Professional Documents

Culture Documents

Portable Diesel Compressors Product Guide

Portable Diesel Compressors Product Guide

Uploaded by

Mayra DiazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Portable Diesel Compressors Product Guide

Portable Diesel Compressors Product Guide

Uploaded by

Mayra DiazCopyright:

Available Formats

People.

Passion. Portable Diesel Compressors

Built for Reliable Performance

Performance.

Demanding conditions demand power you can count on. Chicago Pneumatic portable

compressors are built to deliver that power. From the smallest construction units to

the largest models for high pressure drilling, CP offers a full range to fit your needs. These

robust models are designed for dependable performance in a wide variety of applications.

They’re also easy to maintain and operate, which helps keep productivity high.

Reliable. Flexible.

Easy to Maintain. Simple to Use.

When you need portable jobsite power, you can count on CP compressors. Every model in the line

shares the same dependable design and smart features to enhance productivity. These units are an

excellent partner for pneumatic tools such as rock drills, breakers, air guns, wrenches, dewatering

pumps and abrasive blasting equipment. They can also provide backup power on the jobsite during

power cuts and electrical failures.

STURDY DESIGN

Ensures long-term LOW NOISE LEVEL

EASY ACCESS reliability and durability Compressors are equipped

Canopy doors open up and with an efficient noise-

out of the way for convenient dampening canopy

routine maintenance

FUEL AUTONOMY

No need to refuel during a

work shift, even when running

non-stop at full load

4 Portable Diesel Compressors

LATEST SCREW

ELEMENT TECHNOLOGY

Asymmetric rotors allow LARGE COOLING SURFACE

for increased efficiency. In Allows optimal use in high-

addition, a low rotor speed temperature environments

and few moving parts

minimize wear and tear for

reliable performance and

long service life.

FULLY AUTOMATIC

CLEAN INTAKE AIR

STEP-LESS SPEED

A high performance two-stage air

REGULATOR

intake filter prevents dust and dirt

Adapts engine speed

particles from entering the compressor

to air demand

and engine. A service indicator on

the filter tells you when it needs

replacement.

EFFICIENT FUEL FILTER

High-efficiency multi-step fuel

filtration with water separator

isolates and traps contaminants

to protect the engine

AVAILABLE OPTIONS

USER-FRIENDLY

CONTROL PANEL • After cooler and water separator1

Convenient and

straightforward • Heavy-duty air intake filter for

controls are grouped compressor and diesel engine2

on a single panel for

easy monitoring and • Full ASME, MOM, AS1210 approval

operation

• Cold weather pack for operating in

temperatures below -10˚ C

REPUTABLE ENGINE BRANDS • Available as a fixed unit or with a

Every model has a powerful

towable undercarriage3

engine from a well-known and

respected brand under its solid, 1

Not available for CPS 90, CPS 820-17 and CPS 770-21

weatherproof hood 2

Not available for CPS 90, CPS 130 and CPS 185

3

Not available for 1200-23, 1100-21 and CPS 1000-19

Portable Diesel Compressors 5

General Construction ROBUST

DESIGN

From residential and commercial construction to demolition and road

maintenance, compressed air is essential on the job site to power the RELIABLE

necessary tools. CP offers compressors in a wide range of sizes to fit POWER

the airflow and pressure requirements of the job — all designed to be

robust and reliable to meet the needs of tough, demanding construction

environments.

APPLICATIONS: On construction sites, CP portable air compressors

are typically used to power hand-held pneumatic breakers, air guns,

shotcrete equipment, pneumatic wrenches, nut runners and more.

They are commonly used in applications such as building sites, road

maintenance, bridges, tunnels, concrete pumping and shotcreting.

RECOMMENDED MODELS:

CPS 90, CPS 130, CPS 185, CPS 275 and CPS 400

Nominal Working Pressure: 7 bar (100 psi)

Free Air Delivery Range: 2.5 to 12 m3/min (88 to 424 cfm)

Maximum Ambient Air Temperature: 50 ˚C (122 ˚F)

Other models are also used in specific construction applications.

See pages 12-13 for complete technical data.

ENGINEERED FOR HIGH PERFORMANCE

CP offers a full line of handheld pneumatic

tools for renovation and construction jobs.

6 Portable Diesel Compressors

Portable Diesel Compressors 7

Dimension Stone Quarrying

and Stabilization

Dimension stone quarries, stabilization projects and foundation excavation demand equipment that

can stand up to hot, dust-filled working conditions. CP compressors are designed to do just that.

High-power engines deliver the power margin to work in tough environments. Large fuel tanks allow

uninterrupted operation for a full work shift. Plus, an oversized cooler pack helps ensure reliable

performance in high ambient temperatures. Mechanical compressor controls and mechanically

controlled engines also make CP compressors easy to use and service, which helps operators get

to work fast and stay productive.

APPLICATIONS: CP compressors provide portable power for pneumatic rock drills, block cutters,

dewatering pumps and hand-held pneumatic breakers. They are suited for stabilization projects on

roads and building sites, as well as basement and foundation excavation for apartment blocks and

other buildings.

RECOMMENDED MODELS:

CPS 350-10, CPS 350-12 and CPS 650-12

Nominal Working Pressure: 10 to 12 bar (150 to 170 psi)

Free Air Delivery Range: 10 to 18.4 m3/min (353 to 650 cfm)

Maximum Ambient Air Temperature: 50 to 53 ˚C (122 to 127 ˚F)

Other models are also used in specific dimensional stone quarrying and stabilization applications.

