Professional Documents

Culture Documents

Wet & Dry Riser Designed To BS 9990: Information File

Uploaded by

XAVIER RUBIOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wet & Dry Riser Designed To BS 9990: Information File

Uploaded by

XAVIER RUBIOCopyright:

Available Formats

I N F O R M AT I O N F I L E

Wet & Dry Riser

# 21

Designed to BS 9990

A rising main is a system of pipework, valves and outlets on each floor often found

in high-rise buildings, which allows firefighting water to be easily delivered to all

floors. Rising mains in buildings can be either filled with water (Wet Riser) or empty

(Dry Riser).

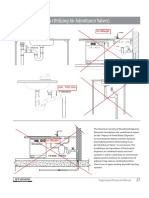

Where mains are supplied from rooftop tanks This inlet should be positioned as close as possible

and pumps in very tall buildings, the mains to the rising main in order to reduce pressure losses.

are referred to as ‘Falling Mains’ or sometimes The inlet breeching unit for a 100mm diameter

‘Downcomers’. The risers remove the need for dry riser has two 65mm male instantaneous

firefighters to have to drag charged fire hoses all the hose connections. For larger diameter dry risers

way up a tall building which could delay firefighting a breeching inlet with four hose connections will

operations or create a hazard during evacuation. be needed. When selecting a location for the inlet

The British Standard used for design, installation, breeching valve the first consideration must be the

testing and maintenance of Wet and Dry Risers safety of firefighters. An access road, suitable for a

is: BS9990 Non-automatic firefighting systems in fire appliances must be provided. This should allow

buildings Code of practice. positioning of the fire appliance to within 18 m and

Approved Document B (Fire Safety) of the preferably within sight of the inlet box. The lower

Building Regulations (England & Wales) requires edge of the inlet box must be located between

that any building more than 18m high, measured 400mm and 600mm above the ground. The inlet is

from the fire brigade access level to the top floor, fitted with a drain valve to drain water from the dry

or which has floors more than 10m below ground fire main at the end of operations.

must be provided with ‘firefighting shafts’ and a Landing valve have a flanged inlet and a

firefighting rising main. If the building has a floor 65mm instantaneous hose connection outlet with

level higher than 18m but less than 50m or has removable blank cap and retaining chain. and a

floors more than 10m below ground, the fire main handwheel to open and shut the valve. They are

can be either a Dry or a Wet riser. When a building installed at each floor level, including the ground

is more than 50m high the rising main has to be floor and should be located inside a red metal box

a Wet riser. In Scotland, the Technical Handbooks with a glass panel, labelled Wet or Dry Riser. Landing

of Scottish Building Standards contain similar valves can have either horizontal or ‘bib nosed’ BAFSA ADVISORY

requirements. connections with a downwards angle. On Dry Rising C O M M E N T:

mains a landing valve may be installed, at roof level

DRY R I S IN G M A I N S for periodic testing, if required by the authority

The pipes in dry risers are empty and are only filled “All Wet and Dry

having jurisdiction. (AHJ)

by the fire brigade when they arrive with water systems should

Usually there is only a single landing valve at

drawn from the nearest fire hydrant and pressurised initially be static

each floor level, but two may be provided if required

by the pump on the fire tender. Some fire mains are pressure tested to

by AHJ’s. Landing valves should preferably be located

described as ‘falling’ mains where they are installed in well-ventilated fire resistant lobbies within the at least one and half

for firefighting below ground level or where a fire firefighting shafts and must be installed with its times the system’s

water supply is provided at high level lowest point at 750 mm above floor level. predicted maximum

The water is supplied to the Dry Riser from operating pressure

the fire tender pump through the inlet breeching AI R REL E AS E VALV E for at least one hour.”

connection on an external wall. The breeching An air release valve must be fitted at the top of the

connections are usually contained in a locked red Dry riser to expel air when filling the main and allow

glass fronted box with the wording ‘Dry Rise Inlet’. ingress when draining the system.

AUGUST 2020 BAFSA.ORG.UK

SE C U R IT Y volume of stored water for a wet riser is two tanks each with a volume

Riser equipment can have brass or bronze components, by installing of 22 500 L . The other 22 500 L can be supplied automatically to the

them in lockable boxes makes them less susceptible to vandalism and theft. two tanks from the service main through ball valves fitted to each tank.

Another option is to install two tanks each with a capacity of 33 750 L so

WAT E R C HAR GED

that there is no dependence a water infill. This allows the fire brigade to

When dry mains have a very large volume they can be permanently use the service main independently.

charged with water from a small water tank of about 300 L capacity with All wet riser tanks must have a facility to allow the fire brigade to

a permanent infill connection to a local water supply which means the replenish their contents. This is done by installing an inlet breeching

fire brigade can commence firefighting operation almost immediately as connection at a convenient and safe location for the fire brigade to pump

they do not have to fill the riser pipe-work. An example of where water water from the service main into the tank/s. High and low water level

charged dry mains can be used is in long underground tunnels where the alarms are fitted to the tanks to monitor the water level. This pipe must

temperature is above 4 Cº at all times. be at least 100mm diameter for tanks that are located no higher than

60m above ground level.

