Professional Documents

Culture Documents

05 Oil Injected Screw GAR 5-14

Uploaded by

Pavel SokolovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 Oil Injected Screw GAR 5-14

Uploaded by

Pavel SokolovCopyright:

Available Formats

ATLAS COPCO

RAILWAY AIR SYSTEMS

Oil-injected Screw Compressor

GAR 5-14

i Less weight, more safety, consequently reliable

The oil-injected, air-cooled GAR 5-14 screw compressors are designed for dedicated railway applications in

extreme ambient conditions. They are a reliable, compact, low-weight, low-noise solution that can be installed

on top of, inside or underneath the vehicle. Available from 500 to 1600 l/min free air delivery.

FEATURES AND BENEFITS

Space-saving design Reliability and durability

Minimal required footprint with a single access side for Minimum amount of moving parts.

maintenance and installation. Use of corrosive resistant materials like stainless steel

Optional air dryer, filters and control cubicle can all be and aluminum.

integrated in a very compact compressor package. Long service intervals.

Integrated fan concept to avoid extra external fans. Gear driven.

Enduring performance Flexible and easy installation

The compressor is designed, built and tested to meet Plug and play system.

the toughest conditions in railway applications (extreme Easy to adapt cooling flow direction.

climatic conditions, high humidity, and shock and Mainly used under or on top of a railway vehicle.

vibrations).

Built in accordance with international railway standards.

1

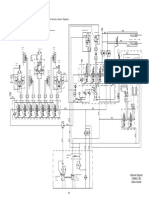

5

2 4 6 7

1 8

3

1 The Full Feature version includes 3 Multi-stage, highly corrosion 6 High precision gears manufactured

integrated filters and a membrane resistant oil separator, with a according to DIN 3961/class 6. Gears

dryer which removes oil and water low (3 ppm) oil carry-over, reduces are oil-lubricated and temperature-

vapor from the compressed air contamination and maintenance controlled by the compressor oil.

in order to protect your air piping requirements.

network and braking system from 7 Integrated cooling fan to optimize

freezing and corrosion. 4 Heavy duty air intake filter for the air flow, which ensures that

efficient operation in dusty the right amount of cooling air is

2 Optimally sized, high efficiency environments. delivered efficiently to where it is

aluminum cooler provides ideal needed with minimal noise.

compressor running temperature 5 Atlas Copco’s patented screw

under all conditions. compression element for optimal 8 High efficiency, totally enclosed fan-

energy efficiency and outstanding cooled (TEFC), IP 55, class F electric

reliability. railway motor for continuous

trouble-free operation with greased-

for-life bearings.

OPTIONS

Different drives The compressor Control pressure switch To adjust the Inlet filter For remote warning in case

can be equipped with different compressor according to air demand by the inlet filter is clogged.

drives, like an AC motor, DC motor measuring the pressure in the system. Heating kit To be able to run the

and hydraulic drive. Alarm pressure switch To indicate that compressor in ambient temperatures

Control voltage connector To easily the compressor is still under pressure between -40 °C (-40 °F) and -25 °C (-13 °F).

connect the control voltage lines. and to prevent the compressor from Motor starter Y/D or DOL.

Motor voltage connector To easily restarting too soon against a too high Customized frame To easily integrate

connect the power voltage lines. back-pressure in case of power supply the complete package into the available

Condensate treatment To treat the interruption. space envelope in, under or on top of

condensate from the filtration line. Anti-rotation switch To signal the the railway vehicle.

Different approvals CE, ASME, SQL. compressor is running and to prevent Noise hood An engineered noise hood

Load/unload valve To be able to the compressor from running in the adapted to the available cooling flow

control the compressor in different opposite direction due to a phase switch directions to protect the compressor

applications. of the electro motor dP-switch. from external parts and to reduce the

noise emission of the complete package.

