Professional Documents

Culture Documents

Gar 11-37

Uploaded by

moisesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gar 11-37

Uploaded by

moisesCopyright:

Available Formats

Atlas Copco

Railway Air Systems

Oil-injected Screw Compressor GAR 11-37

1

2 6

2

5 7

4 8

3

1 The Full Feature variant includes integrated filters and a 5 High efficiency, totally enclosed fan-cooled (TEFC), IP 55, class F

membrane dryer which removes oil and water vapor from the electric railway motor for continuous trouble-free operation with

compressed air to protect your air piping network and braking greased for life bearings

system from freezing and corrosion

6 Heavy duty air intake filter for efficient operation in dusty

2 Optimally sized, high-efficiency aluminum cooler provides ideal environments

compressor running temperature under all conditions

7 Multi-Stage, highly corrosion resistant oil separator, with a low,

3 High precision gears manufactured according to DIN 3961/class 6. 3 ppm oil carry-over, reduces contamination and maintenance

Gears are oil lubricated and temperature controlled by the requirements

compressor oil

8 Atlas Copco’s patented screw compression element for optimal

4 Integrated cooling fan to optimize the airflow, which ensures that energy efficiency and outstanding reliability

the right amount of cooling air is delivered efficiently to where it

is needed with a minimum of noise

Features and Benefits

Compact, Space-Saving Design Reliability & Durability

▸▸ Air dryer, filters and control integrated in a very compact compressor ▸▸ Minimum amount of moving parts

package ▸▸ Use of corrosive resistant materials like stainless steel and aluminum

▸▸ Integrated fan concept ▸▸ Long service intervals

▸▸ Minimum footprint ▸▸ Gear driven

Enduring Performance Flexible & Easy Installation

▸▸ The compressor is designed, built and tested to meet the toughest ▸▸ Plug and play system

conditions in railway applications (extreme climatic conditions, ▸▸ Easy to adapt cooling flow directions

high humidity and shocks & vibrations) ▸▸ Mainly used inside a railway vehicle

▸▸ Built in accordance with all relevant international norms & standards for

railway applications

Options

Different Drives Load/Unload Valve Heating Kit

The compressor can be equipped with different To be able to control the compressor in different To be able to run the compressor in ambient

drives, like an AC motor, DC motor, hydraulic applications temperatures between -40°C and -25°C

drive or pully

Control Pressure Switch Motor Starter

Control Voltage Connector To regulate the compressor according to air Y/D or DOL

To easily connect the control voltage lines demand by measuring the pressure in the

system Customized Frame

Motor Voltage Connector To easily integrate the complete package into

To easily connect the power voltage lines Alarm Pressure Switch the available space envelop in, under or on top

To signalize the compressor is still under of the railway vehicle

Condensate Tank pressure and prevent the compressor from

To collect the condensate from the filtration line restarting too soon against a too high

back-pressure in case of power supply

OSC interruption

To treat the condensate from the filtration line

Anti Rotation Switch

Different Approvals To signalize the compressor is running and to

CE, ASME, SQL prevent the compressor from running in the

opposite direction due to a fase switch of the

electro motor

dP-switch Inlet Filter

For remote signaling in case the inlet filter

is clogged

Technical Specifications

Installed motor Sound pressure

Compressor Capacity* Pressure** Weight

power level

type

l/s l/min cfm kW hp bar(e) psig dB(A) kg lbs

50 Hz version

GAR 11 20.4 1224 43.2 11 15 10 145 70 309 681

GAR 15 29.5 1770 62.5 15 18.5 10 145 71 333 734

GAR 18 35.4 2124 75.0 18.5 22 10 145 72 333 734

GAR 22 45.1 2706 95.6 22 30 10 145 76 333 734

GAR 30 61.3 3678 129.9 30 37 10 145 77 381 840

60 Hz version

GAR 11 18.9 1134 40.0 11 15 10 145 72 309 681

GAR 15 27.8 1668 58.9 15 18.5 10 145 73 333 734

GAR 18 39.7 2382 84.1 18.5 22 10 145 74 333 734

GAR 22 45.8 2748 97.0 22 30 10 145 79 333 734

2935 0949 40 – Printed in Belgium – Subject to alteration without prior notice.

