Professional Documents

Culture Documents

Распылители Берту норма выливаL

Uploaded by

gluykOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Распылители Берту норма выливаL

Uploaded by

gluykCopyright:

Available Formats

• MATERIAL : • NOZZLE BODIES :

Our nozzles are available either in sintered alumina Nozal nozzles are available in two different forms :

or in synthetic resin. • Tips : conventional nozzles with standardised

• Resin : nozzles RFX or RRX, injected synthetic dimensions to fit most nozzle holders and caps.

Used principle Means used Type concerned

resin, which wears well for a reasonable invest- Tips can be provided with lugs to ease their posi-

DIFFERENT WAYS ment. tioning.

TO FIGHT Increase the volume/ha with

nozzles with larger exit orifice

NOZAL AFX or RFX 110°

(flat fan nozzle) • Ceramic : nozzles AFX, ADX or ARX in white sin- • Kwix : monobloc set combining a nozzle insert

against drift tered alumine, very hard-wearing material (nearly with a bayonet cap easy and quick to install on ISO

Increased operating speed and NOZAL AFX or RFX 110° as hard as diamond) for long lasting stability of the nozzle holders.

nozzles with larger exit orifice (flat fan nozzle)

Reduce the nozzles characteristics and performances : flow

percentage of

small droplets rate, coverage and droplet size. PRESENTATION

NOZAL ADX

Support the droplets with air

(nozzle with drift control) Tips Kwix

Tests done by CEMAGREPH according to standard NOZZLE

ISO 5682/1, showed excellent wear resistance of the

Support the droplets with air

NOZAL RRX/ARX TYPE

(nozzle with air injection) NOZAL nozzles.

COMPARATIVE WEAR TEST FOR

DIFFERENT NOZZLES MATERIALS

RFX/AFX ▲ ▲

Inox RRX/ARX ▲

Resin - RFX

Ceramic - AFX ADX ▲

▲

Wear percentage

10 TRIFILET

IMPACT OF NOZZLE TYPE 9

10 % ■ 80 l/ha

and volume/ha 8

7

■ 120 l/ha

• BOOM HEIGHT ADJUSTMENT :

on drift 6

7% 7%

The distance between the target and the boom

Drift %

Wind velocity 3,5m/sec. ITCF base.

5 5,5 %

Time (minute)

influences the distribution’s uniformity.

4 > Source : Cemagref 1997

4% This height is based on :

3

2

• Spray angle : 80° or 110/120°,

• SAFE AND QUICK SELECTION :

NOZAL

1 • Nozzle spacing : 50 or 33 cm

1%

0 The nozzle bodies and caps are of coloured resin for • Meteorological factors (i.e. wind).

Flat fan nozzle Nozzle with drift control Nozzle with air injection

easy and immediate identification of the flow rate of Generally, good spray coverage is achieved by dou-

the nozzles fitted to the boom. The colour coding ble or triple overlapping.

system complies with ISO 10625 standards.

80° 110/120°

• FLOW RATE CONTROL :

Whatever nozzle types you use, it is important to

• Double overlap.

• Triple overlap.

70/80 cm

110/120 cm

45/55 cm

70/75 cm

> A broad field of applications

check them regularly : clogging, damage, etc.

Check the flow rate of each nozzle twice or three

times a year. When their flow exceeds the flow of a • QUALITY :

• NOZAL TRIFILET new nozzle by 10 %, they should be replaced.

- 09/2007

Each nozzle is automatically tested to insure that

variation from nominal flow rate is within +5/-5 %

• 3 orifice nozzle for application of liquid fertili- tolerance (+ or – 5 % regarding French standard

ser without risk of damage to leaf surface. NOZZLE TRIFILET AFNOR NF U26.110)

• Only available as Kwix. FOR LIQUID

• Flow rate in accordance with ISO colour FERTILIZER

coding.

