Professional Documents

Culture Documents

Fly Ash Utilization in Road Construction With Expansive Soil

Uploaded by

G. SASIDHARA KURUPOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fly Ash Utilization in Road Construction With Expansive Soil

Uploaded by

G. SASIDHARA KURUPCopyright:

Available Formats

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 6, June 2017, pp. 559–566, Article ID: IJCIET_08_06_062

Available online at http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=6

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

© IAEME Publication Scopus Indexed

FLY ASH UTILIZATION IN ROAD

CONSTRUCTION WITH EXPANSIVE SOIL

R P Hardaha

Research Scholar, Dr. C. V. Raman University,

Bilaspur, Chhattisgarh, India

M L Agrawal

Department of Civil Engineering, Govt. Engineering College,

Bilaspur, Chhattisgarh, India

Anita Agrawal

Department of Chemistry, J.K. Institute of Engineering,

Bilaspur, Chhattisgarh, India

ABSTRACT

In India, Thermal power plant is the major source of fly ash generation. They

produce more than 184 million-ton fly ash as by product. The Fly ash is obtained from

thermal power stations using pulverised coal as boiler fuel in the form of fine residue.

It creates the dual problem of disposal and environmental pollution. Chhattisgarh

state utilized about 32.69% of fly ash from their production in the year 2015-16. In

recent years, developing countries mainly focused on natural resources and energy

conservation. Such waste products generally deposited in landfills, have been

proposed for use as an alternate materials for construction. Hence we should try to

utilize the fly ash with expansive soil for road construction. This paper, deals with the

evaluation of the mechanical properties of fly ash and expansive soil. In present paper

soil and fly ash, both materials are separately determined and then the two are

combined in proportions of 10, 20, 30, 40 and 50% of fly ash and interpretation the

same with results. The properties like swelling index, Optimum moisture content,

maximum dry density and California Bearing Ratio of the same are evaluated. It is

observed in this research work that use of fly ash is beneficial in road construction

with the expansive soil.

Keywords: Fly ash, Expansive soil, Swelling Index, CBR.

Cite this Article: R P Hardaha, M L Agrawal and Anita Agrawal. Fly Ash Utilization

in Road Construction with Expansive Soil. International Journal of Civil Engineering

and Technology, 8(6), 2017, pp. 559–566.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=6

http://www.iaeme.com/IJCIET/index.asp 559 editor@iaeme.com

Fly Ash Utilization in Road Construction with Expansive Soil

1. INTRODUCTION

Day by day, globalizations and/or modernization increase the power consumption. Hence,

thermal power plants increase their capacity as per requirements or demands. As the power

production increases, fly ash generation from coal/lignite based thermal power stations also

increases. This fly ash requires huge land for dumping, which creates environmental problem.

As per report of Central Electricity Authority, New Delhi on “Fly Ash Generation at

Coal/Lignite Based Thermal Power Stations and its Utilization in the Country”, Fly ash

generation and utilization in India of last five years are tabulated below:

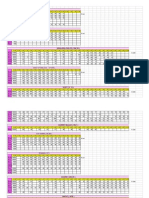

Table 1 Progressive Fly Ash Generation and Utilization in INDIA

(As Per report of Central Electricity Authority)

Sr. No. No. of Year FLY ASH

Coal/lignite Generation Utilization

based TPS (Million –ton) (Million-ton) (%)

1 124 2011-12 145.42 85.05 58.48

2 138 2012-13 163.56 100.37 61.37

3 143 2013-14 172.87 99.62 57.63

4 145 2014-15 184.14 102.54 55.69

5 151 2015-16 176.74 107.77 60.97

Average Utilization= (58.48+61.37+57.63+55.69+60.97) / 5 = 58.82, or say 59%

Figure 1 Generation & utilization of fly ash in India.

