Professional Documents

Culture Documents

A New Calculation Approach To The Energy Balance of A Gas Turbine

Uploaded by

Mahmood ElnagarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A New Calculation Approach To The Energy Balance of A Gas Turbine

Uploaded by

Mahmood ElnagarCopyright:

Available Formats

Proceedings of GT2005

ASME Turbo Expo 2005: Power for Land, Sea and Air

June 6-9, 2005, Reno-Tahoe, Nevada, USA

GT2005-68430

A NEW CALCULATION APPROACH TO THE ENERGY BALANCE OF A GAS TURBINE

INCLUDING A STUDY OF THE IMPACT OF THE UNCERTAINTY OF MEASURED PARAMETERS

Helmer G. Andersen, Dr. Pen-Chung Chen

ALSTOM

2800 Waterford Lake Drive

Midlothian, Virginia 23112

e-mail: helmer.andersen@power.alstom.com

ABSTRACT INTRODUCTION

Computing the solution to the energy balance around a gas As little as 10 years ago, on-line gas turbine performance

turbine in order to calculate the intake mass flow and the calculations were impossible in part due to the limitations in

turbine inlet temperature requires several iterations. This the CPU’s of personal computers. Thus, during performance

makes hand calculations very difficult and, depending on the tests of gas turbine or combined-cycle power plants,

software used, even causes significant calculation times on significant efforts were undertaken without being able to judge

PCs. While this may not seem all that important considering if any measurement error was present. The performance

the power of today’s personal computers, the approach calculation is required in order to calculate the compressor

described in this paper presents a new way of looking at the intake flow and the turbine inlet temperature. The desire to

gas turbine process and the resulting simplifications in the instantly know if the measurements were producing

calculations. meaningful results caused the testing community to push for

on-line measurement evaluation systems. Andersen, Chen and

This paper offers a new approach to compute the energy Hartmann describe one example of an on-line measurement

balance around a gas turbine. The energy balance requires that system in [1]. However, these systems were very slow and

all energy flows going into and out of the control volume be required top of the line PC’s in order to perform the

accounted for. The difficulty of the energy balance equation performance calculations. The duration of the calculations

around a gas turbine lies in the fact that the exhaust gas were driven by the fact that the codes required iterations. In

composition is unknown as long as the intake flow is each iteration enthalpies of multiple mixtures have to be

unknown. Thus, a composition needs to be assumed when calculated, which is time consuming.

computing the exhaust gas enthalpy. This allows the

calculation of the intake flow, which in turn provides a new Interestingly enough, all the efforts to reduce calculation times

exhaust gas composition, and so forth. were focused on improving the coding, such as using more

efficient numeric methods to improve the iterations, and using

By viewing the exhaust gas as a flow consisting of ambient air faster and more efficient computer programming codes, such

and combusted fuel, the described iteration can be avoided. as C++ instead of visual basic. However, none or few efforts

The study presents the formulation of the energy balance were made to solve the root cause of the problem and develop

applying this approach and looks at the accuracy of the result a code that avoids the iteration completely.

as a function of the inaccuracy of the input parameters.

Furthermore, solutions of the energy balance are presented for This paper presents a solution that does not require any

various process scenarios, and the impact of the uncertainty of iterative calculations and thus makes it possible to perform the

key process parameter is analyzed. performance calculations even in spreadsheets. The solution is

based on viewing the problem in a different way. The

Keywords: Performance calculation, gas turbines traditional method views the exhaust gas as a mixture of

unknown composition that needs to be assumed and then

verified/corrected by means of iterations. The method

1 Copyright © 2005 by ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 04/10/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

presented in this paper views the exhaust flow as consisting of

excess air (ambient air), stoichiometric combusted fuel and

water (steam).

NOMENCLATURE

cp: specific heat at constant pressure, (kJ/kg K)

h: specific stagnation enthalpy, (kJ/kg)

LHV: lower heating (calorific) value, (kJ/kg of fuel)

Lmin: amount of air required for stoichiometric combustion,

(kg dry Air/kg fuel)

m: mass flow rate, (kg/s)

p: pressure, (bara, barg)

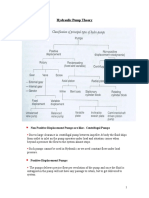

Figure 1: Control volume around a gas turbine

P: power, (kW)

q: specific heat flow rate (kJ/kg s)

Q: heat flow rate (kJ/s)

The following values will typically be measured:

Rh: relative humidity

SH: sensible heat

Intake (cpr0): t, p and Rh.

t: temperature, (deg C)

Compr. Discharge (cpr2): t, p

TIT : turbine inlet temperature

Fuel: composition, flow rate, t

xextr: fraction of extraction air with respect to compressor

Injection fluid: flow rate, t, p

intake flow (mcpr0), (kg/kg of air @ cpr0)

Exhaust (e2): t, p

Electrical: power, paux

x w: fraction of water in the air, (kg/kg of dry air)

The following values are typically estimated based upon

ξi: Mass fraction of the constituent i in a mixture design information:

Losses: bearing, heat, generator, gearbox (if

Subscripts: applicable)

air: air Seal air: flow rates, t

aux: auxiliary Extraction air: m, t

cprod: combustion products

cpr: compressor The schematic and the traditional calculation method is

cpr0: ambient described in detail in [2].

