Professional Documents

Culture Documents

Method Statement For Broken Anchor Bolt-Solomon Rev C

Method Statement For Broken Anchor Bolt-Solomon Rev C

Uploaded by

Mathias Onosemuode100%(1)100% found this document useful (1 vote)

310 views10 pagesOriginal Title

method statement for broken anchor bolt-solomon rev c

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

310 views10 pagesMethod Statement For Broken Anchor Bolt-Solomon Rev C

Method Statement For Broken Anchor Bolt-Solomon Rev C

Uploaded by

Mathias OnosemuodeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

EGP3 ONSHORE PROJECT

Method Statement

for

Repairs of Broken Anchor Bolt

on

Concrete Pedestals

DOCUMENT NO. : ONS-HHI-GP-PRO-ST-0012

ABIODUN

c | 01-Nov-07 | Issue FOR APPRovaL cw | cue

8 | 27-Oct-07 | issueroramprovat | apiopuN | Kw | CHP

A | 25-Sep-07 | issueroRarerovat | apioouN | «ws | CHP

rev | Date COMMENT onic [| cu | appr | Company

CONTRACTOR APPROVAL: COMPANY APPROVAL:

Ci Par Prot Manger REFERENO® ra

a

DATE: 01-Nov-07 _|pate: 21, Ope, 07

CONTRACTOR Doesment Number: Equipment Tag (irappicable)

COMPANY Document Number vrsiet | ovtater | AS! | type [we [S| tet

ngneering echnical ons mM ce | pro | st | on | F

EGP3 - Onshore Project - Method Statement — Repairs of Broken Anchor

Bolts on Conerete Pedestal. _

Revision Log

Rev, Date

a | 25-Sep-2007

Revised

Pages Revision Description

\ Issued for Approval

8 | 27-Oct-2007

1,6,10& 11 Issued for Approval

[CT Gi-Nov-2007

as67 ‘ssued Tor Approval

as

Page 2 079

EGP3 ~ Onshore Project - Method Statement — Repairs of Broken Anchor

Bolts on Concrete Pedestal.

TABLE OF CONTENTS

10 PURPOSE

20 SCORE

30. DEFINATION AND ABREVIATION

40. REFERENCES DOCUMENTS

50. RESPONSIBILITIES

60 PROCEDURE

Page 30f9

EGP3 - Onshore Project - Method Statement — Repairs of Broken Anchor

Bolts on Concrete Pedestal.

1. PURPOSE

This method statement identifies ang illustrates the sequence of operation and methodology trav

9

instalation erection of steel structure ie. while mounting the steet structure columns base plates to

‘would be used for the repairs of broken bolt on concrete pedestal that may accur either du

align with the conerete pedestal anchor bolts and properly clasped for fastening into place, manual

bolting by application of excessive tightening force andlor due 10 material defects not detected

‘uring manufacturer's factory quality control inspection, and during the civil constuction by the

pedestal concrete placement civil team at EGP3 Areas in order to transfer the load applied trom

the base plates onto the foundation

2. SCOPE

The scope of this method statement is from the identilication of a damaged or broken anchor bolt

‘within @ concrete pedestal to its safe removal, instalation of a new anchor bolt and repair of the

Concrete pedestal. It allows for the curing time of the concrete repair and acceptance by the client

3. DEFINITION AND ABBREVIATIONS

ONL, Chevron Nigeria timed

HH) Hyundai Heavy Industries Limited

SUBCONTRACTOR ED-OF Nig. Limited / IOMON

EGP 3 ESCRAVOS Gas Project Phase 3

awac Quality Assurance / Quality Contra!

HSE Health Safety ard Environment

wre inspection and Test Plan

Fc Issued for Construction

4. REFERENCE DODUMENTS

HHI Procedure

ONS-HHI-GP-PRO-CV-0010 Grouting Works

(ONS-HHI-GP-PRO-A-0027 Inspection Procedure for Civil Works

ONS-HHI-GP-PRO-CV-0018 Method Statement for Conerete Repair Works

(ONS-HHI.GP-PRO-QA.0087 Incpection & Test Ptan for erection of steel structures (!7P-S-002)

Page 4 0F9

EGP3 - Onshore Project - Method Statement — Repairs of Broken Anchor

Bolts on Conerete Pedestal.

