Professional Documents

Culture Documents

JCB Wheel Loader PDF

Uploaded by

Aabhishek SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JCB Wheel Loader PDF

Uploaded by

Aabhishek SinghCopyright:

Available Formats

HYDRAULIC

455ZX WHEELED

EXCAVATOR

LOADING SHOVEL

EW

N

A GREAT BUSINESS DECISION

Operating weight: 17880kg, Gross engine power: 165kW (221hp), Full turn tipping load: 11100 kg, Standard shovel capacity: 3.1m³

MORE RELIABLE

DESIGNED AND BUILT TO COPE-UP WITH EVEN THE

MOST DEMANDING SITES, HOUR AFTER HOUR, DAY

AFTER DAY.

Designed to work hard

1 State-of-the-art manufacturing processes like robot

machining, precision paint technology and innovative

assembly techniques to achieve the highest levels of

build quality.

2 Finite element analysis and rig testing ensure superior

structural strength and durability.The 455ZX has

been tested in hot and cold climates to ensure that it

performs anywhere

3 The counterweight and cast quarter pillars protect

the cooling pack and the back end of the machine from

damages. Recessed rear lights are protected within the

solid counterweight.

4 Hoses are neatly routed and clamped through the

articulation joint, well away from any pinch points.

1 2 3

2 455ZX WHEELED LOADING SHOVEL

MORE RELIABLE

Built to last

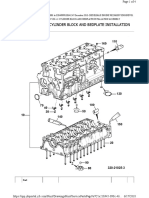

5 JCB DIESELMAX engine feature a heavy-duty cast

iron cylinder block, bedplate, cylinder head and forged

crankshaft to provide more strength and long life.

6 Precision machining provides high tolerance and

accurate location of the 455ZX’s pins and bushes.

7 The 455ZX is fitted with world class components.

A JCB DIESELMAX engine, ZF transmission and axles,

8

Rexroth pumps and a Parker valve block, assure long 5

and reliable service life of the machine.

8 The articulation joint has a heavy-duty box section

(much stronger than a single plate with a boss), a

heavy-duty centre pin and an oversized bush. It also

has twin taper roller bearings on the bottom box joints.

This setup can tolerate both vertical and horizontal

loadings for durability and rigidity. Steering rams are

positioned high up and are protected from damage.

9 A unique 3 stage fuel filtration system along with

a water separator to deal with water, in fuel fine and

large particles. Thus ensuring reliable opearation at

sites where fuel quality is a challenge. 6

455ZX WHEELED LOADING SHOVEL 3

MORE PRODUCTIVE

THE NEW JCB 455ZX GIVES UNMATCHED AND

UNINTERRUPTED PRODUCTIVITY. ITS ENGINE OFFERS

MORE POWER AND TORQUE, WHILE ITS HYDRAULICS AND

LOADER END ARE SET UP TO KEEP CYCLE TIMES SHORT

AND WORKING SHIFTS LONG.

SAVE

UPTO

50,00,000 Powering it all

1 The JCB DIESELMAX 672 engine uses our

latest generation EcoMAX lean-burn combustion

technology for more efficiency and reduced

POWER AND TORQUE CURVES emissions. The 6-cylinder 7.2 litre engine achieves 2

1100 180

high power (165kW) and peak torque (1000Nm)

1000 at low revs for excellent response.

160

900

800 140 2 A state-of-the-art engine management system

700

ensures fuel effieciency and offers optimised

Nm

120

performance at all times.

kW

600

500 100

3 There is a 310-litre fuel tank as standard on the

*In 3 years (T&C Apply)

400

80 455ZX, along with an extremely efficient matching

300

hydraulics, transmission with the engine. This

200

900 1100 1300 1500 1700 1900 2100 2300

60

combination ensures maximum uptime between

RPM refuelling: a welcome feature when you’re

POWER TORQUE working in remote sites where diesel has to be

transported in. 1 3

4 455ZX WHEELED LOADING SHOVEL

MORE PRODUCTIVE

Powerful twin variable displacement piston

pump hydraulics can circulate a massive

226 l/min for fast cycles and excellent

multi-function capability.

Loading productivity

4 Proven Z-bar loader geometry gives exceptional

productivity, due to a comprehensive penetration into

the pile, high breakout forces, good roll-back angles

and faster dig time. The users are also benefited from

reduced tyre wear and more fuel efficiency, making this

machine a great investment for any business.

