Professional Documents

Culture Documents

KKMC Hospital - Scope of Work & Boq: A-Civil Unit

Uploaded by

Mohammed BasheeruddinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KKMC Hospital - Scope of Work & Boq: A-Civil Unit

Uploaded by

Mohammed BasheeruddinCopyright:

Available Formats

KKMC Hospital - SCOPE OF WORK & BOQ

Project Requirements;

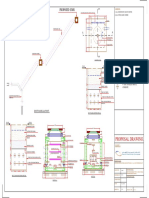

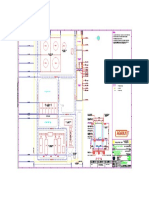

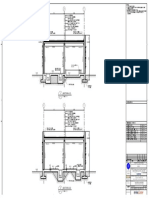

Construction contractor shall construct a Battery Room that will accommodate 312 dry seal battery install in nine (9) sets of battery rack and three (3) units UPS at two separate battery room; first (1) along loading area near the basement to construct new Room with about 4700mm width

X 5370 long and 3750 height, second (2) Upgrading of one room along substation pharmacy by extending the existing wall to 2420mm width x 5730mm long as shown in Equipment Layout Plan drawing but not limited with the following activities;

A-CIVIL Unit Qty. Unit Price Total Price

Battery Room Along Loading Area:

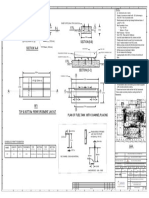

A.1 Supply and Construct concrete reinforce 300mm x 300mm column with Isolated footing with 850mm x 1000mm x 350mm reinforce by 16mm dia steel bar bottom and top as per reference structural drawing. M3 2.5 3500 8,750.0

Supply and Construct floor slab at +600mm FGL, supported with 250mm x 300mm reinforce Tie Beam along the room perimeter. Floor slab shall be reinforce concrete with a minimum thickness of 150mm 35MPa concrete

A.2 M3 4.2 3000 12,600.0

strength, and 10mm diameter steel bar with 150mm C/C spacing, steel trowelled finish with epoxy non- skid coated / color gray.

Supply and Construct roof slab at + 3600mm elevation, supported with 300mm x 250mm reinforce Beam along the room perimeter. Roof slab shall be reinforce concrete with a minimum thickness of 150mm 35MPa concrete

A.3 M3 4.8 3000 14,400.0

strength, and 12mm diameter bottom and top steel bar with 150mm C/C spacing. Ceiling shall be smooth finish painted with semis gloss off white enamel paint.

A.4 Supply, install and compact a required backfilling material to fulfill the required floor elevation of the battery room. Backfilling materials shall be in classified as structural fill materials Class A-1-b. M3 15 150 2,250.0

Supply & Install 6 inched diameter PVC conduit that connected to battery panel to UPS. PVC conduit shall be protected around with the sand cushion, riser shall be PVC 90 degree long radius elbow and PVC materials type shall

A.5 LM 15 65 975.0

conform to type DB, and shall meet the minimum cell classification of PVC 12154 as per ASTM D4396.

Supply & Construct Concrete Masonry Unit Wall at the Front wall of the room interior /exterior wall shall be non-load bearing wall with minimum thickness of 200mm. Wall shall be shall be reinforce with vertical / horizontal

A.6 reinforcement and cells of the CMU shall be fully grouted. Exterior / interior wall shall be plastered with smooth finish painted with semi - gloss enamel paint, light beige color/ ivory. Note existing concrete wall shall be retain M2 14.2 250 3,550.0

and apply with new paint.

Supply & Install water proofing membrane for roof slab: 1.5mm thick PVC water proofing membrane or 2 layers 4mm thick bituminous membrane extended up to 200mm to the wall, aluminum flashing shall be installed at the

A.7 M2 29.3 150 4,395.0

end of the membrane. Water proofing membrane shall be covered with 50mm thick round washed gravel for UV radiation protection.