cpr1: compressor inlet

cpr2: compressor outlet The conventional way to formulate the energy balance for the

ex: excess air (not participating in combustion) indicated control volume is:

extr: extraction PNet + P aux + Q extr + Q loss + Q e2 = Q cpr0 + Q fuel + Q inj (1)

el: electrical (losses i.e. generator, transformer)

e1: expansion turbine inlet (= combustor outlet)

e2: expansion turbine outlet => PNet + P aux + Q extr + Qloss - Qfuel - Qinj = (2)

fuel: fuel m cpr1 * (hcpr0 - he2 ) - (mfuel + m inj - m extr) * he2

gen: generator

heat: heat (losses)

Inj: injection (water or steam) In this equation only the compressor intake flow and the

loss: loss (heat or mass or power) exhaust gas enthalpy are unknown. Assuming an exhaust gas

mech: mechanical (losses, i.e. bearing, gearbox) composition, the compressor intake flow mcpr1 can be

seal: compressor or turbine seal air calculated, which in turn supplies an exhaust gas enthalpy

tur: turbine according to equation (7):

w: water

he2 = x e2, air * he2, air + x e2,w * h e2,w + x cprod * hcprod (7)

x: fraction (note: fractions are always referenced to the

dry air flow)

Refer to the appendix for Equations (3) – (6).

ENERGY BALANCE OF A GAS TURBINE

The following schematic (refer to Figure 1), shows all the With the calculated exhaust enthalpy, the intake flow can be

energy and mass flows that need to be considered when calculated according to equation (1) until the assumed exhaust

formulating the energy balance around a gas turbine. enthalpy is equal to the calculated exhaust enthalpy according

to equation (7).

2 Copyright © 2005 by ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 04/10/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

The enthalpy of the combustion product hcprod is trivial once Note, that all terms used to express me2 are either known or a

the molar flows for the stoichiometric combustion have been function of mcpr0. The next task is to combine the energy and

calculated. It should be noted, that even for Dry Low NOx mass balance equations. The energy balance, as mentioned in

combustors, where the fuel is burnt in an oxygen-rich the previous section, equation (1) is expressed as:

environment, the composition of the exhaust gas is

nevertheless the same as if the fuel were burnt with a PNet+Paux+ Qextr+Qloss + Qe2 = Qcpr0+Qfuel + Qinj (13)

stoichiometric fuel-to-air ratio.

where PNet and Paux are measured. The calculation of the

ENERGY & MASS BALANCE OF A GAS TURBINE energy loss due to extraction air and other losses is shown in

(NEW APPROACH) the appendix, equation (14) – (16).

The energy balance is exactly the same equation as listed In the following each term will either be expressed as a

above. However, the mass balance, while in principal the function of mcpr0 or a known (measured) entity. The exhaust

same, is formulated differently: energy can be expressed as:

Qe2 = ( mcprod + m e2,w + m ex ) * he2 (17)

= mcprod * h cprod + m e2,w * h e2,w + m ex * he2,air (18)

= mfuel * (1 + L min ) * hcprod

+ [ minj +m cpr0 *(1-(xseal,cpr,loss +x seal,tur,loss )*xw] * h e2,w

+ [mcpr0 *(1-(xseal,cpr,loss +x seal,tur,loss )

-m fuel *Lmin - mextr] * h e2,air (19)

Note that all terms except for the compressor intake mass flow

are known. With that, the entire left side of equation (13) is

known or a function of the compressor intake flow. The terms

on the right side are all known or a function of the compressor

intake flow; refer to the appendix for equations (20) – (22).

Figure 2: Mass balance control volume around a The only remaining unknown in the energy equation is the

gas turbine compressor intake flow mcpr0.

The mass balance for the above control volume may be Solving the energy equation with respect to mcpr0 yields the

written as follows: following equation:

mcpr0 + m fuel + m inj = m e2 + m cpr1 *(xseal,cpr,loss +x seal,tur,loss ) mcpr0 = (1 + x w) * [m fuel *(dqcprod - qfuel) (23)

+m extr (8) + dQ inj + P]/(q cpr0 - qe2,w - qe2,air - qseal - qextr)

Equation (23) can be solved directly, as it only has one

The exhaust flow is consisting of: unknown mcpr0. For the significance of the variables used in

• Combustion products equation (23), refer to the appendix equation (24) – (32).

• Excess air (not participating in the combustion

process) Thus, the first goal of the study to present an equation that

• Water (from the injection as well as from the ambient does not require any iteration for the calculation of the

air) compressor intake flow is achieved.

This may be expressed as:

me2 = m cprod + m e2,w + m ex (9)

where:

mcprod = mfuel * (1 + L min ) (10)

me2,w = m inj +m cpr0,air * (1-(xseal,cpr,loss +x seal,tur,loss ) * x w (11)

mex = mcpr0,air *(1-(xseal,cpr,loss +x seal,tur,loss )-mfuel * Lmin - mextr

(12)

3 Copyright © 2005 by ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 04/10/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Mass and energy balance around the combustor:

OTHER GAS TURBINE CONFIGURATIONS

Mass balance:

The most typical performance test by far includes the me1 = m cpr2 + m inj + m fuel (33)

calculation of the compressor intake mass flow. However, due

to cost reductions, single-shaft combined cycle plants where Energy Balance:

the gas turbine and the steam turbine share a generator, are Qcpr2 + Q fuel - Qheat,loss + m inj * h inj = m e1 * h e1 (34)

becoming more common. In order to test such an arrangement,

where the power of the gas turbine cannot be measured, the

intake flow needs to be determined by other means. This Note, that in accordance with ISO 2314, the turbine seal air

could, for instance, be done with a bellmouth measurement. part that is extracted from the compressor and mixed with the

exhaust mass flow me2, is neglected in the above.