5 The innovative Electronic Management System

can perform progressive clutch cut-off for efficient,

productive loader control. This feature controls tractive

effort via the transmission, diverting maximum power

to the loader hydraulics and reducing service brake

wear and fuel consumption.

6 The limited slip differential in the 455ZX are perfect

for slushy terrian.

7 The 455ZX’s selectable loader arm detents, means

that the operators can set loader arm height limitations,

return to dig and float functions to ensure faster cycle

time and enhanced productivity.

4 5 7

455ZX WHEELED LOADING SHOVEL 5

MORE COMFORT MORE SPACIOUS

TO KEEP OPERATORS SAFE AND PRODUCTIVE,

THE NEW 455ZX COMES WITH 3M³ CABIN WHICH

IS SPACIOUS, EASY TO ACCESS AND QUIET. IT ALSO

OFFERS EXCELLENT VISIBILITY AND AN INTUITIVE,

ERGONOMIC CONTROL LAYOUT.

Best-in-class operator comfort

1 For maximum operator comfort, the 455ZX

is fitted with an easily adjustable tilt and telescopic

steering column.

2 A stylish, modern central dash display combines

analogue dials and a colour LCD screen – Excellent visibility is assured with a 3-piece laminated

this displays machine’s health details, service front screen and interior mirrors, an optional reverse

camera and a sloping rear bonnet also help to provide

requirements and operating information.

an all-around view.

3 Optional 3-spool hydraulics enable many

attachments to be used easily for extra versatility of

your machine.

SPACIOUS

CABIN

1 2 3

6 455ZX WHEELED LOADING SHOVEL

MORE COMFORT MORE SPACE

A good place to work

5 Air conditioning and fan comes as standard

on the JCB 455ZX, ensuring that operators can

work comfortably in extreme conditions that

sites have to offer.

6 Ergonomic controls, comfortable seats and

spacious cabin offer fatigue free operation and

enhances productivity of operator.

7 Increased ventilation and easy on-site

communication through sliding windows on

each side.

8 There is more storage behind the rear seat

of this machine, keeping the forward operating

area uncluttered and safe.

9 Additional storage capacity and security is

provided by the lockable tool box on the right-

hand step.

5 7 8 9

455ZX WHEELED LOADING SHOVEL 7

MORE ACCESSIBLE LOW MAINTENANCE

THE NEW 455ZX PROMISES TO

WORK FOR MORE HOURS AT A

LOWER MAINTENANCE COST.

WORLD-CLASS COMPONENTS

ENSURE BUILT-IN QUALITY

LEADING TO RELIABILITY AND

VALUE OF MONEY.

Access all areas

1 Wide-opening gull-wing doors give access to

the 455ZX’s engine bay and cooling packs easily.

2 Daily checks and grease points are accessible

from ground level, which encourage daily

checks.

3 The cooling pack is a single faced unit, allowing

excellent access for cleaning.

1 2 3

8 455ZX WHEELED LOADING SHOVEL

MORE ACCESSIBLE LOW MAINTENANCE

Low maintenace long intervals

4 Grouped test ports give the convenience to check

brakes, steering and hydraulic system pressures

easily on a 455ZX.

5 Replaceable bolt on teeth bucket make it quick

and easy to renew and thus ensuring maximum

uptime.

6 The 455ZX’s electronic monitoring system

relays key information and real time alerts, thereby

safeguarding both machine and the operator.

7 Full hydraulic dual circuit braking with multiple oil

immersed discs give the 455ZX’s braking system a

virtually maintenance-free lifespan.

4 5 6

455ZX WHEELED LOADING SHOVEL 9

MORE EFFICIENT MORE SYTLISH

THE NEW JCB 455ZX IS DESIGNED TO

MOVE MORE MATERIAL IN LESS TIME.

WE’VE BUILT THE ENGINE, AXLES,

DRIVELINE AND HYDRAULICS TO WORK

IN PERFECT HARMONY WITH EACH

OTHER FOR ULTIMATE EFFICIENCY.

1 Wheel speed braking means the brakes rotate

at the same speed as the wheels for heat and drag

reduction, as well as for improved fuel economy.

2 A hydraulic cooling fan automatically reacts to

ambient temperature and adjusts the 455ZX’s

fan speed to optimise cooling and reduce fuel

consumption. This feature also lowers noise levels.

3 JCB’s innovative variable displacement pumps

feed a load-sensing valve block which only

consumes power on demand, providing precise,

1 2 3

efficient loader control.