WE T RI SI N G M A I N S

It is not usual that water tanks for domestic purposes or sprinklers

The pipes in wet risers are full of water at all times and have automatic

are used for wet rising mains.

pumps and stored water which operate when the pressure in the rising

mains drops on the opening of a landing valve. WATE R PRE S S U RE

The water pressure required at the level of the highest landing valve is 8

P U MP S

bar. For a 60m high building the minimum pressure at the water source

If service water supplies is insufficient to serve a wet rising main pumps could be 15 bar or for a 100m high building it could be 20 bar.

and tanks will have to be installed. Wet Risers must have two pumps and

two tanks. The pumps have to be capable of delivering 1,500 l/min which PRE S S URE RE G U LATIN G VALV E S (PRVS )

is enough to supply each of two fire service hoses with 750 l/min. The PRVs are designed to ensure that the pressure in a fire hose does not

pump must be capable of providing 8 bar pressure at each of the two exceed 12 bar when the hose jet is shut.

operating landing valves. Pump arrangement for Wet risers can be either These PRVs are incorporated into the landing valve and regulate the

two electrically-driven units or one electric and one diesel engine driven high pressure in the rising main to a safe 8 bar at the hose connection.

unit. One is the ‘duty’ pump, and the other is a standby should the duty In BS9990 there is an allowable tolerance for flow and pressure at the

pump fail or additional pumping capacity be required. The system has landing valve of 750 (±75) l/min at 8 (±0.5) bar.

a small capacity ‘jockey pump’ which starts automatically to maintain

system pressure and prevent intermittent starting and stopping of the TE STIN G

main pumps. The system should be completely charged with water to a pressure equal

to its design operating pressure measured at the inlet for a period of at

P OW E R SUP P LIES least 15 min. During this period, the system should be checked for any

Where two electrically-powered pumps are used, the preferred power leakage of water. Leaks should be repaired and the system re-tested.

source is two independent incoming electric supplies. If these are not All dry fire mains should be checked every six months to ensure that

available a single incoming electric supply can be used in conjunction all valves are fully serviceable, and a wet pressure test should be carried

with a separate supply which can be an on-site emergency generator. out annually to ensure that there is no leakage. Wet fire mains should be

These two supplies are connected to an automatic changeover panel similarly checked and, in addition, the water storage tanks and booster

which ensures that both pumps have power in the event of any power pumps should be checked for correct operation.

failure. Electric power supplies must be sufficient to allow the wet riser Defects in equipment should be rectified by a competent person.

pumps to run for at least 3 hours. During repairs a notice should be posted on the building and the

fire service should be notified then and as soon as the equipment is

ISOL AT I NG VALVES

serviceable again.

Isolating valves are installed at intervals not exceeding 10 m on the rising

mains so that sections can be isolated to enable repairs to be carried COMPONENTS F OR RISERS

out. These valves should be secured in the open position by a chain and All components to be installed in any system which is to be connected to

padlock or fitted with monitoring devices to indicate at the fire control the service mains or any water company pipework must comply with the

panel if any valve is not fully open. Water Fittings Regulations 1999 or (Scottish) Water Byelaws 2014 and

approved for its intended use by the Water Regulations Advisory Scheme

WAT E R TA NKS

(WRAS) wras.co.uk/

An on-site supply of stored water must be capable of supplying enough

water to provide two landing valves with not less than 750 L/min each PIPE S & FITTIN G S

for at least 45 minutes. The total water requirement for a wet riser would Fire mains should have a nominal bore of 100 mm, designed to withstand

therefore normally be 67 500 L. BS9990 requires that the minimum a pressure of 1.5 half times maximum operating pressure. Commonly

used pipe for Wet and Dry risers is manufactured to BS EN 10255 non-

alloy steel tubes. Fire mains pipework and fittings should be of suitable

heavy quality steel and galvanised where necessary. Pipes for Dry risers

are normally galvanised.

Pipe fittings can be either screwed, grooved or flanged and are

normally galvanised. Usually the straight sections of the rising main are

PRESENTED BY

B RIT IS H AUTOMAT IC F IRE SPRI N K L ER ASSO CI ATI O N joined with mechanical grooved couplings with a long radius tee at each

Unit 12, Kildean Business & Enterprise Hub, floor level that connects to the landing valve with a flanged joint.