Above table shows that in last five years, approximately 59% of fly ash is utilized in India

and 41% is dumped. Similarly, in Chhattisgarh state, fly ash generation and utilization is

given below:

Table 2 Progressive Fly Ash Generation and Utilization in Chhattisgarh

(As Per report of Central Electricity Authority)

Sr. No. of Year FLY ASH

No. Coal/lignite Generation Utilization

based TPS (Million -ton) (Million –ton) (%)

1 11 2011-12 15.74 6.74 42.82

2 11 2012-13 18.81 7.27 38.66

3 14 2013-14 19.68 6.56 33.37

4 15 2014-15 21.91 8.60 39.24

5 19 2015-16 24.23 7.92 32.69

Average Utilization= (42.82+38.66+33.37+39.24+32.69) / 5 = 37.35, or say 37.5%

http://www.iaeme.com/IJCIET/index.asp 560 editor@iaeme.com

R P Hardaha, M L Agrawal and Anita Agrawal

Figure 2 Generation & utilization of fly ash in Chhattisgarh

In Chhattisgarh, approximate 37.5% of fly ash is utilized; it means 62.5% of fly ash is

dumped in land. Hence, with reference to our country, Chhattisgarh state is far behind as per

utilization point of view. Table given below shows the major modes of fly ash utilization in

India:

Table 3 Major Modes of Fly Ash Utilization

(As Per report of Central Electricity Authority)

S. No. Mode 2011-12 2012-13 2013-14 2014-15 2015-16

MT % MT % MT % MT % MT %

1 Cement 38.08 44.77 41.33 41.18 39.17 39.32 43.33 42.20 43.38 40.25

2 Bricks & Tiles 5.83 6.86 9.98 9.94 12.23 12.27 13.33 13.00 14.76 13.69

3 Reclamation of 14.21 16.71 11.83 11.78 11.75 11.78 12.02 11.72 12.53 11.63

low lying area

4 Mine Filling 7.74 9.10 10.34 10.30 11.20 11.24 11.04 10.77 10.33 9.59

5 Ash Dyke 5.86 6.89 10.93 10.89 10.32 10.36 9.80 9.56 10.61 9.84

Raising

6 Roads & Fly 5.54 6.51 6.02 6.00 4.98 5.00 3.40 3.32 5.00 4.64

Over

7 Agriculture 0.88 1.03 2.50 2.49 2.88 2.89 1.97 1.93 2.22 2.06

8 Concrete 0.63 0.74 1.03 1.03 0.91 0.92 0.76 0.74 0.78 0.73

9 Hydro Power -- -- -- -- -- -- 0.005 0.01 0.038 0.03

10 Others 6.28 7.38 6.41 6.39 6.19 6.22 6.87 6.70 8.12 7.54

TOTAL 85.05 100 100.37 100 99.62 100 102.54 100 107.77 100

As shown in table 3, it is clear that maximum consumption of fly ash in cement industry,

then brick and tiles manufacturing, reclamation of low lying area, mine filling, Ash dyke

raising etc. In road and fly overs approximate 5% of fly ash is utilized. Road plays a crucial

role in the development of the country. In this sector, it has a large potential for fly ash

utilization. Hence, especially for soft sub grade soil, more research is required for use of fly

ash in road construction.

In Chhattisgarh, expansive soils are a common problem. For this type of soil in summer

season, the moisture evaporates quickly causing deep and wide shrinkage cracks. On the other

hand, in rainy season water enters the cracks causes’ enormous swelling. Highway

http://www.iaeme.com/IJCIET/index.asp 561 editor@iaeme.com

Fly Ash Utilization in Road Construction with Expansive Soil

embankments in such type of soils suffer severe damages and the pavement gets disrupted, the

soil most of the state are mainly black cotton soil, which is clayey soil that can bear almost no

load when wet. This causes the land to erode heavily during the rainy seasons and especially

the roads are damaged.

Soil possess the following properties if used as a highway material; such as stability,

incompressibility, good drainage, ease in compaction, minimum volume change, permanency

of strength etc

For redemption of soft sub-grade has consisted of a typical approach for removal of poor

soil and its replacement with large quantities of crushed rock. The high cost for removal of

poor soils and transportation of selected aggregates, along with increasing interest in re-usable

industrial by products, has prompted investigations to find solutions that complement the need

of highway construction with those of the environment. Use of fly ash for stabilization of soft

sub-grade is one of these solutions being evaluated.

From the above an attempt has been made to utilize fly ash in 0, 10,20,30,40 and 50 per

cent with black cotton soil and the effect and engineering properties was evaluated.

2. SOIL AND FLY ASH FOR PRESENT STUDY

For this investigation, soil is collected from a depth of 1.5 m below ground level from Raipur,

Chhattisgarh, India. Similarly Fly ash used for present study was brought from M/s Sarda

Energy, Siltara, Raipur.