RESPONSIBILITIES

HHI shall engure that the assigned Subcontractor implements the HES and quality standards

required by the contract, detailed in the appropriate industry codes, clients’ specications, HH!

procedures and this method statement during the execution of the work. Any deviation will be

brought to the clients’ attention promptly, documented and a consensus reached before

continuation of work

The Project Manager reports cirecly to the Project Director and has overall esponsialty for the

execution of the Project in accordance with the contract and the company Health & Safety Policy,

he is responsible for the implementation of Safely, Environment and Quallly procedures on site

supported by discipline managers who control site operations and subeontractars. The Steel

Structure (Construction) Manager in collaboration with the QA/|QC Manager shall monitor the

subcontractor’s compliance with this method statement during execution, HHI QA/QC inspectors.

will peform verification, inspection and test activities as defined in ONS-HHI-GP-PRO-QA.0087

Inspection & Test Plan for Erection of Steel Structure (ITP-S-002) and recard all deviations, repairs

and modifications

The subcontractors’ Project Manager (SCPM) has overall responsibilly for the execution of the:

assigned and subcontracted work scope, reporting direcly to the HHI Steel Structural Manager. He

's responsible for the Health, Safety. and Quality Contral of his assigned werk scaze during

execution. He is to nominate a QC Inspector to witness the repair activities to completion and

produce the final repor,

HHI PROJECT MANAGEMENT

Project Manager

He shall have overall control of the Project, His responsibilities include, but are not limited to the

followings:

‘+ Ensures the implementation of the specific Project Quality Plan throughout the duration of tha

Project, with the assistance of the Quality Control Manager

‘+ The Project Manager shall ensure that only suitably qualified personnel are assigned to the

Project

‘+ Accountable for overall Safely performance of personnel and the implementation and adoption

Of the IF principles on the Project.

Page 5 OF9

EGP3 - Onshore Project - Method Statement — Repairs of Broken Anchor

Bolts on Concrete Pedestal.

Steel Structure Manager

‘The Stee! Structure Manager shall coordinate the engineering activities related to the execution of

the activities within his discipline; he shall be assisted in executing these tasks by discipline

engineers. His responsibilies shall include but not be limited to the folowing:

‘+ Checking the compliance of wark executed in actordans

‘and contractual obligations

ith the Project quality requirernents

‘© Ensuring interdisciplinary coordination to improve the efficiency and effectiveness of personne!

under his control

Ensure the availabilty of current documents necessary for the execution of the work.

‘© As:buill mark up of construction issue drawings including any amendments and modifications

carried out in the fiels

‘+ He shall be responsible for inputs into scheduling activities,

Installation Supervisor

The installation supervisor has the responsi

lity of directing the subcontractor in the execution of

the work ensuring that the repairs are carried out in conformity with drawings and specifications and,

completed on schedule,

Quality Control inspector

The Quality Contiol Inspector shall monitor the application of this method statement and

compliance with HHI’s issued procedures by carrying out inspection activities prescribed by the

relevant ITP

6. PROCEDURE.

6.1 General

‘© When a concrete pedestal anchor bolt has been identified as being damaged andlor broken

and requiring repair, it shall be documented by the HHI QC inspector

+ The type and extent of damage shall be documented and where necessary photographs taken

“The proposed disposition of the concrete pedestal anchor boit will be agreed between HHI

‘Stee! Structural construction team, HHI Engineering and CNL The Proposed disposition shall

‘be documented by the HHI QC inspector and reviewed / approved by CNL prior to final

ecceptance.

+ Prior t9 commencement of the repair works, a barricade shall be put in place to control access.

tothe area

Page 6 OF9

EGP3 - Onshore Project - Method Statement — Repairs of Broken Anchor

Bolts on Concrete Pedestal.

