Professional Documents

Culture Documents

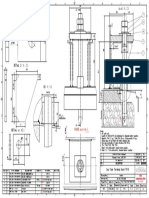

NPT 2" A (1: 5) 6 C-C: 02.04.2020 30.07.2019 KURA Kura

Uploaded by

Alfonso LópezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NPT 2" A (1: 5) 6 C-C: 02.04.2020 30.07.2019 KURA Kura

Uploaded by

Alfonso LópezCopyright:

Available Formats

A (1 : 5)

C C-C NPT 2"

6

A 6

56

B (1 : 5)

10

3

1454.6

1454.6

1578.8

200

26

8

NPT 1/2"

1050

D

2

28

26

28

76.2

NPT 1/2"

C Theoretical Dimensions

With Certificate 3.1 EN 10204 / Welding quality according to DIN EN 25817 C

Painted according to project specifications 8

D (1 : 5) All internal surfaces protected by VCI paper

Pipes and coolers must be provided with identical numbers

All opening have to be tighted against contamination for shipping

Dimension to be met

DIN EN ISO 13920

393.7 5 7

Quantity Object Dimension Material Standard-No. Item Article-No. Remarks kg/Piece

1 Welding neck flange 2" / 150lbs / RF SA-105 ASME B 16.5 1 - 3.1/MTR 2.61

63.5 250 76.2

62

1 Pipe ø60.3x3.9 L=250 SA-106 B - 2 - 3.1 1.36

NPT 1"

ø60.3x3.9

1 Pipe SA-106 B - 3 - 3.1 7.91

L=1454.6

2 2 1 Elbow large 90° / 2" R=76.2 A 234 WPB B19.9 4 - MTR 0.85

2 2 Elbow large 90° / 1 1/4" A 234 WPB B19.9 5 - MTR 0.27

2 R=47.75

47.75 43 1 Socket NPT 2" L=56 St - 6 - - 0.29

2 Socket NPT 1" L=43 St - 7 - - 0.12

92.75 2 Socket NPT 1/2" L=34 St - 8 - - 0.06

1 Revision note Changed (dd.mm.yy) Prepared (dd.mm.yy)

30.07.2019 KURA Scale

Approved (dd.mm.yy) 02.04.2020 KURA

-

Project no. Format

1:10

-

No separate parts list Purpose of application Weight

13.76kg A3

130.5 120 143.2

CAD-System: SolidWorks

General Welding Tolerances DIN EN ISO 13920

Separate parts list, same no. - Replaced by

- No. of sheets Sheet no.

General Tolerances DIN ISO 2768

Fabrication standard Application no. - Replacement for

- 1 1

Tolerance

Permissible deviations in mm for ranges in nominal lengths

class > 0,5 > 3 > 6 > 30 > 120 > 400 > 1000 > 2000 Connecting Pipe 2" Drawing no. Revision

m (medium)

... 3 ... 6 ... 30 ... 120 ... 400 ... 1000 ... 2000 ... 4000

±0,1 ±0,1 ±0,2 ±0,3 ±0,5 ±0,8 ±1,2 ±2

-

- 27 37631 A

Plot: 02.04.2020 Any unpermitted use is subject to prosecution.

You might also like

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- Assembly Belt Tightener Filza (49722)Document1 pageAssembly Belt Tightener Filza (49722)Filza hanifahNo ratings yet

- Centrifugal Pump CoverDocument1 pageCentrifugal Pump Covermavas88069No ratings yet

- 11kv and LV Pin InsulatorsDocument1 page11kv and LV Pin InsulatorsMosa Elnaid ElnaidNo ratings yet

- Bearing Stand PDFDocument1 pageBearing Stand PDFËďdýsson ČhüqűïîanaNo ratings yet

- VoiceDocument2 pagesVoicePaulo CorreaNo ratings yet

- Inventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine FlywheelDocument1 pageInventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine FlywheelMochammad ReshaNo ratings yet

- 402 08 TY01 000.rev2Document1 page402 08 TY01 000.rev2Miro CiglenečkiNo ratings yet

- These Face Case Hardening Upto 58 2 HRC & 0.8 TO 1.2 DEPTH: Forbes & Company LimitedDocument1 pageThese Face Case Hardening Upto 58 2 HRC & 0.8 TO 1.2 DEPTH: Forbes & Company LimitedChandru ChristurajNo ratings yet