3. CHEMICAL COMPOSITION OF FLY ASH

Table 4 Chemical composition of Indian Fly ash

Sr. No. Constituent Percentage Range (%)

1 Silica (SiO2) 49-67

2 Alumina (Al2O3) 16-29

3 Iron Oxide (Fe2O3) 4-10

4 Calcium Oxide (CaO) 1-4

5 Magnesium Oxide (MgO) 0.2-2

6 Sulphur (SO3) 0.1-2

7 Loss on ignition 0.5-3

4. LABORATORY TESTS ON SOILS, FLY ASH &THEIR MIXTURES

In this Experimental study the soil-Fly ash mixtures were prepared by mixing 10,20,30,40 and

50% of fly ash (by weight). All these mixtures were tested in the laboratory as per respective

IS codes for Swelling index, compaction characteristics and California Bearing Ratios.

Free Swell Index-In IS: 2720-Part 40, free swell of a soil is defined as increase in the volume

of a soil without any constraints, on submergence in water. Generally free swell ceases when

the water content reaches the plastic limit. The increase in volume as a percentage of initial

volume of soil is referred swelling index of soil.

Compaction Test- The test were carried out to determine the maximum dry density (MDD)

and optimum moisture content (OMC) of soil mixtures using Heavy compaction (Modified

Proctor Test) as per IS 2720-PartVII-1974. The mould used was 100 mm in diameter and

127.3 mm high. The samples were compacted in 5 layers by applying 25 blows to each layer

with a free fall of 450 mm of 4.89 Kg weight.

http://www.iaeme.com/IJCIET/index.asp 562 editor@iaeme.com

R P Hardaha, M L Agrawal and Anita Agrawal

California Bearing Ratio- The samples were prepared at OMC and compacted using

Dynamic Compaction (Modified Proctor Test) as per IS: 2720-Part VII-1974. The mould used

was 150 mm in diameter and 127.3 mm high. The samples were compacted in 5 layers by

applying 56 blows to each layer with a free fall of 450 mm of 4.89 Kg weight. The

penetration tests were carried out for samples soaked for 96 hours. The rate of penetration of

the plunger was kept at 1.25 mm per minute.

5. RESULTS AND DISCUSSIONS

5.1. Grain Size Analysis

Table 5 Grain size distribution of soil and fly ash

Sr. No. Fly ash Gravel (%) Coarse Sand Medium Sand Fine Sand (%) Silt & Clay

Content (%) (%) (%) (%)

1 0.0 4.80 1.40 2.80 4.40 86.60

2 100 0.00 0.00 0.00 21.00 79.00

Various sizes of particles in a given dry sample is found by a particle size analysis.

Table 6 Geotechnical Properties of Fly Ash:

S. No. Parameter Result/Value

1 Specific Gravity 2.4

2 Plasticity Non-Plastic

3 Maximum Dry Density (gm/cc) 1.2

4 Optimum Moisture Content (%) 35

5 Cohesion (kN/m2) Negligible

6 Angle of Internal Friction (Φ) 340

7 Particle size Distribution (%)

Clay size fraction 0

Silt size fraction 79

5.2. Free Swelling

Table 7 Free Swell Index

S. No. Material Free Swell Index (%)

(Soil+Fly ash)

(%)

1 100+00 66.6

2 100+10 50.0

3 100+20 33.3

4 100+30 20.6

5 100+40 9.10

6 100+50 4.2

Soils that undergo large volume changes with change in water content may be

troublesome if used for highway bases. The volume change can result in bumps in road and

crack the structures, since the volume changes over time may not and usually will not be

equal.

The degree of change in volume in black cotton soil depends upon; (a) amount and type of

clay mineral present (b) Fineness of clay (c) Soil structure (d) Salt concentration in pore water

(e) exchangeable cationvalence. Consolidation of pavement takes much time, due to poor

http://www.iaeme.com/IJCIET/index.asp 563 editor@iaeme.com

Fly Ash Utilization in Road Construction with Expansive Soil

drainage capacity of soil. Shear strength of soil decreases with increase in moisture. Bearing

capacity of soil is very low, resulting in extra thickness of pavement.

From experimental results as shown in table 7, that addition of fly ash reduces the

swelling behaviour of soil. So it is proved that fly ash controls the swell shrink property of

soil.

