0.1 and 0.5 ipatinJmin (2.5 and 12.7 mm)

9.1.4 Record the maximum load carried by the specimen during the test.

9.2 Procedure B:

9.2.1 Measure the width and thickness of the reduced sections to the nearest 0.001 in, using 2 ball-type micrometer or a dial

indicator. Record the width and thickness of both cross-sectional ares.

9.2.2 Mount the test specimen on the split disk test fixture with the reduced sections at the split inthe fixture, Align the test

specimen on the split disk specimen holder so that itis centered on the line joining the points of attachment of the fixture to the

test machine.

9.2.3 Set the speed control at 0.50 in/imin and start the test machine.

9.24 Record the yield and ultimate loads carried by the specimen during the test.

93 Procedure C:

9.3.1 Measure the width and thickness of the prepared areas tothe nearest 0.001 in. using a ball anvil type micrometer. Record

the width and thickness of both prepared cross-sectional areas.

93.2. Mount the test specimen on the outside of the spit disk fixture with the prepared and measured arvas located atthe split

Jn the fixture. Align the test specimen on the test fixture so that it is centered on the line joining the points of attachment fo the

test machine

93.3 Set the speed control at 0.50 inJ/min and start the machine,

9.34 Record the yield poiat and maximum load caztied by the specimen during the test.

9.3.5 Record the crosshead separation required to rupture the test specimen.

9.4 Procedure D:

9.4.1 To the nearest 0,001 in. (0.025 mm), measure the width and thickness ofthe reduced cross section areas using a ball anvil

type micrometer, Record the width and thickness of Specimen | and Specimen 2 reduced eros section areas

9.4.2 Install Specimens 1 and ? into the Procedure D test fixture. See Fig. 2. Specimens shall be located equidistant to the test

fixture pull centerline

9.4.3 Sef the speed control at 0.50 in/min and start the machine,

9.4.4 Record the yield point and maximum load carried by the specimens during the test

Record the crosshead separation required to rupture the test specimen,

10. Caleutation

10.1 Calculate the apparent tensile strength (at yield or rupture, or both) of the specimen using the appropriate equation and

report to three significant figures.

1 SPsidd, Procedure A! o

bai 2

~Procedue B.C, or Dt 2

5 fe

08 bid by

apparent yield or ultimate tensile stress of the specimen, psi (or MP2),

‘maximum or breaking load, or both, Ibf (or N),

minimum cross-sectional area of the two measurements, db, in,

thickness at minimum area, in.

thickness at reduced or test sections, in.,

width at minimum area, in. and

width of reduced or test sections, in

10.2 For each series of tests, calculate the arithmetic mean of all values obtained to thee significant figures and report as the™

average value” for the particular property in question.

10.3 Calculate the standard deviation as follows and report to two significant figures:

sy Get :

2.

‘Copyignted material Scenced to Saud Arc, No futher reptodcton er dstbuton permite

Printed viewed by: usean éawish@aramco com] @ 2013-12-04

ly 02290 - 12

FIG. 48 Fnture for Preparation of Reduced-Section Ring Tensile Spocimens

‘Copyiantod mete Sconce to Saud Aveo, Nother reprodvson a atbuton permite

Patod viewed by: Pusssn darvish@eramco.com) @ 2013-12-06

ly 02290 - 12

FIG. 67 Instrument for Moasuring Ring Tensile Specimens.

ssf aa ®

a

Sr cumnaiaar onan

x 2 Stewie

ek ere

i gee cette er asain

I. Report

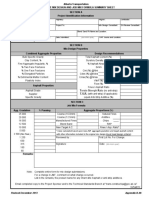

L11 The report shall include the following:

11.1.1 Complete identification of the material tested, including type, source, manufacturer’s code number, forn

dimensions, and previous history

11.12 Fabrication procedure,

11.13 Type specimen used,

IILL4 Thickness and width of test cross-sectional area,

11.1.5 Conditioning, procedure used,

11.1.6 Atmospheric conditions in test room,

I1LLT Number of specimens tested,

11.1.8 Rate of erosshead motion,

11.1.9 Apparent composite tensile suength of each specimen, and average calculated and reported fo thee significant figures,

11.1.10 Standard deviation (estimated) of the sample calculated and reported ro two significant figures,

H1.1.11 Average resin content weight percent of specimens when applicable, and

1.1.12 Date of est

principal

12, Precision and Bias

12.1 Procedures A, B_and C—Because of the nature of the materials and a lack of a wide data base on a variety of applicable

composites, no definitive statement can be made at this time concerning precision and bias of this test method-methos,