146 Drip Road, Stirling FK8 1RW

info@bafsa.org.uk www.bafsa.org.uk If you have a question or seek advice regarding automatic water-based

fire suppression systems, please email the team : ian.gough@bafsa.org.

facebook.com/SprinklersSaveLives uk or joe.mcafferty@bafsa.org.uk. If they do not have an answer for you,

twitter.com/BAFSAfocus Find us on LinkedIn: BAFSA they will know someone who has! FAQs can be found at bafsa.org.uk/

sprinkler-systems/faqs/

© BAFSA 2020 INFO@BAFSA.ORG.UK

You might also like

- Ultraseal CU5 Bag Filter Medium Efficiency Rating: DatasheetDocument2 pagesUltraseal CU5 Bag Filter Medium Efficiency Rating: DatasheetXAVIER RUBIONo ratings yet

- Copper Tube HandbookDocument96 pagesCopper Tube HandbookNguyễn Văn ThànhNo ratings yet

- Rs Pro Ultima Filters: DatasheetDocument3 pagesRs Pro Ultima Filters: DatasheetXAVIER RUBIONo ratings yet

- Studor Technical ManualDocument3 pagesStudor Technical ManualXAVIER RUBIONo ratings yet

- PRV 222Document2 pagesPRV 222Ayman Mohammed Ibrahim AbdouNo ratings yet

- Installation Manual: Variable Refrigerant Flow Outdoor Units 6.0 To 42.0 TonsDocument208 pagesInstallation Manual: Variable Refrigerant Flow Outdoor Units 6.0 To 42.0 TonsXAVIER RUBIONo ratings yet

- Fire Damper InfoDocument14 pagesFire Damper InfoXAVIER RUBIONo ratings yet

- Technicalmanual 2Document24 pagesTechnicalmanual 2Saber ElkassasNo ratings yet

- Indiana Rules for Public Pool SanitationDocument191 pagesIndiana Rules for Public Pool SanitationXAVIER RUBIONo ratings yet

- Fırat PPRC Composite Pipes and FittingsDocument7 pagesFırat PPRC Composite Pipes and FittingsXAVIER RUBIONo ratings yet

- Catalogue Máy L NH Trung Tâm LG Multi V 5 2017Document138 pagesCatalogue Máy L NH Trung Tâm LG Multi V 5 2017Hung Tran67% (3)

- Vent Terminals - UpCodesDocument6 pagesVent Terminals - UpCodesXAVIER RUBIONo ratings yet

- Fırat PPRC Composite Pipes and FittingsDocument7 pagesFırat PPRC Composite Pipes and FittingsXAVIER RUBIONo ratings yet

- Vk-20 Louvre Shutter: Item NoDocument2 pagesVk-20 Louvre Shutter: Item NoXAVIER RUBIONo ratings yet

- Carrier VRFTIP-18-02 Data SheetDocument2 pagesCarrier VRFTIP-18-02 Data SheetXAVIER RUBIONo ratings yet

- BS 6840-10Document28 pagesBS 6840-10Jeff Anderson CollinsNo ratings yet

- BS 3G 210 PTFE Insulated Equipment Wires & Cables, Single - & Multi-Core, With Silver Plated Copper Conductors (190 °C) or Nickel Plated Copper Conductors (260 °C)Document30 pagesBS 3G 210 PTFE Insulated Equipment Wires & Cables, Single - & Multi-Core, With Silver Plated Copper Conductors (190 °C) or Nickel Plated Copper Conductors (260 °C)Chathuranga PriyasamanNo ratings yet

- Wavin: Range 600 Inspection Chambers: Product Technical GuideDocument16 pagesWavin: Range 600 Inspection Chambers: Product Technical GuideXAVIER RUBIONo ratings yet

- BS 5266-6Document12 pagesBS 5266-6Ivan RadovicNo ratings yet

- BS 5622-2Document87 pagesBS 5622-2XAVIER RUBIONo ratings yet

- O Guia Definitivo Long ShortDocument9 pagesO Guia Definitivo Long ShortVinícius SHNo ratings yet

- TankFilling 1102 12.07Document16 pagesTankFilling 1102 12.07Anonymous R9p603bHIgNo ratings yet

- Wavin: Inspection ChambersDocument62 pagesWavin: Inspection ChambersXAVIER RUBIONo ratings yet

- BS 4533-102-17Document14 pagesBS 4533-102-17Arun Jacob CherianNo ratings yet

- Bunding and Spill Management Guidelines Dec 2015Document13 pagesBunding and Spill Management Guidelines Dec 2015Danusha EgodawatteNo ratings yet

- FD Brochure 2017 0601 LR InekoDocument16 pagesFD Brochure 2017 0601 LR InekomoisesNo ratings yet

- 34Document12 pages34Muhammad Azwar AnnasNo ratings yet

- California Code of Regulations, Title 8, Section 3277. Fixed LaddersDocument14 pagesCalifornia Code of Regulations, Title 8, Section 3277. Fixed LaddersXAVIER RUBIONo ratings yet