5.3. Compaction Test

Table 8 Modified Compaction Test of Black Cotton Soil and their admixtures with fly ash

Material

S. OMC MDD

(Soil+Fly ash)

No. (%) (Kg/cm3)

(%)

1 100+00 16.0 1.68

2 100+10 10.7 1.76

3 100+20 12.7 1.74

4 100+30 12.0 1.63

5 100+40 14.5 1.73

6 100+50 15.2 1.62

7 00+100 10.00 1.316

Aim of compacting a soil is to alter the desirable properties like reduction of

compressibility, water absorption and permeability and increase soil strength, bearing

capacity etc. For heavy transport and airports, higher compaction is necessary.

Generally, the following Factors which affect the compacted density of soil are:

• Type of Soil

• Moisture content

• Type of compaction

• Amount of compaction

• Method employed , and

• Admixtures used

As per results shown in table 8, In expansive soil, Maximum Dry Density increased

slightly up to 40% of fly ash, and then it decreased. Hence, It is shown that for depressive

clays the MDD increases first and then decreases with the increase in fly ash content.

5.4. California Bearing Ratio

Table 9 CBR Value of Black Cotton Soil and their admixtures with fly ash

S. Material CBR %

No. (Soil+Fly ash) % Soaked

1 100+00 2.06

2 100+10 2.47

3 100+20 2.47

4 100+30 2.68

5 100+40 2.67

6 100+50 2.47

7 00+100 4.129

This is most widely used method for the design of flexible pavements. Generally,

thickness of the different elements of a pavement is determined by the CBR value.

http://www.iaeme.com/IJCIET/index.asp 564 editor@iaeme.com

R P Hardaha, M L Agrawal and Anita Agrawal

It is observed from table 9, that addition of fly ash increases the California Bearing Ratio

of black cotton soil up to 40% fly ash mixture.

6. CONCLUSIONS

• CBR Value and dry density increases up to 40% fly ash mixture with black cotton soil. This

value is useful in estimating the thickness of flexible pavement.

• As percentage of Fly Ash increased, the free swell index of expansive soil decreases, resulting

in reduced swelling of soil. Thus improving its utility as road material.

• Fly ash utilization as construction material for enhancing the engineering properties of soil

reduces the demand of disposal and hence controls the source of pollution and protects the

environment.

• Fly ash utilization solves landfill problems and to provide geomechanically stable material.

Hence Fly ash is a economical alternative material in construction engineering.

REFERENCES

[1] Report on fly ash generation at coal/lignite based thermal power stations and its utilization

in the country for the year 2011-12 and 2012-13, Central Electricity Authority, New

Delhi, Jan-2014.

[2] Report on fly ash generation at coal/lignite based thermal power stations and its utilization

in the country for the year 2013-14, Central Electricity Authority, New Delhi, Aug-2014.

[3] Report on fly ash generation at coal/lignite based thermal power stations and its utilization

in the country for the year 2014-15, Central Electricity Authority, New Delhi, Oct-2015.

[4] Report on fly ash generation at coal/lignite based thermal power stations and its utilization

in the country for the year 2015-16, Central Electricity Authority, New Delhi, October-

2016.

[5] Khanna S.K., Justo C.E.G.and A Veeraragavan, “Highway Materials and Pavement

Testing” Nem Chand & Bors, Roorkee-2013.

[6] Dr. B.C. Punmia. A.K. Jain & A.K. Jain, “Soil Mechanics and Foundations” Laxmi

Publications (P) Ltd. New Delhi, 2005 IS: 2720-ReleventParts-1974.

[7] Indian Road Congress, Special Publication 58, “Guidelines For Use of Fly Ash In Road

Embankments”, New Delhi, 2001 RC:SP: 20-2002”Indian road congress” 2002

[8] Priyank Goyal, Ashutosh Shanker Trivedi and Manoj Sharma ,” Improvement in

Properties of Black Cotton Soil with an Addition of Natural Fibre (Coir) Derived From

Coconut Covering”, Int. Journal of Engineering Research and Applications ,ISSN : 2248-

9622, Vol. 5, Issue 3, ( Part -5) March 2015, pp.36-37.

[9] Aparna, P.K. Jain, and Rakesh Kumar, “Study of Swelling Behaviour of Black Cotton Soil

Improved with Sand Column”, International Journal of Advances in Engineering &

Technology, July, 2014.,IJAET ISSN: 22311963, Vol. 7, Issue 3, pp. 905-910.

