Professional Documents

Culture Documents

Toepc71061748 PDF

Uploaded by

Bock DharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toepc71061748 PDF

Uploaded by

Bock DharmaCopyright:

Available Formats

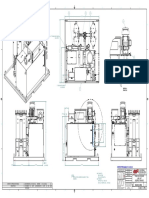

Procedure for Installation and Primary Operation for Models GA80U2004 to 2211 and 4002 to 4168 Remove the

Remove the Keypad, Front Cover, and Wiring Cover

1 7

GA80UXXXXABM 1

GA80UXXXXABAA-CAAAAA

2 2 1

GA

800

https://www.yaskawa.com/ga800qsp1

GA800

TOE

PC7

TOE

PC7

ON-SITE 8 Select the Correct Fuses, Wires, and Wire Strip Length

VIDEO

TOE 106 106

PC7 1748 1741

106 1737 -46

? 18mm

Read and follow the safety and installation procedures in the Installation & Primary Operation X.X~X.X N•m/

X.Xmm

(TOEPC71061737) manual packaged with the drive. 10mm

5.5mm

2 Confirm the Drive and Motor Specifications

VOLTS ≥ HP

RPM

Induction Motor Nameplate

AMPS

DUTY

0.75

2.8

1765

Cont

40

VOLTS 230

HERTZ 60

3 PH

VOLTS AMPS ≥ HP

Induction Motor Nameplate

AMPS

RPM

DUTY

0.75

2.8

1765

Cont

40

VOLTS 230

HERTZ 60

3 PH

AMPS XXXXXXXXX

XXXXXXXXX

AC3PH 200-240V

Uin (nameplate)

Uin AC3PH 380-480V

Yaskawa recommends installing one of the following types of branch circuit protection to maintain compliance with UL 508C.

+10% MAX

-15% MIN

L1

L2

50/60Hz

Semiconductor protective type fuses are preferred. Alternate branch circuit protection devices are also listed.

L3

≥ ≥

Induction Motor Nameplate Induction Motor Nameplate

HP HP HERTZ HERTZ

3 PH 3 PH

HP 0.75 HP 0.75

AMPS 2.8 VOLTS 230 AMPS 2.8 VOLTS 230

RPM 1765 HERTZ 60 RPM 1765 HERTZ 60

DUTY Cont DUTY Cont

40 40

Maximum Time Delay fuse is 175% of drive full load output amps (FLA). This covers any Class CC, J or T class fuse.

200 V Class Wire Gauge Range and Branch Circuit Protection by Drive Model [GA80UXXXX] (Recommended)

3 Collect the Required Tools and Equipment

2004

Terminal 2006 2010 2012 2018 2021 2030 2042 2056 2070 2082 2110 2138 2169 2211

2008

R/L1

14 - 6 14 - 6 14 - 6 14 - 6 8-3 6-1 6 - 1/0 2/0 - 250 2/0 - 250

S/L2

(12) (10) (8) (6) (3) (1) (1/0) (4/0) (250)

T/L3 14 - 6 14 - 6 14 - 6 6 - 1/0 2 - 2/0

U/T1 (14) (10) (6) (1/0) (2/0)

14 - 6 14 - 6 14 - 6 14 - 6 10 - 4 6-3 6-2 3/0 - 300 3/0 - 300

V/T2

(14) (12) (10) (8) (4) (3) (2) (4/0) (300)

W/T3

—

4 Confirm the Correct Drive Installation Environment* —

— — 14 - 3 14 - 3 14 - 3 14 - 3 14 - 3 14 - 3 14 - 3 8-1 4 - 1/0 4 - 2/0 2 - 2/0 2 - 4/0 1/0 - 2/0 1/0 - 2/0

+1

+1 +1 (14) (12) (10) (8) (8) (6) (3) (1) (1/0) (2/0) (2/0) (4/0) (1) (2/0)

+2

? +50 °C

+1

95 RH B1 B1 14 - 10 14 - 10 14 - 10 14 - 10 14 - 10 14 - 10 14 - 10 14 - 8 14 - 8 14 - 6 10 - 4 10 - 3 1 - 2/0 1 - 2/0

(122 °F) +3

B2 B2 (14) (14) (14) (14) (14) (12) (10) (8) (8) (6) (4) (3) (1/0) (2/0)

≤ Pollution

14 - 8 14 - 8 14 - 8 14 - 8 12 - 8 10 - 8 10 - 8 8-6 6-4 6-4 6-4 4 4 - 1/0 4 - 1/0

-10 °C % ≤1000 m

Degree 2

Bussmann

G

Semiconductor¹

(10) (10) (10) (10) (10) (8) (8) (6) (6) (6) (6) (4) (4) (4)

(14 °F) FWH-45B FWH-45B FWH-50B FWH-80B FWH-80B FWH-125B FWH-200B FWH-225A FWH-250A FWH-225A FWH-225A FWH-275A FWH-275A FWH-325A

0 RH • 10 Hz to 20 Hz: 1 G

(3281 ft)

(9.8 m/s², 32.15 ft/s²) Alternate 6

Time- Max.