- Tj82pe5a en PDFDocument4 pagesTj82pe5a en PDFMin MyatNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MFT28 - Greg Plitt's 4-Week Military Fitness Trainer by MET-RxDocument7 pagesMFT28 - Greg Plitt's 4-Week Military Fitness Trainer by MET-RxRayNo ratings yet

- Music and Therapy Bun2Document17 pagesMusic and Therapy Bun2PanteaAlisaNo ratings yet

- Data Sheet Dump ValveDocument2 pagesData Sheet Dump ValveVlade NaumovskiNo ratings yet

- The Prevention of Women & Children Repression Act 2000: A Study of Implementation Process From 2003 To 2013Document9 pagesThe Prevention of Women & Children Repression Act 2000: A Study of Implementation Process From 2003 To 2013Md. Abdul KarimNo ratings yet

- Type 3730-1 Electropneumatic PositionerDocument112 pagesType 3730-1 Electropneumatic PositionerDaniel ReyNo ratings yet

- Nursing Care of The Patient Undergoing Lumbar Spinal Fusion: ReviewsDocument10 pagesNursing Care of The Patient Undergoing Lumbar Spinal Fusion: ReviewsMuammar100% (1)

- Pathology AIIMSDocument26 pagesPathology AIIMSvkNo ratings yet

- Nestle Write UpDocument18 pagesNestle Write UpAnjana CarriNo ratings yet

- API 578 Mock QuestionDocument4 pagesAPI 578 Mock QuestionsheikmoinNo ratings yet

- Dowell's Price List 18.3.2022Document26 pagesDowell's Price List 18.3.2022Sunil WadekarNo ratings yet

- REBA Employee Assessment Worksheet: A. Neck, Trunk and Leg AnalysisDocument1 pageREBA Employee Assessment Worksheet: A. Neck, Trunk and Leg AnalysisAgni JayantiNo ratings yet

- SonoAce R7 v3.01.00 EDocument544 pagesSonoAce R7 v3.01.00 EEcomedical PlussNo ratings yet

- Trisyl Silica Gel: For Oils/Fats and Biofuel RefiningDocument4 pagesTrisyl Silica Gel: For Oils/Fats and Biofuel RefiningJosé Mauricio Bonilla TobónNo ratings yet

- Mbenson hw410 1602c - Unit-9-AssignmentDocument46 pagesMbenson hw410 1602c - Unit-9-Assignmentapi-355858071No ratings yet

- TestDocument4 pagesTestCristina BariNo ratings yet

- 1978 - 90 Day Study or Rhesus Monkey ToxicityDocument4 pages1978 - 90 Day Study or Rhesus Monkey Toxicitygrace poudrierNo ratings yet

- Perfect Scale Pro ManualDocument9 pagesPerfect Scale Pro ManualAnthony VargasNo ratings yet

- A Toxicity Study of Methanolic Extract of Calliandra Surinamensis Seeds On Liver Functions in RodentsDocument9 pagesA Toxicity Study of Methanolic Extract of Calliandra Surinamensis Seeds On Liver Functions in RodentsMediterr J Pharm Pharm SciNo ratings yet

- A4 RelationshipgridDocument32 pagesA4 RelationshipgridjamesNo ratings yet

- Dahong PalayDocument2 pagesDahong PalayAngela MontenegroNo ratings yet

- SIX A Filthy Christmas Miracl JamesDocument55 pagesSIX A Filthy Christmas Miracl JamescarinaNo ratings yet

- Cerberus PRO Product Catalog: Fire Safety Products and AccessoriesDocument253 pagesCerberus PRO Product Catalog: Fire Safety Products and AccessoriesleonardoleitealertaNo ratings yet

- Sydney M PRPDocument23 pagesSydney M PRPapi-465406877No ratings yet

- General Psychology Mid Term ExamDocument2 pagesGeneral Psychology Mid Term Examapi-534780597No ratings yet

- Ghana Off-Grid Solar Farm & Water System DevelopmentDocument1 pageGhana Off-Grid Solar Farm & Water System DevelopmentDaniel NguyenNo ratings yet

- Septic Abortion PDFDocument4 pagesSeptic Abortion PDFmariachrismayaniNo ratings yet

- Cat Helimax 2016 Esp 1Document74 pagesCat Helimax 2016 Esp 1HKM IngenierosNo ratings yet

- A 1116Document15 pagesA 1116Rama S. SinghNo ratings yet

- The Taste of Tradition: Submitted byDocument14 pagesThe Taste of Tradition: Submitted byvijay malikNo ratings yet

- PCOS Diet Cookbook For Newly Diagnosed IndividualsDocument67 pagesPCOS Diet Cookbook For Newly Diagnosed Individualsmavendave4lifeNo ratings yet