See pages 12-13 for complete technical data.

8 Portable Diesel Compressors

Abrasive Blasting MORE

POWER

For large abrasive blasting jobs in shipyards and industrial sites, robust

equipment is a must. Demanding applications such as sandblasting ships HIGHER

and steel require a high volume of air and equipment with extended working FLOW

time. CP compressors are the perfect match, with a range that’s tuned to

different blasting nozzle applications. Large fuel tanks also allow longer

periods of uninterrupted operation, and an aftercooler option is available for

moisture-free operation in dry ice blasting applications.

APPLICATIONS: CP compressors are suitable for abrasive blasting

applications such as deburring and preparing surfaces for painting, anodizing, welding and other

processes that require a clean surface. They are often used on shipyards, steel construction and

large renovation jobs.

RECOMMENDED MODELS:

CPS 400, CPS 850, CPS 830-9, CPS 750-10 and CPS 950-10

Nominal Working Pressure: 7 to 10 bar (100 to 150 psi)

Free Air Delivery Range: 12 to 26.8 m3/min (424 to 946 cfm)

Maximum Ambient Air Temperature: 50 to 53 ˚C (122 to 127 ˚F)

Other models also used in specific abrasive blasting applications.

See pages 12-13 for complete technical data.

Portable Diesel Compressors 9

Blast Hole Drilling

From aggregate to cement to metal ore, blast hole drilling jobs are often located in tough, remote

areas. These conditions require rugged equipment that’s up to the task, and CP has the solution.

CP compressors feature high-power engines to run reliably in high-temperature environments.

Low ambient temperature and high-altitude starting aid options are available as well. Large fuel

tanks also allow extended periods of uninterrupted operation, and the mechanical controls and

components are easy to use and service for maximum uptime.

APPLICATIONS: CP compressors provide portable power for rock drills, dewatering pumps

and hand-held breakers. Common applications include aggregate production for construction

stabilization, cement production in limestone quarries and open pit mining.

RECOMMENDED MODELS:

CPS 750-10, CPS 650-12, CPS 580-14, CPS 950-10 and CPS 900-12

Nominal Working Pressure: 10 to 14 bar (150 to 200 psi)

Free Air Delivery Range: 16.1 to 26.8 m3/min (569 to 946 cfm)

Maximum Ambient Air Temperature: 53 ˚C (127 ˚F)

Other models are also used in specific blast hole drilling applications.

See pages 12-13 for complete technical data.

10 Portable Diesel Compressors

High Pressure Drilling HIGHER

Water wells and geotechnical applications that require very deep drilling

PRESSURE

depend on high-powered air compressors to drive the drill rig. CP compressors

are designed to get the job done. They feature an efficient, fast-reacting DEEPER

speed regulator that delivers consistent outlet pressure for stable hammer/drill

operation and a high penetration rate. High pressure ensures faster operation,

HOLES

while high flow ensures larger drill diameter. And high ambient temperature

operation is standard for reliable performance in demanding conditions, job

after job.

APPLICATIONS: The CP range is suitable for Down The Hole (DTH) and rotary drilling, offering

a comfortable operating zone for drill hole diameters from 4.5 to 8 in (11.4 to 20.3 cm). Common

applications include drilling for water wells and foundations for high-rise buildings, as well as

geotechnical/geothermal applications.

RECOMMENDED MODELS:

CPS 820-17, CPS 770-21, CPS 1200-23, CPS 1100-21 and CPS 1000-19

Nominal Working Pressure: 17 to 23 bar (250 to 330 psi)

Free Air Delivery Range: 21.8 to 34 m3/min (770 to 1,308 cfm)

Maximum Ambient Air Temperature: 50 to 56 ˚C (122 to 133 ˚F)

NOTE: Units CPS 1200-23, CPS 1100-21 and CPS 1000-19 require an external fuel tank and are not available with a

wheeled undercarriage because they are specifically designed to be part of a larger installation. They are typically mounted

on a truck or trailer with a hydraulic or pneumatic drill and ancillary equipment to create a complete drill rig. This design

reduces the compressor footprint and increases efficiency, since all of the equipment on the rig can use a common fuel tank.

Portable Diesel Compressors 11

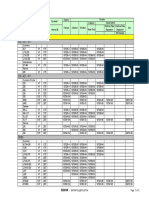

Technical Specifications

and Application Data

DIESEL COMPRESSORS CPS 90 CPS 130 CPS 185 CPS 275 CPS 400 CPS 350-10 CPS 350-12 CPS 850* CPS 830-9*

Nominal Working Pressure bar (psi) 7 (100) 7 (100) 7 (100) 7 (100) 7 (100) 10 (150) 12 (170) 7 (100) 8.6 (125)

Free Air Delivery l/s | cfm | m3/min 42 | 88 | 2.5 58 | 124 | 3.5 88 | 187 | 5.3 132 | 279 | 7.9 200 | 424 | 12 173 | 367 | 10.4 167 | 353 | 10 398 | 844 | 23.9 387 | 819 | 23.2

Minimum Engine Speed rpm 2,400 1,850 1,850 1,400 1,500 1,500 1,500 1,400 1,400

Maximum Engine Speed rpm 3,000 2,400 2,750 2,000 2,300 2,300 2,300 2,200 2,100

Compressor Oil Capacity l (gal) 5.5 (1.5) 8.8 (2.3) 8.8 (2.3) 20 (5.3) 24 (6.3) 24 (6.3) 24 (6.3) 60 (15.9) 60 (15.9)