TECHNICAL SPECIFICATIONS

Sound

Capacity* Installed motor power Pressure** pressure Weight

Compressor type level

l/s l/min cfm kW hp bar(e) psig dB(A) kg lbs

50 Hz version

GAR 5 9.0 540 19.0 5.5 7.5 10 145 56 154 339

GAR 7 13.2 792 28.0 7.5 11 10 145 57 163 359

GAR 10 16.5 990 35.0 11 15 10 145 58 188 414

GAR 14 26.2 1572 55.5 15 20 10 145 64 193 425

60 Hz version

GAR 5 8.5 510 18 5.5 7.5 10 145 56 154 339

GAR 7 12.9 774 27.3 7.5 11 10 145 57 163 359

GAR 10 16.6 996 35.2 11 15 10 145 58 188 414

GAR 14 22.3 1338 55.5 15 20 10 145 64 193 425

Reference conditions:

Absolute inlet pressure: 1 bar (14.5 psi)

Intake air temperature: 20 °C (68 °F)

Effective working pressure: 9.5 bar (138 psi)

Mean noise level measured according to ISO 2151/Pneurop/Cagi PN8NTC2 at 4.6 meter free field

* Unit performance measured at a standard unit (before dryer) according to ISO 1217, Annex C,

latest edition

** Outlet pressures possible between 6 and 13 bar

2935 0948 42 – Subject to alteration without prior notice.

Never use compressed air as breathing air without prior purification in accordance with local legislation and standards. www.atlascopco.com

You might also like

- The Jet Engine, 5th EditionDocument306 pagesThe Jet Engine, 5th Editionmilad100% (3)

- ESD 5 Crawler - Operator's InstructionsDocument51 pagesESD 5 Crawler - Operator's InstructionsPavel SokolovNo ratings yet

- Manual: Installation, Operation & MaintenanceDocument86 pagesManual: Installation, Operation & MaintenanceNhân NgọcNo ratings yet

- Ingersoll Rand SSR M Series CompressorDocument12 pagesIngersoll Rand SSR M Series CompressorNaser100% (1)

- Almig - BELT DATA SHEETS 2012Document34 pagesAlmig - BELT DATA SHEETS 2012Andy ConnersNo ratings yet

- Air Cooled Screw Chiller - APSa VFD TypeDocument70 pagesAir Cooled Screw Chiller - APSa VFD TypeKhaleel ButtNo ratings yet

- Process Design and Equipment SizingDocument5 pagesProcess Design and Equipment Sizingmyself_riteshNo ratings yet

- Aircraft Gas Turbine MaterialsDocument10 pagesAircraft Gas Turbine MaterialsCaio Fazzioli TavaresNo ratings yet

- MotorDocument84 pagesMotorSarath Raghav100% (1)

- Isotherm TurbocompressorsDocument6 pagesIsotherm TurbocompressorsStefanStanisavljavic100% (1)

- Commercial Split Systems Air Conditioning Condensing Units: Product DataDocument52 pagesCommercial Split Systems Air Conditioning Condensing Units: Product Datahipolito padronNo ratings yet

- General Description: Fob4 Ts Technical ManualDocument39 pagesGeneral Description: Fob4 Ts Technical ManualMohammed S.GoudaNo ratings yet

- Manual de Partes RFADocument140 pagesManual de Partes RFALeonardo Benitez100% (1)

- Atlas Copco XAS 186 126 106 116 136 156 146Document6 pagesAtlas Copco XAS 186 126 106 116 136 156 146zona amrullohNo ratings yet

- Atlas Copco ZH 350 ENDocument12 pagesAtlas Copco ZH 350 ENAtlas Copco Compressor Technique100% (1)

- 06 Oil Injected Screw GAR 11-37-2Document2 pages06 Oil Injected Screw GAR 11-37-2RUN GONo ratings yet

- Atlas Copco: Railway Air Systems Oil-Injected Screw Compressor GAR 5-14Document2 pagesAtlas Copco: Railway Air Systems Oil-Injected Screw Compressor GAR 5-14JORGENo ratings yet

- Atlas Copco Railway Air Systems: Oil-Free Scroll Compressor SFR 2-12Document2 pagesAtlas Copco Railway Air Systems: Oil-Free Scroll Compressor SFR 2-12erfan ahmedNo ratings yet

