Professional Documents

Culture Documents

STG FPT 65kva

Uploaded by

mohamadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STG FPT 65kva

Uploaded by

mohamadCopyright:

Available Formats

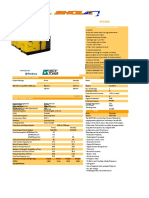

STANDARD SPECIFICATIONS ENGINE / TECHNICAL DATA

65 KVA

1. ENGINE

FPT/IVECO four stroke heavy duty high

Engine Make IVECO/FPT

performance industrial type diesel

engine. Engine Model N45 SM1A

Governing class Mechanical

2. ENGINE FILTRATION SYSTEM Number of Cylinders 4

• Cartridge type dr Cylinder Arrangement in line

•

Bore and Stroke mm litres 104 x 132

• o

ave replaceable Displacement / Cubic Capacity 4.5

elements. Cycle Diesel 4 stroke

3. COOLING RADIATOR Combustion System Direct Injection POWERED

BY:

Radiator and cooling fan, complete with safety Compression Ratio 17.5:1

guards, designed to cool the engine at high Rotation Anti-clockwise, viewed on flywheel

ambient temperatures (consult your dealer for

Aspiration &b Cooling Turbocharged

de-ration factors).

Frequency and Engine Speed 50Hz & 1500rpm 60Hz & 1800rpm

4. EXHAUST SYSTEM Prime Standby Prime Standby

Silencer noise reduction level 14 (dB) Gross Engine Power kWm 54,5 60.0 61.0 67.0

Maximum allowable back 10.0 @50 Hz Fuel Consumption@ 50% load L/hr 7 - 8.2 -

pressure(kPa) @ 75% load L/hr 10.2 - 11.7 -

15.0 @60 Hz

@ 100% load L/hr 13.7 15 15.5 16.9

5. CIRCUIT BREAKER TYPE Total Lubrication System Capacity litres 12.8 12.8 12.8 12.8

3 pole MCB / MCCB (supplied disconnected 10 10 10 10

Total Coolant Capacity (radiator & hoses)

and without cables)

Exhaust Temperature:°C 483 483 385 -

CONTROL PANEL

Radiator Cooling Air Flow (Min): m 3 /sec 1.86 1.86 2.3 -

Make Deep Sea Combustion Air Flow: m3/min 4.33 - 5.77 -

Exhaust Gas Flow:kg/h 325 325 431 -

Model DSE6110/20 Fuel Tank Capacity:litres 160 160 160 160

The DSE6110 i s an Auto Start Control Module

and The DSE6120 is an auto mains(utility)

Failure Control Module for single gen-set applications. DIMENSIONS AND WEIGHT*

Both modules have been designed to work with

electronic engines providing advance engine Lengthmm Widthmm Heightmm Weight* kg ALTERNATOR DATA

monitoringand protection features.

1750 800 1310 778 Stamford

Make

• Transfer between mains(utility) and

* For skid mounted genset without enclosure Model UCI224E

generator power(DSE6120 only)

• Generator frequency KVA 60

• Underspeed, Overspeed KW 48

• Generator volts (L-L, L-N) No. of bearings 1

• Generator current Insulation class H

• Engine oil pressure Output Ratings Prime Standby Total Harmonic Content in linear load <5% , at no load < 1.5%

• Engine coolant temperature Winding Leads 12

380-415 V, 3 ph, 50 Hz, 1500 rpm 58.83 KVA 64.71 KVA

• Fuel level (Warning or shutdown) Ingress Protection IP23

47.06 KW 51.77 KW Excitation System SHUNT

• Hours run counter

• Battery volts 480 V, 3 ph, 60 Hz, 1800 rpm 59.16 KVA 65.08 KVA Winding Pitch 2/3

• Fail to start/stop AVR Model SX460

47.33 KW 52.06 KW

Overspeed 2250 mn-1

• Emergency stop

Voltage Regulation ±1%

• Failed to reach loading voltage/frequency Applicable Voltages: 220/127 V at 60 Hz only (Consult your dealer for more details)

Short Circuit Capacity -

• Charge fail Ratings at 0.8 Power Factor

• Loss of magnetic pick-up signal

• Low DC voltage

• CAN diagnostics and CAN fail/error

The image shown above might not be the final product

STANDARD SPECIFICATIONS

6. FUEL SYSTEM AVAILABLE OPTIONS & ACCESSORIES

RATINGS DEFINITION

On Generating Sets up to 2000 KVA, the We offer a range of optional features and accessories to tailor our

base frame design can be incorporated with Prime Power generating sets to meet your power needs.

an integral fuel tankwith a capacity of

approx. 8 hours running at Full Load. The These ratings are applicable for supplying continuous electrical

breather fuel feed and return lines to the

power (at variable load) in lieu of 2280.0 980.0

Engine and drain plug. commercially purchased power. 10% overload power is available

for 1 hour in 12 hours continuous

7. ALTERNATOR operation.

7.1 INSULATION SYSTEM

Standby Power

• The insulation system is Class H.