12.2. Precision Procedure D?—-. Based on a laboratory round-robin conducted of 30-in and 20-in high density polyethylene pipe,

the precision (one standard deviation) of the Procedure D method for high density polyethylene pipe is as follows:

12.2.1 Within-laboratory, 6 2% (repeatability)

122. Between-laboratory, 6 9% (reproducibility

2 Suoning dan tae ben fled at ASTM Inormona Headgares 2nd mayo died ly equetion eset Repo KALE. 1052, Conet ASTON Customer

‘Series nicest one

‘Copyrighted material icersed to Sau Aramco. No father eprodullon ot dstibution permite

ted / viewed by: ussain.éawish@ormco.coml @ 2019-12-04

hy v2290- 12

12:3. Bias Procedure D—Data obtained using the Procedure D method are believed to be reliable, since accepted techniques of

analysis are used. However, because no referee method is available, no bias statement can be made,

13, Keywords

15.1 apparent tensile strength; hoop tensile strength; plastic pipe; ring segment method; split-disk method

SUMMARY OF CHANGES

Committee F17 has identified the location of selected changes to this standard since the last issue (D2290-08)

that may impact the use of this standard,

‘(Changed title and added Procedure D,

“AS intomatona takes no positon espctng te vay of ay patel Nghe auto cnnecton wi yt manent

in us sandr Usa Bic Strcars re oxroaly aces tal detarrinaton othe voy of ony mus patent hs and ee

oF itingeen of sen ih re erly ha on responsi

This andar ssc reson tay tne bye eset tena coke a must be vious eer fu yrs a

teatro eer eapprovedewiharaun Your commande reine arr vison os etanard oo aeaona nara

‘nd shoud be adresse fo ASTM Iferitoral Headqvates. Your cormens wil receive crt consdeatan a2 mesg fe

‘espana erica conten wich you ay atl you Fel at your comments hve he ested 3a Resi you shut

‘make your ews incyn tno ASTM Commie a0 Stanad, ate acess sre Dow

‘he stands copyrighted by ASTI Intemssonel, 109 Bor Harter Dive, PO Sox C709, est Conahaocan, PA 19420286,

United Stes. navel rpats (gle or mule copes) of Bis sandar may be obtained by cntalag ASTI tthe above

atures or af 6108523885 (phone), 6108520585 (fax) or sendceehaim ry femal)” oF eu foe ASTM whale

fanwnasinorg Permission ngs photocopy the stanca may aGo be secred hom Be AST Webs viniastn or!

copraceTy,

CCopyrihted matraliconsed to Sausi Aramco. No futher reproduction o dstbuton permite,

Pate | iwod by: [Rustan dawsh@arsrca com) @ 2019-1204

COPYRIGHT NOTICE & TERMS OF USE

This document is the copyright of the Publisher. All rights reserved,

The contract allowing you to use this document contains the following terms of use which must be

followed:

(@)__ You may view and print a single copy of a document contained in the Subscription for reference

purposes only and only for internal purposes within the site on which such copies are made,

providing such copies are dated and destroyed after the reference usage, typically no more than 60

working days after use, subject to the exception described in clause (b) below. Such copies may not

be filed to form part of any hard copy reference collection.

(b) Where you have a specification or tender requirement to reproduce a document or portions of a

document as part of its documentation for external submission in response to a tender, the necessary

ages of the document, including the whole document if required, may be reproduced and submitted

provided a copyright notice is included. You shall notify SAI Global of any such use. For internal and

archival purposes only, a paper copy may be attached to your documentation and shall be

considered a permanent part of that documentation.

(©) Under no circumstances are you permitted to reproduce all or part of any document for external

Use or for use in any other site or group of sites, except as set forth in (b) above,

(@) You may not remove any proprietary markings or electronic watermarks, including any

‘copyrights and trademarks.

(e) You may copy a maximum of 25% of the content of a document within the Subscription and

paste it to another document for internal use. The copied content in the new document must contain

‘a copyright notice "Copyright iname of publisher] Date where date is the date of copyrighted material

Such content is licensed for use only for the duration of the relevant Subscription.

() For ISO standards, the material is reproduced from ISO publications under International

Organization for Standardization (ISO) Copyright License number SAI GLOBALIMCEA/2008. Not for

resale. No part of these ISO publications may be reproduced in any form, electronic retrieval system

or otherwise, except as allowed under the copyright law in the country of use, or with the prior written

consent of ISO (Case postale 56, 1211 Geneva 20, Switzerland, email: copyright@iso.org) or ISO's

Members.