- Gar 11-37Document2 pagesGar 11-37moisesNo ratings yet

- 03 Oil Lub. Piston LER, LTR, Oil-Free Piston LFRDocument2 pages03 Oil Lub. Piston LER, LTR, Oil-Free Piston LFRSerban Aurel CosminNo ratings yet

- Atlas Copco Mobility Air Systems: Oil-Free Scroll Compressor SFR 2-12Document2 pagesAtlas Copco Mobility Air Systems: Oil-Free Scroll Compressor SFR 2-12Serban Aurel CosminNo ratings yet

- Kaitec - Bro ISO 50HzDocument10 pagesKaitec - Bro ISO 50Hzwijaya adidarmaNo ratings yet

- CSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorDocument6 pagesCSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorVolodymуr VorobetsNo ratings yet

- AtlasCopco Oil Injected Rotary Screw Compressors Catalogue ALLDocument104 pagesAtlasCopco Oil Injected Rotary Screw Compressors Catalogue ALLacepmuhammadihsan97No ratings yet

- 06D, e 3PDDocument24 pages06D, e 3PDAlberto Saul Rivero PlazaNo ratings yet

- Oil-Injected Rotary Screw Compressors: GA 355-500 (355-500 KW / 450-700 HP)Document8 pagesOil-Injected Rotary Screw Compressors: GA 355-500 (355-500 KW / 450-700 HP)Siva SubramaniyanNo ratings yet

- FX 400-2000Document8 pagesFX 400-2000francisco jose arruda de sousaNo ratings yet

- Xas 47 Spec1 PDFDocument4 pagesXas 47 Spec1 PDFacarisimovicNo ratings yet

- Tasplgd6346 1 V.KDocument8 pagesTasplgd6346 1 V.KPragnesh PrajapatiNo ratings yet

- Portable Diesel Compressors: People. Passion. PerformanceDocument16 pagesPortable Diesel Compressors: People. Passion. PerformancepowermanagerNo ratings yet

- Kaishan-Kaitain-Screw-Compressor-Direct-Couple-ISO-50Hz - JN SeriesDocument10 pagesKaishan-Kaitain-Screw-Compressor-Direct-Couple-ISO-50Hz - JN SeriesSwapnil PatadeNo ratings yet

- Compair l160 l290 SpecDocument12 pagesCompair l160 l290 SpecpfundhNo ratings yet

- VE LightDocument12 pagesVE LightMAZENNo ratings yet

- Mark MSM Mini 22-55 LeafletDocument6 pagesMark MSM Mini 22-55 LeafletzuzinoleksandrNo ratings yet

- Catalogo Classic USADocument8 pagesCatalogo Classic USAOvidiu BalogNo ratings yet

- Product Information: EnglishDocument8 pagesProduct Information: EnglishAndrzej RNo ratings yet

- 201 SHAMAL Cat BORA EN 0214 9041241Document8 pages201 SHAMAL Cat BORA EN 0214 9041241carlosNo ratings yet

- Shanghai Durable Machinery Co., LTD.: Atlas Copco Bolaite Air CompressorDocument18 pagesShanghai Durable Machinery Co., LTD.: Atlas Copco Bolaite Air CompressorJafarov VuqarNo ratings yet

- Product Description GA 55-75 AntwerpDocument8 pagesProduct Description GA 55-75 AntwerpramonNo ratings yet

- 2021 Catalog CGAP R22 R407C 50HzDocument5 pages2021 Catalog CGAP R22 R407C 50HzhemantNo ratings yet

- RS-D and RSF-D Series With Direct Drive: RENNER - The Expert in Screw CompressorsDocument10 pagesRS-D and RSF-D Series With Direct Drive: RENNER - The Expert in Screw CompressorstitiNo ratings yet

- Two-Stage Fixed Speed Screw Air Compressor - UCSDocument6 pagesTwo-Stage Fixed Speed Screw Air Compressor - UCSRUN GONo ratings yet