GAR 30 58.2 3492 123.3 30 37 10 145 80 381 840

GAR 37 69.0 4140 146.2 37 45 10 145 81 392 864

* Unit performance measured at a standard unit (before dryer) according to ISO 1217, Reference conditions:

Annex C, latest edition Absolute inlet pressure: 1 bar (14.5 psi)

** Outlet pressures possible between 6 and 13 bar Intake air temperature: 20ºC (68ºF)

Effective working pressure: 9.5 bar (138 psi)

Mean noise level measured according to ISO 2151/Pneurop/Cagi PN8NTC2 at 4.6 meter

free field

Never use compressed air as breathing air without prior

purification in accordance with local legislation and standards. www.atlascopco.com

You might also like

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Atlas Copco: Railway Air Systems Oil-Injected Screw Compressor GAR 5-14Document2 pagesAtlas Copco: Railway Air Systems Oil-Injected Screw Compressor GAR 5-14JORGENo ratings yet

- 05 Oil Injected Screw GAR 5-14Document2 pages05 Oil Injected Screw GAR 5-14Pavel SokolovNo ratings yet

- 06 Oil Injected Screw GAR 11-37-2Document2 pages06 Oil Injected Screw GAR 11-37-2RUN GONo ratings yet

- TR5010 1Document2 pagesTR5010 1Yellow FalconNo ratings yet

- Atlas Copco piston compressor guideDocument2 pagesAtlas Copco piston compressor guideSerban Aurel CosminNo ratings yet

- G3516 LeDocument4 pagesG3516 Lericva_rj100% (3)

- Tasplgd6346 1 V.KDocument8 pagesTasplgd6346 1 V.KPragnesh PrajapatiNo ratings yet

- Turbair Blower (Type RT)Document2 pagesTurbair Blower (Type RT)Amir AbbaszadehNo ratings yet

- G3520C Spec - 1972 KweDocument4 pagesG3520C Spec - 1972 KweAnonymous 5m1EMDc6idNo ratings yet

- Manual OyM - Compresor 900hDocument2 pagesManual OyM - Compresor 900hCARLOSNo ratings yet

- Atlas Copco Marine Air System MAS (+) GA5+-11Document2 pagesAtlas Copco Marine Air System MAS (+) GA5+-11mahdiNo ratings yet

- ATLAS COPCO SFR 2-12 OIL-FREE SCROLL COMPRESSORDocument2 pagesATLAS COPCO SFR 2-12 OIL-FREE SCROLL COMPRESSORerfan ahmedNo ratings yet

- SC33 50HZ Cummins GeneratorDocument4 pagesSC33 50HZ Cummins GeneratorChen CarolineNo ratings yet

- Diesel Generating Set 330 kVADocument4 pagesDiesel Generating Set 330 kVADefly GustiNo ratings yet

- Natural Gas ContinuousDocument7 pagesNatural Gas ContinuousIbrar HussainNo ratings yet

- STG FPT 65kvaDocument2 pagesSTG FPT 65kvamohamadNo ratings yet

- SC88 Cummins GeneratorDocument4 pagesSC88 Cummins GeneratorChen CarolineNo ratings yet

- Rotrex Technical Datasheet EK10 Rev2.2Document8 pagesRotrex Technical Datasheet EK10 Rev2.2trebeheiramNo ratings yet

- COMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteDocument2 pagesCOMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteCAROLINA MONGUINo ratings yet

- 06D, e 3PDDocument24 pages06D, e 3PDAlberto Saul Rivero PlazaNo ratings yet

- Oil-Injected Rotary Screw Compressors: GA 355-500 (355-500 KW / 450-700 HP)Document8 pagesOil-Injected Rotary Screw Compressors: GA 355-500 (355-500 KW / 450-700 HP)Siva SubramaniyanNo ratings yet

- G3516e 2000Document6 pagesG3516e 2000Zaineb ElhamdiNo ratings yet

- CAT-CWS-1902 (McQuay VRA Added) PDFDocument36 pagesCAT-CWS-1902 (McQuay VRA Added) PDFIsmi IQasuNo ratings yet

- Sigma Frequency Control: SFC Series 18 To 515Document6 pagesSigma Frequency Control: SFC Series 18 To 515Alvaro Ortiz CruzNo ratings yet

- Cg-Prc009-E4 0601Document24 pagesCg-Prc009-E4 0601JX SNo ratings yet

- Power Your Future 4B3.9-G Cummins GeneratorDocument3 pagesPower Your Future 4B3.9-G Cummins GeneratorEman EdlesNo ratings yet

- CSM MAXI CompressorDocument8 pagesCSM MAXI Compressorandy131078No ratings yet

- Especificaciones Del 375Document2 pagesEspecificaciones Del 375jordan navarroNo ratings yet