• Available in green, yellow, lilac, blue, red,

brown, grey and white. • Flow calibration alumine YOUR DEALER

insert

• Diffuser

• Expansion chamber

• Orifice (resin) Rue de l’Industrie - 51200 EPERNAY - FRANCE

société d’EXEL Industries

• NOZAL RFX/AFX CHARACTERISTICS AND SPRAY TABLE

• Conventional flat fan nozzle. NOZZLES

Pressure Flow rate per Application rate in l/ha according to speed and nozzle spacing 50 cm

NOZZLES

Pressure Flow rate per Application rate in l/ha according to speed and nozzle spacing 50 cm

in bar nozzle in l/min in bar in l/min

FLAT FAN NOZZLE • 80° (low volume/ha, green and yellow nozzles) 5 km/h 6 km/h 7 km/h 8 km/h 9 km/h 10 km/h 11 km/h 12 km/h 14 km/h 16 km/h 18 km/h 20 km/h 5 km/h 6 km/h 7 km/h 8 km/h 9 km/h 10 km/h 11 km/h 12 km/h 14 km/h 16 km/h 18 km/h 20 km/h

1,75 0,44 106 88 75 66 59 53 48 44 38 33 29 26 1,75 0,39 94 78 67 59 52 47 43 39 33 29 26 23

or 110° spray angle.

RFX/AFX 2 0,48 115 96 82 72 64 58 52 48 41 36 32 29 2 0,42 101 84 72 63 56 50 46 42 36 32 28 25

• Suited for all applications (herbicide, fungicide, RRX/ARX 2,5 0,54 130 108 93 81 72 65 59 54 46 41 36 32 TRIFILET 2,5 0,48 115 96 28 72 64 58 52 48 41 36 32 29

insecticide…) with a wide volume/ha range. ADX 3 0,59 142 118 101 89 79 71 64 59 51 44 39 35

• Kwix caps for automatic 015 3 0,52 125 104 89 78 69 62 57 52 45 39 35 31

positioning • Available as Tip or Kwix. 015

3,5 0,62 149 124 106 93 83 74 68 62 53 47 41 37

3,5 0,55 132 110 94 83 73 66 60 55 47 41 37 33

4 0,68 163 136 117 102 91 82 74 68 58 51 45 41

• Filter

• Flow rate in accordance with ISO colour 5 0,75 180 150 129 113 100 90 82 75 64 56 50 45

GREEN 4 0,60 144 120 103 90 80 72 65 60 51 45 40 36

coding. GREEN

• Gasket 6 0,84 202 168 144 126 112 101 92 84 72 63 56 50 5 0,66 158 132 113 99 88 79 72 66 57 50 44 40

• Operating pressure between 1,5 and 3 bar for 1,75 0,60 144 120 103 90 80 72 65 60 51 45 40 36 1,75 0,53 127 106 91 80 71 64 58 53 45 40 35 32

optimum droplet size (200 to 350 µ). RFX/AFX 2 0,65 156 130 111 98 87 78 71 65 56 49 43 39 2 0,57 137 114 98 86 76 68 62 57 49 43 38 34

RRX/ARX 2,5 0,72 173 144 123 108 96 86 79 72 62 54 48 43 TRIFILET

• Available in green, yellow, lilac, blue, red, ADX 3 0,79 190 158 135 119 105 95 86 79 68 59 53 47

2,5 0,63 151 126 108 95 84 76 69 63 54 47 42 38

• Insert

brown, grey and white. 3,5 0,85 204 170 146 128 113 102 93 85 73 64 57 51 02 3 0,70 168 140 120 105 93 84 76 70 60 53 47 42

02 4 0,91 218 182 156 137 121 109 99 91 78 68 61 55 3,5 0,75 180 150 129 113 100 90 82 75 64 56 50 45

5 1,01 242 202 173 152 135 121 110 101 87 76 67 61

YELLOW 4 0,80 192 160 137 120 107 96 87 80 69 60 53 48

YELLOW

6 1,11 266 222 190 167 148 133 121 111 95 83 74 67 5 0,89 214 178 153 134 119 107 97 89 76 67 59 53

1,75 0,77 185 154 132 116 103 92 84 77 66 58 51 46 1,75 0,67 161 134 115 101 89 80 73 67 57 50 45 40

AFX 2 0,82 197 164 141 123 109 98 89 82 70 62 55 49 2 0,71 170 142 122 107 95 85 77 71 61 53 47 43

ARX TRIFILET

• NOZAL ADX

2,5 0,92 221 184 158 138 123 110 100 92 79 69 61 55

2,5 0,8 192 160 137 120 107 96 87 80 69 60 53 48

ADX 3 1 240 200 171 150 133 120 109 100 86 75 67 60

025 3 0,88 211 176 151 132 117 106 96 88 75 66 59 53

3,5 1,08 259 216 185 162 144 130 118 108 93 81 72 65

025 4 1,15 276 230 197 173 153 138 125 115 99 86 77 69 3,5 0,95 228 190 163 143 127 114 104 95 81 71 63 57