If the compressor intake flow can be determined by other mcpr0 = m cpr2 + m seal,cpr,loss + m seal,tur,loss (35)

means, all that remains is to solve the above equation with

and

respect to P, which is a trivial problem (one equation, one

unknown). mcpr2 = mcpr0 * (1 -x seal,cpr,loss - x seal,tur,loss ) (36)

INNER ENERGY & MASS BALANCE OF A GAS Combining the above equations (34) and (36) and solving

TURBINE (TIT CALCULATION) them with respect to the turbine inlet enthalpy yields:

The calculation of the turbine inlet temperature TIT requires he1 = [mcpr2 *(hcpr2,air +x w*hcpr2,w )+m fuel *(LHV+ c p,fuel *[t fuel -15.5])

either an energy balance around the combustor or an energy

balance around the turbine. The turbine inlet temperature TIT + m inj *hinj ]/[mcpr2 +m fuel + m inj ] (37)

as defined per ISO2314 is equal to the combustor exit

temperature where the combustor exit flow includes all turbine The composition of the mass flow at the turbine inlet is the

cooling airflows. The energy balance in flow direction around same as it is at the turbine exhaust (e2), and thus it is known

the combustor is the preferred method, although both from the previous section.

obviously yield the same result (this is a good way of checking

the calculation results). Given that the enthalpy of a mixture is equal to the sum of the

enthalpies of the constituents multiplied by the mass fractions

METHOD ONE: MASS AND ENERGY BALANCE of the constituents, the solution presents itself as a set of

AROUND THE COMBUSTOR equations:

The only new term in these equations is the energy term at the hmix (te1 ) = Σ ξi * hi (te1 ) (38)

compressor discharge. Both the composition and the

temperature at that location are known. The mass flow can Depending on the kind of polynomial that is used to

easily be derived via a mass balance around the compressor: approximate the enthalpy of the constituent, the problem may

require an iterative process to determine the turbine inlet

temperature TIT (= te1). The most commonly used enthalpy

polynomials are those referenced in [4]. These equations are

of the 8th order and thus do not permit the calculation of a

direct solution. In order to present a solution that does not

require iterations, the enthalpy equations must be

approximated by an equation of the 2nd order.

By approximating the polynomials to a 2nd order for the entire

expected temperature range, a certain inaccuracy (approx. 1%)

cannot be avoided. However, it permits the calculation to be

done in a spreadsheet without any iteration. The inaccuracy

can be reduced to an insignificant amount, if the polynomials

are approximated for smaller temperature intervals such as

200°C. For a performance calculation that needs to be in

accordance with a certain code, such as PTC 22 (refer to [2]),

the approach may be to use the 2nd order polynomial to

calculate the starting value for the iteration. That way a time

Figure 3: Mass balance control volume consuming iteration can be avoided, and, at the same time, the

around the compressor calculation can claim to be in accordance with the required

codes.

4 Copyright © 2005 by ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 04/10/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

METHOD TWO: ENERGY AND MASS BALANCE IMPACT OF THE MEASUREMENT UNCERTAINTIES

AROUND THE TURBINE ON THE CALCULATED COMPRESSOR INTAKE

MASS FLOW

In the last section of this study, the impact of measurement

uncertainties on the result of the calculated compressor intake

mass flow shall be investigated.

The energy balance rarely yields the correct result on the first

attempt, unless a huge effort has been undertaken to ensure the

correct measurement of all process data. In most cases, a

reasonable attempt will be made to check all measurements,

and then a pre-test run will be initiated. The performance

engineer is now faced with the task to pinpoint the incorrectly

measured process data and correct the measurements.

The following table shows the typically measured data, the

assumed data (based on design information) and the impact

the listed uncertainty will have on the calculated value of

Figure 4: Mass and energy balance control volume mcpr0.

Mass balance: The default value of the uncertainty is 0.5%. Only the bold

me1 = m e2 (39) parameters with a gray background have a different

uncertainty:

• Relative humidity transmitters are not as accurate,

Energy balance: and, in addition, the measured value varies a lot with

PNet + P aux + P loss + P cpr + m e2 * h e2 (40) the location of the transmitter.

= m e1 *he1 +m cpr0,air *x seal,tur *(hseal,tur ,air +x w*hseal,tur,w ) • While laboratories should be able to measure well

within 0.5%, the measurement’s uncertainty is

increased by the uncertainty of how well the sample

Again, in accordance with ISO 2314, the turbine seal airflow represents the fuel used during the test (variations in

is neglected. the fuel quality).