• 20 Hz to 55 Hz: 0.6 G Rating 10 15 20 30 35 50 70 90 110 125 175 225 250 350

Delay

*Refer to the drive manual for installations that exceed these conditions. (5.9 m/s², 19.36 ft/s²) (Class CC, (A)³

J, or T)² 12

Max.

5 Correctly Lift the Drive SCCR 65 65 65 65 65 100 100 100 100 100 100 100 100 100

(kA)

¹Recommended EATON/Bussmann Semiconductor fuse model.

²Class T fuses are fast-acting (non-time delay only).

XXXXXXXXX

? kg XXXXXXXXX ³Maximum fuse ratings are based on ND1 or ND2 ratings, whichever is larger.

< 15 kg

(? lbs)

(< 33 lbs) 400 V Class Wire Gauge Range and Branch Circuit Protection by Drive Model [GA80UXXXX] (Recommended)

4002 4005

MASS : X.X kg Terminal 4009 4012 4018 4023 4031 4038 4044 4060 4075 4089 4103 4140 4168

4004 4007

≥50° R/L1

14 - 6 14 - 6 8 -3 8-3 10 - 4 2 - 2/0 2/0 - 250 2/0 - 250

S/L2

(12) (8) (6) (6) (4) (1/0) (3/0) (4/0)

15 kg + T/L3 14 - 6 14 - 6 14 - 6 14 - 6 10 - 4 12 - 3 10 - 2

(33 lbs +) U/T1 (14) (14) (14) (10) (4) (3) (2)

14 - 6 14 - 6 10 - 4 10 - 4 10 - 6 2 - 2/0 3/0 - 300 3/0 - 300

V/T2

(14) (10) (8) (8) (6) (1) (2/0) (4/0)

W/T3

—

6 Mount the Drive Vertically —

— — 14 - 3 14 - 3 14 - 3 14 - 3 14 - 3 14 - 3 8-1 8-1 10 - 3 10 - 3 10 - 2 6 - 1/0 2 - 4/0 1/0 - 2/0 1/0 - 2/0

+1

+1 +1 (14) (14) (12) (10) (8) (8) (6) (4) (3) (3) (2) (1/0) (2/0) (2) (1/0)

+2

+1

B1 B1 14 - 10 14 - 10 14 - 10 14 - 10 14 - 10 14 - 10 14 - 8 14 - 8 14 - 8 14 - 8 14 - 6 14 - 6 10 - 3 1 - 2/0 1 - 2/0

6m

+3

B2 B2 (14) (14) (14) (14) (14) (12) (10) (10) (8) (8) (6) (6) (3) (1) (1/0)

m

(0.2 Ø5.5

4 in mm

4x ) (0

M5

[#1 .22

0] in)

10 8.2

2m mm

19 m (0.3

m (4.0

(0.7 m 2 in 2 in

5 in ) )

)

Ø11

(0.4 .7 mm

14 - 8 14 - 8 14 - 8 14 - 8 14 - 8 12 - 8 10 - 6 10 - 6 8-4 8-4 6-4 6-4 6-4 4 - 1/0 4 - 1/0

G

19

6 in m

(0.7 m

248 mm (9.76 in)

) 5 in

)

(12) (10) (10) (10) (10) (10) (8) (8) (6) (6) (6) (4) (4) (4) (4)

TO 14

EP

0m

≥ 30 L8 m

Bussmann

mm-35 (5.5

C7

FWH-50B

(1. = 0 1 in

50 mm (2 in)

2 in) )

106

x2

L8

x2

≥ 2-35

=

< 30mm (0.1

174

260 mm (10.24 in)

mm 08

Semiconductor¹

120 (1. in)

2 in)

FWH-50B FWH-60B FWH-60B FWH-80B FWH-90B FWH-150B FWH-200B FWH-200B FWH-225A FWH-250A FWH-275A FWH-275A FWH-300A FWH-325A

in

1-4

mm

(4.7

in)

6

50 mm (2 in)

19

m

(0.7 m

FWH-60B

5 in 30

) 50

mm 30

mm

mm (1.2 in) (1.

(2 2 in)

in)

120

mm

(4.7

mm 6 in)

GA

70

0 Te

(0.2 102 m

4 in m

mpl ) (4.0

ate 2 in

TO )

3.5 9

19

Alternate Max.

EP m

C71 (0.7 m

06 5 in

17

99 )

Time- Rating 15 20 30 40 50 60 70 100 125 150 175 225 250

Delay (Class (A)³ 7 12

x2 x2 CC, J, or T)²

Max.

SCCR 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100

(kA)

¹Recommended EATON/Bussmann Semiconductor fuse model.

²Class T fuses are fast-acting (non-time delay only).

³Maximum fuse ratings are based on ND1 or ND2 ratings, whichever is larger.