- Eccentric TrapDocument1 pageEccentric TrapCốGắngNàoNo ratings yet

- 44 - Flange Coupling Assembly FinalDocument1 page44 - Flange Coupling Assembly Finaladmam jones0% (2)

- Caminito Soleado Guitar 2Document2 pagesCaminito Soleado Guitar 2Emanuel MolinaNo ratings yet

- Frb01a011112 PDFDocument1 pageFrb01a011112 PDFChandru ChristurajNo ratings yet

- 6510A MPU: Reset Srqin DataDocument2 pages6510A MPU: Reset Srqin DataKevyn DouglasNo ratings yet

- GUNJYOU-Clarinete en SibDocument3 pagesGUNJYOU-Clarinete en SibAlejandro OlanNo ratings yet

- Inventorwizard: Miniature Model Steam Engine Horizontal Beam Engine With Centrifugal Pump PulleyDocument1 pageInventorwizard: Miniature Model Steam Engine Horizontal Beam Engine With Centrifugal Pump PulleyAjiSenoNo ratings yet

- UmbrellaDocument3 pagesUmbrellaBeatriz Gómez GarcíaNo ratings yet

- UmbrellaDocument3 pagesUmbrellaBeatriz Gómez GarcíaNo ratings yet

- AS119-4L-30 - Ver.7 DimensionDocument1 pageAS119-4L-30 - Ver.7 DimensionmilicevicbpNo ratings yet

- Tms320c6713bpyp PDFDocument1 pageTms320c6713bpyp PDFHongNo ratings yet

- Mechanical Documentation PDFDocument19 pagesMechanical Documentation PDFmiguelavellanedaNo ratings yet

- O Rosto de Cristo - PartesDocument88 pagesO Rosto de Cristo - PartesnicolemenezesNo ratings yet

- FRB01A011107Document1 pageFRB01A011107Chandru ChristurajNo ratings yet

- Crankcase Cover PDFDocument1 pageCrankcase Cover PDFhmalexisNo ratings yet

- 38 - Screw Jack Assembly FinalDocument1 page38 - Screw Jack Assembly Finaladmam jones100% (1)

- Dame Una OportunidadDocument3 pagesDame Una OportunidadLuis Roca CruzNo ratings yet

- River in Judea - CelloDocument2 pagesRiver in Judea - CelloRey AbellanaNo ratings yet

- Inventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine SupportDocument1 pageInventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine SupportDhino Vega RiosNo ratings yet

- Oil BurnerDocument1 pageOil BurnerFariz AuliaNo ratings yet

- Tous Les Mêmes, BasseDocument2 pagesTous Les Mêmes, BasseMatthias CLEMENTNo ratings yet

- Tous Les Mêmes, BasseDocument2 pagesTous Les Mêmes, BasseMatthias CLEMENTNo ratings yet

- Tous Les Mêmes, BasseDocument2 pagesTous Les Mêmes, BasseMatthias CLEMENTNo ratings yet

- CUERPODocument1 pageCUERPONacho ZelaliaNo ratings yet

- These Tears-Trombone 1Document3 pagesThese Tears-Trombone 1Rooney ChinNo ratings yet

- El Final - Rostros Ocultos (Atzin)Document3 pagesEl Final - Rostros Ocultos (Atzin)Lili Star Moon100% (1)

- Pcology IIIDocument4 pagesPcology IIIAnit DubeyNo ratings yet

- Item 2. 36.DN25.10D1Document1 pageItem 2. 36.DN25.10D1luoiesNo ratings yet

- BELT DRIVE 25 Jan 2024Document1 pageBELT DRIVE 25 Jan 2024bimaditya281No ratings yet

- Salmo 5 (À Minha Voz, Ó Deus Atende) Baixo EDocument2 pagesSalmo 5 (À Minha Voz, Ó Deus Atende) Baixo ERafael AndradeNo ratings yet

- AualDocument1 pageAualRobson NerioNo ratings yet

- Wario Stadium-Saxophone - TénorDocument1 pageWario Stadium-Saxophone - Ténorcarvalho.zackarielNo ratings yet

- Flywheel PDFDocument1 pageFlywheel PDFedward santiago buitrago aguirreNo ratings yet

- Pasko Na Naman March PDFDocument57 pagesPasko Na Naman March PDFDennisNo ratings yet

- Libertango 2nd Violin Part String QuartetDocument2 pagesLibertango 2nd Violin Part String QuartetELISENo ratings yet

- Amor Lunatico - Bajo EléctricoDocument4 pagesAmor Lunatico - Bajo Eléctricojesus david maturana cardonaNo ratings yet

