Professional Documents

Culture Documents

Resume: Kartick Prasad Satapathy MOBILE NO.-7909035104

Uploaded by

KARTICK PRASADOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Resume: Kartick Prasad Satapathy MOBILE NO.-7909035104

Uploaded by

KARTICK PRASADCopyright:

Available Formats

RESUME

KARTICK PRASAD SATAPATHY

MOBILE NO.-7909035104

MAIL ID -KARTICK.PRASAD1992@GMAIL.COM

SUMMARY

Currently working in Neel Metal Products Limited as a Robotic

Simulation Engineer.

Almost 6 years of Experience in the field of Robotics Simulation and

manufacturing Engineering Services(2yrs in design & 4yrs in Simulation)

Experience in Robot Selection, Gun Selection, Weld Spot Distribution and

Robotic Simulation.

Fully Conversant with Various BIW Process e.g SSW, Sealant Application,

Stud Welding, Arc Welding, Spot Welding & Material Handling.

Worked on Different Kind of Tools, Fixtures & End effectors e.g Geo

Welding Fixtures, Handling Grippers, Welding Gripper, Conveyors, Gun

with Gripper etc.

Experience of Building Completely New Work Cells from Given Process to

Layout Finalization.

Good Knowledge of Process study with Takt time and cycle time

Calculation.

Expertise in Delmia V5 R27 & 29.

EDUCATION

Complete Degree in Mechanical Engineering from OXFORD COLLEGE OF

ENGINEEING & MANAGEMENT, ODISHA(Affiliated to Biju pattnaik

University & Technology, Odisha) with 71% in 2014.

SOFTWARE KNOWLEDGE

Delmia V5 R27,R29

Process Simulate 16.0

Fastsuite Edition 2

Catia/Solidworks/Creo

Autocad,Draft sight

WORK EXPIRENCE

I-DESIGN ENGINEERING SOLUTION PRIVATE LTD., Jamshedpur(8th

DEC 2014 to 24th DEC 2016) as a Design Engineer

NEEL METAL PRODUCTS LTD., Gurugram(2nd Jan 2017 to Untill Date)

as a Simulation Engineer.

PROJECT HIGHLIGHT

PROJECT-1: Complete Line Simulation of VE-1900(truck cabin) with 16 robots.

CUSTOMER: VOLVO EICHER COMMERCIAL VEICHLE

SOFTWARE: DELMIA V5 R27

CONCLUSION

Weld spot distribution, Panel feasibility, Gripper & Fixture validation, Robot

Position, Gun finalization

Commonize gun for 2 Robots and save 2 qty gun.

Use Robot with Gantry ,PRB, ATC, conveyor,Lift & Carry ETC.

Giving Kinamatics to Gripper and Fixtures.

Collision free path creation ( for spot welding & handling and Path)

Commonize the full line according to 5 varient .

Simulate according to both 4 & 8 JPH in same line.

PROJECT-2: Complete Line Simulation of SML(truck cabin) with 4 robots.

CUSTOMER: SWARAJ MAJDA LIMITED

SOFTWARE: DELMIA V5 R27

CONCLUSION

Weld spot distribution, Panel feasibility, Gripper & Fixture validation, Robot

Position, Gun finalization

Use Lift & Carry system for cabin movement from stn to stn.

Giving Kinamatics to Gripper and Fixtures.

Collision free path creation ( for spot welding & handling and Path)

PROJECT-3: Complete Line Simulation of X-445 with 6 robots.

CUSTOMER: TATA MOTORS,PUNE

SOFTWARE: DELMIA V5 R27

CONCLUSION

Weld spot distribution, Panel feasibility, Robot Position, Gun finalization

Giving Kinamatics to Fixtures.

Collision free path creation ( for spot welding & handling and Path)

Merging Cells to meet the SPP.

Gun shank modification to offset type according to panel.