® SAI GLOBAL

SAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UK

+44 (0)1344 636300. Fax: +44 (0)1344 291194. E-mail: standards@saiglobal.com. wwnwall.co.uk

SAI GLOBAL, 610 Winters Avenue, Paramus, NJ 07652, USA

‘ 201-986-1131, Fax; 201-986-7886. E-mail: sales@ili-info.com. www.il-info.com

SAI GLOBAL, 286 Sussex Street, Sydney NSW 2000, Australia

‘B: +61 2 8206 6060. Fax: +61 2 8206 6019. E-mail: sales@saiglobal.com. www-saiglobal.com

oprah nate onset Sous Aa, Na ute ert o tion parte.

SSE NSS icre SELON ena Na ren ois

Designation:D636-08-Designation: D638 ~ 10

1

Standard Test Method for

Tensile Properties of Plastics’

“This sad fase der the ted design DAN: te ruber iseely flowing he dseatin indies te yer of

nl caption orn cs fen or fe vera. Are pis as Bey age

Spenein eo tases a eto chnge sae te tree or ego.

“smn has eo pred for a nif the Dermat of Defi,

1. Seope*

1.1 This test method covers the determination of the tensile properties of unreinforced and reinforced plastics in the form of

standard dumbbell-shaped test specimens when tested under defined conditions of pretreatment, femperature, humidity, and testing

machine speed.

1.2 This test method can be usel for testing materials of any thickness up to 14 mm (0.55 in.). However, for testing specimens

in the form of thin sheeting, including film less than 1,0 ram (0.04 in) in thickness, Test Methods D882 is the preferred test method,

‘Materials with a thickness greater than 14 mm (0.55 in.) must be reduced by machining,

1.3 This test method includes the option of determining Poisson's ratio at room temperature,

[Nom } This test method and [SO 527-1 ae tehically equivalent

[Non 2—Mhis tex meio is no iaended o over precise physic procedures. I eecognted thatthe constant ae of eroshead! movernent typeof

‘ext leaves much to be desiced from theorstial siandoin, that wide diferences may exist between rate of crosshead movement and rate ot stain

between gage marks. onthe specimen, and thot te testing speeds specified disguise important eet characteristic of materials in he pasties, Further,

itis realized tha variations inthe thicknesses f test specimens, which are permite by these procedares, produce valations inthe sufacevolume ras

of such specimens, and that these vations may influence the test results. Hence, whete dictly comparable sls are desired, ll samples should be

of equal iicknese. Speci adiinal tet should be used where more peice physical dat are need

Note 3—This est method may be used for esting phenolic molded resin o laminated materials. However, whare hese

insulation, such materials shoul be lsted in seconde with Test Methads D229 and Tet Method DGS.

‘None t—For tne properties of rexisatix composites enforced with rented continous or disconineous high modulus >20-GPa (>3.0% 10

‘psi bers, tests stall be made in accordance with Tet Method D2039/D3035M

1.4 ‘Test data obtained by this test method are relevant and appropriate for use in engineering design,

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

16 This standard does uot purport to address all ofthe safety concems, if any, associated with is use. It isthe responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitacions prior to use

vals reused 3 lesa

2. Referenced Documents

2.1 ASTM Standards?

D229 Test Methods for Rigid Sheet and Plate Materials Used for Electrical Insulation

D412 Test Methods for Vulcanized Rubber and Thermoplastic ElastomersTension

D618 Practice for Conditioning Plastics for Testing

D651 Method of Test for Tensile Strength of Molded Electrical I

D882. Test Method for Tensile Properties of Thin Plastic Sheeting

D883. Terminology Relating to Plastics

1822 Test Method for Tensile-Impact Energy to Break Plastics and Electrical Insulating Materials

1D3039/D3039M Test Method for Tensile Properties of Polymer Matrix Composite Materials

D4000 Classification System for Specifying Plastic Materials

D066 Classification System for Nylon Injection and Extrusion Materials (PA)

S947 Test Methods for Physical Dimensions of Solid Plasties Specimens

Ed Practices for Force Verification of Testing Machines

lating Material

“Te mo ne stn of AST Commie 20 oP ae dnt psy fect D010 on Neil Pipi.

arenaiieappned ip 38-day 20 Ocal appen nabs -torpenecater syne nab He DOF ONSSIOREE HR

