Professional Documents

Culture Documents

Carbonization process converts coal into coke

Uploaded by

Operation TewehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbonization process converts coal into coke

Uploaded by

Operation TewehCopyright:

Available Formats

Carbonization of coal

Carbonization : is a process in which coal is heated in the absence of oxygen.

After combustion, carbonization of coal is the most important use of coal to

produce coke.

Coke : is the solid residue that remains when coal is heated out of contact with air.

Principal use : Coke is basically formed, so that it can be used in iron and steel

manufacture ( metallurgical purpose ) where it provides heat energy and acts as a

reducing agent for iron ore in blast furnace.

Fig .1

The residue from the carbonization process is a non- porous powder or granular

mass, it is known as char.

Char may be used in the form of specially moulded briquettes, in much the same

way as coke.

Carbonization can broadly be divided into two types depending on the

temperature of carbonization as follows :

High Temperature Carbonization : (9000c – 13000c) Coke is produced for

metallurgical purpose. In high temperature carbonization, the yield of gaseous

product is more than liquid products with production of tar relatively low.

Low Temperature Carbonization : (4000C – 7000C) The main aim of low

temperature carbonization is to produce soft coke as a smokeless fuel.

Blast furnaces usually require coke of uniform size with high mechanical strength,

porosity and minimum ash content and volatile matter.

Fig.1 is very simple laboratory illustration of how you can produce coke out of

powdered coal when you heat it,coal gas escapes out through the side tube,coal tar

produced settles down at the bottom of the second tube and ammonia gas dissolves

in water. What's left in the first tube is nothing but coke.

You might also like

- Fly Ash - WikipediaDocument12 pagesFly Ash - WikipediaBabar AliNo ratings yet

- Waste Management at JSW Steel - An Innovative Approach: DR Amit Ranjan ChakrabortyDocument25 pagesWaste Management at JSW Steel - An Innovative Approach: DR Amit Ranjan ChakrabortyAnindya RoyNo ratings yet

- Steel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofDocument8 pagesSteel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofRitesh KumarNo ratings yet

- Energy for Sustainable Development Through Coal UtilizationDocument30 pagesEnergy for Sustainable Development Through Coal UtilizationAkmal Hafeez Muhammad HafeezNo ratings yet

- Presentation On Preparation of Coke in Coke Oven Batteries: Presented By: Anil Kumar KhataiDocument18 pagesPresentation On Preparation of Coke in Coke Oven Batteries: Presented By: Anil Kumar KhataiKhatai Anil KumarNo ratings yet

- Fluxes For Electroslag Refining: Dr. Satadal GhoraiDocument21 pagesFluxes For Electroslag Refining: Dr. Satadal GhoraiGarry's GamingNo ratings yet

- Coal Testing and Analysis MethodsDocument12 pagesCoal Testing and Analysis MethodsIzzan Ferdi AndrianNo ratings yet

- Tecnored Process - High Potential in Using Different Kinds of Solid FuelsDocument5 pagesTecnored Process - High Potential in Using Different Kinds of Solid FuelsRogerio CannoniNo ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- 1 IntroductionDocument13 pages1 IntroductionMiguel TorresNo ratings yet

- Coal Rank and CharacteristicsDocument28 pagesCoal Rank and CharacteristicsMohammed Al-OdatNo ratings yet

- Extraction of ZN FinalDocument20 pagesExtraction of ZN FinalYashodeep Ravindra HireNo ratings yet

- Components of Coal AshDocument4 pagesComponents of Coal AshDulguun BayNo ratings yet

- COAL CHARACTERIZATION AND BLENDING PERSPECTIVEDocument15 pagesCOAL CHARACTERIZATION AND BLENDING PERSPECTIVEbhujakhia_748657110No ratings yet

- Blast Furnace - Material TeknikDocument8 pagesBlast Furnace - Material TeknikDaniel Parsaoran Hamonangan SinagaNo ratings yet

- Blast Furnace Slag B. InggrisDocument8 pagesBlast Furnace Slag B. InggrisBayuPrasetyaPNo ratings yet

- Equipment DesignDocument7 pagesEquipment DesignGodstandAimiuwuNo ratings yet

- Study The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementDocument12 pagesStudy The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementIAEME PublicationNo ratings yet