Air Outlet Valves 2xG3/4" 2xG3/4" 3xG3/4" 1xG11/2" + 3xG3/4" 1xG11/2" + 3xG3/4" 1xG11/2" + 3xG3/4" 1xG11/2" + 3xG3/4" 1xG2" + 1xG3/4" 1xG2" + 1xG3/4"

Engine

Engine Brand Kubota Deutz Deutz Cummins Cummins Cummins Cummins Cummins Cummins

Engine Model D1105 F3M2011 F3M2011 4BT3.9-C80 4BTAA3.9-C130 4BTAA3.9-C130 4BTAA3.9-C130 6CTAA8.3-C240 6CTAA8.3-C240

Engine Power kW (hp) 18.2 (24) 32.5 (44) 36 (48) 60 (80) 97 (130) 97 (130) 97 (130) 179 (240) 179 (240)

Engine Cooling GenCool Oil / Air Oil / Air GenCool GenCool GenCool GenCool GenCool GenCool

Electrical System V 12 12 12 24 24 24 24 24 24

Engine Oil Capacity l (gal) 5.1 (1.3) 6.5 (1.7) 6.5 (1.7) 9 (2.4) 9 (2.4) 9 (2.4) 9 (2.4) 19 (5.0) 19 (5.0)

Fuel Tank Capacity l (gal) 32 (8.5) 80 (21.1) 80 (21.1) 185 (48.9) 185 (48.9) 185 (48.9) 185 (48.9) 350 (92.5) 350 (92.5)

Fuel Autonomy at 100% Load hr 8 16 12 15 10 10 10 11 11

Dimensions

Transport Dimensions without Undercarriage

Length mm (in) 1,580 (62) 1,980 (78) 1,980 (78) 2,235 (88) 2,235 (88) 2,235 (88) 2,235 (88) 3,281 (129) 3,281 (129)

Width mm (in) 1,050 (41) 1,167 (46) 1,167 (46) 1,180 (46) 1,180 (46) 1,180 (46) 1,180 (46) 1,670 (66) 1,670 (66)

Height mm (in) 918 (36) 978 (39) 978 (39) 1,623 (64) 1,623 (64) 1,623 (64) 1,623 (64) 1,868 (74) 1,868 (74)

Operational Weight kg (lb) 475 (1,047) 800 (1,764) 800 (1,764) 1,400 (3,086) 1,580 (3,483) 1,580 (3,483) 1,580 (3,483) 2,725 (6,008) 2,725 (6,008)

Transport Dimensions with Undercarriage

Length mm (in) 2,100 (83) 2,300 (91) 2,300 (91) 2,862 (113) 2,862 (113) 2,862 (113) 2,862 (113) 3,525 (139) 3,525 (139)

Width mm (in) 1,310 (52) 1,400 (55) 1,400 (55) 1,790 (70) 1,790 (70) 1,790 (70) 1,790 (70) 1,770 (70) 1,770 (70)

Height mm (in) 1,205 (47) 1,280 (50) 1,280 (50) 1,908 (75) 1,908 (75) 1,908 (75) 1,908 (75) 2,292 (90) 2,292 (90)

Operational Weight kg (lb) 556 (1,226) 960 (2,116) 960 (2,116) 1,500 (3,307) 1,680 (3,704) 1,680 (3,704) 1,680 (3,704) 3,500 (7,716) 3,500 (7,716)

*Also available with a Cummins 6LTAA8.9-C240 (8900 cc) engine.

APPLICATIONS CPS 90 CPS 130 CPS 185 CPS 275 CPS 400 CPS 350-10 CPS 350-12 CPS 850 CPS 830-9

General Construction

Dimension Stone Quarries

Stabilization

Abrasive Blasting

Dry Ice Blasting

Blast Hole Drilling

High Pressure Drilling

= Common Application = Special Application

12 Portable Diesel Compressors

In addition to specialized applications, most of the CP compressor range can also be used

for backup power in industrial applications, such as during power cuts or service work on

electric-driven industrial compressors. They can also be installed on service trucks to power

pneumatic tools such as nut runners and torque wrenches for roadside maintenance.

CPS 750-10 CPS 650-12 CPS 580-14 CPS 950-10 CPS 900-12 CPS 820-17 CPS 770-21 CPS 1200-23 CPS 1100-21 CPS 1000-19

10 (150) 12 (170) 14 (200) 10 (150) 12 (170) 17 (250) 21 (300) 23 (330) 21 (300) 19 (275)

337 | 713 | 20.2 307 | 650 | 18.4 268 | 569 | 16.1 447 | 946 | 26.8 410 | 869 | 24.6 385 | 816 | 23.1 363 | 770 | 21.8 567 | 1,200 | 34 519 | 1,100 | 31.1 490 | 1,308 | 29.4

1,400 1,400 1,400 1,400 1,400 1,400 1,400 1,900 1,800 1,800

2,200 2,200 2,200 2,000 2,000 2,000 2,000 1,200 1,200 1,200

60 (15.9) 60 (15.9) 60 (15.9) 65 (17.2) 65 (17.2) 70 (18.5) 70 (18.5) 72 (19) 72 (19) 72 (19)