• Flat fan nozzle with air injection. 5 1,28 307 256 219 192 171 154 140 128 110 96 85 77

LILAC 4 1 240 200 171 150 133 120 109 100 86 75 67 60

NOZZLE WITH • 120° spray angle. LILAC

6 1,4 336 280 240 210 187 168 153 140 120 105 93 84 5 1,12 269 224 192 168 149 134 122 112 96 84 75 88

DRIFT CONTROL • Suited for all applications (herbicide, fungicide, 1,75 0,90 216 180 154 135 120 108 98 90 77 68 60 54 1,75 0,79 190 158 135 119 105 95 86 79 68 59 53 47

insecticide…). RFX/AFX 2 0,97 233 194 166 146 129 116 106 97 83 73 65 58 2 0,85 204 170 146 128 113 102 93 85 73 64 57 51

RRX/ARX 2,5 1,08 259 216 185 162 144 130 118 108 93 81 72 65 TRIFILET

• Environment-friendly (drift control). ADX 3 1,18 283 236 202 177 157 142 129 118 101 89 79 71

2,5 0,95 228 190 163 144 127 114 104 95 81 71 63 57

• Only available as Kwix. 3,5 1,28 307 256 219 192 171 154 140 128 110 96 85 77 03 3 1,04 250 208 178 156 139 125 113 104 89 78 69 62

• Flow rate in accordance with ISO colour 03 4 1,37 329 274 235 206 183 164 149 137 117 103 91 82 3,5 1,13 271 226 194 170 151 136 123 113 97 85 75 68

• Flow rate calibration orifice 5 1,53 367 306 262 230 204 184 167 153 131 115 102 92

BLUE 4 1,20 288 240 206 180 160 144 131 120 103 90 80 72

coding. BLUE

6 1,64 394 328 281 246 219 197 179 164 141 123 109 98 5 1,35 324 270 231 203 180 162 147 135 116 101 90 81

• Operating pressure between 1,5 and 6 bar for 1,75 1,19 286 238 204 179 159 143 130 119 102 89 79 71 1,75 1,05 252 210 180 158 140 126 115 105 90 79 70 63

medium-sized droplets between 300 and 500 µ. 2 1,29 310 258 221 194 172 155 141 129 111 97 86 77 2 1,14 274 228 195 171 152 137 124 114 98 86 76 68

• Air-aspirating orifice RFX/AFX

• Available in green, yellow, lilac, blue, red and ADX 2,5 1,44 346 288 247 216 192 173 157 144 123 108 96 86 TRIFILET 2,5 1,27 305 254 218 191 169 152 139 127 109 95 85 76

• Mixing chamber

brown. 3 1,58 379 316 271 237 211 190 172 158 135 119 105 95

• Insert 04 3 1,39 334 278 238 209 185 167 152 139 119 104 93 83

04 3,5 1,70 408 340 291 255 227 204 185 170 146 128 113 102

3,5 1,50 360 300 257 225 200 180 164 150 129 113 100 90

4 1,82 437 364 312 273 243 218 199 182 156 137 121 109

RED RED 4 1,60 384 320 274 240 213 192 175 160 137 120 107 96

5 2,03 487 406 348 305 271 244 221 203 174 152 135 122

6 2,23 535 446 382 335 297 268 243 223 191 167 149 134 5 1,79 440 358 307 269 239 215 195 179 153 134 119 107

1,75 1,50 360 300 257 225 200 180 164 150 129 113 100 90 1,75 1,32 317 264 226 198 176 158 144 132 113 99 88 79

2 1,61 386 322 276 242 215 193 176 161 138 121 107 97 2 1,42 341 284 243 213 189 170 155 142 122 107 95 85

RFX/AFX

• NOZAL RRX/ARX ADX 2,5

3

1,80

1,97

432

473

360

394

309

338

270

296

240

263

216

236

196

215

180

197

154

169

135

148

120

131

108

118

TRIFILET 2,5

3

1,58

1,73

379

415

316

346

271

297

237

260

211

231

190

208

172

189

158

173

135

148

119

130

105

115

95

104

05 3,5 2,12 509 424 363 318 283 254 231 212 182 159 141 127 05

3,5 1,87 449 374 321 281 249 224 204 187 160 140 125 112

• Flat fan nozzle with air-injection. 4 2,28 547 456 391 342 304 274 249 228 195 171 152 137