10 455ZX WHEELED LOADING SHOVEL

MORE SAFETY

IT’S ESSENTIAL TO KEEP WORKSITES SAFE AT ALL

TIMES. THE NEW JCB 455ZX OFFERS GREAT VISIBILITY,

NON-SLIP SURFACES, AIR FILTRATION AND MANY MORE

FEATURES WHICH MAKE THE EQUIPMENT AND THE

SITE SAFER.

Safety first

1 Access steps are inclined and equally spaced,

complemented by well positioned grab handles for

three points of contact at all times.

2 Interior mirrors, exterior mirrors and bonnet

mirrors combine to provide superb all-round visibility.

3 Non-slip walkways and additional grab handle

options allow operators to move around the exterior

of the machine safely.

The 455ZX’s cab is isolated from the chassis by

rubber mounts, which keeps noise and vibration levels

to a minimum. It’s also compliant with ROPS/FOPS

standards, and positively pressurised against dust.

4 Our optional rear-view camera displays an

unobstructed rear view on in-cab colour monitor.

1 2 4

455ZX WHEELED LOADING SHOVEL 11

MORE CARE

WITH OVER 650 DEALER OUTLETS, THE EQUIPMENT WILL

NEVER BE FAR FROM PROFESSIONAL PRODUCT SUPPORT.

AVAILABILITY OF PARTS AND MANPOWER ENSURE THAT

THE MACHINE PERFORMS TO ITS FULL POTENTIAL.

JCB Premier Line Solutions

Choose from exclusive array of warranty support packages which are

tailor made for your business requirements. JCB trained experts and

part availability will keep your businesses moving.

Livelink

Stay in control 24x7 with JCB Advance Telematics System - Livelink.

With real time data monitoring around Service, Security and

Operation of your machines. It is the quickest way to confirm that

your machines are well maintained and in good health, without having

to be physically present near you machines.

Care

JCB Trained Service engineers, parts availability across the strategic

location and 650+ dealer outlets. Ensuring your machines are up all

the time 24x7.

12 455ZX WHEELED LOADING SHOVEL

Stay Connected 24x7

Now be assured of your JCB wheel loading shovel’s service, operation and security with the advanced telematics system called Livelink.

S ERVICE

Livelink will notify you about the service requirement of

O PERATION

Livelink helps you maintain your machine health and manage

S ECURITY

Livelink helps you to keep a track of your machine’s

your machine. It increases the efficiency of your machine and your fleet better by alerting you of any variation in health location, protection and movement.

keeps it in a perfect working conditions. indicators. It lets you know in real time, if your machine is facing

a problem or needs any quick check-up.

Service reminder Machine utilisation report GPS tracking

Reminds you when the service of your machine Maintains machine usage record and helps you Tells you the exact position of

is due; to help you plan your work better. analyse & optimise utilisation of machine. your machine on a map.

Operating hours

Machine data backup Engine status

Alerts you when the machine is used outside

Informs you if your JCB machine’s engine is the working hours, as set by you.

Helps to maintain the records of past services

in an organised manner. switched on or off.

Possible intrusion/ Tow away alert

Critical machine health alerts Helps you save your machine from intruders

and possible tow aways.

Allowing you to know the inside of your

machine from a faraway location. Helps

in taking proactive measures to avoid

breakdown through alerts like;

• Low engine oil pressure. Geofencing

• Water in fuel.

• Coolant temperature. Allows you to keep your machine within the

• Transmission oil temperature. allocated area of work.

455ZX WHEELED LOADING SHOVEL 13

ENGINE ELECTRICAL SYSTEM

Common Rail Direct Injection (CRDi), System voltage Volt 24V

Type

Water cooled diesel engine Alternator output Amp hour 28V 100A

Model JCB DIESELMAX 672 Battery capacity Amp hour 2 x 12V 900CCA

Capacity litres 7.2

Aspiration Turbocharged and after cooler

TYRE SIZE

Cylinders 6

Dimensions

Max gross power to (SAEJ 1995/ISO 14396) kW (hp) 165 (221)