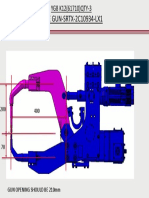

PROJECT-4: Complete Line Simulation of YNC(Tunnel assy.,Long Mbr.assy.,cross mbr

assy.) with 18 robots.

CUSTOMER: MARUTI SUZUKI INDIA LTD.

SOFTWARE: DELMIA V5 R27

CONCLUSION

Weld spot distribution, Panel feasibility, Robot Position, Gun finalization

Simulate tunnel assy. in given area with proper space utilization.

Collision free path creation ( for spot welding & handling and Path)

Use Gun with Gripper for reduce Man Power

Done the Process & Cycle time calculation for Tunnel Assy.

Use side mtg of gun for Better collision free path

PERSONAL INFORMATION

Name : Kartick Prasad Satapathy

Sex : Male

Maritial Status : Married

Nationality : Indian

Hobies : Playing Games in Pc, Try different Software

Maritial Status : Married

Languages Known : English, Hindi, odiya

Date Of Birth : 20.05.1992

Religion : Hindu

Adress : At- UttamNagar, Po-Sovarampur, Dist-Balsore

COST TO COMPANY

Current CTC : 5L

Expected CTC : 7L

DECLARATION

I hereby Declare that the above written particulars are true to the best of my

knowledge & Belief.

Date : Yours Faithfully

Place: Kartick Prasad Satapathy

You might also like

- Resume Kartick PrasadDocument4 pagesResume Kartick PrasadKARTICK PRASADNo ratings yet

- Kartick Prasad ResumeDocument4 pagesKartick Prasad ResumeKARTICK PRASADNo ratings yet

- Lalit Resume-2023-LatestDocument2 pagesLalit Resume-2023-LatestDrew LadlowNo ratings yet

- Shrikant Shinde-1Document4 pagesShrikant Shinde-1Shrikant ShindeNo ratings yet

- Instrumentation Designer - 8+Document5 pagesInstrumentation Designer - 8+john marshalNo ratings yet

- Logesh RagupathiDocument3 pagesLogesh RagupathiSaravanakumar RamdossNo ratings yet

- Ashish Shirsat 9 YRDocument2 pagesAshish Shirsat 9 YRvattipalli murariNo ratings yet

- Jatin Pandey: EducationDocument2 pagesJatin Pandey: EducationJatin PandeyNo ratings yet

- Cvand Cover LetteerDocument5 pagesCvand Cover LetteerMudassar ChaudhryNo ratings yet

- Resume - Product Design EngineerDocument6 pagesResume - Product Design EngineerPradeep RathodeNo ratings yet

- AutoCAD Draftsman (Samad)Document4 pagesAutoCAD Draftsman (Samad)samadNo ratings yet

- AEH Company Profile-1Document14 pagesAEH Company Profile-1Hrishikesh RaiNo ratings yet

- Rahul Updated Resume.Document5 pagesRahul Updated Resume.rahul pandeyNo ratings yet

- Pranav Jadhav Resume YoE 3.3 Design EnggDocument2 pagesPranav Jadhav Resume YoE 3.3 Design EnggRahul PatankarNo ratings yet

- CV Final 04-09-2020 - 04-Sep-20 - 20.31.45Document2 pagesCV Final 04-09-2020 - 04-Sep-20 - 20.31.45Karun KumarNo ratings yet

- Prabhu - CV - Structural DesignerDocument4 pagesPrabhu - CV - Structural DesignerprabhutmuNo ratings yet

- Supriya Vinod Bhirud ResumeDocument5 pagesSupriya Vinod Bhirud ResumeEjaz KNo ratings yet

- Resume Prince Raj 29-08-2022Document3 pagesResume Prince Raj 29-08-2022vijayNo ratings yet

- Sunil Mpatel: Mechatronics EngineerDocument2 pagesSunil Mpatel: Mechatronics EngineerAnonymous ffYiS7CGNo ratings yet