• All windings are impregnated in either a triple These ratings are applicable for supplying continuous electrical

1450.0

dipthermosetting liquid, oil and acid resisting

polyester varnish or vacuum pressure

power (at variable load) in the event of a

impregnated with a special utility power failure. No overload is permitted on these ratings.

polyester resin.

STANDARD REFERENCE CONDITIONS

• Heavy coat of antitracking varnish additional

protection against moisture. Output ratings are presented at 25°C air inlet temperature,

barometric pressure 100 kPa, relative humidity 30%. This

7.2 AUTOMATIC VOLTAGE REGULATOR (AVR)

The fully sealed Automatic Voltage Regulator generating set is designed to operate at high ambient

maintains the Voltage Regulation at ±0.5%. temperatures (up to 55°C), humidity (up to 99%) and 1750

Nominal adjustment by means of a trim pot altitudes. De-ration may apply,please consult your dealer for

incorporated on the AVR.

7.3 MOTOR STARTING an overload capacity

STAUNCH Generators are assembled Some of the

equivalent to 300% of the Full Load impedance at

zero Power Factor can be sustained for 10 l Genset models. in

seconds. tion in this 1310

document is substantially correct at time of printing and

8. MOUNTING ARRANGEMENT may be altered subsequently.

8.1 BASE FRAME Generating Set pictured may include optional accessories.

The complete Generating Set is mounted as a

whole on a heavy duty fabricated steel STAUNCH

Baseframe. 11. DOCUMENTATIONS a set of Operation & Maintenance 800

manual, Circuit wiring diagrams and Commissioning / Fault

8.2 COUPLINGThe Engine and Alternator are ny the Generator.

12. QUALITY STANDARDS The equipment meets the

ACCESSORIES

Alternator rotor.

following standards: BS4999, BS5000, BS5514 IEC 60034,

8.3 ANTI-VIBRATION MOUNTING PADS anti- VDE0530, NEMA MG 1.22 and ISO 8528. • switches

Vibration • Load banks

Alternator feet and the Baseframe thus ensuring 13. WARRANTY All of the Generating Sets are covered • Auxiliary fuel tanks

complete vibration isolation of the rotating under a warranty policy for a period of 12 months. Warranty

assembly.The Fan & Fan Drive along with the of the equipment is in line with manufacturers warranty

• Manual & automatic

Battery Charging

terms & conditions. • Genuine spare partstransfer

8.4 SAFETY GUARDS The Fan & Fan Drive along

with the Battery Charging Alternator are Safety (check warranty statement for more details, as it may vary

Guard protected for personal protection. for different countries)In line with continuous product OPTIONS

development, we reserve the right to change s ations

9. FACTORY TESTS without notice. • Water jacket heater

• The Generating set is load tested before • A variety of generating set

dispatch • Additional protection alarms

• All protective devices control functions and site For further information on all of the standard

load conditions are simulated. The generator and and optional features accompanying this • Water fuel seperator control and synchronizing and

it’s systems are checked before dispatch. product please contact your local dealer or visit: shutdowns

10.EQUIPMENT FINISHING all mild steel

• panels

WWW.STAUNCHMACHINERY.COM

components are fully degreased and painted with • Battery charger

powder coated paint to ensure maximum scuff

resistance and durability.

You might also like

- 250KVA Generator Specs and DataDocument2 pages250KVA Generator Specs and DataShahzad Ali100% (1)

- STG Perkins 135kvaDocument2 pagesSTG Perkins 135kvaromeo ramirez100% (1)

- 50 kVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P50-T1-50 PDFDocument5 pages50 kVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P50-T1-50 PDFTifano KhristiyantoNo ratings yet

- SC88 Cummins GeneratorDocument4 pagesSC88 Cummins GeneratorChen CarolineNo ratings yet

- Flyer 60kva PDFDocument4 pagesFlyer 60kva PDFgymbehNo ratings yet

- MPG-60 KVA-PK generatorDocument4 pagesMPG-60 KVA-PK generatorcafubodoNo ratings yet