GA800 Quick Setup Procedure TOEPC71061748E 1

9

13 Collect and Record Auto-Tuning Data from Motor Nameplate

9 Install the Motor Wiring and Power Wiring

3 PHASE INVERTER DUTY AC INDUCTION MOTOR NAMEPLATE EXAMPLE T1-xx Parameter

Reference Motor Nameplate Data Motor Nameplate Value

(Ex-xx Parameter¹)

MODEL XX 123AAAA123XX-X0 X FRAME 123AX

E

POLES X ENC XXX CODE X DES A TYPE ABC INS X0 A Motor Rated Power kW T1-02 (E2-11)

(HP x 0.746)

B F C

FL FL

VOLTS XXX RPM

XXXX AMPS

XX/XX B Motor Rated Voltage V T1-03 (E1-05)

MAX TEMP.

SF 1.0 DUTY CONT

AMB °C

XX SENSORS

T-STATS C Motor Rated Current (FLA) A T1-04 (E2-01)

G

SERIAL N.L. AMPS XX.X/X.X Motor Rated Frequency (Base

D Hz T1-05 (E1-04/E1-06)

MAX S.E. O.S.E. ROTOR Frequency)

RPM

4200 BRG. 309 BRG.

XXX WK²

X.X

E Motor Pole Count - T1-06 (E2-04)

HZ HP RPM

TORQUE VOLTS AMPS

(LB FT) (HIGH CONN) (HIGH CONN)

F Motor Rated RPM RPM T1-07

1 - 0 XX.X - XX.X

D A

60 XX XXXX XX.X XXX XX.X G Motor No-Load Current² A T1-09 (E2-03)

8 120 XX XXXX XX.X XXX XX.X

- Motor Rated Slip² ³ 0.000 Hz T1-10 (E2-02)

OHMS

R1: .XXX R2: .XXX X1: X.XX X2: X.XX XM: XX.X

R/L1

PH.

S/L2

- Test Mode Selection² - T1-12

T/L3

P/N XXXXXXX

- Motor No-Load Voltage V T1-13

8

IM ¹Auto-Tuning will automatically set the E1-xx and E2-xx parameters. You can manually adjust Ex-xx parameters after Auto-Tuning.

²These values are only necessary for Stationary Auto-Tuning (T1-01 = 1).

³If you do not know this value, leave at the default value of 0.000.

Refer to the Technical Reference

(SIEPC71061737) for more

14

8

9 Energize the Drive and Confirm It Is Ready

information about GFCIs.

U/T1

/T1 R/L1 U/T1

R/L1 U/T1

L1 V/T2

R/L1 V/T W/T3 S/L2 T/L3 V/T2 W/T3 or READY

S/L2 T/L3 V/T2 W/T3

S/L2 T/L3

T

Spacing per local electrical codes

EF3

10 Remove the Tabs and Install the Wiring Cover

External Fault (terminal S3)

Reset

2017/01/01 10:00

FG

READY

R/L

1

S/L

2

T/L

3 15

8

9 Use Auto-Tuning Data from Motor Nameplate to Set Parameters and Auto-Tune the Drive

(AI)

Home Menu

Control Tuning

5x

11 Install the Front Cover and Keypad

Rdy

Enter motor rated power. RUN key : Tuning Start *** EXECUTE AUTO-TUNING ***

Home key : Cancel

Rotational Auto-Tuning End

Stationary Auto-Tuning 1

Stationary Line-Line Resistance 0000.55 kW The motor turns. ... Auto-Tuning Successful

Please be careful.

Range : 0.00~650.00 XX.XXHz/ X.XXA

1 2

16 Set the Drive for LOCAL Control and Check the Motor Rotation Direction

(KPD) (KPD)

12 Determine the Correct Auto-Tuning Method Home JOG 6.00

Motor Connection and Load Condition

6.00

0.02

(KPD)

6.00

6.00 6.00

6.00

0.02 0.02

F A

Use Stationary Auto-Tuning Use Rotational Auto-Tuning READY

T1-01 = 1 T1-01 = 0

GA800 Quick Setup Procedure TOEPC71061748E 2

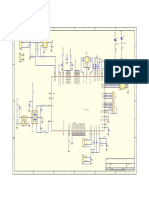

A If the Motor Does Not Rotate in the Correct Direction D Connection Diagram and Terminal Functions

DC Link Terminal Type Signal Level Default

Choke Option Braking Resistor

S1 MFDI 1 Forward run/Stop

U X Option

S2 MFDI 2 Reverse run/Stop

S3 MFDI 3 External fault

2169, 2211 only U

+3 +2 + 1 _ B1 B2 U/T1 S4 MFDI 4

Photocoupler

Fault reset

V S5 MFDI 5 Multi-step speed 1

2004-2082 V/T2 24 V, 6 mA

W S6 MFDI 6 Multi-step speed 2

4002-4044 W/T3

S7 MFDI 7 Jog command

only

R/L1 Baseblock

S8 MFDI 8

command

S/L2

T/L3

GA800 SN MFDI power 0 V -

SC MFDI common -

24 V, 150 mA maximum

S1 MFDI power +

SP -

24 VDC

B Control Circuit Configuration and Accessiblity

S2

MA

Safe disable

MB H1

input 1

-

MC 24 V, 6 mA

Safe disable

S3 H2

input 2

Internal impedance: 4.7 kΩ -

Minimum OFF time: 2 ms

M1 HC

Safe disable

-

≤ 0.4 mm S4 common

(0.01 in) M2

5.5 mm (0.21 in) Response frequency: 0 ~ 32 kHz

Master

≤ 2.5 mm (0.1 in) S5 M3 H level duty: 30 ~ 70%

frequency

RP H level voltage: 3.5 ~ 13.2 V -

M4 reference pulse

L level voltage: 0.0 ~ 0.8 V

S6 train input

Input impedance: 3 kΩ

M5 +V Frequency setting 10.5 V (20 mA maximum) -

S7 M6 -V power supply -10.5 V (20 mA maximum) -

-10 V ~ +10 V/-100% ~ +100% Master frequency

S8 A1 MFAI 1

0 V ~ 10 V/100% reference

2004-2082 (input impedance 20 kΩ)