1xG2" + 1xG3/4" 1xG2" + 1xG3/4" 1xG2" + 1xG3/4" 1xG2" + 1xG3/4" 1xG2" + 1xG3/4" 1xG2" + 1xG3/4" 1xG2" + 1xG3/4" 1xG2" 1xG2" 1xG2"

Cummins Cummins Cummins Cummins Cummins Cummins Cummins Cummins Cummins Cummins

6CTAA8.3-C240 6CTAA8.3-C240 6CTAA8.3-C240 6LTAA8.9-C315 6LTAA8.9-C315 6LTAA8.9-C315 6LTAA8.9-C315 NTA855 BC III NTA 855 BC III NTA855 BC III

179 (240) 179 (240) 179 (240) 232 (311) 232 (311) 232 (311) 232 (311) 321 (430) 309 (415) 295 (395)

GenCool GenCool GenCool GenCool GenCool GenCool GenCool GenCool GenCool GenCool

24 24 24 24 24 24 24 24 24 24

19 (5.0) 19 (5.0) 19 (5.0) 28 (7.4) 28 (7.4) 28 (7.4) 28 (7.4) 32 (8.5) 32 (8.5) 32 (8.5)

No fuel tank available No fuel tank available No fuel tank available

350 (92.5) 350 (92.5) 350 (92.5) 430 (114) 430 (114) 512 (135.3) 512 (135.3)

(external tank needed) (external tank needed) (external tank needed)

11 11 11 12 12 13 13 – – –

3,281 (129) 3,281 (129) 3,281 (129) 3,984 (157) 3,984 (157) 3,984 (157) 3,984 (157) 4,200 (165) 4,200 (165) 4,200 (165)

1,670 (66) 1,670 (66) 1,670 (66) 1,800 (71) 1,800 (71) 1,800 (71) 1,800 (71) 2,200 (87) 2,200 (87) 2,200 (87)

1,868 (74) 1,868 (74) 1,868 (74) 2,200 (87) 2,200 (87) 2,200 (87) 2,200 (87) 2,800 (110) 2,800 (110) 2,800 (110)

2,725 (6,008) 2,725 (6,008) 2,725 (6,008) 4,245 (9,359) 4,245 (9,359) 5,010 (11,045) 5,010 (11,045) 4,300 (9,480) 4,300 (9,480) 4,300 (9,480)

3,525 (139) 3,525 (139) 3,525 (139) 4,210 (166) 4,210 (166) 4,210 (166) 4,210 (166) – – –

1,770 (70) 1,770 (70) 1,770 (70) 1,800 (71) 1,800 (71) 1,800 (71) 1,800 (71) – – –

2,292 (90) 2,292 (90) 2,292 (90) 2,631 (104) 2,631 (104) 2,631 (104) 2,631 (104) – – –

3,500 (7,716) 3,500 (7,716) 3,500 (7,716) 4,600 (10,141) 4,600 (10,141) 5,365 (11,828) 5,365 (11,828) – – –

CPS 750-10 CPS 650-12 CPS 580-14 CPS 950-10 CPS 900-12 CPS 820-17 CPS 770-21 CPS 1200-23 CPS 1100-21 CPS 1000-19

Portable Diesel Compressors 13

Parts and Accessories

Trust Chicago Pneumatic for all the quality parts and lubricants you need to extend the life of your

compressor and eliminate the risk of costly breakdowns. Choose from a full selection of lubricants,

coolants and maintenance kits. These kits provide all the parts you need for scheduled maintenance in

one box, which can help save time and worries.

MAINTENANCE KITS Service Packs Oil Separator Service Kits

250 Hours or Yearly – 1625 0010 41

CPS 90 1625 0010 56

500 Hours or Yearly – 1625 0010 42

CPS 130 500 Hours or Yearly – 1625 0010 44 1625 0010 57

CPS 185 500 Hours or Yearly – 1625 0010 45 1625 0010 57

500 Hours or Yearly – 2912 4554 05

CPS 275 2911 0160 00

1,000 Hours or Yearly – 2912 4555 06

200 Hours or Yearly – 2205 5193 10

CPS 400, CPS 350-10, CPS 350-12 2205 4065 22

1,000 Hours or Yearly – 2205 5193 11

200 Hours or Yearly – 2205 5193 17

CPS 850, CPS 830-9, CPS 750-10,

1,000 Hours or Yearly – 2205 5193 18 Included in 2,000 Hour Kit

CPS 650-12, CPS 580-14

2,000 Hours or Every Two Years – 2205 5193 19

200 Hours or Yearly – 2205 5193 17

CPS 950-10, CPS 900-12 1,000 Hours or Yearly – 2205 5193 18 Included in 2,000 Hour Kit

2,000 Hours or Every Two Years – 2205 5193 19

200 Hours or Yearly – 2205 5193 17

CPS 820-17, CPS 770-21 1,000 Hours or Yearly – 2205 5193 24 Included in 2,000 Hour Kit