• Design data is deemed less accurate than measured

The energy balance around the compressor can be used to values.

derive the compressor power; refer to Figure #3:

Energy balance around the compressor:

Pcpr + Q cpr0 = Qcpr2 +Qseal,loss+Qseal,turb (41)

=> Pcpr = Qcpr2 - Qcpr0 + (Qseal,loss+Qseal,turb ) (42)

Combining the above equations yields:

he1 = [Qcpr2 - Qcpr0 + Qseal,loss + PNet + P aux + P loss

+ me2 *he2 ]/m e2 (43)

If everything is done correctly, equation (37) and equation

(43) should yield the same result.

5 Copyright © 2005 by ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 04/10/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Input Data

Parameter Abbrv. Value Unit delta dMk1 dTIT CONCLUSIONS

Ambient Pres Pcpr0 1013 mbar 5.1 0.0% 0.0

Ambient

Tcpr0 15 °C 1.4 0.2% -1.7

This paper presents a solution to the energy balance around

Temperature the gas turbine that does not require any iterative calculations,

Amb. Rel.

RHcpr0 60 % 6.0 -0.1% -0.1

and thus makes it possible to perform the performance

Humidity calculations even in spreadsheets. The solution is based on

Compr. Disch.

Tcpr2 370 °C 3.2 0.0% 2.6 viewing the problem in a different way. The traditional

Temp. method views the exhaust gas and a mixture of unknown

Fuel Flow Rate mfuel 5.1 kg/s 0.03 0.9% -2.0 composition that needs to be assumed and then verified/

corrected by means of iterations. The method presented in this

Fuel Temp tfuel 150 °C 2.1 0.0% 0.0 study views the exhaust flow as consisting of excess air

Fuel Composition (ambient air), stoichiometric combusted fuel and water

(steam). This approach allows solving the equation directly.

phi_CH4 CH4 95 % vol. 1.0 0.0% 0.0

phi_C2H6 C2H6 2 % vol. 1.0 0.0% 0.0 In order to solve the internal energy balance to gain the turbine

phi_C3H8 C3H8 1 % vol. 1.0 -0.1% 0.2 inlet temperature without iterations, the enthalpy equations

phi_N2 N2 1 % vol. 1.0 -2.7% 4.2 must be approximated with polynomials of the second order.

phi_CO2 CO2 1 % vol. 1.0 -3.7% 7.6 This can be done without sacrificing the accuracy of the result.

Injection Fluid (Steam)

The uncertainty analysis indicates which process parameters

Steam Flow are important to the overall uncertainty of the calculated

minj 12 kg/s 0.06 0.0% -0.2

Rate results. The fuel measurement, both the flow rate as well as

Steam Temp Tinj 320 °C 1.6 0.0% -0.1 the composition, are by far the most important process

Power P 80000 kW 400 -0.3% 1.7 parameters.

Exhaust

Te2 515 °C 2.6 -0.6% 3.6

Temperature

Sealing Flows (Design Data)

REFERENCES

Turb Seal Rel.

xseal,tur 0.432 % 0.1 0.0% -0.3

F Rate [1] Andersen, H., Chen, P-C., and Hartmann, T., “Advanced

Turb Seal loss xseal,tur, Gas Turbine Monitoring and Diagnostic Technology for

0.008 % 0 0.0% 0.0

Rel. F Rate loss Modern Power Plants,” Proceedings of 2003 International

Cpr Seal Rel. F Joint Power Generation Conference, paper no. IJPGC2003-

xseal,cpr 0.13 % 0.1 0.0% 0.0

Rate 40189.

Cpr Seal loss xseal,cpr,

0.065 % 0.1 0.0% 0.0

Rel. F Rate loss [2] ASME Codes and Standards, Gas Turbines, PTC 22-1997

T_Seal_Air “Performance Test Code on Gas Turbines”

tseal 78.5 °C 5 0.0% 0.0

(turb=cpr)

Pgen, [3] ISO Standards, ISO 2314-1989,“Gas Turbines,

Generator Loss loss

1350 kW 14 0.0% 0.0 Acceptance Tests”

Bearing Losses Pbrg, loss 300 kW 10 0.0% 0.0 [4] National Aeronautics and Space Administration, Glenn

Pheat, Research Center, Cleveland, OH, NASA/TP-2002-211556,

Other losses 70 kW 10 0.0% 0.0

loss “Glenn Coefficients for Calculating Thermodynamic

Total (Absolute) 8.7% 24.3 Properties of Individual Species”

Table #1: Required input data with uncertainties and [5] ASME Codes and Standards, Performance Test Codes,

the impact on the results of the energy balance PTC 19.1-1998, “Test Uncertainty”

It is obvious that the focus must be on the fuel flow, both the

flow rate as well as the constituents. In particular, the

constituents that have a significantly different heating value

than methane, such as the inert gases as well as Propane,

Butane, etc. The overall uncertainty of 8.7% as shown above

for the compressor intake flow is hardly acceptable. PCT-19.1,

refer to [5], covers the uncertainty calculation of measurement

data. Furthermore, [2] lists uncertainty requirements for

process measurements.

6 Copyright © 2005 by ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 04/10/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Appendix:

Calculation of the exhaust gas enthalpy:

The exhaust flow is consisting of:

• Combustion products

• Water (from the injection as well as from the ambient

air)

• Excess air (not participating in the combustion

process)

me2 = m cpr0 + m fuel + m inj - m ext (3)

x cprod = m fuel * (1 + L min )/me2 (4)

x e2,wt = [(m cpr0 - m extr) * x w + m inj ]/me2 (5)

x e2, air = 1 - x e2,w - x cprod (6)

Qextr = m extr * h extr = x extr * (hextr,air + x w* hextr,w) * m cpr0,air (14)

Energy loss due to Extraction air:

Note: the composition of the extraction air is the same as

ambient air (wet and dry components).