- Amor Lunatico - Bajo EléctricoDocument4 pagesAmor Lunatico - Bajo EléctricoJesús MaturanaNo ratings yet

- Silhouettez: 2 X M8 2 X 8 (H7)Document1 pageSilhouettez: 2 X M8 2 X 8 (H7)ImranNo ratings yet

- Si Me Dejas No Vale - Flute 1Document2 pagesSi Me Dejas No Vale - Flute 1Jorge Luis Guevara MoraNo ratings yet

- Inventorwizard: Miniature Model Steam Engine Horizontal Beam Engine With Centrifugal Pump ValveDocument1 pageInventorwizard: Miniature Model Steam Engine Horizontal Beam Engine With Centrifugal Pump ValveQTG channelNo ratings yet

- La Gran Señora - BajoDocument3 pagesLa Gran Señora - BajoCaes Diseño y publicidadNo ratings yet

- Item 1 (1: 5) D1: PapacadDocument2 pagesItem 1 (1: 5) D1: Papacadminh hiếu nguyễnNo ratings yet

- Imposible: Trompeta en SiDocument1 pageImposible: Trompeta en Siluis covaNo ratings yet

- I TrumpetDocument1 pageI TrumpetSantiagoNo ratings yet

- Arbore Cotit DesenDocument1 pageArbore Cotit DesenIonel Bogdan NeacșuNo ratings yet

- MARINES CORPS CORPORAL Homenagem Aos Cabos Da Banda Marcial Do CFN-FLAUTIMDocument2 pagesMARINES CORPS CORPORAL Homenagem Aos Cabos Da Banda Marcial Do CFN-FLAUTIMRosinaldo Araújo LimaNo ratings yet

- Here Santa Claus BaritonoDocument2 pagesHere Santa Claus BaritonoMaryuli Hernandez FrancoNo ratings yet

- Dept. Technical Reference Created by Approved byDocument2 pagesDept. Technical Reference Created by Approved byMDM19B034 BAKSHI ANUPAMA SAINo ratings yet

- Ricordati Di Me Alto SaxDocument2 pagesRicordati Di Me Alto SaxSimone SciarrettaNo ratings yet

- Assembly B1C: Front ViewDocument1 pageAssembly B1C: Front Viewmathews josephNo ratings yet

- Unit 6: 121.41in 3084mm 33.7in 854.8mmDocument2 pagesUnit 6: 121.41in 3084mm 33.7in 854.8mmAlfonso LópezNo ratings yet

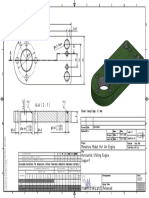

- Oficina3 29/03/2021: Drawn Checked QA MFG Approved DWG No TitleDocument1 pageOficina3 29/03/2021: Drawn Checked QA MFG Approved DWG No TitleAlfonso LópezNo ratings yet

- Kura 13.03.2019 25.03.2019 06.11.2018 KURA KuraDocument1 pageKura 13.03.2019 25.03.2019 06.11.2018 KURA KuraAlfonso LópezNo ratings yet

- Unit 6: 121.41in 3084mm 33.7in 854.8mmDocument2 pagesUnit 6: 121.41in 3084mm 33.7in 854.8mmAlfonso LópezNo ratings yet

- 27 37635 B Motor Base PlateDocument1 page27 37635 B Motor Base PlateAlfonso LópezNo ratings yet

- (Name and Address of Manufacturer) : Body Flanges On ShellsDocument3 pages(Name and Address of Manufacturer) : Body Flanges On ShellsAlfonso LópezNo ratings yet

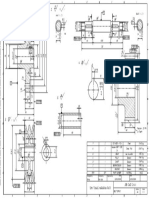

- 40 00001 B Piping Complete: RevisionsDocument1 page40 00001 B Piping Complete: RevisionsAlfonso LópezNo ratings yet

- Oficina3 29/03/2021: Drawn Checked QA MFG Approved DWG No TitleDocument1 pageOficina3 29/03/2021: Drawn Checked QA MFG Approved DWG No TitleAlfonso LópezNo ratings yet

- 27 37635 B Motor Base PlateDocument1 page27 37635 B Motor Base PlateAlfonso LópezNo ratings yet

- 27 37456 B Support Safety Switch: Kura 16.06.2020 19.06.2020 18.04.2018 MB KuraDocument1 page27 37456 B Support Safety Switch: Kura 16.06.2020 19.06.2020 18.04.2018 MB KuraAlfonso LópezNo ratings yet