4005-4044 SN MP 4 mA ~ 20 mA/100%

A2 MFAI 2 0 mA ~ 20 mA/100% Combined w/A1

C/C : GA80XXXXXABAA AC (input impedance 250 Ω)

8 XXXXX SC

0V -10 V ~ +10 V/-100% ~ +100%

SP SINK 0 V ~ 10 V/100%

FM (input impedance 20 kΩ) Auxiliary

+24 V A3 MFAI 3/PTC input 4 mA ~ 20 mA/100% frequency

E (G) - + 0 mA ~ 20 mA/100% reference

FM

(input impedance 250 Ω)

PTC input

RP AC Common 0V -

2110-2138 +V

Connect

4060-4103 0-10 V E(G)

shielded cable

- -

A1 AM

2 kΩ

C/C : GA80XXXXXABAA 4 mA to MA Fault

8 XXXXX

20 mA AC - + Fault relay out 30 VDC, 10 mA ~ 1 A

A2 AM MB 250 VAC, 10 mA ~ 1 A Fault

0V MC Common Minimum load: 5 V, 10 mA -

0-10 V

A3 M1

E (G) MFDO During run

M2

AC 30 VDC, 10 mA ~ 1 A

M3

MFDO 250 VAC, 10 mA ~ 1 A Zero speed

0V M4 Minimum load: 5 V, 10 mA

C Switches and Jumpers on the Control Board

DC -V M5

(120 Ω, 1/2 W) MFDO Speed agree 1

24 V PS M6

PS

700 mA MP Pulse train out 32 kHz maximum Output frequency

D+

FM MFAO 1 0 V ~ +10 V/0% ~ 100% Output frequency

A3

RS-485 D- -10 V ~ +10 V/-100% ~ +100%

D+ D- AM MFAO 2 Output current

AC 4 mA ~ 20 mA

AC Common 0V -

0V

H1 External 24 V PS

PS 21.6 VDC ~ 26.4 VDC, 700 mA -

H2 input

External 24 V PS

HC AC 0V -

ground

D+ D-

A1 SN D+ Communication + MEMOBUS/Modbus, RS-485 -

D- Communication - 115.2 kbps maximum -

A1 A2 A3 FM AM AC Common 0V -

A2

A3

GA800 Quick Setup Procedure TOEPC71061748E 3

E If You Push the Run Button but the Motor Does Not Spin G

8 Troubleshooting Resources for Drive Faults and Alarms

(KPD) EF3

External Fault (terminal S3)

2017/01/01 10:00

Reset

READY

READY

Resource Choose This When: URL QR Code

You have access to the paper copy of the manual that was packaged with the drive.

This manual lists all drive faults and alarms, and offers a selection of causes and

solutions.

Parameters GA800

(KPD) Reference 1

Home d1-01

0

000.00 Hz Installation & Primary https://www.yaskawa.com/

Default : 0.00 Hz Operation TOEPC71061737

toepc71061737

Range : 0.00~60.00

Back Default Min/Max

PDF download

GA800

Parameters Parameters

Reference 1

d1-01

1

000.00 Hz Entry Accepted You want to use your smartphone or tablet and use the embedded help to look up the

Default : 0.00 Hz full complement of causes and solutions to all drive faults and alarms.

Range : 0.00~60.00

Back Default Min/Max

DriveWizard Mobile

(KPD) https://www.yaskawa.com/dwm

10.00 App

0.00

0.00 READY

10 Hz App download

You want to download a PDF of the manual to your smartphone or tablet.

This manual lists the full complement of causes and solutions to all drive faults and

F Parameter Groups alarms and also includes detailed information about drive maintenance, wiring, and

programming.