Tyre size Manufacturer Type Rating Operating weight (kg) Vertical mm Width mm

Max torque Nm @ 1500rpm 1000

23.5x25-20PR BKT L3 20PR 17,880

Emissions BSIII

23.5x25 (crossply) BKT (XL GRIP) E3/L3 20PR 18000 +26 0

CAB 23.5R25 (radial) BKT E3/L3 1* 18020 +12 0

Resiliently mounted ROPS/FOPS structure (tested in accordance with EN347:2008/EN3449: 2008 (Level 2). Entry/exit is

via large rear hinged door, grab handles giving 3 points of contact and anti-slip inclined steps. Forward visibility through a

curved, laminated windscreen with lower glazed quarter panels, two mirror and non heated exterior mirrors. Instrumentation HYDRAULICS

analogue/digital display gauges along with full colour LCD screen including selectable machine and operator menus along Pump type Variable displacement piston pump-load

with service and diagnostic screens. Heating/ventilation provides balanced and filtered air distribution throughout the cab sensing

via powerful 8 kW capacity heater, with air conditioning and climate control system as options. Provision of speakers and Pump 1, max. flow l/min 132

antenna for radio fitment (radio/CD not included). The cab environment is positively pressurised preventing the ingress of dust

Pump 1, max. pressure bar 250

including in-cab recirculation filter. Fabric mechanical suspension seat as standard with various options including vinyl material,

air suspension, heating and deluxe grammer actimo XXL air suspension seat with headrest, twin armrests, lumbar support, Pump 2, max. flow l/min 94

backrest extension, heating and full adjustment. Coat hook, cup holder and additional stowage space. Fuse box positioned at Pump 2, max. pressure bar 310

rear for access to fuses, relays and diagnostic connectors. Hydraulic cycle times at full engine rpm

TRANSMISSION - Arms raise (full bucket) seconds 6.0

Type 4 Wheel drive, Automatic 4 speed transmssion - Bucket dump (full bucket) seconds 1.9

Make ZF - Arms lower (empty bucket) seconds 3.7

Model 4WG190 - Total cycle seconds 11.6

Speed Forward Reverse

1st gear kph 6.5 6.85

SERVICE FILL CAPACITIES

2nd gear kph 12.8 13.49

Hydraulic tank litres 180

3 gear

rd

kph 23.77 24.85

Fuel tank litres 310

4th gear kph 36.04

Engine oil sump litres 28

AXLES Transmission oil system litres 36

Type Limited slip differential Axle oil (front) litres 35

Make and model Front- ZF MTL 3095 II / Rear - ZF MTL 3085 II Axle oil (rear) litres 35

Overall axle ratio 23.33 Engine coolant system litres 37

Rear axle oscillation ±12.5°

Bias ratio 30%

STANDARD EQUIPMENT

STEERING Return to dig, boom kickout, 12V converter, sun visor, interior mirror, left hand and right hand rear view mirror, front light

Q-Amp hydraulic system with steer priority valve operating at 190 bar to provide smooth, low effort response. guard, tail lamp guard, livelink, front screen guard, cabin fan, FM radio with speakers, beacon

steer ram located high in chassis to provide protection from damage. Adjustable steering column. Steering angle ±40°

BRAKES

OPTIONAL EQUIPMENT

Hydraulic power braking on all wheels, operating pressure 80 bar (1160psi). Dual circuit with accumulator back-up provides

maximum safety under all conditions. In board mounted, oil immersed, multi-plate disc brakes with sintered linings reduce heat 3.5 cum bucket, 2.8 cum bucket, 4.8 cum bucket, reversible fan, 3 spool option valve, quick hitch (3 spool), 24V socket in

build up. Wheel speed braking improves performance and reduce wear. Parking brake, electro-hydraulic disc type operating cabin, heated mirror, cold start kit, emergency steer pump, rear view camera, rear view mirror, cigarette lighter, additional

on transmission output shaft. worklight, white noise horn, air suspension+heated seat, radial tyre

14 455ZX WHEELED LOADING SHOVEL

TURNING RADIUS LOADER DIMENSIONS

R3 (M) Maximum turn

radius over shovel Assumes the fitment of BKT 23.5- 25 -20PR L3 tyres

R1 Inside turn radius

R2 Radius over tyre Shovel mounting Direct Direct Direct Direct Direct Direct Direct Direct

R3 Turn radius over shovel Shovel type General purpose General purpose General purpose Coal bucket

Shovel equipment Tipped teeth penetration “Reversible toeplate no teeth” Tipped teeth & toe plate No teeth “Reversible

segments toeplate

no teeth”