A.8 Scupper drain 300mm x 200mm shall be install to the lowest point of the roof for water drainage system connected with 50mm PVC pipe down spout. lot 1 800 800.0

Supply & Install Metal Door with 2200mm x 1200 mm double wall single leaf exterior metal door on metal frame, includinh all hardwares hinges, automatic door closer, door lock. Location of the door is as per shown in the

A.9 layout drawing. Reinforce concrete door column and lintels beam shall be provided on the door opening. Door frame shall be fixed to the reinforced concrete elements firmly with use of expansion/anchor bolt. Door panel shall lot 1 11000 11,000.0

painted with semi- gloss color beige enamel paint.

A.10 Buried concrete structure shall be protected coated with 2 layers of coal tar epoxy. M2 10 60 600.0

A.11 Room identification and safety signboard shall be installed on wall besides the entrance door by screws. Plate/signboard shall made of aluminum with durable enamel paint and font shall be screen painted. lot 1 250 250.0

A.12 Painting the existing wall M2 46.2 70 3,234.0

Battery Room at Substation Pharmacy Area:

B.1 Demolish the existing wall and use the steels studs 16.8 M2 60 1,008.0

Supply and Install double wall and new gypsum board shall be as per existing or shall conform to ASTM C36 with at least one (1) hour fire resistant and minimum thickness of 16mm. Gypsum wall board shall be attached to the

B.2 44 M2 185 8,140.0

steel stud system with self -drilling wall screws. Joints between the adjacent gypsum boards may be reinforced and concealed with tape joints syste.

Supply and Install additional steel studs system shall be supply and install as per existing specification or manufacture in accordance with ASTM C645; lock forming quality, hot –dip galvanized, with coating class G-90

B.3 1 lot 20000 22,000.0

(275gms/m2), with 1.5mm thickness. Metal door 1200 x 2200 and Door frame with accerories

B.4 Painting as per exisitng 48.78 M2 70 3,400.0

C- ELELCTRICAL

The contractor shall install 9 cabinets(to be provided by Taqqat Global Co.) inside the constructed rooms each panel shall equipped with 42 batteries(to be provided by Taqqat Global Co.), all cabinets shall be fixed with anchor

C.1 1 6500 6,500.0

bolt to the floor slab from all sides.

C.2 Contractor should extend the DC cables(to be provided by Taqqat Global Co.) from the cabinets to the UPS’s using the conduits. 1 2500 2,500.0

Contractor should extend the cables (3*1C*70mm²) from the UPS’s to the tapping points with length of 50M * 4 cables for each UPS through 4" pipes for each UPS including horizontal drilling, conduits welding’s, fixing and

C.3 1 7500 7,500.0

supports.

C.4 Contractor should supply 500 M cable of the following configuration (1C*70MM², 600/1000V, XLPE). 500 m 11 5,500.0

C.5 Contractor shall supply and install all required lighting, (indoor and outdoor), including the emergency light. LOT 32,500.0

C.6 Contractor should supply and install Fire Alarm system( with audible and siren capabiltiy only)in both rooms and extend the siren and alarm indicator upto control room, if needed. LOT 8,500.0

C.7 Contractor should supply and install power panel for the parallel operation of the intensive care UPS’s equipped by the following (main breaker 400A + TWO BREAKERS 250 A). LOT 12,500.0

C.8 Contractor should supply ,install and connect all the equipment and cabinets to existing grounding if available otherwise provide new grouding whereever needed. LOT 1 22,000.0

C.9 Contractor shall supply and install power panel in both rooms rated for the following loads: 16,500.0

Air conditions

LIGHTING

one spare breaker

power receptacles.

D- MECHANICAL:

A/C:

Outside loading area concrete room shall be equipped with 2* 50 % split A/C, 5000 BTU, from well-known brand (LG or ZAMIL) contractor shall guarantee that the changeover between A/C units should be automatically(every 8

D.1 2 7500 15,000.0

hours).

Pharmacy substation Internal Gibson board room shall be equipped with 2* 50 % split A/C, 2500 BTU, from well-known brand, contractor shall guarantee that the changeover between A/C units should be automatically(every 8

D.2 2 7500 15,000.0

hours).

D.3 Contractor should provide 3 years maintenance fo all A/C's. 4 1200 4,800.0

NOTE: Maximum temperature in both room must not exceed more than 18 Degree Celcius.