- 27 37635 B Motor Base PlateDocument1 page27 37635 B Motor Base PlateAlfonso LópezNo ratings yet

- 26 29729 A Corner Leg 2000: 31.05.2018 24.05.2018 MB CBDocument1 page26 29729 A Corner Leg 2000: 31.05.2018 24.05.2018 MB CBAlfonso LópezNo ratings yet

- Kura 13.03.2019 25.03.2019 06.11.2018 KURA KuraDocument1 pageKura 13.03.2019 25.03.2019 06.11.2018 KURA KuraAlfonso LópezNo ratings yet

- Ultrasonic Flowmeter Sets: Non-Invasive Pipe Flow Measurement, Easy Operation and Data Logging OptionDocument1 pageUltrasonic Flowmeter Sets: Non-Invasive Pipe Flow Measurement, Easy Operation and Data Logging OptionAlfonso LópezNo ratings yet

- 27 37456 B Support Safety Switch: Kura 16.06.2020 19.06.2020 18.04.2018 MB KuraDocument1 page27 37456 B Support Safety Switch: Kura 16.06.2020 19.06.2020 18.04.2018 MB KuraAlfonso LópezNo ratings yet

- 26 29731 A Strut: 31.05.2018 24.05.2018 MB CBDocument1 page26 29731 A Strut: 31.05.2018 24.05.2018 MB CBAlfonso LópezNo ratings yet

- 27 37440 B Strut: MB 30.05.2018 31.05.2018 08.03.2018 MB CBDocument1 page27 37440 B Strut: MB 30.05.2018 31.05.2018 08.03.2018 MB CBAlfonso LópezNo ratings yet

- 27 37440 B Strut: MB 30.05.2018 31.05.2018 08.03.2018 MB CBDocument1 page27 37440 B Strut: MB 30.05.2018 31.05.2018 08.03.2018 MB CBAlfonso LópezNo ratings yet

- All Dimensions Are In: in (MM)Document2 pagesAll Dimensions Are In: in (MM)Alfonso LópezNo ratings yet

- 26 29729 A Corner Leg 2000: 31.05.2018 24.05.2018 MB CBDocument1 page26 29729 A Corner Leg 2000: 31.05.2018 24.05.2018 MB CBAlfonso LópezNo ratings yet

- 26 29728 A Corner Leg 2000: 31.05.2018 24.05.2018 MB CBDocument1 page26 29728 A Corner Leg 2000: 31.05.2018 24.05.2018 MB CBAlfonso LópezNo ratings yet

- 27 37440 B Strut: MB 30.05.2018 31.05.2018 08.03.2018 MB CBDocument1 page27 37440 B Strut: MB 30.05.2018 31.05.2018 08.03.2018 MB CBAlfonso LópezNo ratings yet

- 27 37440 B Strut: MB 30.05.2018 31.05.2018 08.03.2018 MB CBDocument1 page27 37440 B Strut: MB 30.05.2018 31.05.2018 08.03.2018 MB CBAlfonso LópezNo ratings yet

- 27 37630 A Connecting Pipe 2": 02.04.2020 30.07.2019 KURA KuraDocument1 page27 37630 A Connecting Pipe 2": 02.04.2020 30.07.2019 KURA KuraAlfonso LópezNo ratings yet

- 13M014Document2 pages13M014Alfonso LópezNo ratings yet

- 28.10.2020 15.07.16 MB Kura: M (Medium)Document1 page28.10.2020 15.07.16 MB Kura: M (Medium)Alfonso LópezNo ratings yet

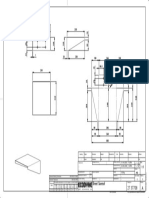

- 27 37708 A Sheet Sunroof: 02.04.2020 01.04.2020 KURA KuraDocument1 page27 37708 A Sheet Sunroof: 02.04.2020 01.04.2020 KURA KuraAlfonso LópezNo ratings yet

- 26 49493 A Shim Plate: 16.04.2018 09.03.2018 MB CBDocument1 page26 49493 A Shim Plate: 16.04.2018 09.03.2018 MB CBAlfonso LópezNo ratings yet

- Proton Transfer in Water, Channels and Bioenergetic ProteinsDocument27 pagesProton Transfer in Water, Channels and Bioenergetic ProteinsAlfonso LópezNo ratings yet