[10] Stephen George Emmanuel, Yitendra Kumar Bind,” A Study of the Swelling Behaviour of

Soil Mixed with Different Ratios of Fly Ash as a Partial Substitute” ,International Journal

of Research in Engineering Technology and Management ISSN 2347 – 7539, Volume:

02 Issue: 02 | Mar-2014, P.P. 1-2.

[11] Brajesh Mishra, “A Study on Engineering Behavior of Black Cotton Soil and its

Stabilization by Use of Lime”, International Journal of Science and Research (IJSR) ISSN

(Online): 2319-7064, Volume 4 Issue 11, November 2015, p.p.290-294.

http://www.iaeme.com/IJCIET/index.asp 565 editor@iaeme.com

Fly Ash Utilization in Road Construction with Expansive Soil

[12] S. Lhamu and M. Hussain, “Swelling Behaviour of Fly Ash Stabilized Expansive Soil,”

Proceedings of Indian Geotechnical Conference , December 22-24,2013, Roorkee, p.p.1-8.

[13] Sarat Kumar Das and Partha Sarathi Parhi ,”Stabilization of Expansive Soil Using Alkali

Activated Fly Ash,” Proceedings of Indian Geotechnical Conference December 22-

24,2013, Roorkee, p.p. 1-4.

[14] G Radhakrishnan ,Dr M Anjan Kumar and Dr GVR Prasada Raju, “Swelling Properties of

Expansive Soils Treated with Chemicals and Flyash”, American Journal of Engineering

Research (AJER), e-ISSN : 2320-0847 p-ISSN : 2320-0936, Volume-03, Issue-04, pp-

245-250

[15] Saeid. Amiralian, Amin. Chegenizadeh, and Hamid. Nikraz, “Laboratory Investigation on

the Effect of Fly Ash on the Compressibility of Soil”, International Conference on Civil

and Architectural applications (ICCAA'2012) December 18-19, 2012 Phuket

(Thailand),p.p. 84-88.

[16] Pratima Kumari, Proff Prafulla Sharma and Proff J.P.Singh, “Swelling Behaviour of

Expansive Soil Mixed with Lime and Fly Ash as Admixture,” International Journal of

Innovative Research in Science, Engineering and Technology, ISSN(Online): 2319-

8753,ISSN (Print): 2347- 6710, Vol. 4, Issue 6, June 2015,p.p.4364-4372.

[17] Indian Road Congress, Special Publication 58, “Guidelines for Use of Fly Ash In Road

Embankments”, New Delhi 2001.

[18] E Saibaba Reddy and K. Rama Sastri, “Measurement of Engineering Properties of Soils”,

New Age International Publishers, New Delhi. First edition 2002.

[19] Syed Saifali, R. A khil, S. Lakshmipathi and Afshan Sheikh, Construction of a Building

Using Fly Ash Concrete. International Journal of Civil Engineering and Technology, 8(4),

2017, pp. 1809 –1814

[20] M.S. Krishna Hygrive, I. Siva Kishore and KJB Chari Comparative Study on Compressive

Strength of Fly Ash Concrete. International Journal of Civil Engineering and Technology

(IJCIET) 2017, pp. 1737–1745

[21] Vidat Choudhary and Salmabanu Luhar, Fly Ash Utilization: A Review, International

Journal of Civil Engineering and Technology, 8(4), 2017, pp. 301–312.

http://www.iaeme.com/IJCIET/index.asp 566 editor@iaeme.com

You might also like

- Chemical and Mechanical Stabilization: B M. D, College of Engineering and Computer Science, California StateDocument3 pagesChemical and Mechanical Stabilization: B M. D, College of Engineering and Computer Science, California StateAnkur YashNo ratings yet

- Characterization of Fly Ash For Their Effective Management and Utilization-Rakesh Kumar Behera, Mining Engg. 10605029 (2006-2010) ProjectDocument11 pagesCharacterization of Fly Ash For Their Effective Management and Utilization-Rakesh Kumar Behera, Mining Engg. 10605029 (2006-2010) ProjectYugandhar DamallaNo ratings yet

- Bitumen 1Document10 pagesBitumen 1Athiyo MartinNo ratings yet

- Fly Ash Characteristics and UsesDocument8 pagesFly Ash Characteristics and UsesG. SASIDHARA KURUPNo ratings yet

- Curing of Lime SamplesDocument14 pagesCuring of Lime SamplesFahim MarwatNo ratings yet