- SC315 60HZ Cummins Generator STAMFORDDocument4 pagesSC315 60HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Brosur Datasheet Cummins - 150 Kva Prime Sae 165 SilentDocument6 pagesBrosur Datasheet Cummins - 150 Kva Prime Sae 165 SilentPusat GensetNo ratings yet

- TCMO 28 CompresorDocument2 pagesTCMO 28 CompresorLuis FuenmayorNo ratings yet

- STG Perkins 135kvaDocument2 pagesSTG Perkins 135kvaromeo ramirez100% (1)

- Cat 3520 Gas EngineDocument3 pagesCat 3520 Gas EngineJafarShojaNo ratings yet

- Sullair 900electricDocument2 pagesSullair 900electricchavezramirez.carlosdanielNo ratings yet

- CSA VSD Brochure 2Document4 pagesCSA VSD Brochure 2fachjrianNo ratings yet

- CSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorDocument6 pagesCSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorVolodymуr VorobetsNo ratings yet

- Qsl9G: Gas Compression ApplicationsDocument4 pagesQsl9G: Gas Compression ApplicationsRio YusufNo ratings yet

- Screw Compressors: Complex Needs - Smarter SolutionsDocument2 pagesScrew Compressors: Complex Needs - Smarter SolutionsMauricioNo ratings yet

- ACDS-R410A-50-60Hz MS0495C 0315 CsDocument40 pagesACDS-R410A-50-60Hz MS0495C 0315 CsMARCOSNo ratings yet

- C3000 50HZ Cummins Generator STAMFORDDocument4 pagesC3000 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Technical PG620 (Rev)Document7 pagesTechnical PG620 (Rev)W Winarto100% (1)

- AIRCENTER CatálogoDocument8 pagesAIRCENTER CatálogojesuskohNo ratings yet

- Lehe1612 04Document10 pagesLehe1612 04mvlNo ratings yet

- Diesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ Data Center ContinuousDocument4 pagesDiesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ Data Center ContinuousLwin PhyoNo ratings yet

- Air Cooled Screw Chiller - APSa VFD TypeDocument70 pagesAir Cooled Screw Chiller - APSa VFD TypeKhaleel ButtNo ratings yet

- Isotherm TurbocompressorsDocument6 pagesIsotherm TurbocompressorsStefanStanisavljavic100% (1)

- Cummins 1100 (50 HZ) : GensetsDocument3 pagesCummins 1100 (50 HZ) : Gensetskariem noweerNo ratings yet

- VHP Series Four L5794Gsi: With Esm2 and Empact Emission Control SystemDocument2 pagesVHP Series Four L5794Gsi: With Esm2 and Empact Emission Control Systemjordan navarroNo ratings yet

- Catálogo Compresores Baja Presion-AersenDocument32 pagesCatálogo Compresores Baja Presion-AersenJuan Camilo RestrepoNo ratings yet

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410ADocument12 pagesThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410AcarlosNo ratings yet

- File - 1918 - File0120 (1) .PDF - AeroserviciosDocument2 pagesFile - 1918 - File0120 (1) .PDF - AeroserviciosKazem QarebeiglooNo ratings yet

- C13 Genset BrochureDocument9 pagesC13 Genset Brochureeugene okohNo ratings yet

- New LK TB Cu Aircooled Had 3 22 PDFDocument58 pagesNew LK TB Cu Aircooled Had 3 22 PDFluisalonsomelendezNo ratings yet

- Packaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzDocument8 pagesPackaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzMavista TechnicNo ratings yet

- Screw Compressors: Complex Needs - Smarter SolutionsDocument2 pagesScrew Compressors: Complex Needs - Smarter SolutionsMauricioNo ratings yet

- DetentionDocument8 pagesDetentionLab RatNo ratings yet

- MODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocument4 pagesMODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDefly GustiNo ratings yet

- Automan enDocument4 pagesAutoman enNicolás CanelliNo ratings yet

- Technical Sheet QEP S10 50Hz 3p AVR CON ELR 12V3.0Document2 pagesTechnical Sheet QEP S10 50Hz 3p AVR CON ELR 12V3.0moisesNo ratings yet

- Technical Sheet QEP S14 50Hz 3p AVR CON ELR 12V3.0Document2 pagesTechnical Sheet QEP S14 50Hz 3p AVR CON ELR 12V3.0moisesNo ratings yet

- Technical Sheet QEP W210 50Hz 3p3.0Document2 pagesTechnical Sheet QEP W210 50Hz 3p3.0moisesNo ratings yet

- Compressor GAR 5Document10 pagesCompressor GAR 5moisesNo ratings yet

- Technical Sheet QEP S14 50Hz 3p AVR CON ELR 12V3.0Document2 pagesTechnical Sheet QEP S14 50Hz 3p AVR CON ELR 12V3.0moisesNo ratings yet