BROWN

NOZZLE WITH AIR • 110° spray angle. BROWN 5 2,54 610 508 435 381 339 305 277 254 218 191 169 152 4 2,00 480 400 343 300 267 240 218 200 171 150 133 120

6 2,79 670 558 478 419 372 335 304 279 239 209 186 167 5 2,23 535 446 382 335 297 268 243 223 191 167 149 134

INJECTION • For application under adverse weather 1,75 1,80 432 360 309 270 240 216 196 180 154 135 120 108 1,75 1,58 379 316 271 237 211 190 172 158 135 119 105 95

conditions and requiring the best possible 2 1,93 463 386 331 290 257 232 211 193 165 145 129 116 2 1,70 408 340 291 255 227 204 185 170 146 128 113 102

drift management. RFX/AFX 2,5 2,16 518 432 370 324 288 259 236 216 185 162 144 130 TRIFILET 2,5 1,90 456 380 326 285 253 228 207 190 163 143 127 114

3 2,37 569 474 406 356 316 284 259 237 203 178 158 142

• Calibration output orifice

• Environment-friendly (drift control). 06 06 3 2,09 502 418 358 314 279 251 228 209 179 157 139 125

3,5 2,55 612 510 437 383 340 306 278 255 219 191 170 153

• Air-aspirating orifice • Only available as Kwix. 4 2,74 658 548 470 411 365 329 299 274 235 206 183 164

3,5 2,24 538 448 384 336 299 269 244 224 192 168 149 134

• Flow rate in accordance with ISO colour GREY GREY 4 2,41 587 482 413 362 321 289 263 241 207 181 161 145

• Air-aspirating depression 5 3,05 732 610 523 458 407 366 333 305 261 229 203 183

chamber

coding. 6 3,35 804 670 574 503 447 402 365 335 287 251 223 201 5 2,68 643 536 459 402 357 322 292 268 230 201 179 161

1,75 2,41 578 482 413 362 321 289 263 241 207 181 161 145

• Mixing chamber • Operating pressure between 3 and 6 bar 1,75 2,11 506 422 362 317 281 253 230 211 181 158 141 127

2 2,58 619 516 442 387 344 310 281 258 221 194 172 155 2 2,26 542 452 387 339 301 271 247 226 194 170 151 136

for large-sized air-filled droplets allowing RFX/AFX 2,5 2,88 691 576 494 432 384 346 314 288 247 216 192 173 TRIFILET

2,5 2,53 607 506 434 380 337 304 276 253 217 190 169 152

• Insert the drop to split when it touches the target 3 3,16 758 632 542 474 421 379 345 316 271 237 211 190

(350 to 710 µ). 08 3,5 3,41 818 682 585 512 455 409 372 341 292 256 227 205 08 3 2,77 665 554 475 416 369 332 302 277 237 208 185 166

3,5 2,99 718 598 513 449 399 359 326 299 256 224 199 179

4 3,65 876 730 626 548 487 438 398 365 313 274 243 219

• Available in green, yellow, lilac and blue. WHITE WHITE 4 3,2 768 640 549 480 427 384 349 320 274 240 213 192

5 4,08 979 816 699 612 544 490 445 408 350 306 272 245

6 4,48 1075 896 768 672 597 538 489 448 384 336 299 269 5 3,58 859 716 614 537 477 430 391 358 307 269 239 215

The volume/ha is given for flow rate with liquid fertiliser with a clear liquid with 1.3 density

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- SRi PRO Devilbiss Small GunDocument1 pageSRi PRO Devilbiss Small GunLuís GuerreiroNo ratings yet

- DS DispenseJet DJ 9500 NordsonASYMTEKDocument2 pagesDS DispenseJet DJ 9500 NordsonASYMTEKsiva vickyNo ratings yet

- Plaquette-Radial 2021 Exe LDDocument3 pagesPlaquette-Radial 2021 Exe LDfabrizioNo ratings yet

- Saw Tooth and Disc Pocket GuideDocument2 pagesSaw Tooth and Disc Pocket GuideTHEPEAR46No ratings yet