Do Siretisr oferty ann is he a os span a La ean gaara ss teat ot some 1

$ermeee Art sande te AST nes swat comet ATTA Cota Sone radon Foal Bt PAT Sa

scien lors rere end Dosme Sanyo nh AST nb

Winans peated ens of Be Sti sana fenced om ewe op

A Summa

epigh © AST nin, 10 mor Ds, PO Bac OE, Coban, PADRE, Ud Ses

1

of Changes setion appoars atthe end of thls standard

Copyrighted mates eens fo Saudi Aramco, No further renrduston ar dabution permite,

Pntad/viewod by: Puseain darwiah@aromoa com) @ 2019-12.04

Ay vee -10

[E83 Practice for Verification and Classification of Extensometer Systems

E132 Test Method for Poisson's Ratio at Room Temperature

[E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 1S Standard:*

180 527-1 Determination of Tensile Properties

3, Terminology

3.1. Definicions—Definitions of terms applying t this test method appear in Terminology D883 and Annex A2,

4, Significance and Use

4.1. This test method is designed to produce tensile property data for the control and specification of plastic materials. These data

are also useful for qualitative characterization and for research and development. For many materials, there may be a specification

that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the

specification, Therefore, itis advisable to refer to that material specification before using this test method. Table 1 in Classification

1D4000 lists the ASTM materials standards that currently exist.

4.2 ‘Tensile properties may vary with specimen preparation and with speed and environment of testing, Consequently, where

precise comparative results are desired, these factors must be carefully controled.

42.1 Its realized that a material cannot be tested without also testing the method of preparation ofthat material. Hence, when

‘comparative tests of materials per se are desired, the greatest care must be exercised to ensufe that all samples are prepared in

exactly the same way, unless the testis to include the effects of sample preparation. Similarly, for referee purposes or comparisons

within any given series of specimens, care must be taken to secure the maximum degree of uniformity in details of preparation,

treatment, and handling.

43 Tensile properties may provide useful data for plastics engineering design purposes. However, because of the high degree

of sensitivity exhibited by many plastics to rate of straining and environmental conditions, data obtained by this test method cannot

be considered valid for applications involving Ioad-time scales or environments widely different from those of this test method

In cases of such dissimilarity, no reliable estimation of the limit of usefulness can be made for most plastics. This sensitivity to

rate of straining and environment necessitates testing over a broad load-time scale (Including impact and creep) and range of

environmental conditions if tensile properties are to sufice for engineering design purposes,

Nore 5—Since the existence ofa tue elastic Limit in plastics (asin many other organic materials and in many metas is debetable, the proprity of

applying the term “sastie modus” ints quowed, generally accepted definition w describe the "stihess” or “igi” ofa plastic has been seicusly

‘questioned, The exact sressstain characteristics of plastic materials are highly dependent on such factors as ate of aplication of stress, temperature,

Brevious history of specimen, etc. However, stess-sinin enrves for plastics, determined as desribed in this tet metho, almost always show a linear

Feglon at low steses, and a sah tne draw eangent this portion othe curve peas calelation ofan elastic modus ofthe usally defines yp.

Such a constants useil i its abitary nature and dependence on time, temperature, and similar actors are realized

5. Apparatus

S.L Testing Mackine—A testing machine of the constant-rate-of-crosshead-movement type and comprising essentially the

following:

S.L.1 Fived Member—A fixed or essentially stationary member carrying one grip.

5.1.2 Movable Meniber—A movable member carrying a second grip.

5.13 Grips~Grips for holding the test specimen between the fixed member and the movable member of the testing machine

can be either the fixed or solf-aligning type.

5.1.3.1 Fixed grips are rigidly attached tothe fixed and movable members of the testing machine. When this type of grip is used

extreme care should be taken to ensure thatthe test specimen is inserted and clamped so that the long axis of the test specimen

coincides with the direction of pull through the center line of the grip assembly.

5.1.32 Self-aligning grips are attached to the fixed and movable members of the testing machine in sucl a manner that they

will move freely into alignment as soon as any load is applied so that the long axis of the test specimen will coincide with the

rpessne inp ts

fnimn hewge Se

ibe yee ao

lope 23s wes tauazabt

lipPe 20 amon! 2180 pss IS

lore = 2) wd BM ade OND

lore 2) 834 ose ats

Ube 20 aa

‘TABLE 10 Tenelie Break Elongation, for Nine Laboratories, Six

Materials

Tae Vaias Expressed n Peco Ua

etoral speed 7

inna Average 6) *B a

ie aes mse

ire oS mk2tmag B07

lore = m2? 4S B18

tbee = mth? awa

ues = 2g Bs?)

a SI

13.1.1 Tables 5-10 are based on a round-robin test conducted by the polyolefin subcommittee in 1988, involving eight

polyethylene materials tested in ten laboratories. For each material, all samples were molded at one source, but the individual

specimens were prepared at the laboratories that tested them. Fach test result was the average of five individual determinations.