- What Is Carbonization?Document17 pagesWhat Is Carbonization?vijaykumarboniNo ratings yet

- Spontaneous Combustion of CoalDocument31 pagesSpontaneous Combustion of CoalEstradove SatheeshNo ratings yet

- Coal For Metallurgical Coke Production PDFDocument24 pagesCoal For Metallurgical Coke Production PDFS SITAPATI100% (1)

- Fair Use NoticeDocument32 pagesFair Use NoticeTarvesh KumarNo ratings yet

- GATE exam chemistry questions from 1990-1997Document39 pagesGATE exam chemistry questions from 1990-1997Naresh NaniNo ratings yet

- Productive Recycling of BOF Sludge in Integrated PlantDocument5 pagesProductive Recycling of BOF Sludge in Integrated PlantJorge MadiasNo ratings yet

- BF Cast House Product & DesignDocument50 pagesBF Cast House Product & DesignHara Prasad MurtyNo ratings yet

- 2010 Blast Furnace Coke Properties and The Influence On Off Gas Dust - Licentiate Thesis PDFDocument67 pages2010 Blast Furnace Coke Properties and The Influence On Off Gas Dust - Licentiate Thesis PDFLongdragon KingNo ratings yet

- MT308 Fuels, Furnaces and RefractoriesDocument3 pagesMT308 Fuels, Furnaces and RefractoriesMerrin John VarkeyNo ratings yet

- Decomposition Reaction of LimestoneDocument4 pagesDecomposition Reaction of LimestoneNovie ArysantiNo ratings yet

- Raw Materials For Manufacturing of Superior Quality Mgo-C BricksDocument8 pagesRaw Materials For Manufacturing of Superior Quality Mgo-C Bricksjom erfNo ratings yet

- Production of IronDocument15 pagesProduction of IronMassy KappsNo ratings yet

- Session-1-Introduction and Coke MakingDocument51 pagesSession-1-Introduction and Coke MakingHeroNo ratings yet

- Coal PetrologyDocument29 pagesCoal PetrologyIlham El-sirazhyNo ratings yet

- Sariska Tiger Reserve Environmental ProjectDocument24 pagesSariska Tiger Reserve Environmental ProjectAni AwesomeNo ratings yet

- Sintering ProcessDocument4 pagesSintering ProcessNicollas Matheus100% (1)

- Waste Water - Coke PlantDocument13 pagesWaste Water - Coke PlantSejla Becirovic Cehajic100% (1)

- Collection and Preparation of Coke Samples For Laboratory AnalysisDocument4 pagesCollection and Preparation of Coke Samples For Laboratory Analysisharrison_sNo ratings yet

- BF SlagDocument9 pagesBF SlagSuresh BabuNo ratings yet

- 4 AodDocument5 pages4 AodSonu MishraNo ratings yet

- Ash Content of CoalDocument3 pagesAsh Content of CoalSaad Ahmed0% (1)

- Laboratory Study of An Organic Binder For Palletization of A Magnetite ConcentrateDocument8 pagesLaboratory Study of An Organic Binder For Palletization of A Magnetite ConcentrateMaya CiamikNo ratings yet

- Iron MakingDocument26 pagesIron Makingsumit ranjanNo ratings yet

- Igneous Rock TexturesDocument5 pagesIgneous Rock Texturesapi-3808551No ratings yet

- Progress of Special Steel-Making Process in Japan: Yoshio IshiharaDocument15 pagesProgress of Special Steel-Making Process in Japan: Yoshio IshiharaChandra Shekar EmaniNo ratings yet

- Lecture21 PDFDocument4 pagesLecture21 PDFMIzan NursiadiNo ratings yet

- CORROSION RATE ANALYSIS ,, Assignment 1Document4 pagesCORROSION RATE ANALYSIS ,, Assignment 1Muhammad MustafaNo ratings yet

- Cement QuestionsDocument3 pagesCement QuestionsprasadNo ratings yet

- Clean Coal TechnologyDocument9 pagesClean Coal TechnologyHaider AliNo ratings yet

- Unit - 4 Fuels and CombustionDocument21 pagesUnit - 4 Fuels and CombustionpruebaNo ratings yet