- UntitledDocument12 pagesUntitledHaseeb ChaudhryNo ratings yet

- Adn enDocument91 pagesAdn enAnonymous cPzveVRHINo ratings yet

- Fig 950 950GDocument1 pageFig 950 950GAsmaaNo ratings yet

- 17 FRDE FX Serie Eng 2 - 1Document1 page17 FRDE FX Serie Eng 2 - 1Augusto BellezaNo ratings yet

- 2724-2726 PH - ORP ElectrodesDocument4 pages2724-2726 PH - ORP ElectrodesHeber MagdielNo ratings yet

- Firekill: Model: OH-L2Document2 pagesFirekill: Model: OH-L2Canberk KarahanNo ratings yet

- New Look & Larger Diameter of Coverage!: High-AngleDocument2 pagesNew Look & Larger Diameter of Coverage!: High-AngleChristian Ve GaNo ratings yet

- 810-701 Crseals Handbook Rotary Shaft Apr-2018Document86 pages810-701 Crseals Handbook Rotary Shaft Apr-2018Anonymous VNu3ODGavNo ratings yet

- 810-701 CRSeals Handbook v-RING Apr-2018Document27 pages810-701 CRSeals Handbook v-RING Apr-2018Anonymous VNu3ODGavNo ratings yet

- Des FlexDocument18 pagesDes Flexsoni10483No ratings yet

- 370D4 2F 6RStandardsDocument1 page370D4 2F 6RStandardsAlejandro ParradoNo ratings yet

- 632dd56ea1181d38877ef2eb LoKr Solution Brochure EN UKDocument5 pages632dd56ea1181d38877ef2eb LoKr Solution Brochure EN UKPatrickKisulaNo ratings yet

- CPE5-013 MA4 ProductSheetDocument4 pagesCPE5-013 MA4 ProductSheetAjmal ArshadNo ratings yet

- Sample Introdruction For Icp Ms and Icp Oes PDFDocument4 pagesSample Introdruction For Icp Ms and Icp Oes PDFThejeswarNo ratings yet

- 2019 Browning Catalog FirearmsDocument98 pages2019 Browning Catalog FirearmsPajero PowerNo ratings yet

- 2d - RS Rotary Air Blower PDFDocument6 pages2d - RS Rotary Air Blower PDFHoàn Đức VinhNo ratings yet

- 810-701 CRSeals Handbook GREASE Apr-2018Document3 pages810-701 CRSeals Handbook GREASE Apr-2018Anonymous VNu3ODGavNo ratings yet

- Raphael RayDocument6 pagesRaphael RayEDITH Y HUGONo ratings yet

- DNT 041 VentralizerDocument1 pageDNT 041 VentralizerJosé Luis Bastidas RosasNo ratings yet

- Dynabolt CatalogDocument3 pagesDynabolt Cataloggirlie fabroNo ratings yet

- Catalogue English Blind Rivet FastenersDocument128 pagesCatalogue English Blind Rivet Fastenersbenkendimbizzat56No ratings yet

- Data Sheets Welbond Model 5600 High Pressure Globe Valve Yarway en en 9878790Document12 pagesData Sheets Welbond Model 5600 High Pressure Globe Valve Yarway en en 9878790Miyka'el PaunNo ratings yet

- Review FinishnailersDocument8 pagesReview FinishnailersJon DavisNo ratings yet

- Snap LoccatwebDocument16 pagesSnap Loccatwebnick martinNo ratings yet

- Data AL Series Threaded Insert DataDocument3 pagesData AL Series Threaded Insert DataJuan RamirezNo ratings yet

- B695B SprayDry BulletinDocument24 pagesB695B SprayDry Bulletinduong nguyenNo ratings yet

- Abnt NBR 15514Document20 pagesAbnt NBR 15514Andre alexander dos santosNo ratings yet

- 810-701 CRSeals Handbook PRESSURE Apr-2018Document4 pages810-701 CRSeals Handbook PRESSURE Apr-2018Anonymous VNu3ODGavNo ratings yet

- NailorCatalog HospitalCleanRoomSteriSysLinear92LSDocument34 pagesNailorCatalog HospitalCleanRoomSteriSysLinear92LSNemo NeoNo ratings yet