Each laboratory obtained three test results for each material. Data from some laboratories could not be used for various reasons,

and this is noted in each table,

13.12 Table 11 is based on a repeatability study involving a single laboratory. The two materials used were unfilled

polypropylene types. Measurements were performed by a single technician on a single day. Each test result is an individual

‘determination. Testing was run using two Type B-I extensometers for transverse and axial measurements at a test speed of 5

movavi

* Supponing dca er avi from ASTM Heedguartus Regs! RRID2-115 forth 1984 oud ob aed RRDDO1N70 er he 1988 owed ai

TABLE 6 Tensile Stress at Veld, 10% ps, for Elght Laboratories,

Three Materials

a

Bascrione ‘m0 Onaa O46) 00 Oase

CCahdose cette bunyare «S01 Oss Ozer Ose Bee

eve saa’ coer 0917 0100 _ ane?

Covytistted material Senseo Saud zameo, No ther rexoduckon or trio permite

Pinto! viewed by: (hussain davish@ramco com] @ 2013-12-06

fly ve38- 10

TABLE 7 Elongation at Viok

%s, for Eight Laboratorioe, Throe

Materials

Mean So a

Gao aatate bua —~«S OTe 75

Some 489021 bss 089156

Poiprepyen am 0% 56 tzr_ 15

‘TABLE 11 Poisson's Ratio Repeatability Data for One Laboratory

‘and Two Polypropylene Materials

eee ‘eis Ena as Ba Fao

Pe Lena Squares aon ose

PP #2 Ghee 009 oes

Pr re tase Squares avio ce

13.1.3 In Tables 2-11, for the materials indicated,

ind for test results that derived from testing five specimens:

13.13.1 5, is the within-laboratory standard deviation of the average; J, =2.83 S,. (See 13.1.3: for application of /,)

13.132 Sp is the between-laboratory standard deviation of the average’ Ig = 2.83 Sp. (See 13.1:34 for application of Ip.)

13.133 Repeatability—in comparing two test results for the same material, obtained by the same operator using the same

equipment on the same day, those test results should be judged not equivalent if they differ by more than the /, value for that

‘material and conditio

13.134 Repraducibiligr—In comparing two test results for the same material, obtained by different operators using different

equipment on different days, those test results should be judged not equivalent if chey differ by more than the Jy value for that

‘material and condition. (This applies between different Inborstories or between different equipment within the same laboratory.)

13.1.3.5 Any judgment in accordance with 13.1.3.3 and 13.1.3.4 will have an approximate 95 % (0.95) probability of being

13.1.36 Other formulations may give somewhat different results

13.137 For further information on the methodology used in this section, see Practice E691.

1313.8 The precision of this test method is very dependent upon the uniformity of specimen preparation, standard practices

for which are covered in other documents.

13.2 Bias—There are no recognized standards on which to base an estimate of bias for this test method.

1. Keywords

14.1 modulus of elasticity: percent elongation; plastics; tensile properties: tensile strength

ANNEXES

(Mandatory Information)

Al. TOE COMPENSATION

Al.1 In a typical stress-srain curve (Fig. Al.1) there is a toe region, AC, that does not represent a property of the material

I isan artifact caused by a takeup of slack and alignment or seating of the specimen. In order to obtain correct values of such

parameters as modulus, strain, and offset yield point, this zntifact must be compensated for to give the comected zero point on the

strain of extension axis,

AL2 In the case of a material exhibiting a region of Hookean (linear) behavior (Fig. Al.1), a continuation of the near (CD)

region of the curve is constructed through the zero-stress axis, This intersection (B) is the corrected zero-steain point from which

all extensions or strains must be measured, including the yield offset (BE), if applicable. The elastic modulus can be determined

by dividing the stress at any point along the line CD (or its extension) by the sirain atthe same point (measured from Point B,

efined as zero-strain).

AL3_ In the case of a material that does not exhibit any linear reaion (Fig. A1.2), the same kind of toe correction of the

zero-strain point can be made by constructing @ tangent to the maximum slope atthe inflection point (H). Ths is extended to

intersect the stain axis at Point B’, the corrected zero-strin point. Using Point B’ as zero strain, the stress at any point (G') on

the curve can be divided by the strain at that point co obtain a secant modulus (slope of Line 8’ G’). For those materials with no

linear egion, any attempt to use the tangent through the inflection point as a basis for determination of an offset yield point may

result in unacceptable error.