A: Initialization d: Reference Settings H: Terminal Functions n: Special Adjustment q: DriveWorksEZ Parameters

A1 Initialization d1 Frequency Reference H1 Digital Inputs n1 Hunting Prevention r: DriveWorksEZ Connections

A2 User Parameters d2 Reference Limits H2 Digital Outputs n2 Auto Freq. Regulator (AFR) T: Motor Tuning

b: Application d3 Jump Frequency H3 Analog Inputs n3 High Slip/Overexcite Braking U: Monitors Drive

Maintenance &

TOEPYAIXXX001.pdf

b1 Operation Mode Selection d4 Freq. Ref. Up/Down & Hold H4 Analog Outputs n4 AOLV Tuning U1 Operation Status Monitors https://www.yaskawa.com/

Troubleshooting

DC Injection Braking and toepyaiga8001

b2 d5 Torque Control H5 Modbus Communication n5 Feed Forward Control U2 Fault Trace Manual XXX00

Short Circuit Braking

XXX00

b3 Speed Search d6 Field Weakening/Forcing H6 Pulse Train Input/Output n6 Online Tuning U3 Fault History

XXX00 PDF download

b4 Timer Function d7 Offset Frequency H7 Virtual Inputs/Outputs n7 EZ Drive U4 Maintenance Monitors

XXX00

b5 PID Control E: Motor L: Protection Functions n8 PM Motor Control Tuning U5 PID Monitors

b6 Dwell Function E1 V/f Pattern for Motor 1 L1 Motor Protection o: Keypad-Related Settings U6 Operation Status Monitors

b7 Droop Control E2 Motor 1 Parameters L2 Power Loss Ride Through o1 Keypad Display U8 DriveWorksEZ Monitors

b8 Energy Saving E3 V/f Pattern for Motor 2 L3 Stall Prevention o2 Keypad Operation

b9 Zero Servo E4 Motor 2 Parameters L4 Speed Detection o3 Copy Keypad Function

C: Tuning E5 PM Motor Settings L5 Fault Restart o4 Maintenance Monitors

C1 Accel & Decel Time E9 Motor Setting L6 Torque Detection o5 Log Function

C2 S-Curve Characteristics F: Options L7 Torque Limit

H Additional Resources I Customer Feedback

C3 Slip Compensation F1 PG Option Setup (Encoder) L8 Drive Protection

Comments or questions about this document? Please consider following us on social media:

C4 Torque Compensation F2 Analog Input Option L9 Drive Protection 2 Fill out our online form:

C5 Auto Speed Regulator (CSR) F3 Digital Input Option Mobile App Product Manuals www.youtube.com/yaskawayea

C6 Duty & Carrier Frequency F4 Analog Output Option www.linkedin.com/company/18822

F5 Digital Output Option

www.twitter.com/yaskawa

F6 Communication Option

F7 Ethernet Options Headquarters Address:

or

DriveWizard® Mobile •PDFs

Commissioning •Online HTML5-Searchable Email us: technical_documentation@yaskawa.com YASKAWA AMERICA, INC.

Smartphone App •Manuals App Call us: 1-800-YASKAWA (927-5292) 2121 Norman Drive South

www.yaskawa.com/DRV-F-0006

https://www.yaskawa.com/dwm https://www.yaskawa.com/ga800manuals Waukegan, IL 60085

GA800 Quick Setup Procedure TOEPC71061748E 4 USA

You might also like

- Prologue: Managerial Accounting and The Business EnvironmentDocument156 pagesPrologue: Managerial Accounting and The Business EnvironmentMarcus MonocayNo ratings yet

- Oman O&G Blocks PDFDocument1 pageOman O&G Blocks PDFSathishNo ratings yet

- Concession Map 16.01.2019Document1 pageConcession Map 16.01.2019Mithilesh KumarNo ratings yet

- Concession Map 16.01.2019Document1 pageConcession Map 16.01.2019Sathish100% (4)

- C7 Cat - Dcs.sis - ControllerDocument2 pagesC7 Cat - Dcs.sis - Controllerrodinei80% (5)

- RAB PLTS Hybrid 1kWp-ScheneiderDocument4 pagesRAB PLTS Hybrid 1kWp-ScheneiderilhamNo ratings yet

- PHY130 Lab Report 2Document7 pagesPHY130 Lab Report 2Declan Gale Anak DellyNo ratings yet

- Cold ST - by Block: PQ3211 LP801S LP 180uh 34.5TDocument2 pagesCold ST - by Block: PQ3211 LP801S LP 180uh 34.5TАлексейNo ratings yet

- BN44 00422B PDFDocument2 pagesBN44 00422B PDFGrzegorz GrzędaNo ratings yet

- Cold ST - by Block: PQ3211 LP801S LP 180uh 34.5TDocument2 pagesCold ST - by Block: PQ3211 LP801S LP 180uh 34.5Tiuri63No ratings yet

- Cold ST - by Block: PQ3211 LP801S LP 180uh 34.5TDocument2 pagesCold ST - by Block: PQ3211 LP801S LP 180uh 34.5TCarlos GonçalvesNo ratings yet

- BN44 00422B PDFDocument2 pagesBN44 00422B PDFHermin ToadiNo ratings yet

- Fa Rsag7.820.1947Document3 pagesFa Rsag7.820.1947ies837No ratings yet

- ESP: 03301.T025/26 2 A 1: Key PlanDocument1 pageESP: 03301.T025/26 2 A 1: Key PlanJorgeNo ratings yet

- Schema ReceptorDocument1 pageSchema ReceptorDaniel TaradaciucNo ratings yet

- Layout of Platform Ladder For HSD FO Tank R1 - CommentedDocument1 pageLayout of Platform Ladder For HSD FO Tank R1 - CommentedDass DassNo ratings yet