- DRE - English enDocument8 pagesDRE - English envijaykmjNo ratings yet

- Portable Air Compressor: EXPORT-Air-Compressors-C185-T2.indd 1 4/25/2013 2:19:34 PMDocument4 pagesPortable Air Compressor: EXPORT-Air-Compressors-C185-T2.indd 1 4/25/2013 2:19:34 PMalex limachiNo ratings yet

- Packaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzDocument8 pagesPackaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzMavista TechnicNo ratings yet

- FFO OR RM MU Ulla A: Rotary Screw CompressorsDocument8 pagesFFO OR RM MU Ulla A: Rotary Screw CompressorsQco MyNo ratings yet

- Elgi EG 90 160kW 50Hz D I PDFDocument8 pagesElgi EG 90 160kW 50Hz D I PDFMAZENNo ratings yet

- EG Series Screw Air Compressors: Life Source of IndustriesDocument8 pagesEG Series Screw Air Compressors: Life Source of Industriespadhu_pNo ratings yet

- 38au 7 25 03PDDocument60 pages38au 7 25 03PDhccingeniriasasNo ratings yet

- CompAir D75-275RSDocument8 pagesCompAir D75-275RSIbram GunarsaNo ratings yet

- 27 1 15 L07 L22 RS Brochure GBDocument8 pages27 1 15 L07 L22 RS Brochure GBjennlin.changNo ratings yet

- S3378 1217Document12 pagesS3378 1217eliot martinezNo ratings yet

- 50VT 16PD CPDocument40 pages50VT 16PD CPJesmar VonNo ratings yet

- RS (F) - PRO 3,0 Â 18,5 - Brochure - ENDocument16 pagesRS (F) - PRO 3,0 Â 18,5 - Brochure - ENRUN GONo ratings yet

- Reliability & Efficiency Without Compromise: L30 - L45 L30 - L45 L30RS - L45RSDocument8 pagesReliability & Efficiency Without Compromise: L30 - L45 L30 - L45 L30RS - L45RSRon Don jrNo ratings yet

- CSM MAXI CompressorDocument8 pagesCSM MAXI Compressorandy131078No ratings yet

- XAS 146-186pb enDocument6 pagesXAS 146-186pb enSergei KurpishNo ratings yet

- 38RMDocument26 pages38RMMohamed SaadAllah67% (3)

- 04 Oil-Free Auxiliary Piston LFPR, LFXRDocument2 pages04 Oil-Free Auxiliary Piston LFPR, LFXRSerban Aurel CosminNo ratings yet

- SM Series Kaeser CompressorrenDocument16 pagesSM Series Kaeser CompressorrenarieprachmanNo ratings yet

- V1 019 04 EN - WebDocument32 pagesV1 019 04 EN - Web3238NDNo ratings yet

- What's: Fluids HandlingDocument4 pagesWhat's: Fluids HandlingRaul TejedaNo ratings yet

- Static Blower: FDN-H Series FGN-H SeriesDocument7 pagesStatic Blower: FDN-H Series FGN-H SeriesAung Thiha SoeNo ratings yet

- Turbair Blower (Type RT)Document2 pagesTurbair Blower (Type RT)Amir AbbaszadehNo ratings yet

- Mobilair M 100: Portable CompressorsDocument8 pagesMobilair M 100: Portable CompressorsJosue Neftali VargasNo ratings yet

- Rooftop Units: Lennox Landmark 50HzDocument8 pagesRooftop Units: Lennox Landmark 50HzMatias AcuñaNo ratings yet

- Catalog Stationary Screw Compressors A en V 1 2 WebDocument24 pagesCatalog Stationary Screw Compressors A en V 1 2 WebRoman ChubaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Brahma Pumps MaintananceDocument19 pagesBrahma Pumps MaintanancePavel SokolovNo ratings yet

- 01 Hydraulic Diagram U4 PHCDocument1 page01 Hydraulic Diagram U4 PHCPavel SokolovNo ratings yet