Copyrighted mate lcensed to Saud Ararnco, No uth rao a stibton permed,

Prine iewod by: sean darwih@aramoa con) @ 2013-12-04

ily De38-10

Nowe 1—Some chart recondrs plot she avittor image ofthis graph

FIG. A1.1 Material with Hookean Region

Noms 1-Some chat reotders plot she minor image of this graph

FIG. Al.2 torial with No Hookoan Region

A2. DEFINITIONS OF TERMS AND SYMBOLS RELATING TO TENSION TESTING OF PLASTICS

2.1. elastic limit—the greatest stress which a material is capable of sustaining without an

complete release of the stress. It is expressed in force per unit area, usually megapascals (pounds-force per square inch),

Nom A2.{-—Measured vues of proportional init and elastic limit vary greatly with te sensivityand accuracy ofthe esting equipment, ecceicity

the sale 10 whieh the sresestain diagram is ploted, and other factors. Consequently, those values are usually repleced by yield sengh

A2.2_elongation—the increase in length produced in the gage length of the test specimen by a tensile load. Ic is expressed in

units of fength, usually millimetres (inches). (Also known as exvension.)

[Nowe A2.2—Elongation and strain values ar valid only in esses where wiformiy of specimen behavior within the gaze length is present, nthe ease

of materials exhtng necking phenomena, sch values ate ony of guaative wit after aalamentof yield poi. This due to inability fo ensure

thot necking will encompass the ent: length between the gage marks pir to speci

en flare.

B

permanent stra

Copyrighted metal Seansed to Saud Aramco, No futher reproduction dst permite,

Prnted viewed by: [hussain darwish@aamco.coml @ 2019+12.08

Aly 0638 - 10

of the specimen over which strain or change in length is determined

A23- gage length—the original length of that port

A24 modulus of elasticig—the ratio of stress (nominal) to corresponding strain below the proportional limit of a material. Tt

is expressed in force per unit area, usually megapascals (pounds-force per square inch). (Also known as elaste madilus of Young's

modulus).

Nowe A2.3—The sess-sitan eons of many plates do not conform to Hooke’s law throughout the elastic range but deviate therefiom even at

stresses well below dhe elastic init Pr seh mveials the slope ofthe tangent othe stress-strain curve at aw sues is uselly taken asthe modulus

of elasticity, Since the existence ofa trae proportional iit in plastics is dsbatable, the propriety of applying the tenn “medals of easy” o describe

‘ho snes or rigidity fa plastic has Been seriously questioned. The exact stress-strain etareteritis of plastic maternal are very dependent on such

factors rate of sessing, temperature, previous specimen history, te. However, such a vale fe useful 4s arity nate and dependence an ine,

temperature, and other fects ae relied.

A25_ necking—the localized reduction in eross section which may occur in a material under tensile stess.

A26_ offset yield strengtl—the stress at which the strain exceeds by a specified amount (the offset) an extension of the initial

proportional portion of the stress-strain curve. [tis expressed in force per unit area, usually megapascals (pounds-force per square

inch),

[Nove A2.4—This measurement I useful fer mates whose sss-sain curve ia the ylld range is of gradual cuvatre, The offet yield strength

can be derived from a sress-tain curve as follows Fig. AZ)

‘On the suai axis ay of OM equal tothe spaced ost

Dray OA tangent othe fia srsight-line ponion of the stress-strain euve

“Through Af draw a ine MN paralll co OA tnd nea the intersection of MN with theses stein curve.

‘Tho rss atte pint of imorsectn +i he “ost yield strong” The spaced valve of the offect must be stated asa percent ofthe orignal gage

Tong in conjuction withthe strength value. Example: 0.1% offe yield stength =.» MPa (por yield strength 30.1% offset. MPa (si

A2.7 percent elongation—the elongation of a test specimen expressed as a percent of the gage length,

A28. percent elongation at break and yield:

A28.1 percent elongation at break—the percent elongation at the moment of rupture of the test specimen.

A2.8.2 percent elongation at yield—the percent elongation at the moment the yield point (A222) is attained in the test

specimen.

29. percent reduction of area (nominal)—the difference betwen the original cross-sectional area measured at che point of

rupture after breaking and after all retraction has ceased, expressed as a percent of the original area

A210. percent reduction of area (true)—the difference between the original cross-sectional area ofthe test specimen and the

tinimum cross-sectional area within the gage boundaries prevailing t the moment of rupture, expressed as a percentage of the

‘original area.