Shovel capacity (SAE heaped) m3 2.8 3.1 3.3 3.5 3.3 3.5 4.8 5.0

Shovel capacity (struck) m3 2.497 2,791 2.993 3.137 2.993 3.137 3.972 4.110

Shovel width mm 2800 2800 2800 2800 2800 2800 3231 3231

STATIC DIMENSIONS ENGINE Shovel weight kg 1538 1614 1708 1757 1754 1803 1838 2100

A Overall length mm 7,984

Maximum material density kg/m3 1995 1790 1664 1557 1664 1557 1134 1063

B Axle to pivot pin mm 1,622

C Wheel base mm 3,300 Tipping load straight kg 12353 12276 13170 10371 13170 10371 13086 12824

D Axle to counterweight face mm 1,994 Tipping load full turn kg 11170 11100 10975 10893 10975 10893 10891 10629

E Minimum ground clearance mm 470 Payload (50% FTTL) kg 5585 5550 5490 5450 5490 5450 5446 5315

F Height over exhaust mm 3,318

G Width over cab mm 1,400 Maximum breakout force kN 175 164 154 148 154 148 139 132

H Width over tyres mm 2,702 M Dump angle maximum degrees 45 45 45 45 45 45 45 45

H1 Wheel track mm 2,100 N Roll back angle full height degrees 67 67 67 67 67 67 67 67

J Height over cab mm 3,370

O Roll back at carry degrees 45 45 45 45 45 45 45 45

J1 Over all height with beacon mm 3,714

Total weight kg 17,800 P Roll back at ground level degrees 39 39 39 39 39 39 39 39

R1 Inside turn radius mm 3211 Q Load over height mm 3822 3822 3831 3831 3822 3822 3769 3734

R2 Radius over tyre mm 5913

R Dump height (45 ° dump) mm 2741 2741 2887 2845 2741 2699 2724 2647

Inside turn radius over tyres mm 3,182

Maximum turn radius over shovel mm 6,554 S Dig depth mm 74 74 91 109 109 109 125 160

Articulation angle degrees ±40 T Reach at dump height mm 1183 1183 1085 1039 1183 1135 1288 1321

Data based on machine equipped with direct mounted

V Pin height mm 4107 4107 4107 4107 4107 4107 4107 4107

3.1 m3 bucket with toe plates and bolt on teeth &

23.5- 25 -20 PR L3 BKT Reach maximum (45°dump) - horizontal arm mm 2140 2140 2032 2074 2140 2182 2088 2120

R3 Maximum turn radius over shovel mm 6603 6637 6565 6591 6637 6670 6832 6865

Operating weight (includes 80Kg operator and full fuel kg 17805 17880 18000 18042 18000 18042 18084 18346

tank (includes aux tank)

Standard

* All dimensions, weights and timings are variable within 1.5% JCB reserves the right to change specifications without prior notice.

455ZX WHEELED LOADING SHOVEL 15

ONE COMPANY, OVER 300 MACHINES.

Dealer’s stamp: JCB INDIA LIMITED : 23/7 Mathura Road, Ballabgarh - 121 004 Haryana, India.

Tel.: + 91 129 4299000 Fax : +91 129 2309050 E-mail : delhi.marketing@jcb.com

Website : www.jcbindia.com

©2009 JCB Sales. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other means,

electronic, mechanical, photocopying or otherwise, without prior permission from JCB Sales. All references in this publication to operating weights, sizes, capacities

and other performance measurements are provided for guidance only and may vary dependant upon the exact specification of machine. They should not therefore be

relied upon in relation to suitability for a particular application. Guidance and advice should always be sought from your JCB Dealer. JCB reserves the right to change

specifications without notice. Illustrations and specifications shown may include optional equipment and accessories. The JCB logo is a registered trademark of J C

Bamford Excavators Ltd.

You might also like

- 670D 672D 770D 772D 870D 872D Motor Graders Uptime Maintenance PlannerDocument4 pages670D 672D 770D 772D 870D 872D Motor Graders Uptime Maintenance PlannerNelson Andrade Velasquez100% (1)

- Lister D Engine ManualDocument29 pagesLister D Engine Manualetr420100% (1)

- CAT D6R2-Brochure PDFDocument24 pagesCAT D6R2-Brochure PDFalvaro gavrielNo ratings yet

- Brochure, Hitachi, EX1200-5D, DKAEX1200HT (06-05)Document11 pagesBrochure, Hitachi, EX1200-5D, DKAEX1200HT (06-05)Rolando CastilloNo ratings yet