- QEP 8 50Hz 3p: EngineDocument2 pagesQEP 8 50Hz 3p: EngineKen VikstromNo ratings yet

- QEP 7 50Hz 3p ELR Product ReferenceDocument2 pagesQEP 7 50Hz 3p ELR Product ReferencemoisesNo ratings yet

- QEP 6 50Hz 1p ELR Technical SpecsDocument2 pagesQEP 6 50Hz 1p ELR Technical SpecsmoisesNo ratings yet

- Technical Sheet QEP 8 50Hz 3p AVR ELR3.0 PDFDocument2 pagesTechnical Sheet QEP 8 50Hz 3p AVR ELR3.0 PDFmoisesNo ratings yet

- Atlas Copco QIX 16-540Document8 pagesAtlas Copco QIX 16-540mkNo ratings yet

- Technical Sheet QEP 4 50Hz 1p3.0 PDFDocument2 pagesTechnical Sheet QEP 4 50Hz 1p3.0 PDFmoisesNo ratings yet

- QEP 7 50Hz 3p ELR Product ReferenceDocument2 pagesQEP 7 50Hz 3p ELR Product ReferencemoisesNo ratings yet

- DSE8620 Operators ManualDocument127 pagesDSE8620 Operators ManualAdalberto Moura Dos SantosNo ratings yet

- QEP 8 50Hz 3p: EngineDocument2 pagesQEP 8 50Hz 3p: EngineKen VikstromNo ratings yet

- QEP 6 50Hz 1p ELR Technical SpecsDocument2 pagesQEP 6 50Hz 1p ELR Technical SpecsmoisesNo ratings yet

- QEP 3.5 50Hz 1p: EngineDocument2 pagesQEP 3.5 50Hz 1p: EngineKen VikstromNo ratings yet

- Technical Sheet QEP 4 50Hz 1p3.0 PDFDocument2 pagesTechnical Sheet QEP 4 50Hz 1p3.0 PDFmoisesNo ratings yet

- Boosters Guide Brochure SpanishDocument8 pagesBoosters Guide Brochure SpanishDebora Daniela Sandoval SevenantsNo ratings yet

- 056-075 CS Lang TrainDocument1 page056-075 CS Lang TrainliberwiccaNo ratings yet

- Heatless Desiccant Dryers Leaflet English 2935 8850 03 PDFDocument2 pagesHeatless Desiccant Dryers Leaflet English 2935 8850 03 PDFmoisesNo ratings yet

- DSE8610 MKII Operator ManualDocument208 pagesDSE8610 MKII Operator ManualBruno Pessotti100% (1)

- Deep Sea Electronics: DSE4610 / DSE4620 Configuration Suite PC Software ManualDocument52 pagesDeep Sea Electronics: DSE4610 / DSE4620 Configuration Suite PC Software ManualSuhardiman100% (1)

- Doosan Infracore Engine Line Up Brochure PDFDocument8 pagesDoosan Infracore Engine Line Up Brochure PDFMariano MacchiNo ratings yet

- Atlas Copco Rock Drill Oil: An Environmentally Safe Lubricant That Combines Technology and EnvironmentDocument4 pagesAtlas Copco Rock Drill Oil: An Environmentally Safe Lubricant That Combines Technology and EnvironmentmoisesNo ratings yet

- Atlas Copco Rock Drill Oil: An Environmentally Safe Lubricant That Combines Technology and EnvironmentDocument4 pagesAtlas Copco Rock Drill Oil: An Environmentally Safe Lubricant That Combines Technology and EnvironmentmoisesNo ratings yet

- Storage Procedure For Caterpillar Products (0355, 7000) : ShutdownDocument21 pagesStorage Procedure For Caterpillar Products (0355, 7000) : Shutdownmoises0% (1)

- Catfines Paper 5510 0207 00 Web PDFDocument62 pagesCatfines Paper 5510 0207 00 Web PDFStefas Dimitrios100% (1)

- DSE8610 MKII Operator ManualDocument208 pagesDSE8610 MKII Operator ManualBruno Pessotti100% (1)

- PB-G-D1146 D1146T P086ti Pu086 Pu086t Pu086ti-65.99898 8108a-0403-EngDocument61 pagesPB-G-D1146 D1146T P086ti Pu086 Pu086t Pu086ti-65.99898 8108a-0403-Engezegol78595% (20)

