Professional Documents

Culture Documents

Shimadzu BK120 X-Ray Table - Installation Manual

Uploaded by

tomas duran0 ratings0% found this document useful (0 votes)

7 views26 pagesInstallation manual

Original Title

Shimadzu BK120 X-Ray Table - Installation manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentInstallation manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views26 pagesShimadzu BK120 X-Ray Table - Installation Manual

Uploaded by

tomas duranInstallation manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

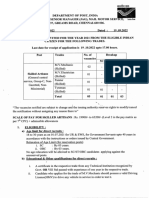

Manual No.: M511-E308

Revision : A

X-RAY RADIOGRAPHY TABLE

BK-120M, BK-120MK

INSTALLATION MANUAL

This manual is for professional service engineers.

It bears no relation to the usual operation.

SHIMADZU CORPORATION

KYOTO VAPAN

Contents

1. Introduction

2. Preparation for Installation

2.1 Installation Room ...

2.2 Installation Tools ....

23 Unpacking

3. Floor Work ..

4. Assembly and Installation ..

41 ForEurope

42. For others

5. Adjustment wu... a seve Soh

5.1 Table Top Vertical Movement Stop Switches

5.2 Table Top Move-up Temporary Stop Switch

6. Inspection —

6.1 Inspection for Installation .

62 Periodic Inspection

7-1

7-1

ToL

- 7-1

7. Maintenance ...

7.1 Information for USER’s appropriately qualified technical personnel

7.2. Consumable parts

7.3 Replacement of fuse

BK-120M Equipment drawing...

BK-120MK Equipment drawing ...

503-06192

- 503-06198

MS11 - E308

[NO TEXT]

MS11 - E308

1. Introduction

This manual describes installation of the X-ray radiography table BK-120M, BK-

120MK, From installation to adjustment are described in tum. Read this manual thoroughly

before starting the installation work.

BK-120M BK120MK

Fig. 1-1

Cautions on installation

(1) Never irradiate X-rays beyond necessity.

(2) Make sure to tum off the power when performing wiring.

The separation devices are following:

VOLTAGE device

100V__ | the power SW of the Xray generator

200, 400V_| the power SW of the TRANS UNIT

Forothers | 100,200V | the power SW of the X-ray generator

For Europe

(3) Take appropriate measures when handling heavy objects so that thumbs and fingers

are not caught and that the waist is not damaged,

(4) During installation of disassembled components, make sure that stoppers are appro-

priately provided.

(5) Only for Europe.

The shipping cable is not IEC approved for 400V that terminal marks are “L” and

ae

‘Therefore exchange the cable for IEC approved cable.

MSI1 - £308

Specification for cable is following;

Nominal VOLTAGE UO/U 300/500V

NO. of WIRE more 2

CONDUCTOR

SIZE 1.0sq,mm,

DIA. of OUTER INSULATOR

less than 15mm.

DIELECTRIC WITHSTANDING

TEST VOLTAGE 3000V/1min.

CONDUCTIVE RESISTANCE (reference)

35.70HM/km — @20 deg.C

TEMPERATURE RANGE

-5°C to +70°C

1-2

‘M511 - E308

2. Preparation for Installation

2.1. Installation Room

Check the following items for the installation room.

Trem Description

Outside dimensions of BK-120M | Equipment drawing 503-06192

Outside dimensions of BK-120MK | Equipment drawing 503-06198

Installation floor area ‘5,000W x 3,500W (recommended)

Weight ‘Approx. 320 kg

Single-phase, 100V, 1A, 50/60Hz

Single-phase, 200V, 5A, SO/60Hz

Single-phase, 100V, 0.1KVA, SO/60H2|

For Europe

I ‘Single-phase, 400V, IKVA, S0/60Hz

Power supplies

2.2 Installation Tools

Prepare the following tools for installation

Quantity

e289eee8000

MS11 - E308

Conerete drill...

Anchor bolt M12 (offered as accessories of BK-120M, BK-120MK)

Measuring tape

Level

Phillips-head screwdriver .....

Soeoons

‘Monkey spanner

Tester

Hexagon rod wrench

2.3 Unpacking

The BK-120M, BK-120MK is disassembled into the following components in a pack.

— (Floating ble — (Floating table

tap assembly top assembly

©®e® 6868

M511 - B308

(@Bucky device @Bucky device

BF-10H BF-I0HK,

BK-120M

Fig. 2.1

Main body (including foot switches) 1 set

Floating table top assembly... Lset

Bucky device BF-10H (BK-120M) .