- Leroy Dmello 2022 Updated Resume.Document5 pagesLeroy Dmello 2022 Updated Resume.LeroyNo ratings yet

- Prabhaharan.P: No. 10, Sarojini Street ExtnDocument6 pagesPrabhaharan.P: No. 10, Sarojini Street ExtnMANI BHARATH GANESANNo ratings yet

- CV Design EngineerDocument3 pagesCV Design EngineerAhmed ShariffNo ratings yet

- Abhishek Ugnx 2+ SeatingDocument2 pagesAbhishek Ugnx 2+ SeatingYuuvraj SinghNo ratings yet

- Kasu La Nagara JuDocument4 pagesKasu La Nagara JuMuhammad Rafi sayedNo ratings yet

- Ashfaque Ahmed: Engineer - PipingDocument3 pagesAshfaque Ahmed: Engineer - PipingMasoodMiyanNo ratings yet

- E-Mail: Cell: 00966-0572923751: Shabeer.SDocument5 pagesE-Mail: Cell: 00966-0572923751: Shabeer.Ssikander843562No ratings yet

- Elv DraftsmanDocument2 pagesElv Draftsmanmohamed razeethNo ratings yet

- Naukri NitinNamdevRane. 18315862 - 06 06 - 1Document3 pagesNaukri NitinNamdevRane. 18315862 - 06 06 - 1Jerish JohnNo ratings yet

- Sanjeev CVDocument4 pagesSanjeev CVmddilshadalam439No ratings yet

- BenchmarkDocument4 pagesBenchmarkKiran KumarNo ratings yet

- Ravi Babaladi: Job SummaryDocument2 pagesRavi Babaladi: Job SummaryRavi BabaladiNo ratings yet

- Resume Ravi2Document2 pagesResume Ravi2Ravi BabaladiNo ratings yet

- Resume FormatDocument3 pagesResume FormatSandeep ChoudharyNo ratings yet

- Ram Feb 2020Document2 pagesRam Feb 2020piyush sokhiNo ratings yet

- PDMSDocument3 pagesPDMSravirawat15No ratings yet

- Cover Letter For The Job Application: Bikash GuptaDocument3 pagesCover Letter For The Job Application: Bikash GuptaMukharram KhanNo ratings yet

- MaeezAslami Shaikh 551585356Document3 pagesMaeezAslami Shaikh 551585356RAM SANNo ratings yet

- Yenuguthala Chandra Sekhar: Cad EngineerDocument4 pagesYenuguthala Chandra Sekhar: Cad Engineerchandrasekhar y47No ratings yet

- Leroy Dmello 2022 Updated Resume.Document5 pagesLeroy Dmello 2022 Updated Resume.LeroyNo ratings yet

- Ravi Babaladi: Experience SummaryDocument3 pagesRavi Babaladi: Experience SummaryRavi BabaladiNo ratings yet

- Nagendra B N: #4, 33 Main Road Astalashmi Layout Sarakki Kere 6 Phase JP Nagar Bangalore-5600078Document6 pagesNagendra B N: #4, 33 Main Road Astalashmi Layout Sarakki Kere 6 Phase JP Nagar Bangalore-5600078muhamad erfanNo ratings yet

- Shailesh Ashok Chaudhari - r02Document3 pagesShailesh Ashok Chaudhari - r02Shailesh ChaudhariNo ratings yet

- Pratham Sharma: Carrier ObjectivesDocument2 pagesPratham Sharma: Carrier ObjectivesPrathamNo ratings yet

- Akash Pawar Contact No: +91 9049282593 B.E. (Mechanical) E-MailDocument3 pagesAkash Pawar Contact No: +91 9049282593 B.E. (Mechanical) E-MailPushpa MandloiNo ratings yet