A2.I1 Poisson's Ratio—The absolute value of the ratio of transverse strain to the corresponding axial strain resulting from

uniformly distributed axial stess below the proportional limit of the material

A212 proportional limit—the greatest stress which a material is capable of sustaining without any deviation from

proportionality of stress to strain (Hooke’s law). It is expressed in force per unit area, usually megapascals (pounds-foree per

square inch).

Stress

// OM? Specifies

Offset

Stroin

FIG. A2.1 Offset Veld Strength

4

Copyrighted msec icensed fo Saudi Aramco, No fer reproduction otstrbution permite,

Pred | viewed by: fusean darvish@aremco com] @ 2079-12-04

ly Des8-10

A213 rate of loadinng—the change in tensile load carried by the specimen per unit time. It is expressed in force per unit time,

usually newtons (pounds-force) per minute. The initial rate of loading can be calculated from the initial slope of the load versus

time diagram,

A2.14 rate of straining—the change in tensile strain per unit ime. It is expressed either as strain per unit time, usually metres

per metre (inches per inch) per minute, or percent elongation per unit time, usually percent efongation per minute. The initial rate

of straining can be calculated from the initial slope of the tensile strain versus time diagram.

Nom A25~The iil rat of sining i synonymous with the rate of crosshead movement divided by the inal distance between erssheads only

ina machine with constant rae of eossbead moverent and when the specimen has a uiform orginel cross section, des net “neck dove,” and dacs

‘01 sip i the jaws,

A215 rate of stressing (nominal)—the change in tensile stress (nominal) per unit time. It is expressed in force per unit area

pet unit time, usually megapascals (pounds-force per square inch) per minute, The initial rate of stressing can be caleulated from

the initial slope of the teasile stess (nominal) versus time diagram,

Nowe A2.6—Tho inal rte of sessing as determined inthis manner has only limited physical significance. It does, howeve, roughly describe the

average rte at which the initial sess (nominal erred by the test specimen is applied. Ite afeted by the elcty and ow characteris ofthe

materials being texed. AC the yield point, de rae of suesing (ve) may eoatiaue 1 have a pesive value ifthe cross-sectional area is decreasing.

A216 secant modulus—te ratio of stess (nominal) to corresponding strain at any specified point on the stress-strain curve

Ikis expressed in force per unit area, usually megnpascals (pounds-foree per square inch), and reported together with the specified

[Nore A2.?—This messuroment is usually employed in place of modulus of elasticity inthe case of materials whose ses.strain diagram does not

‘demonstte proportionality of sites co sain,

A2.17sirain—the ratio of the elongation to the gage length ofthe test specimen, thats, the change in length per unit of original

Tength, It is expressed as a dimensionless ratio,

A2.I7.1 nominal strain at break—the strain at the moment of rupture relative to the original grip separation,

A218 tensile strength (nominal) —the maximum tensile sress (nominal sustained by the specimen during a tension test. When

the maximum stress occurs atthe yield point (A2.22), it shall be designated tensile strength at yield. When the maximum stress

‘occurs at break, it shall be designated tensile strength at break,

A2.19 tensile sness (nominal)—the tensile load per unit area of minimum original cross section, within the gage boundries,

carried by the test specimen at any given moment, It is expressed in force per unit area, usually megapascals (pounds-force per

square inch),

Nowe. A2.8—The expression of tensile properties interns ofthe minimum signal cross seton Is almost uiversaly wed in procte. tn the ease of

smatrals exhibiting high extensibility o necking, or Bath (A2.16), nominal suas esleulaons may not be meaningful beyond the yield point (A2.22)

fo othe extensive reduction in cost setional sea tht ensues. Under tome circumstances it may’ e desirable to expess te eile properties pr unit

of sinimom prevailing eros section. These properties ae called te tensile propetes (at ite tensile ses, ee)

A220 tensile siress-strain curve—a diagram in which values of tensile stress are plotied as ordinates against corresponding

values of tensile strain as abscissas,

A221 true strain (see Fig. A2.2) is defined by the following equation for ey:

r= faves mun, van

er

GL" increment of elongation when the dtm Dewees he gage mai

= agin doe fees pds mao

EE Gane boweengnpe mate a my te

A2.22_yleld point—the frst point on the stress-srain curve at which an increase in strain occurs without an inerease in stress

(ig. A23),

ay

Vy

FIG. A22Illusttation of True Strain Equation

‘Copyrighted mat oenee to Saud Aramco, No further raroducton ar atbation permite,

Printed | vowed by: [ssa dawish@aramco con} @ 2013-12-08

Aly 638-10

Nowe AZ9—Only materials whose suessstin curves exhibit «point of zero slope may be considered as having a ye point

Nowe AZ10—Some materials exhibits astnt “break” cr discontnulty in the secsstisin curve fn the elastic region. This bre is no yet pom

by deficition. However, this point may prove useful for material chactsizaton in some cass.