- Macbook Pro (14-Inch, 2021) : Repair ManualDocument162 pagesMacbook Pro (14-Inch, 2021) : Repair Manualmiruna apostolNo ratings yet

- BREVA 750: Fixing A Broken GearboxDocument52 pagesBREVA 750: Fixing A Broken GearboxMarkoNo ratings yet

- Centrifugal Pump Installation Operation MaintenanceDocument168 pagesCentrifugal Pump Installation Operation MaintenanceJunMamauagDelaCruzNo ratings yet

- 320KVA DG Set Part CatalogueDocument168 pages320KVA DG Set Part CatalogueAabhishek Singh100% (2)

- LV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring InstructionsDocument113 pagesLV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring Instructionsedvaldo alves pintoNo ratings yet

- Telecom Standards ManualDocument123 pagesTelecom Standards ManualsoresaNo ratings yet

- Internal Audit Process and ActivitiesDocument20 pagesInternal Audit Process and ActivitiesFreddy ReyesNo ratings yet

- OM PC450-7K - SN K40001-45001 PDFDocument404 pagesOM PC450-7K - SN K40001-45001 PDFAdminDTS AdminDTSNo ratings yet

- A25C Volvo Filtros y CantidadesDocument3 pagesA25C Volvo Filtros y CantidadesHugo BelloNo ratings yet

- MHT10160Document512 pagesMHT10160Razvan MitruNo ratings yet

- A Great Business Decision: Hydraulic Excavator Wheeled Loading ShovelDocument5 pagesA Great Business Decision: Hydraulic Excavator Wheeled Loading ShovelandrewgeorgecherianNo ratings yet

- 6.0-P.pf1 Hydrostatic Sensor Paver - APPOLO 550Document4 pages6.0-P.pf1 Hydrostatic Sensor Paver - APPOLO 550anoopsurendran100% (1)

- Çukurova Backhoe Loaders: Yedek Parça Kataloğu Spare Parts ManualDocument200 pagesÇukurova Backhoe Loaders: Yedek Parça Kataloğu Spare Parts ManualАлексей100% (1)

- JCB Wheel Loader PDFDocument16 pagesJCB Wheel Loader PDFAabhishek SinghNo ratings yet

- JCB Wheel Loader PDFDocument16 pagesJCB Wheel Loader PDFAabhishek SinghNo ratings yet

- Powerstar VX 4035 8x4Document2 pagesPowerstar VX 4035 8x4Tiago AlvesNo ratings yet

- 380engine Parts ManualDocument108 pages380engine Parts Manualkokila infraltdNo ratings yet

- Pumpa Za Upravljenje Cat 725 PDFDocument3 pagesPumpa Za Upravljenje Cat 725 PDFnikosbbwNo ratings yet

- Third Party Assurance QuestionnaireDocument38 pagesThird Party Assurance Questionnaireholamundo123No ratings yet

- Framework7 TutorialDocument67 pagesFramework7 TutorialMaylen RivasNo ratings yet

- SD300SD200 enDocument10 pagesSD300SD200 enBhagoo Hathey100% (1)

- R945Document20 pagesR945equipment9278No ratings yet

- PC400 8 - PC400LC 8 - Cen00223 03 PDFDocument24 pagesPC400 8 - PC400LC 8 - Cen00223 03 PDFhendra hardyNo ratings yet

- 428F2 LRC LRG AEHQ7434-00Document20 pages428F2 LRC LRG AEHQ7434-00Pample HouetteNo ratings yet

- 002 CAT-6015 UndercarriageDocument16 pages002 CAT-6015 UndercarriageGracia Sedi100% (1)

- A 30 C Parts Range GuideDocument2 pagesA 30 C Parts Range GuideToaderIonutNo ratings yet

- PC800-8/LC-8: Hydraulic ExcavatorDocument24 pagesPC800-8/LC-8: Hydraulic ExcavatorAnwar ShafaruddienNo ratings yet

- Work Shop Manual GR 12 - 477 Matr 1-5302-625Document48 pagesWork Shop Manual GR 12 - 477 Matr 1-5302-625Por Pengleng100% (2)

- AP 240 enDocument6 pagesAP 240 enJoão GuardadoNo ratings yet

- LPT As Per Asme & IsoDocument2 pagesLPT As Per Asme & IsosbmmlaNo ratings yet

- BD85Document4 pagesBD85Bipin KumarNo ratings yet

- Daewoo Solar 210W-VDocument16 pagesDaewoo Solar 210W-VAndrea797No ratings yet

- Hydrostatic Vibratory Plates 365-712 Kilos AVH 5020 / 6020 / 7010Document6 pagesHydrostatic Vibratory Plates 365-712 Kilos AVH 5020 / 6020 / 7010Aurelian BogdanNo ratings yet