‘+ The Concrete Pedestal in which the anchor bott is embedded shall be carefully driled using a

onerete Driling Machine, Thereafter, hand tools ( e.g. Chisel and Medium size Hammers}

shal be uses to break open the concrete pedestal, wth the driled holes as guide to expose

the reinforcement bars.

‘+ Mechanicaland tools shall be made available with all necessary safe guards for the

‘operation, the worker's safety and that af workers in the vicinity wil be considered by

conducting a specific risk assessment of the area and any necessary precautions shall be put

in place

‘+ Ifthe broken anchor bolt(s) are in a concrete pedestal with an already installed stee! structure

stanchion(s}, i shall be removes by dismantling for proper access.

+ During preparation and grouting repair works of the broken anchor bolts/pedestals, the

folowing guidelines shall be adopted in accordance with the Method Statement for Concrete

Repair Works (ONS-HHI-GP-PRO.CV-0018)

8). The Concrete Pedestal shall be carefuly marked-out by the Discipline Manager, showing

the driting points. Workers shall wear adequate PPE whilst driling, breaking and chipping.

the concrete pedestal, the pedestal mat into which the anchor bolt is embedded, brush

Cleaning of the broken ichipped surface and the pouring of the Concrete / mortar.

bb). The piece of the embedded broken anchor bolt shall be carefully detached from the

‘exposed reinforcement network, and a new anchor bolt shall be carefully set, bonded and

propery aligned in place by the Surveyor using necessary precision tools and instruments,

«)_ Brushes of good quality shall be available for cleaning the broken/chipped rough surface for

the application of the epoxy mortar onto the pedestal to ensure adequate bonding at the

interface of the fresh Concrete (C35) with the remaining Concrete Pedestal

d)_ The exposed re-enforcoment bars shall be power brushed to ciean metal to remove all

traces of rust and concrete residue. If this is insufficient to remove all the dobris, blast

cleaning shall be uses.

©), Wood formwork shail be bull, put in place and adequalely braced and supparied, iis to be

fiumly secured to prevent any movement during filing/pouring of the Conerete. The Epoxy

resin bonding agent is to be properly mixed and applied in accordance with tha

‘manufacturers instructions to ensure that the required adhesion/bonding level is attainment

Page 70f9

EGP3 - Onshore Project - Method Statement — Repairs of Broken Anchor

Bolts on Concrete Pedestal.

) The subcontractors QC Inspector shall check and confirm the survey points and formivork

has been carried out as specified before asking HHI QC inspector to verify. This "Hold"

point myst be correct before continuing

48). The stipuiated curing time tor she Structural grace Concrete (C35) shall be observed to

‘ensure adequate minimum strength required by he pedestal is attained before foad

placement va Erection and Installation of Stee! Structure Columns

+ On completion of the above processes, the Stee! Structure Stanchions earlier removed shall

be re-erected and properly installed by ensuring necessary alignments, plumb setting and

bolts snug-tightening checks. Thereatter, the formwork(s) for grouting shall be set in place on

the concrote pedestals aboul the Stee! Structure Stanchion’s base plate and grouting works:

carried out in accordance with the approved Method Statement for Grouting and Padding

(ONS-HHI-GP-PRO-ST-0008).

+ Grouting process shall ensure the gouge made for access to effect the removal ofthe broken

anchor ball piece from the concrete mat on top of which the pedestal is cast is adequately

filled with the flowable cementitious grout material and no air is trapzed.

The Steel Structure Manager shall ensure that only competent and skiled erectors are used in the

erection and bolt tightenizg of steel structural members in order to prevent future occurrence.

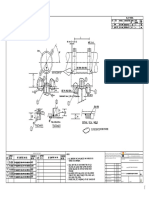

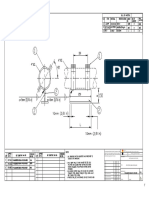

‘See the sketch below for the BROKEN ANCHOR BOLT removalirepfacement repairs.