2,000 Hours or Every Two Years – 2205 5193 25

1,000 Hours or Yearly – 9096 9404 10

CPS 1200-23, CPS 1100-21, CPS 1000-19 9096 9404 13

2,000 Hours or Every Two Years – 9096 9404 11

14 Portable Diesel Compressors

CPS 850

CPS 275 CPS 830-9

CPS 400 CPS 750-10 CPS 1200-23

CPS 130 CPS 350-10 CPS 650-12 CPS 950-10 CPS 820-17 CPS 1100-21

SERVICE KITS CPS 90 CPS 185 CPS 350-12 CPS 580-14 CPS 900-12 CPS 770-21 CPS 1000-19

Road Axle Bearings Braked 1625 0010 05 1625 0010 07 — — — — —

Road Axle Bearings Non Braked — 1625 0010 08 — — — — —

Unloading Valve 2911 0051 00 2911 0051 00 2911 0074 00 2910 3003 00 2910 3003 00 2910 3003 00 2910 3003 00

Speed Regulator 2911 0052 00 2911 0052 00 2911 0052 00 2911 0052 00 2911 0052 00 2911 0052 00 2910 3606 00

Brake Shoes 2911 0067 00 1625 0010 06 — — — — —

2910 4041 00

Element Mounting 2911 0147 00 2911 0141 00 — — — —

2911 0120 00

Air Temperature Switch 1605 0636 00 1605 0636 00 — 2205 1767 56 1605 0636 00 2205 1769 92 —

Cooling Water Temperature Switch — — 2205 1765 82 1605 0636 00 2205 1767 52 2205 1767 52 —

Engine Oil Pressure Switch — — 2205 1764 16 2205 1764 18 2205 1764 18 2205 1764 18 —

Regulating Valve — — 2911 0090 00 2910 3005 00 2910 3005 00 2910 3005 00 2910 3005 00

Minimum Pressure Valve — — 2205 4905 97 2205 4905 98 2205 4905 98 2254 4905 98 2914 8345 00

Thermostatic Valve — — — 2205 5265 20 2205 5265 20 2205 5265 20 1202 5869 05

Oil Stop Valve — — — 2205 5193 92 2906 0094 00 2911 0118 00 2911 0118 00

Engine Oil Compressor Oil

FLUID CAPACITIES L (gal) L (gal)

CPS 90 5.1 (1.3) 5.5 (1.5)

CPS 130, CPS 185 6.5 (1.7) 8.8 (2.3)

CPS 275 9 (2.4) 20 (5.3)

CPS 400, CPS 350-10, CPS 350-12 9 (2.4) 24 (6.3)

CPS 850, CPS 830-9, CPS 750-10

19 (5.0) 60 (15.9)

CPS 650-12, CPS 580-14

CPS 950-10, CPS 900-12 28 (7.4) 65 (17.2)

CPS 820-17, CPS 770-21 28 (7.4) 75 (19.8)

CPS 1200-23, CPS 1100-21, CPS 1000-19 32 (8.5) 72 (19)

LUBRICANTS

(All models) Size Part Number

GENOIL – Standard Engine Oil 5 Liter Can 1626 2262 00

GENOIL – Standard Engine Oil 20 Liter Can 1626 2263 00

GENOIL – Cold Start Engine Oil 5 Liter Can 1626 2258 00

GENOIL – Cold Start Engine Oil 20 Liter Can 1626 2259 00

GENOIL – M Standard Compressor Oil 5 Liter Can 1626 2260 00

GENOIL – M Standard Compressor Oil 20 Liter Can 1626 2261 00

GENOIL – S Cold Start Compressor Oil 20 Liter Can 1630 0175 00

COOLANTS

(All models except CPS 130 and CPS 185) Size Part Number

Gencool EG 5 Liter Can 1626 2255 00

Gencool EG 20 Liter Can 1626 2256 00

Gencool Concentrate 5 Liter Can 1626 2257 00

Portable Diesel Compressors 15

Over 100 Years of Experience

Since 1901 the Chicago Pneumatic name has represented high-

performance tools and equipment designed for an extensive range

of applications. Today, Chicago Pneumatic has a global reach, with

local customer centers around the world. Chicago Pneumatic tools

and air compressors are tailored to the needs of the industrial,

vehicle service, and construction markets. Every day we develop

and manufacture new products that are meant to meet your

demands not only today, but tomorrow as well.

For more information, please contact your CP partner:

Use only authorized parts. Any damage or malfunction caused by the use of unauthorized parts is not covered by Warranty or Product Liability.

Subject to technical modifications.

December 2013

2957 0760 00

www.cp.com

You might also like

- Elgi EG 90 160kW 50Hz D I PDFDocument8 pagesElgi EG 90 160kW 50Hz D I PDFMAZENNo ratings yet

- Transfer Switch Controller: Software Version 1.7Document52 pagesTransfer Switch Controller: Software Version 1.7powermanagerNo ratings yet

- Practical Applicationof IEEE 485-1997 PDFDocument6 pagesPractical Applicationof IEEE 485-1997 PDFcpassarellaNo ratings yet

- HPCL Disaster MGMT Control PlanDocument64 pagesHPCL Disaster MGMT Control PlanKiran BhattNo ratings yet

- BoostLi Energy Storage Module ESM-48100A1 User Manual (6936)Document44 pagesBoostLi Energy Storage Module ESM-48100A1 User Manual (6936)moises quispe100% (1)

- AGRE IndustrialPistons Leaflet en LRDocument20 pagesAGRE IndustrialPistons Leaflet en LRmogwai71No ratings yet

- Rooftop Units: Lennox Landmark 50HzDocument8 pagesRooftop Units: Lennox Landmark 50HzMatias AcuñaNo ratings yet

- CompAir L160-L250 PDFDocument4 pagesCompAir L160-L250 PDFjohovitch100% (2)