The loss term may be expressed as:

Qloss = mcpr0 *(xseal,cpr,loss *hseal,cpr,loss +x seal,tur,loss *hseal,tur,loss ) (15)

+ Q el + Q heat + Q mech

= mcpr0,air *[x seal,cpr,loss *(hseal,cpr,loss,air +x w * hseal,cpr,loss,w ) (16)

+x seal,tur,loss * (hseal,tur,loss,air + x w * hseal,tur,loss,w )]

+ Q el + Q heat + Q mech

The energy from the intake air, the fuel and injected water or

steam may be expressed as:

Qcpr0 = m cpr0,air * (hcpr0,air + x w * hcpr0,w ) (20)

Qfuel = m fuel *(LHV+SH)=mfuel *(LHV+c p,fuel *[t fuel -15.5]) (21)

Qinj = m inj * h inj (22)

Abreviations:

dqcprod = (1+ L min ) * hcprod - Lmin * h e2,air (24)

qfuel = (LHV+ c p,fuel *[t fuel - 15.5]) (25)

dQinj = m inj * (he2,w - hinj ) (26)

P = P Net + Σ losses (mech & electrial) (27)

qcpr0 = (hcpr0,air + x w * hcpr0,w ) (28)

qe2,w = [1-(xseal,cpr,loss +x seal,tur,loss )-xextr]*x w*he2,w (29)

qe2,air = [1-(xseal,cpr,loss +x seal,tur,loss )-xextr]*he2,air (30)

qseal = x seal,cpr,loss *(hseal,cpr,loss,air +x w*hseal,cpr,loss,w ) (31)

+x seal,tur,loss *(hseal,tur,loss,air +x w*hseal,tur,loss,w )

qextr = x extr * (hextr,air + x w* hextr,w) (32)

7 Copyright © 2005 by ASME

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 04/10/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

You might also like

- GT Internal Flow Systems Modeling PDFDocument376 pagesGT Internal Flow Systems Modeling PDFMahmood ElnagarNo ratings yet

- GT Internal Flow Systems Modeling PDFDocument376 pagesGT Internal Flow Systems Modeling PDFMahmood ElnagarNo ratings yet

- Fixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsFrom EverandFixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsRating: 4 out of 5 stars4/5 (5)

- Gas Turbine Performance Calculation ExcelDocument3 pagesGas Turbine Performance Calculation ExcelPlant Drain100% (1)

- MatlabDocument47 pagesMatlabalkadyasNo ratings yet

- Machine Learning Absolute Beginners Introduction 2ndDocument128 pagesMachine Learning Absolute Beginners Introduction 2ndud90% (61)

- PT6T36Document234 pagesPT6T36thomas100% (3)

- PRV Sizing For Exchanger Tube RuptureDocument5 pagesPRV Sizing For Exchanger Tube RuptureNavid Sajedi80% (5)

- A New Calculation Approach To The Energy Balance of A Gas Turbine Including A Study of The Impact of The Uncertainty of Measured ParametersDocument8 pagesA New Calculation Approach To The Energy Balance of A Gas Turbine Including A Study of The Impact of The Uncertainty of Measured Parameters..........................No ratings yet

- Improvement of Gas Turbine Performance TestDocument4 pagesImprovement of Gas Turbine Performance TestKrishna VenkataramanNo ratings yet

- Sense'' Testing Combined Cycle Plants Competitive: Performance FOR IN IndustryDocument11 pagesSense'' Testing Combined Cycle Plants Competitive: Performance FOR IN IndustryharkiranrandhawaNo ratings yet

- A Loss Method For Exergy Auditing of Steam BoilersDocument8 pagesA Loss Method For Exergy Auditing of Steam BoilersDaris BaihaqiNo ratings yet

- Of Steam Turbine-Generators: I Method For Predicting The PerformanceDocument40 pagesOf Steam Turbine-Generators: I Method For Predicting The PerformancenckpourlasNo ratings yet

- Energy Conversion and Management: Zuming Liu, Iftekhar A. KarimiDocument13 pagesEnergy Conversion and Management: Zuming Liu, Iftekhar A. KarimiJairoVidalNo ratings yet

- Performance of Axial Compressor StagesDocument11 pagesPerformance of Axial Compressor StagesBiswajit JenaNo ratings yet

- Modelling producer gas engine pressure with wrinkled flame theoryDocument10 pagesModelling producer gas engine pressure with wrinkled flame theoryRahneesh MklNo ratings yet

- The Analysis of Heat Transfer in Automotive Turbochargers: Nick BainesDocument8 pagesThe Analysis of Heat Transfer in Automotive Turbochargers: Nick BainesMuhtasim FuadNo ratings yet

- A Comparative Study of Different Methods of Correcting Combined Cycle Thermal PerformanceDocument18 pagesA Comparative Study of Different Methods of Correcting Combined Cycle Thermal PerformanceJung Kyung WooNo ratings yet