- Bearing Arrangement For A Drum-Displacer™: Examples of Application Engineering WL 13 516 EADocument2 pagesBearing Arrangement For A Drum-Displacer™: Examples of Application Engineering WL 13 516 EAArief WicaksonoNo ratings yet

- BRG Isn BR3010 - 0709 - WebDocument8 pagesBRG Isn BR3010 - 0709 - Webrrobles011No ratings yet

- Tyfo SCH-41 Composite - Fibra de Carbono - Compuesto LaminarDocument2 pagesTyfo SCH-41 Composite - Fibra de Carbono - Compuesto LaminarROBERTO BERNAOLANo ratings yet

- SUREFLEX Elostomer Coupling - J TypeDocument9 pagesSUREFLEX Elostomer Coupling - J TypeYuswardi -No ratings yet

- Nitrile Rubber InsulationDocument2 pagesNitrile Rubber InsulationSushil WadiyeNo ratings yet

- Bee LokDocument1 pageBee LokjaymuscatNo ratings yet

- NSK - HusillosRectificadosCompact FA SeriesDocument8 pagesNSK - HusillosRectificadosCompact FA SeriespitNo ratings yet

- Tyfo SCH-41 CompositeDocument2 pagesTyfo SCH-41 Compositeyusak santosoNo ratings yet

- Sz-Stranding Line: With Unique Stranding TechnologyDocument4 pagesSz-Stranding Line: With Unique Stranding TechnologyAS TorrealbaNo ratings yet

- Louvre DamperTandem DamperengfinDocument16 pagesLouvre DamperTandem DamperengfinDan PascaruNo ratings yet

- GD 5000 Technical Data Sheet Rev2 (Jan 22)Document1 pageGD 5000 Technical Data Sheet Rev2 (Jan 22)HKC EQUIPEMENTSNo ratings yet

- Velco SuggestedDocument1 pageVelco Suggestedvishal.nithamNo ratings yet

- Precision and Saturn Series NozzlesDocument6 pagesPrecision and Saturn Series NozzlesYerkin MartinezNo ratings yet

- 810-701 Crseals Handbook Metal Face Apr-2018Document5 pages810-701 Crseals Handbook Metal Face Apr-2018Anonymous VNu3ODGavNo ratings yet

- Gauge Cock ValveDocument6 pagesGauge Cock ValveGarry Bernard NelsonNo ratings yet

- 2021 Catalog: For CO and Fiber Laser Consumables Replacement Parts Suitable For MazakDocument42 pages2021 Catalog: For CO and Fiber Laser Consumables Replacement Parts Suitable For MazakTayfur AydınNo ratings yet

- Centricut Catalogue 2019 - Laser - MazakDocument42 pagesCentricut Catalogue 2019 - Laser - MazakIvan YordanovNo ratings yet

- CAT 2020 Laser BLM-AdigeDocument22 pagesCAT 2020 Laser BLM-AdigeBilly PanNo ratings yet

- Red/Refl/Renm Silencer Sheets: Rectangular Elbow SilencersDocument2 pagesRed/Refl/Renm Silencer Sheets: Rectangular Elbow SilencersMohamedNo ratings yet

- Endura Tek Cartridge FilterDocument2 pagesEndura Tek Cartridge Filterdavid izrahias dzib balamNo ratings yet

- Albuz Ade en 10 PDFDocument1 pageAlbuz Ade en 10 PDFValeriy ValkovetsNo ratings yet

- Laminar Flow HeadersDocument1 pageLaminar Flow HeadersFelipe JaimesNo ratings yet

- Amortiguador de Vibraciones Tipo SVDDocument3 pagesAmortiguador de Vibraciones Tipo SVDivan chavezNo ratings yet

- 339377ea - Pistolas AirproDocument12 pages339377ea - Pistolas AirproMichel MichelNo ratings yet

- Yarway Series 4300/4600/4800 Liquid Level GaugesDocument7 pagesYarway Series 4300/4600/4800 Liquid Level Gaugesreza saputraNo ratings yet

- 810-701 Crseals Handbook SKF Speedi-Sleeve Apr-2018Document17 pages810-701 Crseals Handbook SKF Speedi-Sleeve Apr-2018Anonymous VNu3ODGavNo ratings yet