- Dynapac Tandem Asphalt RollersDocument12 pagesDynapac Tandem Asphalt Rollerseunice19970315No ratings yet

- Mobilair M120-23Document8 pagesMobilair M120-23purchasingNo ratings yet

- 03 Oil Lub. Piston LER, LTR, Oil-Free Piston LFRDocument2 pages03 Oil Lub. Piston LER, LTR, Oil-Free Piston LFRSerban Aurel CosminNo ratings yet

- CompAir D75-275RSDocument8 pagesCompAir D75-275RSIbram GunarsaNo ratings yet

- DRE - English enDocument8 pagesDRE - English envijaykmjNo ratings yet

- Ficha Técnica CAT CS-583DDocument12 pagesFicha Técnica CAT CS-583DMilson MoreiraNo ratings yet

- 05 Oil Injected Screw GAR 5-14Document2 pages05 Oil Injected Screw GAR 5-14Pavel SokolovNo ratings yet

- Mobilair M27 Utility: Portable CompressorsDocument2 pagesMobilair M27 Utility: Portable CompressorsBrised Cera BarbozaNo ratings yet

- Dynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700Document8 pagesDynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700danielfbarradas1370No ratings yet

- Southern Cross Compressors KHE BrochureDocument7 pagesSouthern Cross Compressors KHE Brochurerafaelmelo89No ratings yet

- Compair L-Series-L07 - 11Document8 pagesCompair L-Series-L07 - 11Nazrul IslamNo ratings yet

- 06 Oil Injected Screw GAR 11-37-2Document2 pages06 Oil Injected Screw GAR 11-37-2RUN GONo ratings yet

- Atlas Copco: Railway Air Systems Oil-Injected Screw Compressor GAR 5-14Document2 pagesAtlas Copco: Railway Air Systems Oil-Injected Screw Compressor GAR 5-14JORGENo ratings yet

- Catalogo Cargador Frontal ATM Wm500 ESDocument7 pagesCatalogo Cargador Frontal ATM Wm500 ESManuel JuncanNo ratings yet

- Ficha Tecnica 2475Document12 pagesFicha Tecnica 2475bofok65411No ratings yet

- Pneumatic RollerDocument8 pagesPneumatic RollerIrfan SaeedNo ratings yet

- 3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Document2 pages3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Sebastian SalazarNo ratings yet

- Reliability & Efficiency Without Compromise: L30 - L45 L30 - L45 L30RS - L45RSDocument8 pagesReliability & Efficiency Without Compromise: L30 - L45 L30 - L45 L30RS - L45RSRon Don jrNo ratings yet

- Lennox ZCB060S4BDocument8 pagesLennox ZCB060S4BChouchen WejdenNo ratings yet

- PubliciteDocument12 pagesPubliciteHugues DescharmesNo ratings yet

- Leaflet Xavs378 Xahs408 Stagev enDocument8 pagesLeaflet Xavs378 Xahs408 Stagev enSuperbagyoNo ratings yet

- CP PetDocument4 pagesCP PetjayeshNo ratings yet

- USOIL FREE Oil FreeScrewComps 07 2017 Tcm9 1089882Document28 pagesUSOIL FREE Oil FreeScrewComps 07 2017 Tcm9 1089882RyanNo ratings yet

- CSM MAXI CompressorDocument8 pagesCSM MAXI Compressorandy131078No ratings yet

- Xas 47 Spec1 PDFDocument4 pagesXas 47 Spec1 PDFacarisimovicNo ratings yet

- Keaser CompresorDocument28 pagesKeaser CompresorGersy CadilloNo ratings yet

- Vibratory Soil Compactor: Stage II CompliantDocument12 pagesVibratory Soil Compactor: Stage II Compliantguillermo springNo ratings yet

- Reliability & Efficiency Without Compromise: Rotary Screw CompressorsDocument8 pagesReliability & Efficiency Without Compromise: Rotary Screw CompressorsabdurohmanNo ratings yet

- RS (F) - PRO 3,0 Â 18,5 - Brochure - ENDocument16 pagesRS (F) - PRO 3,0 Â 18,5 - Brochure - ENRUN GONo ratings yet

- PDF - USCSD - CSD Series - 9-27-2023 - 46-160752Document12 pagesPDF - USCSD - CSD Series - 9-27-2023 - 46-160752Fauzi DillahNo ratings yet

- Polaris Brochure - CATALOGUEDocument11 pagesPolaris Brochure - CATALOGUEKarthikeyan VisvakNo ratings yet

- CB 214D ManualDocument12 pagesCB 214D ManualZoranNo ratings yet

- EnviroAire Vs Series VS15 VS110 Oil Less Rotary Screw Compressor BrochureDocument16 pagesEnviroAire Vs Series VS15 VS110 Oil Less Rotary Screw Compressor Brochurekornrat7661No ratings yet

- Compair l160 l290 SpecDocument12 pagesCompair l160 l290 SpecpfundhNo ratings yet

- Penguin 600315.321Document4 pagesPenguin 600315.321elad0% (1)

- Product CatalogDocument60 pagesProduct CatalogLEKH021No ratings yet

- KOBELCO - KNW Series CDocument8 pagesKOBELCO - KNW Series CKopral Jono0% (1)

- SM Series Kaeser CompressorrenDocument16 pagesSM Series Kaeser CompressorrenarieprachmanNo ratings yet