Bucky device BF-10HK (BK-120MK)

‘Trans unit (BK-120MK, only for Europe) ..

Installation parts

Anchor bolt M12 ..

Resin shoe for compression belt .

Bolt M12 X30 nn

Spare fuse 250VAC, SA (slow-blow type)

Spare fuse 250VAC, 1A (slow-blow type)

1 set

a. set

I set

RRR e

@

‘@Trans unit

BK-120MK.

After unpacking, make sure that no nonconformity is detected in each compo-

nent.

3. Floor Work

Perform the floor work to fix the BK-120M, BK-120MK on the floor. (The BK-120M,

BK-120MK cannot stand by itself while the table top is moved. Make sure to fix the BK-

120M, BK-120MK to the floor.)

(1) Mark anchor bolt positions on the floor in accordance with the equipment drawing.

(2) When marking in the step (1) is finished, make holes on the floor using a concrete

drill, and strike anchor bolts offered as accessories into the holes.

MS11 - E308

[NO TEXT]

MS11 - E308

4. Assembly and Installation

4.1 For Europe

4.1.1 Removing the cover

Unscrew the outer cover fixing screws.

Remove the outer cover.

Unscrew the inner cover fixing screws.

Rene

Remove the inner cover.

Fig. 4.1

4.12 Fix the main body on the floor.

(Ef there are deformations on the floor, repair them with liners, etc., assure

level of the BK-120MK, then fix it. While level is adjusted, mounting holes on a

main body floor plate can be used as jack screw holes. When assuring level, place

a level on the table top.)

4.13 Exchange the power cable (400V)

The shipping cable is not IEC approved cable that terminal marks are “L” and

‘Therefore exchange the cable for IEC approved cable.

4-1

MSI - 308

Trans unit

Fig. 4.2

4.1.4 Connect the power cable (400V) and the ground cable to the PLUG BOARD.

CNoTE]

Residual voltage of motor starting capacitor is more than 60V.

Do not touch the terminals of TR1 and BK CONT PCB “U’, “V", “Y",

Keep pushing the switch for 10 sec, residual voltage is discharged and

touch the terminals safety.

BK-CONT PCB

TRI

D

Discharge SW

Fig. 4.3

Connect the trans unit to the table with the power cable (200V) and ground

cable.

‘Connect the table to the X-ray high voltage generator with the power cable

(100V),

MS11 - E308

Connect the foot switch cable to the BK-CONT PC Board.

Lay out the foot-switch cable along the power cable that is already laid out.

When phototimers are used, fix the phototimer cable together with other

cables.

Make sure that the wiring from the BK-CONT PC Board to the Bucky device

goes along with the Bucky cable which has been already wired,

Powercable Metal fixture

Ground cable

Foot switch cable

Fig. 4.4

4.1.5 Confirm the setting of the DIP switch provided on the BK-CONT PC Board.

Usually, it has been already set as shown below when shipped from the factory.

Swi States | Remark

Fi on ‘Always OW

2 OF ‘Always OFF

3 OFF ‘Always OFF

+ | oN ‘Always ON

5 on ‘Always ON

6 OF ‘Alvays OFF

7 OF ‘Alvays OFF

$ (OFF | Calimator lp lig simahancously wien he fot switch ned on

4.16 Itis recommended to let the power cable, the ground cable and the phototimer

cable go outside from the cable fixture of the BK-120MK main body and treat

them in a pit below the floor.

4.1.7 Fix the Bucky device to the mounting frame with bolts.

Connect the Bucky cable to the BF-CONT PC Board. Connect the Bucky han-

dle switch cable to the Bucky cable.

When phototimers are used, treat the phototimer cable together with the Bucky

cable. (For details, refer to the instruction manual of the Bucky device.)

4-3

M511 - E308

‘switeh cable

Fig. 4.5

4.1.8 Fixing the table top

1. Unscrew the stopper bolt (hexagon socket head cap screw: M10) on the left-

to-right moving frame (the rear side).

2. Mount the table top from the unscrewed stopper bolt side. (The caution

plate stuck on the aluminum side-rail of the table top should be on the front

side.)

3. Screw the stopper bolt immediately after mounting the table top.

CAUTION

Make sure to attach a stopper to assure safety. If the stopper is not

attached, the table top and a patient may drop together in the worst case,

and the patient may be injured.