- CV SinghDocument4 pagesCV SinghAjad SinghNo ratings yet

- DibyenduchelDocument4 pagesDibyenduchelArindam DasNo ratings yet

- Vijetha ResumeDocument3 pagesVijetha ResumemargondlaNo ratings yet

- K.Suresh - Structural Detailer CVDocument5 pagesK.Suresh - Structural Detailer CVRamkishore ChelvinMurugeshNo ratings yet

- Harsh Bhimani C.V.0404Document2 pagesHarsh Bhimani C.V.0404Harsh BhimaniNo ratings yet

- Background: Piping/Mech/Cad & Sp3D Designer Mob. No.: 08828459024Document3 pagesBackground: Piping/Mech/Cad & Sp3D Designer Mob. No.: 08828459024sahaNo ratings yet

- Resume For R & D - Npd-Process EngineerDocument5 pagesResume For R & D - Npd-Process EngineerpramodNo ratings yet

- Nikhilsahud@gmail DotcomDocument4 pagesNikhilsahud@gmail DotcomKarthik SekarNo ratings yet

- Sunil Kumar: Email MobileDocument3 pagesSunil Kumar: Email MobileSunil Kumar PoddarNo ratings yet

- Harsh Bhimani B H: Address: Phone: EmailDocument2 pagesHarsh Bhimani B H: Address: Phone: EmailHarsh BhimaniNo ratings yet

- Naukri QamarAlam (18y 0m)Document8 pagesNaukri QamarAlam (18y 0m)Shubha S SNo ratings yet

- Sagar DhumalDocument2 pagesSagar Dhumalranaware ajinkyaNo ratings yet

- L +009660533812404 Aqama Status:Transferable Objectives: June 2015 To Present, Saudi ArabiaDocument3 pagesL +009660533812404 Aqama Status:Transferable Objectives: June 2015 To Present, Saudi ArabiaSyed Ehtesham aliNo ratings yet

- Sidram V. Kedar: Curriculum VitaeDocument3 pagesSidram V. Kedar: Curriculum VitaesidramNo ratings yet

- Getting Startedwith Maya 8Document682 pagesGetting Startedwith Maya 8KARTICK PRASADNo ratings yet

- Simulation of Spot Welding Robot For Automotive Manufacturing ApplicationDocument14 pagesSimulation of Spot Welding Robot For Automotive Manufacturing ApplicationKARTICK PRASADNo ratings yet

- Basics Guide: Autodesk Maya 2020Document40 pagesBasics Guide: Autodesk Maya 2020KARTICK PRASADNo ratings yet

- Government of Odisha: Office of Special Relief CommissionerDocument11 pagesGovernment of Odisha: Office of Special Relief CommissionerKARTICK PRASADNo ratings yet

- This Is A System-Generated Statement. Hence, It Does Not Require Any SignatureDocument15 pagesThis Is A System-Generated Statement. Hence, It Does Not Require Any SignatureKARTICK PRASADNo ratings yet

- Curriculum Vitae: Ronit Rajendra PatilDocument3 pagesCurriculum Vitae: Ronit Rajendra PatilKARTICK PRASADNo ratings yet

- Wibu Licensing Guide Cenit PDFDocument15 pagesWibu Licensing Guide Cenit PDFKARTICK PRASADNo ratings yet

- GSTCredit Note DL2202112 AD81754Document1 pageGSTCredit Note DL2202112 AD81754KARTICK PRASADNo ratings yet

- Gram Panchayat List of Balasore District: Block: BahanagaDocument10 pagesGram Panchayat List of Balasore District: Block: BahanagaKARTICK PRASAD100% (2)

- Shubham Jaiswal: Education CredentialsDocument3 pagesShubham Jaiswal: Education CredentialsKARTICK PRASADNo ratings yet

- Yta Dash Process - Rev 3RD - 5 May 20Document28 pagesYta Dash Process - Rev 3RD - 5 May 20KARTICK PRASADNo ratings yet