- 65 KVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P65-T1-50Document5 pages65 KVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P65-T1-50Rizky UtomoNo ratings yet

- 65 KVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P65-T1-50Document5 pages65 KVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P65-T1-50Rizky UtomoNo ratings yet

- 250kw 50HZ Cummins Marine GeneratorDocument3 pages250kw 50HZ Cummins Marine GeneratorChen Caroline100% (1)

- MODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocument4 pagesMODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDefly GustiNo ratings yet

- 640kw Cummins Marine GeneratorDocument3 pages640kw Cummins Marine GeneratorChen CarolineNo ratings yet

- 80kw Cummins Marine GeneratorDocument3 pages80kw Cummins Marine GeneratorChen CarolineNo ratings yet

- G140X G140QXDocument7 pagesG140X G140QXKhawaja Kashif QadeerNo ratings yet

- 280kw Cummins GeneratorDocument3 pages280kw Cummins GeneratorChen CarolineNo ratings yet

- Lehm20288-00 Marine AuxiliaryDocument4 pagesLehm20288-00 Marine AuxiliaryDedi MaryadiNo ratings yet

- OE Spec MTU10V1600DS560 3D 50Hz 1 18Document5 pagesOE Spec MTU10V1600DS560 3D 50Hz 1 18Bao Le VietNo ratings yet

- Page: M-1 of M-8 © 2021 Caterpillar All Rights Reserved MSS-EPG-1160820256964075-002 PDFDocument8 pagesPage: M-1 of M-8 © 2021 Caterpillar All Rights Reserved MSS-EPG-1160820256964075-002 PDFDranreb Eric BersaminaNo ratings yet

- Boulevard 50 2T: Workshop ManualDocument154 pagesBoulevard 50 2T: Workshop ManualLasseBSætre100% (1)

- SS 30008689 1000028973 019Document7 pagesSS 30008689 1000028973 019Mohyedin Ganjian aboukheiliNo ratings yet

- 800kw Cummins Marine GeneratrorDocument3 pages800kw Cummins Marine GeneratrorChen CarolineNo ratings yet

- Diesel Engine - Marine Gen Set PowerDocument2 pagesDiesel Engine - Marine Gen Set PowerTaufan ArifNo ratings yet

- Diesel Generating Set 330 kVADocument4 pagesDiesel Generating Set 330 kVADefly GustiNo ratings yet

- SS 11240728 1000028919 129Document12 pagesSS 11240728 1000028919 129Samir YahiaNo ratings yet

- 62 5 Kva Silent DG SetDocument3 pages62 5 Kva Silent DG SetArjun GhoshNo ratings yet

- VTA28G6Document3 pagesVTA28G6chanchan100% (1)

- DC-850 60hzDocument2 pagesDC-850 60hzJunnie Alvin AgravanteNo ratings yet

- 4BTAA3.3-G12: EPA Tier 3 CertifiedDocument3 pages4BTAA3.3-G12: EPA Tier 3 CertifiedLawternay Stevaneli BritoNo ratings yet

- DPX-15703A - Perkins 66 kVA (1103A-33T)Document7 pagesDPX-15703A - Perkins 66 kVA (1103A-33T)Edwin GallegosNo ratings yet

- SPS400TALDocument2 pagesSPS400TALbereketNo ratings yet

- MODEL: SP110 Industrial Range Powered by Perkins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocument4 pagesMODEL: SP110 Industrial Range Powered by Perkins: Diesel Generating Set 400/230 V - 50 HZ - 3phasePM Gen careNo ratings yet

- APD66PDocument4 pagesAPD66PmhmmdNo ratings yet

- Reliable 45kVA Generating Set FeaturesDocument4 pagesReliable 45kVA Generating Set FeaturesSadiman SadimanNo ratings yet

- Atp 2000 4016tag2a Lsa 52.3S6Document2 pagesAtp 2000 4016tag2a Lsa 52.3S6Is LamNo ratings yet

- Cummins 125 KVADocument4 pagesCummins 125 KVAZein Ardha101No ratings yet

- APD10PDocument4 pagesAPD10PNayabNo ratings yet

- MTU 12V1600 DS730 400-230V 728 kVA Diesel GeneratorDocument5 pagesMTU 12V1600 DS730 400-230V 728 kVA Diesel GeneratorphuongNo ratings yet

- c4.4 Marine Genset SpecsheetDocument4 pagesc4.4 Marine Genset SpecsheetBilel Ben SlamaNo ratings yet

