Professional Documents

Culture Documents

PD Measurements On Rotating Machines

Uploaded by

Juan Sebastian Juris ZapataOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PD Measurements On Rotating Machines

Uploaded by

Juan Sebastian Juris ZapataCopyright:

Available Formats

8 PD Measurements on Rotating Machines

Stator insulation faults are the second most common cause of failure in large rotating machines. Partial discharge

(PD) is a reliable measurement parameter used to assess the condition of insulation in rotating machines. PD

occurs in the insulation system of rotating machines, where the local electric field stress exceeds the local electrical

strength. The insulation materials typically used for rotating machines are resistant to a certain level of PD. An

increase of PD activity can indicate insulation degradation caused by overheating, load cycling or mechanical stress.

Successful PD measurement in stator windings is often based on the separation of parallel PD sources, and

the distinction between harmful PD, normal PD occurrences and external noise inevitably present in industrial

surroundings. To achieve this, the following separation and advanced noise suppression techniques are applied:

Synchronous multi-channel Figure 1

data acquisition

3PARD (3-Phase Amplitude

Relation Diagram)

Multi-spectral evaluation

3CFRD (3-Center Frequency

Relation Diagram)

Automated cluster

separation

For interpretation of the

measured and separated pattern,

a list of typical patterns can be

helpful, as shown in Figure 1.

Classification of PD patterns for rotating machines

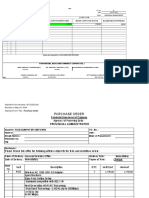

The accessibility of the star point determines the measurement setup to be used for PD measurement. Figure 2

shows a basic measurement setup for an applied voltage, single-channel PD measurement on the open star point of

a rotating machine. The test voltage (no specific voltage source) is applied at the open star point. Using an MCC 117

coupling capacitor with the MPD 800 measurement device, the PD measurements are performed phase by phase

(Phase U1 in Figure 2) where the unused terminals are grounded. The setup is as described in IEC 60034-27: open

star point. This measurement setup aims to achieve an assessment of the winding insulation between the phase

and the laminated core.

Figure 2

Basic setup for PD measurement on the open star-point of a rotating machine.

OMICRON even supports the setup of a combined measurement system using 3 channels as shown in Figure 3. This

enables the measurement of winding insulation capacitance, Power Factor/Dissipation Factor (PF/DF) and PD in one

setup using the CPC 100 and CP TD15 as the voltage source and the CP CR 600 for reactive power compensation

with the open star point (if accessible). The additional BLI2 on top of the coupling capacitor is used as a blocking

impedance to filter undesired PD from the voltage supply (CP TD15) in the standard IEC measurement frequencies

of 100 - 500 kHz.

This measurement setup offers many advantages. It is lightweight with a portable voltage source due to the

compensation of losses. The parallel measurement of capacitance, PF/DF and PD is possible with no additional

setup. Complete information about the condition of winding insulation can also be obtained. As a result, this

combined measurement saves a lot of time.

Figure 3

Combined measurement setup for capacitance, tan(δ) and PD

You might also like

- A Guide For Partial Discharge Measurements On Medium Voltage (MV) and High Voltage (HV) ApparatusDocument8 pagesA Guide For Partial Discharge Measurements On Medium Voltage (MV) and High Voltage (HV) ApparatuskashifNo ratings yet

- Cable Sizing CalculationDocument15 pagesCable Sizing CalculationKhairul AshrafNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Technical Service Manual For OxymagDocument118 pagesTechnical Service Manual For OxymagArnoldo Daza100% (6)

- AC 21-46 v3.0Document7 pagesAC 21-46 v3.0JNo ratings yet

- Method Statement For Partial Discharge Measurement: Application NoteDocument11 pagesMethod Statement For Partial Discharge Measurement: Application NoteInsan AzizNo ratings yet

- PD Measurements On Power TransformersDocument3 pagesPD Measurements On Power TransformersJuan Sebastian Juris ZapataNo ratings yet

- DDS 50 2007 (Part 1)Document32 pagesDDS 50 2007 (Part 1)Talal Ghazi100% (1)

- Ref 19 80Document4 pagesRef 19 80vkNo ratings yet

- Neta World Warren Industry TopicsDocument4 pagesNeta World Warren Industry TopicsDhruvam PandyaNo ratings yet

- The Use of Absolute LimitsDocument11 pagesThe Use of Absolute LimitsMUSTAKUL ALAM BARLASKARNo ratings yet