- Service Parts List: Transmission 157TE30510-1 4266298Document64 pagesService Parts List: Transmission 157TE30510-1 4266298BALA100% (1)

- MLA PresentationDocument8 pagesMLA PresentationPaijo TejoNo ratings yet

- Destec G RangeBrochureDocument16 pagesDestec G RangeBrochureltrongluanvn100% (2)

- Automotive Transmission Systems: Course Plan and SyllabusDocument5 pagesAutomotive Transmission Systems: Course Plan and SyllabusRaja RamachandranNo ratings yet

- Tolerance and FitsDocument36 pagesTolerance and Fitsdevin wibowoNo ratings yet

- Edr 01 Dec 2018Document21 pagesEdr 01 Dec 2018AMALENDU PAULNo ratings yet

- Lube Oil Analysis ReportDocument11 pagesLube Oil Analysis ReportPhilic RohitNo ratings yet

- Fmea HXDocument2 pagesFmea HXNora NaranjoNo ratings yet

- LPA In-Line Pumps Extension Series 50HzDocument4 pagesLPA In-Line Pumps Extension Series 50Hzmarpaung saberindoNo ratings yet

- Sherco Motorcycle Assembly InstructionsDocument48 pagesSherco Motorcycle Assembly Instructionshermenegildo99No ratings yet

- Three Hinge ArchDocument12 pagesThree Hinge ArchnicholasNo ratings yet

- HDH Desalination PDFDocument20 pagesHDH Desalination PDFDianita Citra Dewi100% (1)

- Hanger SupportsDocument18 pagesHanger SupportsPeterDoner100% (1)

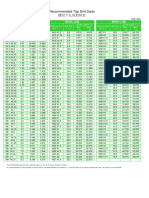

- Recommended Tap Drill SizesDocument4 pagesRecommended Tap Drill SizesJason-chungNo ratings yet

- Control Valve Dx28 Solar III 20287132gDocument58 pagesControl Valve Dx28 Solar III 20287132gAlejandro Mayr100% (1)

- Design and Optimization of A Centrifugal Pump Impeller With Ansys - OptislangDocument3 pagesDesign and Optimization of A Centrifugal Pump Impeller With Ansys - OptislangHayderAlSamawiNo ratings yet

- Lab 5: Pelton Turbine ENGR 3471 - Fluid Mechanics LaboratoryDocument4 pagesLab 5: Pelton Turbine ENGR 3471 - Fluid Mechanics LaboratoryMD Al-AminNo ratings yet

- Product Information on Servo-Hydraulic Load FramesDocument3 pagesProduct Information on Servo-Hydraulic Load FramesAnilNo ratings yet

- FEDR15180 - Discharge Nozzle 180º FEDRxx180 - Rv04Document3 pagesFEDR15180 - Discharge Nozzle 180º FEDRxx180 - Rv04EMMA VIDALNo ratings yet

- Avesta Nicrmo-3: Welding Wire TigDocument1 pageAvesta Nicrmo-3: Welding Wire TigKathir VelNo ratings yet

- Shaft LayoutDocument21 pagesShaft LayoutAmmar SafwtNo ratings yet

- General Service Checklist - BIKE PDFDocument7 pagesGeneral Service Checklist - BIKE PDFmanasNo ratings yet

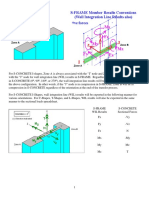

- Wall Integration Conventions S-CONCRETE R11 S-FRAMEDocument3 pagesWall Integration Conventions S-CONCRETE R11 S-FRAMESyed RaziuddinNo ratings yet

- Bus Bid Sheet With Cross RefDocument56 pagesBus Bid Sheet With Cross ReftylerNo ratings yet

- Theme 2 Newtonian Mechanics Part 1Document9 pagesTheme 2 Newtonian Mechanics Part 1Iedah Mohd100% (2)

- Tucson 2010Document92 pagesTucson 2010edi100% (1)

- Investigation of Vibration Isolation Performance of Trench Type Wave BarriersDocument111 pagesInvestigation of Vibration Isolation Performance of Trench Type Wave Barriersonur.toygarNo ratings yet

- ZF 5HP19HL PDFDocument4 pagesZF 5HP19HL PDFwilderNo ratings yet

- Hydro Jetting Machine CatalogueDocument19 pagesHydro Jetting Machine Cataloguehydro jetting machine pressure jetNo ratings yet

- AMERICAN Pipe Manual Linings and Coatings 5 24 21Document15 pagesAMERICAN Pipe Manual Linings and Coatings 5 24 21Ludi D. LunarNo ratings yet