- CatalogueDocument4 pagesCatalogueRakeshNo ratings yet

- APD66PDocument4 pagesAPD66PThuyaNo ratings yet

- Design Specifications: Is Permitted On These Ratings. 12 Hour Period - Contact Us For The Other Running PeriodsDocument4 pagesDesign Specifications: Is Permitted On These Ratings. 12 Hour Period - Contact Us For The Other Running PeriodsmhmmdNo ratings yet

- VTA28-G5: Fuel OptimizedDocument3 pagesVTA28-G5: Fuel OptimizedIslam HemdanNo ratings yet

- JCB Diesel Generator Technical Specifications g60rxDocument7 pagesJCB Diesel Generator Technical Specifications g60rxDisdNo ratings yet

- WPG344Document4 pagesWPG344Kevin AndrianNo ratings yet

- 360KW Cummins Marine GensetDocument3 pages360KW Cummins Marine GensetChen CarolineNo ratings yet

- C3000 50HZ Cummins Generator STAMFORDDocument4 pagesC3000 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Generator Model: P 200: Prime Power 200 KVA 160 KWDocument4 pagesGenerator Model: P 200: Prime Power 200 KVA 160 KWMuhammad AtifNo ratings yet

- KP-F D XXGV OperationManual EDocument7 pagesKP-F D XXGV OperationManual EabathunNo ratings yet

- AQT 10 EditDocument3 pagesAQT 10 EditbassemNo ratings yet

- AQT 110 EditDocument3 pagesAQT 110 EditbassemNo ratings yet

- DEPCO DC-501 1800rpm - 1622605917Document2 pagesDEPCO DC-501 1800rpm - 1622605917Gab MercadoNo ratings yet

- Cummins 60 KVADocument4 pagesCummins 60 KVAMasri NurdinNo ratings yet

- Catalogo Planta Fawde Accc-Af25 0Document4 pagesCatalogo Planta Fawde Accc-Af25 0Jackson QuintinoNo ratings yet

- SS 10278979 1000028914 155Document12 pagesSS 10278979 1000028914 155Mohit electricalsNo ratings yet

- MODEL: SC1650 Industrial Range Powered by Cummins: Diesel Generating Set 440/254V - 60 HZ - 3phaseDocument4 pagesMODEL: SC1650 Industrial Range Powered by Cummins: Diesel Generating Set 440/254V - 60 HZ - 3phaseRonald BoocNo ratings yet

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Features: 70 Series - Line Monitoring RelayDocument9 pagesFeatures: 70 Series - Line Monitoring RelayGoran PanticNo ratings yet

- Accessories Leaflet enDocument4 pagesAccessories Leaflet enmohamadNo ratings yet

- SPD AcDocument2 pagesSPD AcmohamadNo ratings yet

- Pixsys ATR 142Document47 pagesPixsys ATR 142froilan ochoaNo ratings yet

- Autonics TCN Manual PDFDocument2 pagesAutonics TCN Manual PDFArturo ValentinNo ratings yet

- Finder Relays Series 60 PDFDocument6 pagesFinder Relays Series 60 PDFElenilson SampaioNo ratings yet

- Strainers enDocument51 pagesStrainers enmohamadNo ratings yet

- Powder 9 KGDocument2 pagesPowder 9 KGmohamadNo ratings yet

- 02-Cue 90 KWDocument5 pages02-Cue 90 KWmohamadNo ratings yet

- 12 KGDocument2 pages12 KGmohamadNo ratings yet

- Carbon SteelDocument29 pagesCarbon SteelmohamadNo ratings yet

- SPD AcDocument2 pagesSPD AcmohamadNo ratings yet

- Electrical Technician-Jad SalloumDocument3 pagesElectrical Technician-Jad SalloummohamadNo ratings yet

- NEF Series N67 TM4 165kW: Non Emissions CertifiedDocument3 pagesNEF Series N67 TM4 165kW: Non Emissions CertifiedmohamadNo ratings yet

- Plate Compactor stpc106dDocument1 pagePlate Compactor stpc106dmohamadNo ratings yet

- Delivery NoteDocument1 pageDelivery NotemohamadNo ratings yet

- Ind 21Document3 pagesInd 21mohamadNo ratings yet

- Tutorial 1Document1 pageTutorial 1Ashutosh TomarNo ratings yet

- 3.1 Stainless Steel Exhaust BellowsDocument5 pages3.1 Stainless Steel Exhaust Bellowsguichen wangNo ratings yet

- Screen Changer (10130061) - 20220822 - 201011Document4 pagesScreen Changer (10130061) - 20220822 - 201011Luissss Gonzalez VelazquezNo ratings yet