- Excavator: Cummins QSB 4.5 84.3 KW (113 HP) 15,400 KG 0.6 MDocument9 pagesExcavator: Cummins QSB 4.5 84.3 KW (113 HP) 15,400 KG 0.6 MKoay B HNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerAnsh MishraNo ratings yet

- 980a2542 PDFDocument58 pages980a2542 PDFMichael DavenportNo ratings yet

- Wheel Loader CatalogueDocument24 pagesWheel Loader CatalogueHusam Al-JamalNo ratings yet

- JCB432ZXDocument10 pagesJCB432ZXpangapuvvuNo ratings yet

- JCB EPC 432Document2 pagesJCB EPC 432Er Avdhesh Kumar KushwahaNo ratings yet

- Cukurova - Backhoe Loader 880 (NEW)Document2 pagesCukurova - Backhoe Loader 880 (NEW)Felipe Douglas da Silva100% (1)

- Bliss Price ListDocument19 pagesBliss Price ListprintNo ratings yet

- Service Manual: 1 2 3 A B C D E F G KDocument6 pagesService Manual: 1 2 3 A B C D E F G KРоман Кузів0% (1)

- FMC Catalogue Tarcze CierneDocument145 pagesFMC Catalogue Tarcze CierneTomasz BuśkiewiczNo ratings yet

- AP2D Series PumpDocument12 pagesAP2D Series PumpSoeLettNo ratings yet

- Ec460b Main PDFDocument1 pageEc460b Main PDFNaing Min HtunNo ratings yet

- Loggers. 125A L 220A L 225A L 220E L 225EDocument16 pagesLoggers. 125A L 220A L 225A L 220E L 225Eemezib100% (3)

- VMT 860 Brochure Issue 2Document16 pagesVMT 860 Brochure Issue 2Florin Paraschivescu100% (1)

- Millyard Loaders: Engine 950M 962M Maximum Power SAE J1995Document32 pagesMillyard Loaders: Engine 950M 962M Maximum Power SAE J1995Patryk GiżyńskiNo ratings yet

- SPC 450DX Oct 2013 PDFDocument155 pagesSPC 450DX Oct 2013 PDFPIJUSH NANDINo ratings yet

- thông số kt hyundai robex r60w-9s PDFDocument8 pagesthông số kt hyundai robex r60w-9s PDFTrung Điênđiện Lanh OtoNo ratings yet

- SAUER DANFOSS Bln-96-0001-E PDFDocument8 pagesSAUER DANFOSS Bln-96-0001-E PDFEdu Hdez100% (1)

- 214e - 3cx 14' Excavator End Spare Parts4Document5 pages214e - 3cx 14' Excavator End Spare Parts4Cristian CanteroNo ratings yet

- 01 - MOTOR - ENGINE - D MSTDocument16 pages01 - MOTOR - ENGINE - D MSTMeleștean MihaiNo ratings yet

- R922 R976 Multi User Tier4Final US AI 2020 12Document60 pagesR922 R976 Multi User Tier4Final US AI 2020 12I am a Celtic100% (1)

- D65ex D65PX-12Document254 pagesD65ex D65PX-12Sam100% (2)

- JCB+Attachments+Brochure+pdf NewDocument31 pagesJCB+Attachments+Brochure+pdf NewMohit KunduNo ratings yet

- Wear Parts JS200 9802 5830Document1 pageWear Parts JS200 9802 5830Case CaseNo ratings yet

- KS En013eup PDFDocument24 pagesKS En013eup PDFElvis Justo Choquegonza GomezNo ratings yet

- Doosan dx140Document17 pagesDoosan dx140anzor100% (1)

- Sandvik DP1100: ApplicationDocument4 pagesSandvik DP1100: ApplicationAnbarasanNo ratings yet

- Terex 860 SX, 860 EliteDocument2 pagesTerex 860 SX, 860 EliteYogan100% (1)

- 770ex Magnum: High On ProductivityDocument4 pages770ex Magnum: High On ProductivityВолодимир КривкоNo ratings yet