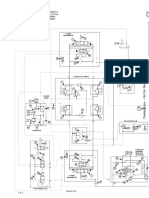

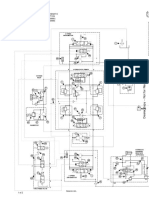

- Hydraulic/Hydrostatic Schematic With 2 Speed and High Flow Option S330 (S/N A02040001 - A02059999) (S/N A02140001 - A02159999)Document2 pagesHydraulic/Hydrostatic Schematic With 2 Speed and High Flow Option S330 (S/N A02040001 - A02059999) (S/N A02140001 - A02159999)gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC & 2 Speed Option: S175 (S/N A3l511001 - A3l519999)Document2 pagesHydraulic/Hydrostatic Schematic With SJC & 2 Speed Option: S175 (S/N A3l511001 - A3l519999)AlexandrNo ratings yet

- Legend: Hydraulic/Hydrostatic Schematic With 2 Speed Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesLegend: Hydraulic/Hydrostatic Schematic With 2 Speed Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC and High Flow Option S330 (S/N A02040001 - A02059999) (S/N A02140001 - A02159999)Document2 pagesHydraulic/Hydrostatic Schematic With SJC and High Flow Option S330 (S/N A02040001 - A02059999) (S/N A02140001 - A02159999)gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic S330 (S/N A02040001 - A02059999) (S/N A02140001 - A02159999)Document2 pagesHydraulic/Hydrostatic Schematic S330 (S/N A02040001 - A02059999) (S/N A02140001 - A02159999)gluykNo ratings yet

- Legend: Hydraulic/Hydrostatic Schematic With SJC Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesLegend: Hydraulic/Hydrostatic Schematic With SJC Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC and 2 Speed Option S330 (S/N A02040001 - A02059999) (S/N A02140001 - A02159999)Document2 pagesHydraulic/Hydrostatic Schematic With SJC and 2 Speed Option S330 (S/N A02040001 - A02059999) (S/N A02140001 - A02159999)gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC and 2 Speed Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesHydraulic/Hydrostatic Schematic With SJC and 2 Speed Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- V 0944legend 2Document2 pagesV 0944legend 2gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC and High Flow Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesHydraulic/Hydrostatic Schematic With SJC and High Flow Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- Legend: Hydraulic/Hydrostatic Schematic With SJC Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesLegend: Hydraulic/Hydrostatic Schematic With SJC Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC, 2 Speed and High Flow Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesHydraulic/Hydrostatic Schematic With SJC, 2 Speed and High Flow Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- V 0860legend 2Document2 pagesV 0860legend 2gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC, 2 Speed and High Flow Option With SJCDocument2 pagesHydraulic/Hydrostatic Schematic With SJC, 2 Speed and High Flow Option With SJCalexandrNo ratings yet

- s330 Cab 6Document6 pagess330 Cab 6gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC & 2 Speed Option: S175 (S/N A3l511001 - A3l519999)Document2 pagesHydraulic/Hydrostatic Schematic With SJC & 2 Speed Option: S175 (S/N A3l511001 - A3l519999)AlexandrNo ratings yet

- V 0940legend 2Document2 pagesV 0940legend 2gluykNo ratings yet

- Legend: Hydraulic/Hydrostatic Schematic With 2 Speed Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesLegend: Hydraulic/Hydrostatic Schematic With 2 Speed Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- s330 SJC 6Document6 pagess330 SJC 6gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With 2 Speed Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesHydraulic/Hydrostatic Schematic With 2 Speed Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesHydraulic/Hydrostatic Schematic S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- s330 Mainframe 6Document6 pagess330 Mainframe 6gluykNo ratings yet

- Hydraulic/Hydrostatic Schematic With High Flow Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)Document2 pagesHydraulic/Hydrostatic Schematic With High Flow Option S330 (S/N A02011001 - A02040000) (S/N A02111001 - A02140000)gluykNo ratings yet

- s330 SJC 6Document6 pagess330 SJC 6gluykNo ratings yet

- Wiring Schematic: STD Cab HarnessDocument2 pagesWiring Schematic: STD Cab HarnessAlexandrNo ratings yet

- Cyl Head 3408EDocument3 pagesCyl Head 3408EgluykNo ratings yet

- s330 Acs 6Document6 pagess330 Acs 6gluykNo ratings yet

- s330 Cab 6Document6 pagess330 Cab 6gluykNo ratings yet

- Wiring Schematic: (Options)Document6 pagesWiring Schematic: (Options)gluykNo ratings yet