Pose 80F9

EGP3 - Onshore Project - Method Statement ~ Repairs of Broken Anchor

Bolts on Concrete Pedestal.

Broken Anchor Bolt

Exposed Existing

(M32 X 680) to be replaced

Re-enforcement

Bar of the Pedestal

Cracked Broken Anchor Portion of Conorete Pedestal Coated with Epoxy

Resin bonding agent Ensures strong, durable bond between the old and the

new Concrete

CRACKING OF THE CONCRETE PEDESTAL FOR REMEOVAL / REPLACEMENT OF THE

BROKEN ANCHOR BOLT / RE-GROUTING

Broken Anchor Bolt to be replaced after eracking the concrete pedestal (All Dimension in mm),

Page 90f9

Page | of |

Nigec EGP3 Lead QA Engineer (L9esc1087-smb)

From: Mourad, Emad M [Contractor]

Sent: Monday, November 12, 2007 11:07 PM

To: —_Nigec EGP3 Lead QA Engineer (L9esc1087-smb)

Subject: RE: Concrete Pedestal Repair

Dave,

Looks ok, however | am litie concern about shipping concrete to replace # braken anchor in a small pedestal. | recommend

for small pedestal where the volume of removed conerete is relatively large to overall pedestal size, concrete of the entire

pedestal to be removed, then 10 be poured monolithically after replacing the bolt In larger pedestal or footing this procedure is

ick. Epoxy bondirg agent ( item “e” - section 6.1) should be used in all cases.

Regards,

Emad

From: Nigec EGP3 Lead QA Engineer (L9¢s¢1087-smb)

Sent: Fricay, November 02, 2007 7:30 AM

To: Mourad, Emad M [Contractor]

Ce: Nigec EGP3 Onshore Const MGR (L9esc991)

Subject: Concrete Padestal Repair

Emad,

Please find the attached draft Method Statement, ONS-HHI-GP-PRO-ST-0012 Rec-C, Repair of Concrete Pedestal with

Broken Anchor Bolt, HHI have prepared this document here at Escravos site with input and guidance from our EGP3 Team.

‘Would appreciate your review/comment of the dacument before we permit any repair work to commence.

Thanks and regards

DAVE OUTHWAITE

(Alternating with Mike Deere)

EGP3 Onshore Lead QA Engineer

Chevron Nigeria Limited

Escravos, Nigeria ESCRAVOS

(Office: +234 1367 6863, GAS PROJECT

(Mobile: +234 (0) 8055889108 PHASE 3

+Email L9esct087@chevron.com

Radio /D 726039 Call Sign EGP 62

‘This message may contain confidential information that is legally privileged and is intended only for the use of the parties to

whom itis addressed. If you are not an intended recipient, you are hereby notified that any disclosure, copying, distribution or

use of any information in this message Is strictly prohibited, If you receive this message in error, please notify me immediately

at the e-mailitelephone numbers above.

12/2/2007

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Topsides 1 - Equipment ListDocument22 pagesTopsides 1 - Equipment ListMathias OnosemuodeNo ratings yet

- Internal Blasting and Painting Procedure For Storage TankDocument31 pagesInternal Blasting and Painting Procedure For Storage TankMathias Onosemuode100% (3)

- Costing Steelwork #1: Offices FocusDocument7 pagesCosting Steelwork #1: Offices FocusMathias OnosemuodeNo ratings yet

- SPDC 5 CW327597 - NCDMB Commercial TemplateDocument21 pagesSPDC 5 CW327597 - NCDMB Commercial TemplateMathias OnosemuodeNo ratings yet

- Attachment 4 Scope of WorkDocument5 pagesAttachment 4 Scope of WorkMathias OnosemuodeNo ratings yet

- Gas Liquid Separator V 2001 DatasheetDocument1 pageGas Liquid Separator V 2001 DatasheetMathias OnosemuodeNo ratings yet

- Basteel Perimeter Systems: Citadel Security Fence SystemDocument5 pagesBasteel Perimeter Systems: Citadel Security Fence SystemMathias OnosemuodeNo ratings yet