- Power Input: IN GND BS Comp EN SS SWDocument10 pagesPower Input: IN GND BS Comp EN SS SWjesurajanNo ratings yet

- President Lincoln II Version 3 SchematicDocument13 pagesPresident Lincoln II Version 3 Schematicalf100% (1)

- Planos 9978Document34 pagesPlanos 9978Omar50% (2)

- Concession Map-16.01.2019 PDFDocument1 pageConcession Map-16.01.2019 PDFa.hasan67050% (2)

- ss3900 Ept360015c MosfetDocument1 pagess3900 Ept360015c MosfetANSELMO LIMA0% (1)

- Copia Controlada: ESP: 03101.T136Document1 pageCopia Controlada: ESP: 03101.T136Samuel MuñozNo ratings yet

- A A A A A A: Tank Testing Plan With Sounding TablesDocument1 pageA A A A A A: Tank Testing Plan With Sounding TablesMD shawonNo ratings yet

- 220 M6 0330 00006Document1 page220 M6 0330 00006jhonNo ratings yet

- Eep 000097 0102148005 3 ST Det 0684 R02Document1 pageEep 000097 0102148005 3 ST Det 0684 R02Vikram DalalNo ratings yet

- Unifilar Interlegis 2022205Document1 pageUnifilar Interlegis 2022205Diego LeiteNo ratings yet

- Puisque Tu Pars PartitionDocument4 pagesPuisque Tu Pars PartitionLADURELLE JEROMENo ratings yet

- Roll Groove Distribution 3-01-2024Document18 pagesRoll Groove Distribution 3-01-2024Ahmed KassemNo ratings yet

- General Notes:: Dhi Qar Combined Cycle Power Plant ProjectDocument1 pageGeneral Notes:: Dhi Qar Combined Cycle Power Plant Projectmustafa1989ocNo ratings yet

- Bluesky Cineral S-2932N - TS-2933 - 2 - Vers - o - TDA9575 - Esquema - El - TricoDocument1 pageBluesky Cineral S-2932N - TS-2933 - 2 - Vers - o - TDA9575 - Esquema - El - TricoJorge Soares100% (1)

- Ruuvitag Revb6 SchematicDocument1 pageRuuvitag Revb6 SchematicJimmy HunterNo ratings yet

- Caterpillar 3500B and 3500C. SchematicDocument2 pagesCaterpillar 3500B and 3500C. SchematicАлексейNo ratings yet

- CNN008311 Diagrams and DrawingsDocument40 pagesCNN008311 Diagrams and DrawingsandraNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- HH45, HH55, HH65, and HH75 Harvester Heads Electrical SystemDocument2 pagesHH45, HH55, HH65, and HH75 Harvester Heads Electrical SystemGilvan JuniorNo ratings yet

- Pinout PDFDocument2 pagesPinout PDFAnonymous rKRWKIwM1No ratings yet

- H047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDocument1 pageH047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDedeNazaludinNo ratings yet

- 16 mm2 (SC) 16 mm2 (SC) : 16 Diodes 7 Diodes Fuse ShuntDocument2 pages16 mm2 (SC) 16 mm2 (SC) : 16 Diodes 7 Diodes Fuse ShuntBùi Quang DuyNo ratings yet

- OPPO A71 - SCHDocument34 pagesOPPO A71 - SCHbudiNo ratings yet

- Issued For Construction: Level 0 FFL 0.022Document1 pageIssued For Construction: Level 0 FFL 0.022Sadique PkNo ratings yet

- TV HyundaiDocument12 pagesTV HyundaiJORGE LUIS PANTOJANo ratings yet

- Philips 715g3308-1 32pfl5404 PsuDocument4 pagesPhilips 715g3308-1 32pfl5404 PsuFonos ServisNo ratings yet

- 220 M6 0310 00032Document1 page220 M6 0310 00032nestor159357No ratings yet

- 7 2 PDFDocument19 pages7 2 PDFDenNo ratings yet

- 01 B276e5 MaaDocument1 page01 B276e5 MaaRenxio KahuaNo ratings yet

- Vulfpeck - Disco UlyssesDocument20 pagesVulfpeck - Disco Ulyssesgbezu11No ratings yet

- Ga Drawing Gs18123-550rev1Document1 pageGa Drawing Gs18123-550rev1Francisco VeraNo ratings yet

- Hydraulic Diagram J104-0142: Pcui BDocument3 pagesHydraulic Diagram J104-0142: Pcui BTarik FekraneNo ratings yet

- AmpegDocument2 pagesAmpegquietchannelNo ratings yet

- Circuit Diagram 353472Document2 pagesCircuit Diagram 353472Daniel GuevaraNo ratings yet

- LG - KG77 Circuit DDocument11 pagesLG - KG77 Circuit DJuan CharaNo ratings yet

- Power+Supply+RSAG7 820 4716+hisenseDocument1 pagePower+Supply+RSAG7 820 4716+hisenseBruno SamosNo ratings yet

- I45 (TCk4531) - MAIN - SCH - V1.1pdfDocument16 pagesI45 (TCk4531) - MAIN - SCH - V1.1pdfcoliuntung02No ratings yet