®

= ~S

Caton abel

Stopper

Lateral movement frame

(rearfac)

Table top

‘Mounting bolt with rubber

Fig. 4.6

4-4

M511 - E308

4.1.9 Attach the main body cover

Fix the cover following the removing procedure in Section 4.1 in reverse order,

4.2 For others

4.2.1 Removing the Cover

4.2.1.1 Incase of BK-120M:

Unscrew the cosmetic cover fixing bolts.

Remove the cosmetic cover.

Unscrew the stay fixing bolts.

Rene

Remove the stay. (Keeping the stay hooked by the loosened center bolt

makes this work easier.)

®

Fig. 4.7

4-5

M511 - E308

4.2.1.2 In case of BK-120MK:

1. Unscrew the outer cover fixing screws.

2, Remove the outer cover.

3. Unscrew the inner cover fixing screws.

4.

Remove the inner cover.

Fig. 4.8

4.2.2 Fix the main body on the floor.

(if there are deformations on the floor, repair them with liners, etc., assure

level of the BK-120M, BK-120MK, then fix it. While level is adjusted, mounting

holes on a main body floor plate can be used as jack screw holes. When assuring

level, place a level on the table top.)

4.2.3 Connect the power cable and the ground cable to the X-ray high voltage gener-

ator and the ground respectively.

‘Connect the foot switch cable to the BK-CONT PC Board.

Lay out the foot-switch cable along the power cable that is already laid out.

When phototimers are used, fix the phototimer cable together with other

cables

Make sure that the wiring from the BK-CONT PC Board to the Bucky device

goes along with the Bucky cable which has been already wired.

4-6

MS11 - E308

Bucky cable

Powercable Metal fxture

Ground cable

Foot switch cable

Fig. 4.9

4.2.4 Confirm the setting of the DIP switch provided on the BK-CONT PC Board.

Usually, it has been already set as shown below when shipped from the factory.

‘Swi States Remark

1 on | Always ON

2 OFF Always OFF

3 OFF Always OFF

4 ON ‘Always ON

5 on ‘Always ON

6 OFF Always OFF

fi OFF Always OFF

8 OFF | Collimator lamp lights simultaneously when the foot switch tamed on.

4.2.5 _Itis recommended to let the power cable, the ground cable and the phototimer

cable go outside from the cable fixture of the BK-120M, BK-120MK main body

and treat them in a pit below the floor.

42.6 Fix the Bucky device to the mounting frame with bolts.

Connect the Bucky cable to the BF-CONT PC Board. Connect the Bucky han-

dle switch cable to the Bucky cable.

When phototimers are used, treat the phototimer cable together with the Bucky

cable. (For details, refer to the instruction manual of the Bucky device.)

MSI1 - E308

& Becky ck

switch cable

Fig. 4.10

4.2.7 Fixing the table top

1. Unscrew the stopper bolt (hexagon socket head cap screw: M10) on the left-

to-right moving frame (the rear side).

2. Mount the table top from the unscrewed stopper bolt side. (The caution plate

stuck on the aluminum side-rail of the table top should be on the front side.)

3. Screw the stopper bolt immediately after mounting the table top.

(CAUTION

Make sure to attach a stopper to assure safety. If the stopper is not

attached, the table top and a patient may drop together in the worst case,

and the patient may be injured.

Caution label

Lateral movement frame

(tear face)

Table top

Mounting bolt with rubber

Fig. 4.11

4.2.8 Attach the main body cover

Fix the cover following the removing procedure in Section 4.1 in reverse order.

4-8

MS11 - E308

Adjustment

Each portion is already adjusted when shipped from the factory. However, the adjust-

ment values may be deviated by disassembly and assembly. Adjust each portion if neces-

sary.

5.1 Table Top Vertical Movement Stop Switches

Adjust the switch positions so that the LS-1 is actuated when the table top reaches

the highest position and that the LS-2 is actuated when the table top reaches the lowest

position.

Bellows cover | _ Metal cover

Highest table position 900zaEa 850mm

Lowest table position 350mm 535mm

5.2 Table Top Move-up Temporary Stop Switch

The temporary stop function is valid exclusively while the table top is moving up.

The temporary stop position can be arbitrarily set within the range in which the dis-

tance between the table top and the floor is 600 to 700mm.