- Oil Gas Custody Data Sheet 2Document52 pagesOil Gas Custody Data Sheet 2Mathias OnosemuodeNo ratings yet

- Action Items 22 - Equipment PreservationDocument5 pagesAction Items 22 - Equipment PreservationMathias OnosemuodeNo ratings yet

- Action Items 11 - Equipment PreservationDocument6 pagesAction Items 11 - Equipment PreservationMathias OnosemuodeNo ratings yet

- Tilting Frying Pan: Macadams Macadams Macadams MacadamsDocument2 pagesTilting Frying Pan: Macadams Macadams Macadams MacadamsMathias OnosemuodeNo ratings yet

- O027 BCL Camp ST DWG 0001 BDocument1 pageO027 BCL Camp ST DWG 0001 BMathias OnosemuodeNo ratings yet

- Heavy Duty Moulder: Macadams Macadams Macadams MacadamsDocument2 pagesHeavy Duty Moulder: Macadams Macadams Macadams MacadamsMathias OnosemuodeNo ratings yet

- Mini Bread & Roll Moulder With 4 Piece Attachment: Macadams Macadams Macadams MacadamsDocument2 pagesMini Bread & Roll Moulder With 4 Piece Attachment: Macadams Macadams Macadams MacadamsMathias OnosemuodeNo ratings yet

- Belshaw Donut Robots: MacadamsDocument2 pagesBelshaw Donut Robots: MacadamsMathias OnosemuodeNo ratings yet

- Weld Details A Weld Details B: Cloude Denote Scope of WorkDocument1 pageWeld Details A Weld Details B: Cloude Denote Scope of WorkMathias OnosemuodeNo ratings yet

- Contract 5-KCDP-A Re-Vamp 6. Contract 6-Revamp KCDP-B: RD NDDocument1 pageContract 5-KCDP-A Re-Vamp 6. Contract 6-Revamp KCDP-B: RD NDMathias OnosemuodeNo ratings yet

- Calculations Based On Motor HPDocument4 pagesCalculations Based On Motor HPMathias OnosemuodeNo ratings yet

- Hydrotest Package-UgDocument11 pagesHydrotest Package-UgMathias OnosemuodeNo ratings yet

- O027 BCL Camp Ar DWG 0031 1Document1 pageO027 BCL Camp Ar DWG 0031 1Mathias OnosemuodeNo ratings yet

- Consolidated Commerical Form 1Document71 pagesConsolidated Commerical Form 1Mathias OnosemuodeNo ratings yet

- Annex 2 YARD BOQ8-submitDocument28 pagesAnnex 2 YARD BOQ8-submitMathias OnosemuodeNo ratings yet

- Offshore Project SummaryDocument3 pagesOffshore Project SummaryMathias OnosemuodeNo ratings yet

- Fyip NG01009295 Sbka1 MP 2358 00002 PDFDocument1 pageFyip NG01009295 Sbka1 MP 2358 00002 PDFMathias OnosemuodeNo ratings yet

- New Offshore Project - Jacket 1Document3 pagesNew Offshore Project - Jacket 1Mathias OnosemuodeNo ratings yet

- Commercial Submission For Printing and Stampimg SerivesDocument2 pagesCommercial Submission For Printing and Stampimg SerivesMathias OnosemuodeNo ratings yet

- Fyip NG01009295 Sbka1 MP 2358 00004Document1 pageFyip NG01009295 Sbka1 MP 2358 00004Mathias OnosemuodeNo ratings yet

- BUDGETARY QUOTATION FOR FABRICATION OF RISER CLAMP, RISER ANCHOR-SunnyDocument6 pagesBUDGETARY QUOTATION FOR FABRICATION OF RISER CLAMP, RISER ANCHOR-SunnyMathias OnosemuodeNo ratings yet

- Tool Equipment Rental Schedule - 2017 2018Document70 pagesTool Equipment Rental Schedule - 2017 2018Mathias OnosemuodeNo ratings yet