- 06-810 Ul-Fm Ig100Document154 pages06-810 Ul-Fm Ig100Rizki Fadillah100% (1)

- Oracle EBS R12.2.6 Application Tier Cloning With Step by StepDocument10 pagesOracle EBS R12.2.6 Application Tier Cloning With Step by Stepdoyenblog100% (1)

- REPORT OF SUPPLIES AND MATERIALS ISSUED From Jan. To Dec. 2014Document5 pagesREPORT OF SUPPLIES AND MATERIALS ISSUED From Jan. To Dec. 2014Jonelyn Capalad100% (2)

- MSEDCL - End User Training Manual - Consolidation of CGRF Cases - Zone-JEDocument17 pagesMSEDCL - End User Training Manual - Consolidation of CGRF Cases - Zone-JEanandNo ratings yet

- Subsurface Ventilation Systems MVS-SVE - Chapter04Document36 pagesSubsurface Ventilation Systems MVS-SVE - Chapter04Ghita Noerma GuphitaNo ratings yet

- VLSI Testing &testability VLSI Testing &testability VLSI Testing &testabilityDocument8 pagesVLSI Testing &testability VLSI Testing &testability VLSI Testing &testabilityishansi agrawalNo ratings yet

- Tracer BPL SMS EL V2.0 PDFDocument2 pagesTracer BPL SMS EL V2.0 PDFmuhamad agusNo ratings yet

- Summer Training Report, ITI Mankapur, GondaDocument31 pagesSummer Training Report, ITI Mankapur, GondaAMAENo ratings yet

- Xspider ManualDocument236 pagesXspider Manualady_marinescuNo ratings yet

- VP Marketing Product Development in NYC Resume Sherri SwihartDocument2 pagesVP Marketing Product Development in NYC Resume Sherri SwihartSherriSwihartNo ratings yet

- Kaizen EventsDocument35 pagesKaizen EventsIndhu SharmaKSNo ratings yet

- DatasheetDocument79 pagesDatasheetJoeltell1307 LopezNo ratings yet

- 4-H Communications Toolkit 4H1560 PDFDocument179 pages4-H Communications Toolkit 4H1560 PDFMistor Dupois WilliamsNo ratings yet

- 4 - Switching MCQ QuestionsDocument6 pages4 - Switching MCQ QuestionsMohamed Alfarash100% (1)

- Catalogo/Catalogue: Green Power GeneratorsDocument24 pagesCatalogo/Catalogue: Green Power GeneratorsNabil AbdenbaouiNo ratings yet

- Ducati Diavel ABS WiringDocument1 pageDucati Diavel ABS WiringKhoảng LặngNo ratings yet

- Review of LadleDocument6 pagesReview of LadlezsmithNo ratings yet

- Pizza Hut.. StrategicDocument12 pagesPizza Hut.. StrategicAyushi Garg100% (1)

- 84B540865AB RevCDocument34 pages84B540865AB RevCivanNo ratings yet

- ULTRADYN Hollow Fiber Modules FS10 FE10 User Manual PDFDocument20 pagesULTRADYN Hollow Fiber Modules FS10 FE10 User Manual PDFjpsingh75No ratings yet

- QuickRide LogcatDocument117 pagesQuickRide LogcatThala VetrivelNo ratings yet

- AS ING Rev0 PDFDocument38 pagesAS ING Rev0 PDFNguyen Quyet ThangNo ratings yet

- Discover ANSTODocument17 pagesDiscover ANSTOowirwojNo ratings yet

- Siemens ET200M Systems ManualDocument240 pagesSiemens ET200M Systems ManualAndrey ZimnitskiyNo ratings yet

- Smart Card NikkiDocument17 pagesSmart Card NikkimaheshfbNo ratings yet

- Assignment No.1 Title-Case Study Based Assignment On Method StudyDocument4 pagesAssignment No.1 Title-Case Study Based Assignment On Method Studyshreyas mithariNo ratings yet

- SPG CAL 50 008 A4 Calculation Genset FoundationDocument11 pagesSPG CAL 50 008 A4 Calculation Genset FoundationOmar PerpatihNo ratings yet

- Master ArbeitDocument94 pagesMaster Arbeitjibran_javed6764100% (2)

- Overview of FilmDocument6 pagesOverview of FilmMahade Hasan DipuNo ratings yet

- SDK-Python Interface ENG V1.0Document32 pagesSDK-Python Interface ENG V1.0Chandru ChristurajNo ratings yet