- Mahindra Earthmaster - An IntroductionDocument24 pagesMahindra Earthmaster - An IntroductionDhimate BhaaratNo ratings yet

- VOLVO EC360C HR EC360CHR EXCAVATOR Service Repair Manual PDFDocument19 pagesVOLVO EC360C HR EC360CHR EXCAVATOR Service Repair Manual PDFfjjsjekdmme0% (1)

- Agco 819799 AK043026-1 PageDocument2 pagesAgco 819799 AK043026-1 PageGilang Patra Prendayasa100% (1)

- 455zx - Brochure PDFDocument16 pages455zx - Brochure PDFDhru Ti100% (1)

- Wa380-6 Vess000803 1002Document16 pagesWa380-6 Vess000803 1002Iing SolihinNo ratings yet

- JCB - Backhoe Loader SpecificationDocument2 pagesJCB - Backhoe Loader SpecificationAabhishek SinghNo ratings yet

- Jcb220Lc Xtra: Hydraulic ExcavatorDocument20 pagesJcb220Lc Xtra: Hydraulic ExcavatorAabhishek SinghNo ratings yet

- Head OfficeDocument2 pagesHead OfficeAabhishek SinghNo ratings yet

- 35th Annual Dive Show: - Convention Center, San Diego, CaliforniaDocument2 pages35th Annual Dive Show: - Convention Center, San Diego, CaliforniaHà ViNo ratings yet

- PPSC Lecturer Math (2017) Available QuestionsDocument5 pagesPPSC Lecturer Math (2017) Available QuestionsMujahid KhanNo ratings yet

- Coffer Slabs FormworkDocument16 pagesCoffer Slabs FormworkHans JonesNo ratings yet

- Iso 8528-5 2013Document42 pagesIso 8528-5 2013Kalaimany ArumuggamNo ratings yet

- Resume ScreeningDocument5 pagesResume Screeningafmrokptolziea100% (1)

- Syringe Robot ArmDocument12 pagesSyringe Robot ArmAnjali YadavNo ratings yet

- The Role of Trust and Brand Images in Meditation of E-Wom Effects On Purchase DecisionsDocument8 pagesThe Role of Trust and Brand Images in Meditation of E-Wom Effects On Purchase DecisionsVi PodebratNo ratings yet

- Bua Phupa TicketDocument1 pageBua Phupa Ticketdevendra singhNo ratings yet

- Computer Network, Unit 4Document20 pagesComputer Network, Unit 4shivaniNo ratings yet

- C2 Project Proposal FinalDocument32 pagesC2 Project Proposal FinalLargado RjayNo ratings yet

- Ticket 2740569062Document2 pagesTicket 2740569062Rahul DhamaniyaNo ratings yet

- Fitting A MK2.5 Spoiler PDFDocument7 pagesFitting A MK2.5 Spoiler PDFAlexandru-Mihai NitaNo ratings yet

- Smartank Brochure EN ESDocument12 pagesSmartank Brochure EN ESemiliano.succiniNo ratings yet

- Building Java Programs A Back To Basics Approach 4th Edition Reges Test Bank 1Document13 pagesBuilding Java Programs A Back To Basics Approach 4th Edition Reges Test Bank 1thomashayescdrjaymwgx100% (26)

- N2A19603 Parts Invoice RBR22M005906Document3 pagesN2A19603 Parts Invoice RBR22M005906RKNo ratings yet

- Gmail - FW - Receipt For Your E-Ticket Request 14391559 - DINITHI - ALAGIYADURAGEMS, PNR# KJGLYJ, CAT A SUBLOADDocument3 pagesGmail - FW - Receipt For Your E-Ticket Request 14391559 - DINITHI - ALAGIYADURAGEMS, PNR# KJGLYJ, CAT A SUBLOADDanidu KaveenNo ratings yet

- Affidavit of Loss - JOSE RONALDO MARTINEZDocument1 pageAffidavit of Loss - JOSE RONALDO MARTINEZJUAN MIGUEL GUZMANNo ratings yet

- Datasheet 1N5220Document4 pagesDatasheet 1N5220LAB14 B1No ratings yet

- Bir Tax 2022Document79 pagesBir Tax 2022DENNIS RAMIREZNo ratings yet

- Богданов А.А. Из психологии общества. - 1905 PDFDocument341 pagesБогданов А.А. Из психологии общества. - 1905 PDFspirospotNo ratings yet

- Jns BearingDocument189 pagesJns Bearingsaiful.laku2No ratings yet