- Lime Calcination: Gupta Sudhir Kumar, Anushuya Ramakrishnan, and Yung-Tse HungDocument2 pagesLime Calcination: Gupta Sudhir Kumar, Anushuya Ramakrishnan, and Yung-Tse HungSaurabh NayakNo ratings yet

- Bulding Materials IIIDocument29 pagesBulding Materials IIIKaushik JayaveeranNo ratings yet

- Carbonisation of CoalDocument14 pagesCarbonisation of CoalNikhil TanwarNo ratings yet

- VSK process specification for small cement plantsDocument3 pagesVSK process specification for small cement plantsArjun Chetri BhandariNo ratings yet

- Utilization of Fly Ash and Rice Husk Ash As A Supplement To Concrete Materials - A Critical ReviewDocument9 pagesUtilization of Fly Ash and Rice Husk Ash As A Supplement To Concrete Materials - A Critical Reviewijetrm journalNo ratings yet

- Tutorial 1 Hmete 510Document3 pagesTutorial 1 Hmete 510TINOTENDASHE MAKONESENo ratings yet

- Sinter Plant JSPL, RaigarhDocument14 pagesSinter Plant JSPL, RaigarhJatin BangaliNo ratings yet

- Laboratory Sinter Results DeterminationDocument10 pagesLaboratory Sinter Results DeterminationMohsin ALiNo ratings yet

- High Purity AluminaDocument13 pagesHigh Purity AluminaNilay JoshiNo ratings yet

- Coal Quality IndiaDocument54 pagesCoal Quality IndiarajeevkumarrajeevNo ratings yet

- Clays and Clay Minerals: Proceedings of the Fourteenth National Conference, Berkeley, CaliforniaFrom EverandClays and Clay Minerals: Proceedings of the Fourteenth National Conference, Berkeley, CaliforniaS. W. BaileyNo ratings yet

- Chemical Composition and Properties of Dry Fly AshDocument1 pageChemical Composition and Properties of Dry Fly AshOperation TewehNo ratings yet

- Task Manager 20 20 User ManualDocument114 pagesTask Manager 20 20 User ManualOperation TewehNo ratings yet

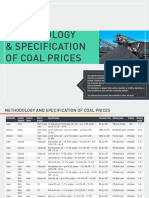

- Metal Expert: Methodology & Specification of Coal PricesDocument8 pagesMetal Expert: Methodology & Specification of Coal PricesOperation TewehNo ratings yet

- JR-Embedding Images in Base64Document1 pageJR-Embedding Images in Base64Operation TewehNo ratings yet

- Guidelines For Sample Collecting and Analytical MethodsDocument16 pagesGuidelines For Sample Collecting and Analytical MethodsKshitish RayNo ratings yet

- BDBDocument59 pagesBDBSa RaNo ratings yet

- Geology CSRDocument8 pagesGeology CSRGaurav SrivastavaNo ratings yet

- Swell Calculator: by Nathan CoolDocument2 pagesSwell Calculator: by Nathan CoolOperation TewehNo ratings yet

- Assignment 09 TemplateDocument2 pagesAssignment 09 TemplateviruNo ratings yet

- Impact of Weathering On Coking CoalDocument6 pagesImpact of Weathering On Coking CoalOperation TewehNo ratings yet

- Selectivities of Laboratory Flotation AnDocument29 pagesSelectivities of Laboratory Flotation AnOperation TewehNo ratings yet

- Alat CSRDocument11 pagesAlat CSROperation TewehNo ratings yet

- Properties of CoalDocument3 pagesProperties of CoalKratika SharmaNo ratings yet

- Eite Activity BoundariesDocument146 pagesEite Activity BoundariesOperation TewehNo ratings yet

- Coal DocumentationDocument74 pagesCoal DocumentationOperation TewehNo ratings yet

- Mineral Matter in CoalDocument3 pagesMineral Matter in CoalOperation TewehNo ratings yet

- Analisa Sieve Size PDFDocument1 pageAnalisa Sieve Size PDFOperation TewehNo ratings yet

- Improve Quality of PDFDocument10 pagesImprove Quality of PDFOperation TewehNo ratings yet

- Coal to Coke and Steel: How Metallurgical Coal is Used to Make SteelDocument4 pagesCoal to Coke and Steel: How Metallurgical Coal is Used to Make SteelOperation TewehNo ratings yet