- Freudenberg-NOK Sealing Technologies OverviewDocument34 pagesFreudenberg-NOK Sealing Technologies Overviewprakash 3No ratings yet

- Dismantle, Inspect and Assemble DPA PumpDocument3 pagesDismantle, Inspect and Assemble DPA PumpNduati JohnNo ratings yet

- p3000 Englisch 03 2009Document9 pagesp3000 Englisch 03 2009Alejandro SorianoNo ratings yet

- Tapflo ManualDocument51 pagesTapflo ManualElkan Jeveshan NaidooNo ratings yet

- ROOT CAUSE ANALYSIS REPORT - R137Document3 pagesROOT CAUSE ANALYSIS REPORT - R137Karthii AjuNo ratings yet

- CAT Electric Drives Product Catalogue eDocument37 pagesCAT Electric Drives Product Catalogue eDaniel AnacletoNo ratings yet

- RG125F - 92-94 Vues EclateesDocument125 pagesRG125F - 92-94 Vues EclateesJacquetNo ratings yet

- Codigos DD15Document32 pagesCodigos DD15JuanChanNo ratings yet

- JCB Original Spare Parts ListDocument4 pagesJCB Original Spare Parts ListTarang agrawalNo ratings yet

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 216Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 216Andi KaNo ratings yet

- Volvo Trucks MID Fault CodeDocument1 pageVolvo Trucks MID Fault CodeJan Svein HammerNo ratings yet

- Tata Motors Presentation SlideDocument7 pagesTata Motors Presentation SlideOmor FarukNo ratings yet

- Clark PWD 36 Forklift Service Repair ManualDocument20 pagesClark PWD 36 Forklift Service Repair ManualkfsmmeNo ratings yet

- Pulsar N-160 BS6 - SPCDocument78 pagesPulsar N-160 BS6 - SPCrefaccionariabajaj.camp267% (3)

- Afex Caterpillar-D11tDocument1 pageAfex Caterpillar-D11tenricoNo ratings yet

- 2015 Ram 2500 4WD Crew Cab 149 SLT in Indianapolis, in Indianapolis RAM Ram 2500 Tom O'Brien CJDR - IndianapolisDocument1 page2015 Ram 2500 4WD Crew Cab 149 SLT in Indianapolis, in Indianapolis RAM Ram 2500 Tom O'Brien CJDR - IndianapolisCloud ZuriNo ratings yet

- Aw 55-50 Gearbox Parts + ConvertersDocument6 pagesAw 55-50 Gearbox Parts + ConvertersArkadiusz CieślaNo ratings yet

- RSNAV Installation GuideDocument21 pagesRSNAV Installation GuideDorin ValentinNo ratings yet

- CVT / TCM Calibration Data "Write" Procedure: Applied VehiclesDocument24 pagesCVT / TCM Calibration Data "Write" Procedure: Applied VehiclesАндрей ЛозовойNo ratings yet

- Avanza / Xenia starting ignition and charging systemsDocument1 pageAvanza / Xenia starting ignition and charging systemsArdina Praja MartantoNo ratings yet

- Quarry Drilling BrochureDocument14 pagesQuarry Drilling BrochureMindrillNo ratings yet

- Passion PRO Feb 2017Document262 pagesPassion PRO Feb 2017sudhirNo ratings yet

- Premium Heavy-Duty Diesel Engine Oil: Pertamina Meditran SX Ultra Gle SAE 15W-40 API CJ-4Document2 pagesPremium Heavy-Duty Diesel Engine Oil: Pertamina Meditran SX Ultra Gle SAE 15W-40 API CJ-4agnovNo ratings yet

- Impact (1) Can Controllers PDFDocument24 pagesImpact (1) Can Controllers PDFGeanie TawodzeraNo ratings yet

- Ford AOD E Transmission Service and Repair ManualDocument112 pagesFord AOD E Transmission Service and Repair ManualVictor FederNo ratings yet

- Manual Mercedes-Benz ML (2011) (389 Páginas)Document2 pagesManual Mercedes-Benz ML (2011) (389 Páginas)Enrique Martinez HerranzNo ratings yet

- Cooling Fan: Ymms: Jun 3, 2020 Engine: 2.0L Eng License: Vin: Odometer: 2016 Audi A6 PremiumDocument3 pagesCooling Fan: Ymms: Jun 3, 2020 Engine: 2.0L Eng License: Vin: Odometer: 2016 Audi A6 Premiumbyungchul kimNo ratings yet