- xCE734 Soil StabilizationDocument1 pagexCE734 Soil StabilizationG. SASIDHARA KURUPNo ratings yet

- An Overview of Traditional and Non Traditional StaDocument10 pagesAn Overview of Traditional and Non Traditional StaG. SASIDHARA KURUPNo ratings yet

- Fly Ash As An Embankment MaterialDocument3 pagesFly Ash As An Embankment MaterialG. SASIDHARA KURUPNo ratings yet

- Geotechnical Applications of Waste Materials PDFDocument5 pagesGeotechnical Applications of Waste Materials PDFG. SASIDHARA KURUPNo ratings yet

- Lab Cvl212v1Document37 pagesLab Cvl212v1Rishabh RajNo ratings yet

- Technical Report Documentation PageDocument136 pagesTechnical Report Documentation PagePauline Anne WilsonNo ratings yet

- Impact of Groundwater Quality On Soil Properties and Crop Production Under Khartoum State Condition PDFDocument3 pagesImpact of Groundwater Quality On Soil Properties and Crop Production Under Khartoum State Condition PDFG. SASIDHARA KURUPNo ratings yet

- CE Civil EngineeringDocument2 pagesCE Civil EngineeringSushant KhandekarNo ratings yet

- K501018494 PDFDocument11 pagesK501018494 PDFG. SASIDHARA KURUPNo ratings yet

- UC Riverside Previously Published WorksDocument12 pagesUC Riverside Previously Published WorksG. SASIDHARA KURUPNo ratings yet

- Study of Water Salinity Effect On Geotechnical Behavior of Soil Structure Using Response Surface Method (RSM), (Case Study: Gotvand Dam)Document10 pagesStudy of Water Salinity Effect On Geotechnical Behavior of Soil Structure Using Response Surface Method (RSM), (Case Study: Gotvand Dam)G. SASIDHARA KURUPNo ratings yet

- Feasibility of Saline Soil Reinforced With Treated Wheat Straw and LimeDocument11 pagesFeasibility of Saline Soil Reinforced With Treated Wheat Straw and LimeG. SASIDHARA KURUPNo ratings yet

- Basic and Applied Soil Mechanics by Gopal RanjanDocument1 pageBasic and Applied Soil Mechanics by Gopal RanjanG. SASIDHARA KURUPNo ratings yet

- S2-Soil Dynamics and Machine Foundation (516) .Text - MarkedDocument2 pagesS2-Soil Dynamics and Machine Foundation (516) .Text - MarkedHari RamNo ratings yet

- محتوى رطوبيييDocument17 pagesمحتوى رطوبيييzeekoNo ratings yet

- Soil Salinity: July 2020Document19 pagesSoil Salinity: July 2020G. SASIDHARA KURUPNo ratings yet

- Effect of Sea Water Intrusion On Geotechnical Behavior of Soil A ReviewDocument7 pagesEffect of Sea Water Intrusion On Geotechnical Behavior of Soil A ReviewG. SASIDHARA KURUPNo ratings yet

- Not 0062019 0842019Document4 pagesNot 0062019 0842019kiranappuNo ratings yet

- SDMF Question Paper 1Document2 pagesSDMF Question Paper 1G. SASIDHARA KURUPNo ratings yet

- Iarjset-Agni-Pankh 16Document5 pagesIarjset-Agni-Pankh 16G. SASIDHARA KURUPNo ratings yet

- Mulyono 2018 IOP Conf. Ser.: Earth Environ. Sci. 118 012038Document7 pagesMulyono 2018 IOP Conf. Ser.: Earth Environ. Sci. 118 012038sausanNo ratings yet

- S2-Soil Dynamics and Machine Foundation (517) .Text - MarkedDocument3 pagesS2-Soil Dynamics and Machine Foundation (517) .Text - MarkedHari RamNo ratings yet

- Grouts Grouting PDFDocument4 pagesGrouts Grouting PDFG. SASIDHARA KURUPNo ratings yet

- Biostructural Erosion Control MenasheDocument7 pagesBiostructural Erosion Control MenasheG. SASIDHARA KURUPNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fossil Fuels: Grade Level: 4 - 6Document12 pagesFossil Fuels: Grade Level: 4 - 6api-438357435No ratings yet

- 2020 11 Isolation-Rooms PlumbingDocument13 pages2020 11 Isolation-Rooms PlumbingZidd PerezNo ratings yet

