100% found this document useful (1 vote)

572 views27 pagesCementing Design - Final

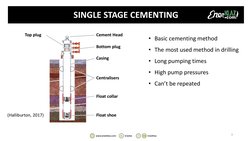

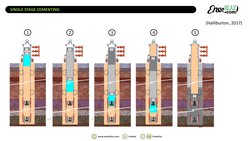

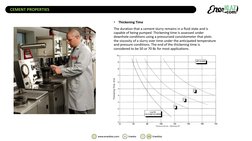

Cementing is the most important non-drilling function in drilling activities because it determines the life of the well. Its main functions are bonding the casing to the formation, providing support for the casing, and preventing movement of formation fluids behind the casing. There are different cementing methods like single stage cementing, thru-drill pipe cementing, and outside cementing. Cement properties include viscosity, density, thickening time, slurry yield, fluid loss, free water, and compressive strength. Additives are used to control properties and include accelerators, density control additives, retarders, and fluid loss reducers. Basic cementing calculations involve density and specific gravity.

Uploaded by

BIGBOAZ XXCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

572 views27 pagesCementing Design - Final

Cementing is the most important non-drilling function in drilling activities because it determines the life of the well. Its main functions are bonding the casing to the formation, providing support for the casing, and preventing movement of formation fluids behind the casing. There are different cementing methods like single stage cementing, thru-drill pipe cementing, and outside cementing. Cement properties include viscosity, density, thickening time, slurry yield, fluid loss, free water, and compressive strength. Additives are used to control properties and include accelerators, density control additives, retarders, and fluid loss reducers. Basic cementing calculations involve density and specific gravity.

Uploaded by

BIGBOAZ XXCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Cementing Introduction: Introduces the importance and main functions of cementing in drilling activities, setting the stage for detailed cementing techniques.

- Single Stage Cementing: Explains the single stage cementing process including its benefits and steps, essential for understanding primary cementing protocols.

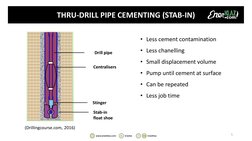

- Thru-Drill Pipe Cementing (Stab-In): Details the stab-in cementing technique, focusing on its advantages and operational efficiency during well completion.

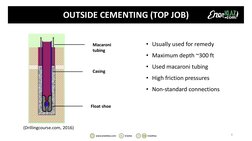

- Outside Cementing (Top Job): Describes the top job cementing technique used for remedial purposes, indicating usage scenarios and pressure challenges.

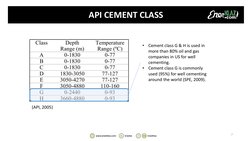

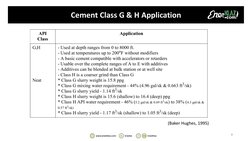

- API Cement Class: Presents specifications of different API cement classes with applications tailored for varied operational environments in well cementing.

- Cement Properties: Discusses critical properties such as viscosity, density, thickening time, and yield; essential for optimizing cementing strategies.

- Cement Additives: Covers additives and their roles such as accelerators, retarders, fluid loss reducers, and friction reducers, important for cement performance enhancement.

- Basic Cementing Calculation: Outlines core calculations necessary in cementing operations including density, volume, and specific gravity assessments.

- Example and Answers: Provides calculation examples with solutions, aiding in practical understanding of cementing calculations under various conditions.

- Question: Presents a sample question related to cementing calculations and methods, facilitating application of learned concepts.