- Exergy Analysis of A 420MW Combined Cycle Power PlantDocument9 pagesExergy Analysis of A 420MW Combined Cycle Power PlantRakibHassanAkashNo ratings yet

- Energy Audit For Power PlantsDocument13 pagesEnergy Audit For Power Plantsnavratan61No ratings yet

- Energy Conversion and Management: Hang Li, Wei Su, Liyan Cao, Feng Chang, Wenkai Xia, Yiping DaiDocument10 pagesEnergy Conversion and Management: Hang Li, Wei Su, Liyan Cao, Feng Chang, Wenkai Xia, Yiping DaiANTHONY PAUL ALCARRAZ HUARANGANo ratings yet

- Applied Energy: Hui Xie, Can YangDocument12 pagesApplied Energy: Hui Xie, Can YangLAVNo ratings yet

- Exhaust Manifold Pressure Estimation Diesel Equipped With A VGT TurbochargerDocument7 pagesExhaust Manifold Pressure Estimation Diesel Equipped With A VGT TurbochargerpeterNo ratings yet

- Thermodinamic AnalysysDocument13 pagesThermodinamic AnalysysLeandro BuosiNo ratings yet

- Gas Turbine Compressor System Design Using Dynamic Process SimulationDocument7 pagesGas Turbine Compressor System Design Using Dynamic Process SimulationLTORRESMNo ratings yet

- Cost FucntionsDocument8 pagesCost Fucntionscalla80No ratings yet

- Cylinder Air Charge Estimator in Turbocharged SI-Engines: Per Andersson, Lars ErikssonDocument10 pagesCylinder Air Charge Estimator in Turbocharged SI-Engines: Per Andersson, Lars ErikssonPietGuerrillaNo ratings yet

- Development of A Marine Diesel MeanDocument12 pagesDevelopment of A Marine Diesel Meangpb76No ratings yet

- Improving Thermal Power Plant PerformanceDocument7 pagesImproving Thermal Power Plant PerformanceJaydeep kunduNo ratings yet

- Combined Brayton and Steam Rankine Cycle: Paper TopicDocument3 pagesCombined Brayton and Steam Rankine Cycle: Paper TopicAtharva ChodankarNo ratings yet

- Nonlinear Model Predictive Control For A Heavy-Duty Gas Turbine Power PlantDocument6 pagesNonlinear Model Predictive Control For A Heavy-Duty Gas Turbine Power PlantrismayudhaNo ratings yet

- PAPER80 ASME Rev30GDocument18 pagesPAPER80 ASME Rev30GDipak PatelNo ratings yet

- ME 325 Final Project Combined Cycle Efficiency OptimizationDocument3 pagesME 325 Final Project Combined Cycle Efficiency Optimizationazeem sheikhNo ratings yet

- Waste Heat Recovery PDFDocument16 pagesWaste Heat Recovery PDFadnanibrahimNo ratings yet

- Gas Turbine Compressor System Design Using Dynamic Process Simulation PDFDocument7 pagesGas Turbine Compressor System Design Using Dynamic Process Simulation PDFredhotriderNo ratings yet

- Simulation of CO2 Capture Using MEA Scrubbing A Flowsheet Decomposition Method PDFDocument13 pagesSimulation of CO2 Capture Using MEA Scrubbing A Flowsheet Decomposition Method PDFSuprio KamalNo ratings yet

- Jurnal PropulsiDocument15 pagesJurnal PropulsiMuhammad Raihan AtallahNo ratings yet

- Gas ExpanderDocument12 pagesGas ExpanderArun KumarNo ratings yet

- Simulationof CHPEnergyDocument7 pagesSimulationof CHPEnergyNEETIGYA CHAURASIANo ratings yet

- Gas Turbine Vs Gas EngineDocument16 pagesGas Turbine Vs Gas EngineMUHAMMAD AHMEDNo ratings yet

- Zhang2016 PDFDocument14 pagesZhang2016 PDFHéctor Jorge Bravo PastorNo ratings yet

- Model-Based Estimation of Gas Leakage in Wind Turbine AccumulatorsDocument11 pagesModel-Based Estimation of Gas Leakage in Wind Turbine AccumulatorsMoroko69No ratings yet

- A Method To Improve Exergtic Efficiency of Power Plant Cycle by Heat PipesDocument7 pagesA Method To Improve Exergtic Efficiency of Power Plant Cycle by Heat PipesArih FadiNo ratings yet

- Propane ProjectDocument9 pagesPropane ProjectVILLA KGAMADINo ratings yet

- Engineering Design and Exergy Analyses For Combustion Gas Turbine Based Power Generation SystemDocument23 pagesEngineering Design and Exergy Analyses For Combustion Gas Turbine Based Power Generation SystemInemie-ebi NiweighaNo ratings yet

- Energy Exergy and Exergoeconomic Analysis of Two Supercr 2021 Applied ThermDocument16 pagesEnergy Exergy and Exergoeconomic Analysis of Two Supercr 2021 Applied ThermApiwit Jumnonjit100% (1)

- Energy Integration of Fired Heaters Into Overall Processes: James Varghese and Santanu BandyopadhyayDocument24 pagesEnergy Integration of Fired Heaters Into Overall Processes: James Varghese and Santanu BandyopadhyayJesse Haney IIINo ratings yet