- Compresores Ga 100 PDFDocument16 pagesCompresores Ga 100 PDFFranklin Esteban CárdenasNo ratings yet

- EG Series Screw Air Compressors: Life Source of IndustriesDocument8 pagesEG Series Screw Air Compressors: Life Source of Industriespadhu_pNo ratings yet

- Specalog CS533EDocument16 pagesSpecalog CS533Earfa ujianto100% (1)

- Single Drum Vibratory Rollers: BW211D-50, BW211PD-50Document4 pagesSingle Drum Vibratory Rollers: BW211D-50, BW211PD-50EndraNo ratings yet

- KRSD Brochure 3 2018Document5 pagesKRSD Brochure 3 2018wijaya adidarmaNo ratings yet

- CPS 400 JD Series Compressors Flyer US v4 tcm332-3538872Document2 pagesCPS 400 JD Series Compressors Flyer US v4 tcm332-3538872jamalhabbas742No ratings yet

- Linha L e LSRDocument8 pagesLinha L e LSRaplicacao.evolucaoNo ratings yet

- Single Stage Rotary: World Class Efficiency ReliabilityDocument5 pagesSingle Stage Rotary: World Class Efficiency ReliabilitySethuraman Kumarappan (KPCL)No ratings yet

- CompAir L Series Rotary Screw 20 30 HP1Document8 pagesCompAir L Series Rotary Screw 20 30 HP1فتحي الجمل فتحي الجملNo ratings yet

- Atlas Copco Railway Air Systems: Oil-Free Scroll Compressor SFR 2-12Document2 pagesAtlas Copco Railway Air Systems: Oil-Free Scroll Compressor SFR 2-12erfan ahmedNo ratings yet

- Ingersoll Rand Rotary Screw Air Compressors 15 To 50 HP Brochure JECDocument11 pagesIngersoll Rand Rotary Screw Air Compressors 15 To 50 HP Brochure JECMardeni OliveiraNo ratings yet

- Polaris LRDocument11 pagesPolaris LRDavid Lionel Fernandez ValdiviaNo ratings yet

- Portable Air CompressorDocument4 pagesPortable Air CompressorAlejandroO.VargasNo ratings yet

- USSXSMSK - SX SM SK Series - 07 2019 - 46 37080 PDFDocument8 pagesUSSXSMSK - SX SM SK Series - 07 2019 - 46 37080 PDFkagasaw023No ratings yet

- Portable Air Compressor: EXPORT-Air-Compressors-C185-T2.indd 1 4/25/2013 2:19:34 PMDocument4 pagesPortable Air Compressor: EXPORT-Air-Compressors-C185-T2.indd 1 4/25/2013 2:19:34 PMalex limachiNo ratings yet

- Series R Rtac 500-1500 KW: Unmatchable Value in Class A Efficiency Air-Cooled ChillersDocument8 pagesSeries R Rtac 500-1500 KW: Unmatchable Value in Class A Efficiency Air-Cooled ChillerssalahcalimeroNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 11 - FloortightDocument8 pages11 - FloortightpowermanagerNo ratings yet

- 6 - BomDocument8 pages6 - BompowermanagerNo ratings yet

- IATCO Catalog 2017Document24 pagesIATCO Catalog 2017powermanagerNo ratings yet

- Eaton Fuller Transmission Super Parts Book Trip0916 en UsDocument158 pagesEaton Fuller Transmission Super Parts Book Trip0916 en UspowermanagerNo ratings yet

- CT 144360Document2 pagesCT 144360powermanagerNo ratings yet

- Capstone Micro Turbine ORCDocument32 pagesCapstone Micro Turbine ORCpowermanagerNo ratings yet

- Light Waterwell Series: Atlas Copco Waterwell Drilling RigsDocument4 pagesLight Waterwell Series: Atlas Copco Waterwell Drilling Rigspowermanager100% (1)

- Eaton Fuller 11 Speed Transmissions Brochure trsl0253 en UsDocument2 pagesEaton Fuller 11 Speed Transmissions Brochure trsl0253 en UspowermanagerNo ratings yet

- Xrvs 1000 Service PDFDocument10 pagesXrvs 1000 Service PDFpowermanagerNo ratings yet

- Eaton A 7786 Hydraulic Clutch Release Yoke Improved Seal Retainer Technical Service Bulletin Taib0853 en UsDocument2 pagesEaton A 7786 Hydraulic Clutch Release Yoke Improved Seal Retainer Technical Service Bulletin Taib0853 en UspowermanagerNo ratings yet

- PTHS1200Document112 pagesPTHS1200powermanagerNo ratings yet

- ST7 Battery - Technical SpecificationDocument8 pagesST7 Battery - Technical SpecificationpowermanagerNo ratings yet

- Operation and Maintenance Manual 4.03Document103 pagesOperation and Maintenance Manual 4.03powermanagerNo ratings yet

- Operation and Maintenance Manual 4.05Document104 pagesOperation and Maintenance Manual 4.05powermanagerNo ratings yet

- Atlas Copco Portable Air: The New Drillair™ Range of CompressorsDocument2 pagesAtlas Copco Portable Air: The New Drillair™ Range of CompressorspowermanagerNo ratings yet

- Stop Compressing Air - Start Controlling It!: Smart Air Xc4004 ControllerDocument1 pageStop Compressing Air - Start Controlling It!: Smart Air Xc4004 ControllerpowermanagerNo ratings yet