- Group Corporate HR - Training Calendar For JANUARY 2021Document1 pageGroup Corporate HR - Training Calendar For JANUARY 2021KARTICK PRASADNo ratings yet

- Gun Modification For 61710 Yg8 K12Document1 pageGun Modification For 61710 Yg8 K12KARTICK PRASADNo ratings yet

- DESIGN CalculationDocument47 pagesDESIGN CalculationZayyan Romjon100% (2)

- FlairsTech - SE Introduction 01Document58 pagesFlairsTech - SE Introduction 01tahazamzamNo ratings yet

- Pile Formula CP4 Hiley Metric PDFDocument4 pagesPile Formula CP4 Hiley Metric PDFsstibisNo ratings yet

- CSDocument2 pagesCSharry khanNo ratings yet

- Compaction of SoilDocument5 pagesCompaction of SoilthisulaNo ratings yet

- Learning Lessons From Forensic Investigation of Corrosion FailuresDocument7 pagesLearning Lessons From Forensic Investigation of Corrosion FailuresjorgebbcaargNo ratings yet

- Charles W. Barbrey: Cbarbre@clemson - EduDocument2 pagesCharles W. Barbrey: Cbarbre@clemson - EduChase BarbreyNo ratings yet

- Work Transfer Authorization (WTA) ProcedureDocument15 pagesWork Transfer Authorization (WTA) ProcedureOkinawa TeakNo ratings yet

- Handbook of Petroleum Refining ProcessesDocument5 pagesHandbook of Petroleum Refining Processeselsayed amerNo ratings yet

- Calculations of Slab Thickness and Dead Load & Live Load For BuildingDocument10 pagesCalculations of Slab Thickness and Dead Load & Live Load For BuildingAlaa SalimNo ratings yet

- Wbcs ExaminationDocument19 pagesWbcs ExaminationMUMPI RAHAMANNo ratings yet

- Insights Into Sustainable EngineeringDocument24 pagesInsights Into Sustainable Engineeringcmanning17No ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentAshraful HasanNo ratings yet

- HPS Catalog Dry-Type Medium VoltageDocument15 pagesHPS Catalog Dry-Type Medium VoltageEmilio SalazarNo ratings yet

- Software System Safety HandbookDocument247 pagesSoftware System Safety HandbookbtjajadiNo ratings yet

- Chapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructuresDocument2 pagesChapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructureskapsarcNo ratings yet

- Engg CollegesDocument3,660 pagesEngg CollegeseraparnagoelNo ratings yet

- Implementation of Lean Construction Techniques For Minimizing The Risks Effect On Construction ProjectDocument49 pagesImplementation of Lean Construction Techniques For Minimizing The Risks Effect On Construction ProjectJohn PaulNo ratings yet

- Hydro Culv 21Document10 pagesHydro Culv 21rungekutasaNo ratings yet

- Company Profile PT. FIBDocument23 pagesCompany Profile PT. FIBziedan alfahrizyNo ratings yet

- Sbi 189Document101 pagesSbi 189Zhaneta AvtanskaNo ratings yet

- IIT Delhi GATE Sore Cut Off For MDocument3 pagesIIT Delhi GATE Sore Cut Off For MNataraja perumalNo ratings yet

- BBC Profile 2075Document13 pagesBBC Profile 2075XenoldNo ratings yet

- Establishment ListDocument3 pagesEstablishment ListRiya100% (1)

- CV FinalDocument1 pageCV Finalapi-417066611No ratings yet

- Blackbook Sample For Engineering ProjectsDocument26 pagesBlackbook Sample For Engineering ProjectsVikas Beri100% (3)

- FM200 SpecDocument14 pagesFM200 SpecDak Serik100% (1)

- Risk Assessment of Floating Offshore Wind Turbine Based On Correlation FMEADocument7 pagesRisk Assessment of Floating Offshore Wind Turbine Based On Correlation FMEA洪琳雅No ratings yet