- Customer Project Name Drawing No Revision No Order No Senkronizasyon Panosu-DSE8610-PERKINS-4012 E3-190509825 R00 4012840-10-30 KM CompanyDocument22 pagesCustomer Project Name Drawing No Revision No Order No Senkronizasyon Panosu-DSE8610-PERKINS-4012 E3-190509825 R00 4012840-10-30 KM CompanyHawzhin AbdulrahmanNo ratings yet

- HCD-ECL77BT - ECL99BT DiagramaDocument14 pagesHCD-ECL77BT - ECL99BT DiagramaAmin Santana100% (1)

- 96pcaa00003-Amp PcbaDocument2 pages96pcaa00003-Amp PcbaassistenzadavidoffstoreNo ratings yet

- G78 (A) G78 (A) G78 (A) G78 (A) G78 (A) G78 (A)Document1 pageG78 (A) G78 (A) G78 (A) G78 (A) G78 (A) G78 (A)Serg GarkushaNo ratings yet

- ESP32-EVB Rev DDocument1 pageESP32-EVB Rev DAlexNo ratings yet

- DVA T4 Amp Low (Scheme)Document1 pageDVA T4 Amp Low (Scheme)palprodNo ratings yet

- FinalDocument1 pageFinalredNo ratings yet

- T17m202-02300-205mi-00002 (Im8-65519-4)Document1 pageT17m202-02300-205mi-00002 (Im8-65519-4)Rodrigo RaddatzNo ratings yet

- VESTEL 17MB45m-2Document9 pagesVESTEL 17MB45m-2eduardoNo ratings yet

- TrendsampleDocument1 pageTrendsampleBock DharmaNo ratings yet

- 005 1053 Sbp2 Pendant Install Manual Print 06-10-2020 2up No CropsDocument14 pages005 1053 Sbp2 Pendant Install Manual Print 06-10-2020 2up No CropsBock DharmaNo ratings yet

- Motor PG Feedback Line Driver Interface: Installation ManualDocument50 pagesMotor PG Feedback Line Driver Interface: Installation ManualBock DharmaNo ratings yet

- Manufacturing: 18.210 Variations From Rated Voltage and Rated FrequencyDocument7 pagesManufacturing: 18.210 Variations From Rated Voltage and Rated FrequencyBock DharmaNo ratings yet

- Mh097 C Track BrochureDocument4 pagesMh097 C Track BrochureBock DharmaNo ratings yet

- TF42-1.0 Thermal Overload Relay: Product-DetailsDocument5 pagesTF42-1.0 Thermal Overload Relay: Product-DetailsBock DharmaNo ratings yet

- TeSys D - K and SK Control Relays - CA2KN40G7Document3 pagesTeSys D - K and SK Control Relays - CA2KN40G7Bock DharmaNo ratings yet

- Valparaiso Community School Corporation 2018-2019 School Year CalendarDocument1 pageValparaiso Community School Corporation 2018-2019 School Year CalendarBock DharmaNo ratings yet

- MG 1 Part 5 - CranesDocument7 pagesMG 1 Part 5 - CranesBock DharmaNo ratings yet

- Reflx 45: Collision Avoidance System Instruction ManualDocument17 pagesReflx 45: Collision Avoidance System Instruction ManualBock DharmaNo ratings yet

- How To Achieve A Good Electrical Connection: What Size Is Your Landing Point? Overlap (Recommended For Punched Bars)Document1 pageHow To Achieve A Good Electrical Connection: What Size Is Your Landing Point? Overlap (Recommended For Punched Bars)Bock DharmaNo ratings yet

- SIEPC71061737Document1,026 pagesSIEPC71061737Alberto MolinaNo ratings yet

- Flex EX2 Receiver Select Systems: Radio Control Equipment Instruction ManualDocument39 pagesFlex EX2 Receiver Select Systems: Radio Control Equipment Instruction ManualBock DharmaNo ratings yet

- Three-Phase AC Power Electronics: Topic Coverage: Features and Benefi TsDocument2 pagesThree-Phase AC Power Electronics: Topic Coverage: Features and Benefi TsBock DharmaNo ratings yet

- Indiana Property Tax Benefits: State Form 51781 (R14 / 1-20) Prescribed by The Department of Local Government FinanceDocument5 pagesIndiana Property Tax Benefits: State Form 51781 (R14 / 1-20) Prescribed by The Department of Local Government FinanceBock DharmaNo ratings yet

- Laserguard2: Laser Collision Avoidance SystemDocument34 pagesLaserguard2: Laser Collision Avoidance SystemBock DharmaNo ratings yet

- SIEPC71061737Document1,026 pagesSIEPC71061737Alberto MolinaNo ratings yet

- TOEPYAIGA8002Document644 pagesTOEPYAIGA8002Wilfredo MolinaNo ratings yet

- Av85 Gen Iiiman PDFDocument10 pagesAv85 Gen Iiiman PDFBock DharmaNo ratings yet

- PL Ga800 01 PDFDocument50 pagesPL Ga800 01 PDFBock DharmaNo ratings yet

- Claim For Homestead Property Tax Standard / Supplemental DeductionDocument2 pagesClaim For Homestead Property Tax Standard / Supplemental DeductionBock DharmaNo ratings yet