- Valves 3408EDocument3 pagesValves 3408EgluykNo ratings yet

- Kaibigan, Kabarkada, Kaeskwela: Pinoy Friendships and School LifeDocument47 pagesKaibigan, Kabarkada, Kaeskwela: Pinoy Friendships and School LifeGerald M. LlanesNo ratings yet

- ZEROPAY WhitepaperDocument15 pagesZEROPAY WhitepaperIlham NurrohimNo ratings yet

- Decolonization DBQDocument3 pagesDecolonization DBQapi-493862773No ratings yet

- Mywizard For AIOps - Virtual Agent (ChatBOT)Document27 pagesMywizard For AIOps - Virtual Agent (ChatBOT)Darío Aguirre SánchezNo ratings yet

- MODULE 8. Ceiling WorksDocument2 pagesMODULE 8. Ceiling WorksAj MacalinaoNo ratings yet

- Artificial Intelligence and Expert Systems: Management Information Systems, 4 EditionDocument27 pagesArtificial Intelligence and Expert Systems: Management Information Systems, 4 Editionabhi7219No ratings yet

- Notes 3 Mineral Dressing Notes by Prof. SBS Tekam PDFDocument3 pagesNotes 3 Mineral Dressing Notes by Prof. SBS Tekam PDFNikhil SinghNo ratings yet

- Warranty FormDocument13 pagesWarranty FormEmpyrean Builders Corp.No ratings yet

- Montessori Vs WaldorfDocument4 pagesMontessori Vs WaldorfAbarnaNo ratings yet

- His 101 Final ReportDocument15 pagesHis 101 Final ReportShohanur RahmanNo ratings yet

- QFW Series SteamDocument8 pagesQFW Series Steamnikon_fa50% (2)

- CHAPTER THREE-Teacher's PetDocument3 pagesCHAPTER THREE-Teacher's PetTaylor ComansNo ratings yet

- Project - Dreambox Remote Video StreamingDocument5 pagesProject - Dreambox Remote Video StreamingIonut CristianNo ratings yet

- Norm ANSI PDFDocument1 pageNorm ANSI PDFAbdul Quddus Mat IsaNo ratings yet

- Code of Conduct For Public OfficialDocument17 pagesCode of Conduct For Public OfficialHaNo ratings yet

- R917007195 Comando 8RDocument50 pagesR917007195 Comando 8RRodrigues de OliveiraNo ratings yet

- Article1414509990 MadukweDocument7 pagesArticle1414509990 MadukweemmypuspitasariNo ratings yet

- 11 - Chapter 3Document27 pages11 - Chapter 3sam000678No ratings yet

- Solutions - HW 3, 4Document5 pagesSolutions - HW 3, 4batuhany90No ratings yet

- KPR College of Arts Science and Research: Marketing ManagementDocument127 pagesKPR College of Arts Science and Research: Marketing ManagementSekar M KPRCAS-CommerceNo ratings yet

- Heart Attack Detection ReportDocument67 pagesHeart Attack Detection ReportAkhil TejaNo ratings yet

- A Database For Handwritten Text Recognition ResearchDocument5 pagesA Database For Handwritten Text Recognition Researchtweety492No ratings yet

- Pathophysiology: DR - Wasfi Dhahir Abid AliDocument9 pagesPathophysiology: DR - Wasfi Dhahir Abid AliSheryl Ann PedinesNo ratings yet

- The Future Mixed TensesDocument4 pagesThe Future Mixed TensesChernykh Vitaliy100% (1)

- Prevention of Power Theft Using Concept of Multifunction Meter and PLCDocument6 pagesPrevention of Power Theft Using Concept of Multifunction Meter and PLCMuhammad FarhanNo ratings yet

- Majan Audit Report Final2Document46 pagesMajan Audit Report Final2Sreekanth RallapalliNo ratings yet

- Hasan Bin Ekram: Career ObjectiveDocument3 pagesHasan Bin Ekram: Career ObjectiveHasan SarikNo ratings yet

- Is.2750.1964 SCAFFOLDING PDFDocument32 pagesIs.2750.1964 SCAFFOLDING PDFHiren JoshiNo ratings yet

- Business Mathematics (Matrix)Document3 pagesBusiness Mathematics (Matrix)MD HABIBNo ratings yet

- Jmac TempDocument5 pagesJmac TempDan GerNo ratings yet