E-Ventilation ducts:

E.1 Both Rooms should be equipped by ventilation ducts with fine filter and exhaust fan 40*40cm, with non-return flab. 2 2500 5,000.0

F-Drainage:

F.1 Proper drainage system in both rooms shall include but not limited to the following:

Roof drainage, 1 3,000.0

A/C drainage… etc. 2 3,000.0

G-Paint:

G.1 Contractor shall paint the rooms by epoxy paint and final touch same like existing color and materials. 4,000.0

Total 261,152.00

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Wsi PSDDocument18 pagesWsi PSDДрагиша Небитни ТрифуновићNo ratings yet

- PC-ITP-001 - Backfilling and ExcavationDocument2 pagesPC-ITP-001 - Backfilling and ExcavationHusam zayedNo ratings yet

- Master Data Managment MDM Reference Architecture WhitepaperDocument15 pagesMaster Data Managment MDM Reference Architecture WhitepaperpavithraNo ratings yet

- Foamed ConcreteDocument23 pagesFoamed ConcretebhanukerniNo ratings yet

- Synchronization Techniques PDFDocument11 pagesSynchronization Techniques PDFDemarco Dayanghirang FormalejoNo ratings yet

- IPsec VPN To Microsoft Azure PDFDocument9 pagesIPsec VPN To Microsoft Azure PDFDaniel ÁvilaNo ratings yet

- The Technique of Marquetry PDFDocument5 pagesThe Technique of Marquetry PDFMattia50% (2)

- Royal Model Flushometer: BG U XYV YJ YKDocument1 pageRoyal Model Flushometer: BG U XYV YJ YKMohammed BasheeruddinNo ratings yet

- Ovalyn Undercounter Lavatory Vf-0470Lm: Vitreous ChinaDocument1 pageOvalyn Undercounter Lavatory Vf-0470Lm: Vitreous ChinaMohammed BasheeruddinNo ratings yet

- Squat Closets: Commercial ProductsDocument1 pageSquat Closets: Commercial ProductsMohammed BasheeruddinNo ratings yet

- Task-Ii: General and Academic ModulesDocument2 pagesTask-Ii: General and Academic ModulesMohammed BasheeruddinNo ratings yet

- Angle Valves Angle Valves Angle Valves Angle ValvesDocument1 pageAngle Valves Angle Valves Angle Valves Angle ValvesMohammed BasheeruddinNo ratings yet

- IdealStandard B0704 Product-SheetDocument1 pageIdealStandard B0704 Product-SheetMohammed BasheeruddinNo ratings yet

- Technical Data: Recessed Paper Towel Dispenser and Waste ReceptacleDocument1 pageTechnical Data: Recessed Paper Towel Dispenser and Waste ReceptacleMohammed BasheeruddinNo ratings yet

- As-Built: TANK-2 TANK-3 TANK-1Document1 pageAs-Built: TANK-2 TANK-3 TANK-1Mohammed BasheeruddinNo ratings yet

- NL Master Specification Guide For Public Funded Buildings: Issued 2008/03/18Document7 pagesNL Master Specification Guide For Public Funded Buildings: Issued 2008/03/18Mohammed BasheeruddinNo ratings yet

- Manhole Detail.-Proposal-1Document1 pageManhole Detail.-Proposal-1Mohammed BasheeruddinNo ratings yet

- As-Built: Fire Water Tank (Existing)Document1 pageAs-Built: Fire Water Tank (Existing)Mohammed BasheeruddinNo ratings yet

- Manhole Detail. Proposal 2Document1 pageManhole Detail. Proposal 2Mohammed BasheeruddinNo ratings yet

- Item Description Qnty Unit Rate Amount Electrical InstallationDocument10 pagesItem Description Qnty Unit Rate Amount Electrical InstallationMohammed BasheeruddinNo ratings yet

- Radiator - Kts-Sec-Bsdg-Arc-103Document1 pageRadiator - Kts-Sec-Bsdg-Arc-103Mohammed BasheeruddinNo ratings yet

- Section A-A 1: Metscco Heavy Steel Industries Co. LTDDocument1 pageSection A-A 1: Metscco Heavy Steel Industries Co. LTDMohammed BasheeruddinNo ratings yet

- Aux Transformer - Kts-Sec-Bsdg-Arc-105Document1 pageAux Transformer - Kts-Sec-Bsdg-Arc-105Mohammed BasheeruddinNo ratings yet