- Improving Steam Power Plant Efficiency Through Exergy Analysis: Ambient TemperatureDocument4 pagesImproving Steam Power Plant Efficiency Through Exergy Analysis: Ambient TemperatureRizki KumbangNo ratings yet

- PinchDocument14 pagesPinchYounes AgrouazNo ratings yet

- General Characteristics of Single Shaft Microturbine Set at Variable Speed Operation and Its Optimization PDFDocument13 pagesGeneral Characteristics of Single Shaft Microturbine Set at Variable Speed Operation and Its Optimization PDFsdustjklNo ratings yet

- Energy Integration of Fired Heater: IMEC04-2003Document17 pagesEnergy Integration of Fired Heater: IMEC04-2003Wejden YaakoubyNo ratings yet

- Literature Review On Gas TurbineDocument6 pagesLiterature Review On Gas Turbinefuhukuheseg2100% (1)

- Pinch White Paper (Rev 3) 2012Document21 pagesPinch White Paper (Rev 3) 2012Energy_ExpertNo ratings yet

- 2011 Improvement Power Plant EfficiencyDocument6 pages2011 Improvement Power Plant EfficiencyjmpbarrosNo ratings yet

- Performance Corrections For Steam Turbines With Multi-Pressure CondenserDocument8 pagesPerformance Corrections For Steam Turbines With Multi-Pressure CondenserSujeet Kumar50% (2)

- Liu 2017Document12 pagesLiu 2017Kim Ryan DinglasanNo ratings yet

- The Analysis of Heat Transfer in Automotive TurbochargersDocument12 pagesThe Analysis of Heat Transfer in Automotive TurbochargersyaminijayaramanNo ratings yet

- Total Site Exergy Analysis Using A New CDocument14 pagesTotal Site Exergy Analysis Using A New Ca7510378No ratings yet

- Cheayb Et Al. 2019Document14 pagesCheayb Et Al. 2019Musa AliyuNo ratings yet

- Performance Analysis On Liquid-Cooled Battery Thermal Management For Electric Vehicles Based On Machine LearningDocument16 pagesPerformance Analysis On Liquid-Cooled Battery Thermal Management For Electric Vehicles Based On Machine LearningSélim BoutlaneNo ratings yet

- Boiler Efficiency Monitoring and Boiler Losses Analysis: A ReviewDocument4 pagesBoiler Efficiency Monitoring and Boiler Losses Analysis: A ReviewaliNo ratings yet

- Combined Cooling, Heating, and Power Systems: Modeling, Optimization, and OperationFrom EverandCombined Cooling, Heating, and Power Systems: Modeling, Optimization, and OperationNo ratings yet

- The Steam Engine and Turbine - A Text Book for Engineering CollegesFrom EverandThe Steam Engine and Turbine - A Text Book for Engineering CollegesNo ratings yet

- Modeling, Analysis and Optimization of Process and Energy SystemsFrom EverandModeling, Analysis and Optimization of Process and Energy SystemsNo ratings yet

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- Machine LearniingDocument31 pagesMachine Learniinganshul77No ratings yet

- A Practical Guide For Gas Turbine Performance AnalysisDocument10 pagesA Practical Guide For Gas Turbine Performance Analysispaul.eastwood9991100% (1)

- Gas Turbine PerformancexlsDocument15 pagesGas Turbine PerformancexlsMahmood ElnagarNo ratings yet

- Linear Algebra Review (Op3onal) : Matrices and VectorsDocument25 pagesLinear Algebra Review (Op3onal) : Matrices and Vectorsshabbir4791No ratings yet

- TP 2002 211556Document297 pagesTP 2002 211556Claudia StanciuNo ratings yet

- Juha Kaikko: Performance Prediction of Gas Turbines by Solving A System of Non-Linear EquationsDocument104 pagesJuha Kaikko: Performance Prediction of Gas Turbines by Solving A System of Non-Linear EquationsMahmood ElnagarNo ratings yet

- Safari - 22 Mar 2020 at 2 - 41 PMDocument1 pageSafari - 22 Mar 2020 at 2 - 41 PMMahmood ElnagarNo ratings yet

- CFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesDocument7 pagesCFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesMahmood ElnagarNo ratings yet

- Development of Gas Turbine Performance Models Using A Generic SimuDocument10 pagesDevelopment of Gas Turbine Performance Models Using A Generic SimuMahmood ElnagarNo ratings yet

- ADVANCED USER-FRIENDLY GAS TURBINE PERFORMANCE CALCULATIONS On A Personal PCDocument8 pagesADVANCED USER-FRIENDLY GAS TURBINE PERFORMANCE CALCULATIONS On A Personal PCMahmood ElnagarNo ratings yet

- ADVANCED USER-FRIENDLY GAS TURBINE PERFORMANCE CALCULATIONS On A Personal PCDocument8 pagesADVANCED USER-FRIENDLY GAS TURBINE PERFORMANCE CALCULATIONS On A Personal PCMahmood ElnagarNo ratings yet

- Juha Kaikko: Performance Prediction of Gas Turbines by Solving A System of Non-Linear EquationsDocument104 pagesJuha Kaikko: Performance Prediction of Gas Turbines by Solving A System of Non-Linear EquationsMahmood ElnagarNo ratings yet