When shipped from the factory, the switch L3 is adjusted so that it is actuated when

the table top reaches 700mm.

pee

Ls3

MSI - E308

[NO TEXT]

‘M511 - E308

6. Inspection

6.1. Inspection for Installation

6.1.1 Make sure that dusts or foreign objects are not adhered to the screw area of the

elevating jack before attaching the covers

Lubrication of the serew.

Duss or foreign objects

‘Smooth operation ofthe

elevating jack.

6.1.2 Make sure that the elevating jack operates smoothly ahd the screw area of the

elevating jack is lubricated normally.

6.1.3 Make sure that the bearing for supporting the table top operates smoothly.

6.1.4 Make sure that the bolts and nuts are not loose,

6.1.5 Make sure that the tension of jack belt is appropriate.

MSI - B308

If the tension is not appropriate, adjust it by moving the motor while loosening

the fixing bolts of the motor mounting board.

6.1.6 Refer to the Operating manual for Bucky device about the inspection of Bucky

device.

6.2 Periodic Inspection

Check the installation inspection items, and at the same time check the jack as fol-

lows.

(2) Lift or lower the table top, and stop it at the position where the hole of the outer

link is on the inner link. (Refer to Fig. 6-3.)

(2) Put a M16 hexagon socket head cap sorew in the hole and hold it with a nut (to

prevent the link from falling).

(3) Measure the dimension A in Fig. 6-4. Replace the jack if A is less than 3.5 mm.

(4) If Ais more than 3.5 mm, wipe off the grease on the screw and apply new grease.

(Use the grease specified by our company.)

Specified grease: Cosmo grease Ginga No. 2

(5) Remove the M16 bolt and nut.

M16 hexagon socket

head cap serew and nut

Fig. 6.3

MSI - E308

Power supply SR2

| 1

rd

Powersupply SR2~ |_| j--~> | 1

ee

ieee

‘a

il BK-CONT PC Board

bowel bone! ‘Terminal block

aeeeeeeeeee

Cf Girona terrinal block

Aero

——s

Fuse holder

BK-120M, BK-120MK LAYOUT OF CONTROL UNIT

MS11 - E308

[NO TEXT]

MS11 - E308

Maintenance

7.1 Information for USER's appropriately qualified technical personnel

SHIMADZU will make available on following information for the USER’s appropri-

ately qualified technical personnel.

Name

Document sumber

BK-120 M/IMK Connection diagram 503-03736

'BK-120 MK Connection diagram (For Europe) 5303-03902,

BK-CONT CIRCUIT diagram 5303-03727

BK-120MK Parts list ‘MS11-4006

7.2 Consumable parts

‘The consumable parts used for BK-120MK are as follows:

When replacing the parts, use the regular parts with following part number:

Name Part number

‘V-belt M27 032-2015

Jack: NI40-UBL1S8C (1) 511-32028

Fuse: 313001 (250VAC, 1A) 072-01664-20

Fuse: 313005 (250VAC, 5A) 072-01664-33

Fuse: 3AB-326005 (250VAC, SA, ON TRAS UNIT) | _ 072-01665-30

7.3 Replacement of fuse

Only service personnel and USER’s appropriately qualified technical personnel are

allowed to replace the fuse.

Please do not allow users to replace them.

MSI - B308

[NO TEXT]

M511 - E308

You might also like

- FDR Clinica BrocDocument6 pagesFDR Clinica Brocboobesh kumar dNo ratings yet

- India Post Skilled Artisans Posts Notification and Application FormDocument9 pagesIndia Post Skilled Artisans Posts Notification and Application Formboobesh kumar dNo ratings yet

- BME Association 2016-17 To 2020-21Document44 pagesBME Association 2016-17 To 2020-21boobesh kumar dNo ratings yet

- MMS Chennai Notification 19sept2022Document9 pagesMMS Chennai Notification 19sept2022boobesh kumar dNo ratings yet

- Dak Adalat - Press ReleaseDocument1 pageDak Adalat - Press Releaseboobesh kumar dNo ratings yet

- Philips Ultrasound, Inc. Document Number 989605349120017 G Document TitleDocument6 pagesPhilips Ultrasound, Inc. Document Number 989605349120017 G Document Titleboobesh kumar dNo ratings yet

- Philips Ultrasound, Inc: See PDM For ApprovalsDocument10 pagesPhilips Ultrasound, Inc: See PDM For Approvalsboobesh kumar dNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)