- Riyadh Cables Group Company: ISO 9001: 2015 ISO 14001: 2015 OHSAS 18001: 2007Document12 pagesRiyadh Cables Group Company: ISO 9001: 2015 ISO 14001: 2015 OHSAS 18001: 2007Mohammed BasheeruddinNo ratings yet

- FUEL TANKR3-Layout1Document1 pageFUEL TANKR3-Layout1Mohammed BasheeruddinNo ratings yet

- Section C-C 1: Metscco Heavy Steel Industries Co. LTDDocument1 pageSection C-C 1: Metscco Heavy Steel Industries Co. LTDMohammed BasheeruddinNo ratings yet

- Elevation - 1 1: Metscco Heavy Steel Industries Co. LTDDocument1 pageElevation - 1 1: Metscco Heavy Steel Industries Co. LTDMohammed BasheeruddinNo ratings yet

- A C D E B: Metscco Heavy Steel Industries Co. LTDDocument1 pageA C D E B: Metscco Heavy Steel Industries Co. LTDMohammed BasheeruddinNo ratings yet

- PIC18LF26 27 45 46 47 55 56 57K42 Data Sheet 40001919E PDFDocument833 pagesPIC18LF26 27 45 46 47 55 56 57K42 Data Sheet 40001919E PDFCiprian SiposNo ratings yet

- GFF - Flat Roof PDFDocument19 pagesGFF - Flat Roof PDFSêlva AvlêsNo ratings yet

- Turfpave HDDocument2 pagesTurfpave HDAnonymous 1uGSx8bNo ratings yet

- JEC Prog - Design of CorbelDocument6 pagesJEC Prog - Design of CorbelhjuzarNo ratings yet

- Java4s Com HibernateDocument5 pagesJava4s Com HibernatevijayNo ratings yet

- GRI 8450-3 Data SheetDocument4 pagesGRI 8450-3 Data SheetJMAC SupplyNo ratings yet

- 1-Introduction To Soil Mechanics (Introduction)Document57 pages1-Introduction To Soil Mechanics (Introduction)Farhat Iqbal Malik100% (1)

- Speed Dowel Brochure 0811 ReducedDocument4 pagesSpeed Dowel Brochure 0811 ReducedwilliamptyNo ratings yet

- Xy PCDocument34 pagesXy PCtimbe08No ratings yet

- Installation NotesDocument12 pagesInstallation Notessagor sagorNo ratings yet

- CTW R Three: Moisture Content of Soil Water ContentDocument9 pagesCTW R Three: Moisture Content of Soil Water ContentVOJNo ratings yet

- Bank Al-Ahly Vendr List 2017Document24 pagesBank Al-Ahly Vendr List 2017mohammed sarwatNo ratings yet

- Media Piracy Detection Using Artificial Intelligence, Machine Learning and Data MiningDocument3 pagesMedia Piracy Detection Using Artificial Intelligence, Machine Learning and Data MiningIJRASETPublicationsNo ratings yet

- VastuSamvad Jan Apr2016Document12 pagesVastuSamvad Jan Apr2016Saurabh KesarwaniNo ratings yet

- Concrete PipeDocument4 pagesConcrete PipeHazim HaNo ratings yet

- Code of Professional Conduct - 1989Document15 pagesCode of Professional Conduct - 1989Shivam AroraNo ratings yet

- Method Statement For Temporary OpeningDocument1 pageMethod Statement For Temporary Openingvaibhav_sparshNo ratings yet

- Software Configuration ManagementDocument7 pagesSoftware Configuration ManagementHarsh ShahNo ratings yet

- Sotrafer-Quality Observation Complaince Tracking Record.Document63 pagesSotrafer-Quality Observation Complaince Tracking Record.mitendra singhNo ratings yet

- Al Furjan Villas (+971544050522)Document6 pagesAl Furjan Villas (+971544050522)Aarti Bablani AroraNo ratings yet

- Vidhan BhavanDocument10 pagesVidhan Bhavanaastha545No ratings yet

- Document Management Systems - Wiki - SCN WikiDocument4 pagesDocument Management Systems - Wiki - SCN Wikimatrix20102011No ratings yet