- Ultracote 635 HBDocument3 pagesUltracote 635 HBCherbee Ferrer100% (1)

- Procedure No. L&T/ Kkro / Mech / WP 01: Procedure For Wps / PQR & Welder QualificationDocument6 pagesProcedure No. L&T/ Kkro / Mech / WP 01: Procedure For Wps / PQR & Welder QualificationdiptiNo ratings yet

- Scotchcast Electrical Resin 8: Two-Part, Room-Curing, Semiflexible, Unfilled, Epoxy Liquid ResinDocument4 pagesScotchcast Electrical Resin 8: Two-Part, Room-Curing, Semiflexible, Unfilled, Epoxy Liquid ResinIñaki GarateNo ratings yet

- 2012 International Buyer's Guide: Materials Preparation and Analysis Consumables Equipment and AccessoriesDocument53 pages2012 International Buyer's Guide: Materials Preparation and Analysis Consumables Equipment and AccessoriesAndrés RodríguezNo ratings yet

- Chem Form 4Document1 pageChem Form 4baskieNo ratings yet

- Dos A OilDocument5 pagesDos A OilimranNo ratings yet

- 17 Samss 008Document8 pages17 Samss 008Eagle SpiritNo ratings yet

- UL Design No. XR725 - 2020Document6 pagesUL Design No. XR725 - 2020Carlos Mena FalconNo ratings yet

- PNS 492002 Steel Bars For Concrete Reinforcement - SpecificationDocument18 pagesPNS 492002 Steel Bars For Concrete Reinforcement - SpecificationStandpro Testing CenterNo ratings yet

- Dimas 2009 PDFDocument31 pagesDimas 2009 PDFlaurentiu_filipescuNo ratings yet

- Laboratory Activities 4, 5 and 6Document10 pagesLaboratory Activities 4, 5 and 6REX IAN BONGALESNo ratings yet

- Processing and Properties of Sewing Threads: Indian Journal of Textile Research August 2009Document10 pagesProcessing and Properties of Sewing Threads: Indian Journal of Textile Research August 2009Randhir Kumar GuptaNo ratings yet

- Comparison Between Marshall MethodDocument57 pagesComparison Between Marshall MethodAbdullah100% (1)

- Presentation-Rigid-pavement Design-Fig-Current - 2019Document9 pagesPresentation-Rigid-pavement Design-Fig-Current - 2019Uduebor MichealNo ratings yet

- Aerocon C Board Technical ManualDocument44 pagesAerocon C Board Technical Manualsri projectssNo ratings yet

- Crepe Paper 2017-05-29-FINALDocument2 pagesCrepe Paper 2017-05-29-FINALPruthvi KrishnaNo ratings yet

- HALLEUR ROAD. Slab Engineering Plan Amdt 1 - 9.9.22Document1 pageHALLEUR ROAD. Slab Engineering Plan Amdt 1 - 9.9.22Shane LaonatdNo ratings yet

- BhagalpurDocument22 pagesBhagalpurApoorva NatrajNo ratings yet

- Vestolit BR Textile-Coatings Web EN 2022-10Document12 pagesVestolit BR Textile-Coatings Web EN 2022-10Betty GonzálezNo ratings yet

- 30crnimo8: Steel GradeDocument2 pages30crnimo8: Steel GradewemersonsrNo ratings yet

- Water LeakageDocument34 pagesWater LeakageKousalya Mk100% (2)

- Iso TS 6521-2-2021Document16 pagesIso TS 6521-2-2021wodonit136No ratings yet

- One-Way Slab Design: (Based On BS8110:2000-Part1)Document2 pagesOne-Way Slab Design: (Based On BS8110:2000-Part1)mayphyo100% (1)

- HSCO-projects Reference 2010-2015 PDFDocument5 pagesHSCO-projects Reference 2010-2015 PDF袁袁No ratings yet

- UN Numbers of ChemicalsDocument62 pagesUN Numbers of ChemicalsTimuçin ÇolakelNo ratings yet

- DensityDocument2 pagesDensityPeeyush TripathiNo ratings yet

- Ansi Awwa C509-15 PDFDocument48 pagesAnsi Awwa C509-15 PDFEslam Elsayed100% (1)

- New - Jan 2012 DuebaDocument21 pagesNew - Jan 2012 DuebaJessy LingNo ratings yet