- 6991 1321 01b AHB (Diatest PHC)Document27 pages6991 1321 01b AHB (Diatest PHC)Pavel SokolovNo ratings yet

- 15hu Hydraulic Schematic DE130 55kW - 1502Document1 page15hu Hydraulic Schematic DE130 55kW - 1502Pavel SokolovNo ratings yet

- 01 Hydraulic Diagram U4 PHCDocument1 page01 Hydraulic Diagram U4 PHCPavel SokolovNo ratings yet

- T Series Engines OHbk - Issue 5Document44 pagesT Series Engines OHbk - Issue 5christiam tevesNo ratings yet

- 262 Crawler Hydr DiagramsDocument2 pages262 Crawler Hydr DiagramsPavel SokolovNo ratings yet

- Test Bank For Equipment Theory For Respiratory Care 5th Edition by WhiteDocument28 pagesTest Bank For Equipment Theory For Respiratory Care 5th Edition by WhitebridgetlinhhlehNo ratings yet

- Air Brake ManualDocument81 pagesAir Brake ManualBageNo ratings yet

- John Crane-Up-Stream-Pumping-BrochureDocument3 pagesJohn Crane-Up-Stream-Pumping-BrochureManuel GarciaNo ratings yet

- Module 14 Sample QuesDocument37 pagesModule 14 Sample QuesPiyush100% (1)

- Oil Injected Rotary Screw Compressors With Direct Transmission, Fixed or Variable SpeedDocument12 pagesOil Injected Rotary Screw Compressors With Direct Transmission, Fixed or Variable SpeedDewanjee AshrafNo ratings yet

- Chapter 6 I Law For Control Volume: ME1100 Thermodynamics Lecture Notes Prof. T. SundararajanDocument12 pagesChapter 6 I Law For Control Volume: ME1100 Thermodynamics Lecture Notes Prof. T. Sundararajanmechmuthu1No ratings yet

- Manual de Service Mitsubishi ELectric SEZ MDocument50 pagesManual de Service Mitsubishi ELectric SEZ MCutare ZafycomNo ratings yet

- Midea MSV1 07 09 12HRN1 CRN1Document37 pagesMidea MSV1 07 09 12HRN1 CRN1Giselma ZéoNo ratings yet

- Unior 1561 Pistol PneumaticDocument4 pagesUnior 1561 Pistol PneumaticVladimir ArsicNo ratings yet

- Quiz BowlDocument10 pagesQuiz BowlponcatoeraNo ratings yet

- Aeropress XR 46Document1 pageAeropress XR 46NESNo ratings yet

- 2 of 3 (Process Simulation) How To Do It RightDocument24 pages2 of 3 (Process Simulation) How To Do It RightErwinApriandiNo ratings yet

- Models For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationDocument11 pagesModels For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationElias TascaNo ratings yet

- (Part 1) M-Thermal 12&14kw (3 Phase) Technical Manual - System OutlineDocument22 pages(Part 1) M-Thermal 12&14kw (3 Phase) Technical Manual - System OutlineSerban TiberiuNo ratings yet

- Part No.: 88290006-541 Date: March, 2003Document66 pagesPart No.: 88290006-541 Date: March, 2003Rheza Putra AprilianNo ratings yet

- Pros and Cons of Different Light Mast TechnologiesDocument3 pagesPros and Cons of Different Light Mast Technologiestonystark axcelNo ratings yet

- TutorialDocument32 pagesTutorialCorrado MulasNo ratings yet

- LDocument5 pagesLAditi DasNo ratings yet

- Unit Pmcc-Unit-1: LT CableDocument2 pagesUnit Pmcc-Unit-1: LT CableSwagat PradhanNo ratings yet

- Solar Thermal Air Conditioning Technology Reducing The FootprintDocument32 pagesSolar Thermal Air Conditioning Technology Reducing The FootprintIBRAHIM UMAR ALISJAHBANANo ratings yet

- Aeon 4000Document2 pagesAeon 4000SAUL OSPINONo ratings yet

- Sala FormatDocument82 pagesSala FormatLemuel ReñaNo ratings yet