- TP 2002 211556Document297 pagesTP 2002 211556Claudia StanciuNo ratings yet

- A Computer Method For Thermal Power Cycle ClculationDocument8 pagesA Computer Method For Thermal Power Cycle ClculationMahmood ElnagarNo ratings yet

- Magoosh GRE Math Formula EbookDocument33 pagesMagoosh GRE Math Formula EbookLavina D'costa100% (1)

- Juha Kaikko: Performance Prediction of Gas Turbines by Solving A System of Non-Linear EquationsDocument104 pagesJuha Kaikko: Performance Prediction of Gas Turbines by Solving A System of Non-Linear EquationsMahmood ElnagarNo ratings yet

- Juha Kaikko: Performance Prediction of Gas Turbines by Solving A System of Non-Linear EquationsDocument104 pagesJuha Kaikko: Performance Prediction of Gas Turbines by Solving A System of Non-Linear EquationsMahmood ElnagarNo ratings yet

- A Practical Guide For Gas Turbine Performance AnalysisDocument10 pagesA Practical Guide For Gas Turbine Performance Analysispaul.eastwood9991100% (1)

- Wittig RTL. Oil Free Rotary Compressors.: For Installation On Bulk TankersDocument7 pagesWittig RTL. Oil Free Rotary Compressors.: For Installation On Bulk Tankersmogwai71No ratings yet

- Ref. Standards For Gas CylindersDocument4 pagesRef. Standards For Gas CylindersJayesh VishnuswamiNo ratings yet

- Plano Eléctrico Serie FDocument13 pagesPlano Eléctrico Serie FFelipeNicolasSilvaNo ratings yet

- Santosh G Kelshekar - AssortedDocument10 pagesSantosh G Kelshekar - AssortedscemanjuNo ratings yet

- Ata 35Document38 pagesAta 35Geovanni Riquelme LooNo ratings yet

- Phosphorus, Sulfur, and Silicon CompoundsDocument72 pagesPhosphorus, Sulfur, and Silicon CompoundsVU GIANGNo ratings yet

- Uniformity Index - Catalytical Converter-TestDocument13 pagesUniformity Index - Catalytical Converter-Testjeetendra222523No ratings yet

- Fallas Sistema Hidrualico ImplementosDocument7 pagesFallas Sistema Hidrualico ImplementosEdin raul Yalle rafaelNo ratings yet

- (H-EP) Expanded Perlite: Low Temperature and Cryogenic InsulationDocument2 pages(H-EP) Expanded Perlite: Low Temperature and Cryogenic InsulationKamesh KalgiNo ratings yet

- Liquid Nitrogen Commissioning ProceduresDocument3 pagesLiquid Nitrogen Commissioning ProceduresMOHAN RAVICHANDRANNo ratings yet

- D-35 Nitrogen Inert Gas SystemDocument12 pagesD-35 Nitrogen Inert Gas SystemEvgeny BabkovNo ratings yet

- Peng-Robinson (PR) : Use of Equations of State and Equation of State Software PackagesDocument7 pagesPeng-Robinson (PR) : Use of Equations of State and Equation of State Software PackagesgeorgenzNo ratings yet

- Flash Point TutorialDocument8 pagesFlash Point TutorialS. GreenNo ratings yet

- Design and Development of A Regenerative Blower For EVA Suit VentilationDocument18 pagesDesign and Development of A Regenerative Blower For EVA Suit VentilationBrahimABDNo ratings yet

- Henry's Law - WikipediaDocument14 pagesHenry's Law - WikipediaZakria Shah100% (1)

- 05 - Annex A Technical ProposalDocument7 pages05 - Annex A Technical Proposalarun Rajanna100% (1)

- US Maritime Service Training Manual - Engineering Branch TrainingDocument152 pagesUS Maritime Service Training Manual - Engineering Branch Trainingmihalikj2190No ratings yet

- AD00539M NUFLO Gas Turbine MeterDocument2 pagesAD00539M NUFLO Gas Turbine MeterVirnando NainggolanNo ratings yet

- Biogas PDFDocument18 pagesBiogas PDFkarácsonyi krampuszNo ratings yet

- Pcpumps: ProiexDocument3 pagesPcpumps: ProiexSavalia HardikNo ratings yet

- Group C-Flow MeasurementDocument10 pagesGroup C-Flow Measurement214164No ratings yet

- Uniphos Kwiksense Digital Smart Gas Transmitter: Salient FeaturesDocument3 pagesUniphos Kwiksense Digital Smart Gas Transmitter: Salient Featuresraushan mishraNo ratings yet

- Accurately Calculate Nitrogen RequirementDocument6 pagesAccurately Calculate Nitrogen RequirementRachel BaileyNo ratings yet

- PE5970 ES Menon Gas Hydraulics Class NotesDocument59 pagesPE5970 ES Menon Gas Hydraulics Class NotesKevin Kivanc IlgarNo ratings yet

- V70808 0001Document18 pagesV70808 0001maronnamNo ratings yet

- Chapter 4: FoamDocument28 pagesChapter 4: FoamjavierNo ratings yet

- Water HammerDocument30 pagesWater Hammerbhavesh shuklaNo ratings yet

- GW491QE Petrol Engine Service Manual Lubrication+systemDocument7 pagesGW491QE Petrol Engine Service Manual Lubrication+systemAlbert BriceñoNo ratings yet