- PTS1600 T4 Datasheet PDFDocument2 pagesPTS1600 T4 Datasheet PDFpowermanagerNo ratings yet

- Xamthvs 900 1150 CD7 PDFDocument6 pagesXamthvs 900 1150 CD7 PDFpowermanagerNo ratings yet

- Atlas Copco Xrvs 577Document132 pagesAtlas Copco Xrvs 577Joseph IlaganNo ratings yet

- Rental Book - India PDFDocument24 pagesRental Book - India PDFpowermanagerNo ratings yet

- Atlas Copco Rental: 100% Oll-Free Air Compressor Diesel DrivenDocument1 pageAtlas Copco Rental: 100% Oll-Free Air Compressor Diesel DrivenpowermanagerNo ratings yet

- Boosters Guide Brochure English PDFDocument5 pagesBoosters Guide Brochure English PDFpowermanagerNo ratings yet

- MSDB J Type Vertical 15 Way Data SheetDocument3 pagesMSDB J Type Vertical 15 Way Data SheetMekaNo1DNo ratings yet

- g1013 UsDocument260 pagesg1013 UstienNo ratings yet

- Variable Frequency GeneratorDocument8 pagesVariable Frequency GeneratorSARAVANANo ratings yet

- The SunDocument16 pagesThe Sun3XTR3M3 ᜰ꙰ꦿ NJRNo ratings yet

- Cbs 305Document8 pagesCbs 305josenamelNo ratings yet

- Hydrocarbon Processing 01 2012Document95 pagesHydrocarbon Processing 01 2012Ionela PoenaruNo ratings yet

- Simulation of A Wireless Power Transfer System For Electric Vehicles With Power Factor CorrectionDocument6 pagesSimulation of A Wireless Power Transfer System For Electric Vehicles With Power Factor Correctionwalidghoneim1970No ratings yet

- Brosur Pompa Horisontal Multistage Franklin Type MHDocument20 pagesBrosur Pompa Horisontal Multistage Franklin Type MHkamdani msiNo ratings yet

- 2014 Alternator OverhaulDocument14 pages2014 Alternator Overhaulเพียร มานะNo ratings yet

- Variable Geometry Diffuser Extended TravelDocument22 pagesVariable Geometry Diffuser Extended TravelPerkins CikawungNo ratings yet

- P&I Diagram Ri-Fliessbild: MWM Beijing / Voith Paper 1329360 Tem Evo, Akr / Nox 500 T 4513Document1 pageP&I Diagram Ri-Fliessbild: MWM Beijing / Voith Paper 1329360 Tem Evo, Akr / Nox 500 T 4513周庆卓No ratings yet

- DIY DC ArcWelderDocument3 pagesDIY DC ArcWeldersituationsNo ratings yet

- 1550402978050 growatt pv inverter modbus rs485 rtu protocol v3.05 客户版Document15 pages1550402978050 growatt pv inverter modbus rs485 rtu protocol v3.05 客户版JohanNo ratings yet

- Challenges Faced by Pump Manufacturers: Guided Sales ConfiguratorsDocument10 pagesChallenges Faced by Pump Manufacturers: Guided Sales ConfiguratorssahirprojectsNo ratings yet

- Vibration FatigueDocument5 pagesVibration Fatiguesajith sajeevanNo ratings yet

- 1C-Tabugoc - LA2 Plant CellDocument5 pages1C-Tabugoc - LA2 Plant CellClint Jhun TabugocNo ratings yet

- Géotechnique Lecture 2011: Foundation Design For Offshore Wind TurbinesDocument78 pagesGéotechnique Lecture 2011: Foundation Design For Offshore Wind TurbinesRahul KolateNo ratings yet

- Using 3D Thermal Modeling To Improve Performance RequirementsDocument5 pagesUsing 3D Thermal Modeling To Improve Performance RequirementsClef GonadanNo ratings yet

- Two Step Impedance Matching Using Quarter Wave Transformers For Resistive and Non-Resistive LoadsDocument19 pagesTwo Step Impedance Matching Using Quarter Wave Transformers For Resistive and Non-Resistive LoadsJ SanyalNo ratings yet

- Performance Test of AIR CONDITIONING SYSTEMDocument20 pagesPerformance Test of AIR CONDITIONING SYSTEMZa YonNo ratings yet

- Nurture Test Series / Joint Package Course (Aiot) : Distance Learning ProgrammeDocument11 pagesNurture Test Series / Joint Package Course (Aiot) : Distance Learning ProgrammePrakhar KataraNo ratings yet

- Science 4 Q3 Week 7Document11 pagesScience 4 Q3 Week 7monica saturninoNo ratings yet

- Top 10 Solar CompaniesDocument4 pagesTop 10 Solar CompaniesRashi entertainmentNo ratings yet

- Goods Receipt Goods ReciptDocument129 pagesGoods Receipt Goods ReciptharshNo ratings yet

- Rural Sustainable Development: A Case of Mota Borsara VillageDocument5 pagesRural Sustainable Development: A Case of Mota Borsara VillageGRD JournalsNo ratings yet

- Kerone (An Iso 9001: 2008 Certified Company)Document36 pagesKerone (An Iso 9001: 2008 Certified Company)aashishNo ratings yet

- LCA - Beverage PKG Detritus.Document15 pagesLCA - Beverage PKG Detritus.Ponglert ChanthornNo ratings yet