- External Heatsink Installation Kit: Instruction ManualDocument24 pagesExternal Heatsink Installation Kit: Instruction ManualBock DharmaNo ratings yet

- SL Ga800 01 PDFDocument85 pagesSL Ga800 01 PDFBock DharmaNo ratings yet

- SL56 DS 702900 2 F PDFDocument2 pagesSL56 DS 702900 2 F PDFBock DharmaNo ratings yet

- Northstar Instruction Manual Supplement: Sensor Module Installation For High Humidity/Wash-Down and Marine EnvironmentsDocument2 pagesNorthstar Instruction Manual Supplement: Sensor Module Installation For High Humidity/Wash-Down and Marine EnvironmentsBock DharmaNo ratings yet

- Northstar Slim Tach Sl56 6 Easy Steps To InstallationDocument16 pagesNorthstar Slim Tach Sl56 6 Easy Steps To InstallationBock DharmaNo ratings yet

- Instruction Manual: BrandDocument12 pagesInstruction Manual: BrandBock DharmaNo ratings yet

- Toepyaiga8001 PDFDocument384 pagesToepyaiga8001 PDFBock DharmaNo ratings yet

- Av85 Gen Iiiman PDFDocument10 pagesAv85 Gen Iiiman PDFBock DharmaNo ratings yet

- Instruction Manual: BrandDocument12 pagesInstruction Manual: BrandBock DharmaNo ratings yet

- 3.3 Motherboard SchematicsDocument49 pages3.3 Motherboard SchematicsJoanna WęgielNo ratings yet

- Chapter 12.1.2 Respiratory Substrates and RQDocument30 pagesChapter 12.1.2 Respiratory Substrates and RQnie20060301No ratings yet

- TDBFP - Gear Pump API 676 PDFDocument42 pagesTDBFP - Gear Pump API 676 PDFRamon A. Ruiz O.No ratings yet

- Value For Money Analysis.5.10.12Document60 pagesValue For Money Analysis.5.10.12Jason SanchezNo ratings yet

- 6.5 Tectonics and EvidencesDocument28 pages6.5 Tectonics and Evidencesbook wormNo ratings yet

- VISTA LAND AND LIFESCAPES INC FinalDocument9 pagesVISTA LAND AND LIFESCAPES INC Finalmarie crisNo ratings yet

- Q4 Tle 9 WK3Document5 pagesQ4 Tle 9 WK3Mj MartNo ratings yet

- Questionnaire On Teaching Learning 1Document4 pagesQuestionnaire On Teaching Learning 1Sonia Agustin100% (1)

- What Is System and Subsystem? What Is Its Relationship?Document6 pagesWhat Is System and Subsystem? What Is Its Relationship?Mulugeta kinde100% (1)

- EN Paper-5Document11 pagesEN Paper-5isabellemdelmasNo ratings yet

- Admissions: Application ProceduresDocument13 pagesAdmissions: Application Proceduresisber7abdoNo ratings yet

- KV Admission EnclosureDocument1 pageKV Admission EnclosureLaishram PilotNo ratings yet

- Cognitive Factors in LearningDocument3 pagesCognitive Factors in LearningNad DeYnNo ratings yet

- PIRCHLDocument227 pagesPIRCHLapi-3703916No ratings yet

- Design Guide For Overhead CranesDocument3 pagesDesign Guide For Overhead CranesralluinNo ratings yet

- Tutorial Set (Queing Model)Document5 pagesTutorial Set (Queing Model)Samuel kwateiNo ratings yet

- 2006 Estes Model Rocketry CatalogDocument44 pages2006 Estes Model Rocketry CatalogMisesWasRightNo ratings yet

- Wilkerson Case Study FinalDocument5 pagesWilkerson Case Study Finalmayer_oferNo ratings yet

- Misconceptions Can Be Referred To As A Preconceived Notion or A Conceptual MisunderstandingDocument14 pagesMisconceptions Can Be Referred To As A Preconceived Notion or A Conceptual MisunderstandingPhilippeggyjaden YongNo ratings yet

- Well Control - Pore PressureDocument31 pagesWell Control - Pore PressureMiguel Pinto PonceNo ratings yet

- Directorate of Pension, Provident Fund & Group Insurance: WWW - Wbepension.gov - inDocument37 pagesDirectorate of Pension, Provident Fund & Group Insurance: WWW - Wbepension.gov - inSandipan RoyNo ratings yet

- H-Beam Catalogue JindalDocument4 pagesH-Beam Catalogue JindalVikram DalalNo ratings yet

- Scib RC PipesDocument4 pagesScib RC PipesterrylimNo ratings yet

- BRT SylabussDocument29 pagesBRT SylabussAadityaNo ratings yet

- Lesson 12 FastenersDocument9 pagesLesson 12 FastenersEmerson John RoseteNo ratings yet

- Aviation EbookDocument36 pagesAviation Ebookmeroka2000No ratings yet

- TCS303 Pumping Station ControllerDocument17 pagesTCS303 Pumping Station ControllerNAdreaNo ratings yet