A223 yield strengoh—the stress at which a material exhibits a specified limiting deviation from the proportionality of stress

to strain, Unless otherwise specified, this stress will be the stress at the yield point and when expressed in relation to the tensile

strength shal be designated cither tensile strength at yield or tensile stress at yield as requited in A2.18 (Fig. A2.3). (See affiet yield

strength.)

SRL

RS eS

o- Seer gee pmo

RENE!

FIG. A29 Tensile Designations

A224 Symbols—The following symbols may be used forthe above terms:

Copyrighted material icarsed to Sous Aramco. No further reproduction or distribution permed

Peete | vwed by: fussae dareh@sromen con) @ 2015-1204

iy Des8—10

‘syroat tem

w Load

aw therm oad

t ‘lstarce betes gage mais a any tne

te (gia! setance btseen gage ares

5 Distaneobotroen gage male st mamon of rupkro

a Ingen of dae btwn ie ras organ

A Dial ras seston aes

a Treromat of rose spool aca

A Generel hl pt neti ess aes

a Cost ecoel aoa pot frp, measured a tho

‘remanent

2 Internet of ess

. Tenet song at ak rorinah

our Tenatosengh at beak (ve)

A Seain

% ‘oe, a break

ae Percentage elongation

YP. ‘ets pt

€ Modus easton

A2.25 Relations between these various terms may be defined as follows:

o oa

% WiAduree Ws alg tnd)

od Wrasere Wis behing ed)

Maes ly

os wan

Taut = mut,

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- SECTION 09 96 00 High Performance Coatings GeneralDocument8 pagesSECTION 09 96 00 High Performance Coatings Generalraja qammarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Calibration Certificate For UTMDocument2 pagesCalibration Certificate For UTMraja qammar100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Astm D6223D6223M-16Document3 pagesAstm D6223D6223M-16raja qammarNo ratings yet

- MPW Approval for Bobayan ProjectDocument45 pagesMPW Approval for Bobayan Projectraja qammarNo ratings yet

- SECTION 03 41 00 Structural Precast Concrete Part 1 - GeneralDocument16 pagesSECTION 03 41 00 Structural Precast Concrete Part 1 - Generalraja qammarNo ratings yet

- Jelsa EnglDocument1 pageJelsa Englraja qammarNo ratings yet

- Concrete Trial Mix: Jabbar Al Ahmad Causeway Project MPW Hyundai E &CDocument2 pagesConcrete Trial Mix: Jabbar Al Ahmad Causeway Project MPW Hyundai E &Craja qammarNo ratings yet

- Ubc 2008 Spring Dykeman DonnaDocument304 pagesUbc 2008 Spring Dykeman Donnaraja qammarNo ratings yet

- Test Covered PDFDocument1 pageTest Covered PDFraja qammarNo ratings yet

- Hydrometer Test: King Fahd University of Petroleum & Minerals CE 353 Soil Mechanics LaboratoryDocument9 pagesHydrometer Test: King Fahd University of Petroleum & Minerals CE 353 Soil Mechanics Laboratoryraja qammarNo ratings yet

- Measurement of Rate of Absorption of Hardened ConcreteDocument3 pagesMeasurement of Rate of Absorption of Hardened Concreteraja qammarNo ratings yet

- T S R T.S.R.: (Dd-Mmm-Year)Document2 pagesT S R T.S.R.: (Dd-Mmm-Year)raja qammarNo ratings yet

- Concure 1315 (White) : Eco-Friendly, Acrylic Based, White Curing Compound, Sealer and Dust ProoferDocument4 pagesConcure 1315 (White) : Eco-Friendly, Acrylic Based, White Curing Compound, Sealer and Dust Prooferraja qammarNo ratings yet

- Solubility of Asphalt Materials in Trichloroethylene: Standard Test Method ForDocument3 pagesSolubility of Asphalt Materials in Trichloroethylene: Standard Test Method Forraja qammarNo ratings yet

- TDS-BS 3262 Thermoplastics PDFDocument2 pagesTDS-BS 3262 Thermoplastics PDFraja qammarNo ratings yet