- Dry Type Transformers Partial Discharge Diagnosis Paper ETG 2018 Engelen ENUDocument6 pagesDry Type Transformers Partial Discharge Diagnosis Paper ETG 2018 Engelen ENUAsim JamilNo ratings yet

- Instruction To IEC 60270Document4 pagesInstruction To IEC 60270vtechelectric33% (3)

- An0002 Efm32 Hardware Design ConsiderationsDocument16 pagesAn0002 Efm32 Hardware Design ConsiderationsRam SakthiNo ratings yet

- Partial Discharge Measurements On Power Transformers: Case StudiesDocument8 pagesPartial Discharge Measurements On Power Transformers: Case StudiesMauricio AgudeloNo ratings yet

- HINLJR00BUA-ED00002a DC Cable Sizing CalculationDocument18 pagesHINLJR00BUA-ED00002a DC Cable Sizing CalculationBADRI VENKATESHNo ratings yet

- PD Knowledge Rules For Insulation Condition Assessment of Power Cables Version 23-07-01Document9 pagesPD Knowledge Rules For Insulation Condition Assessment of Power Cables Version 23-07-01SISWANTONo ratings yet

- Lecture 07. IEEE 1584 Arc Flash CalculationsDocument5 pagesLecture 07. IEEE 1584 Arc Flash CalculationskrcdewanewNo ratings yet

- EcodialAdvanceCalculation HelpDocument33 pagesEcodialAdvanceCalculation HelpChàng NgốcNo ratings yet

- Published by The Institute of Electrical and Electronics Engineers and TitledDocument4 pagesPublished by The Institute of Electrical and Electronics Engineers and Titledtawanda1984No ratings yet

- Ieee 1584 Calculo de Arc FlashDocument5 pagesIeee 1584 Calculo de Arc FlashJesus FuentesNo ratings yet

- MPD Article How To Measure Partial Discharge 2020 ENUDocument2 pagesMPD Article How To Measure Partial Discharge 2020 ENUkashifNo ratings yet

- Ecodial Advance Calculation 4.1Document33 pagesEcodial Advance Calculation 4.1Youwan LeeNo ratings yet

- Partial Discharge Detection in Medium Voltage Stators Using An AntennaDocument6 pagesPartial Discharge Detection in Medium Voltage Stators Using An Antennadayini roslizanNo ratings yet

- Xr1 e Rotor Earth Fault RelayDocument12 pagesXr1 e Rotor Earth Fault RelayKrisada ThongkamsaiNo ratings yet

- Design of Single-Phase Online Uninterruptible PoweDocument6 pagesDesign of Single-Phase Online Uninterruptible Powetshibanguglodi008No ratings yet

- Technical Help: Ecodial Advance Calculation 4.2Document44 pagesTechnical Help: Ecodial Advance Calculation 4.2Alonso CoradoNo ratings yet

- Optoelectronics I:: Element14 Learning CenterDocument13 pagesOptoelectronics I:: Element14 Learning CenterAjay VermaNo ratings yet

- bpw34 AvrDocument4 pagesbpw34 AvrNedim Avicena AlićNo ratings yet

- Applications Note 02Document4 pagesApplications Note 02Anonymous NR43tawQfDNo ratings yet

- Partial Discharge As A Quality Assurance Test For Motor Stator WindingsDocument6 pagesPartial Discharge As A Quality Assurance Test For Motor Stator WindingsKUNALJAYNo ratings yet

- A Practical Activity Report Submitted For Engineering DESIGN-II (UTA-014)Document8 pagesA Practical Activity Report Submitted For Engineering DESIGN-II (UTA-014)Ritwik MehtaNo ratings yet

- A Temperature-Insensitive Simple Current-Mode Multiplier/Divider Employing Only Multiple-Output CDTADocument4 pagesA Temperature-Insensitive Simple Current-Mode Multiplier/Divider Employing Only Multiple-Output CDTAIDESNo ratings yet

- A Fully Isolated Delta-Sigma ADC For Shunt Based Current SensingDocument9 pagesA Fully Isolated Delta-Sigma ADC For Shunt Based Current Sensingpramani90No ratings yet

- Recent Developments in IEEE and IEC Standards For Off Line and On Line Partial Discharge Testing of Motor and Generator Stator WindingsDocument6 pagesRecent Developments in IEEE and IEC Standards For Off Line and On Line Partial Discharge Testing of Motor and Generator Stator WindingspanicoscribdNo ratings yet

- DC Ground Fault Detection Provided For UpsDocument8 pagesDC Ground Fault Detection Provided For UpscatalinccNo ratings yet

- Table A-1: SS DDDocument48 pagesTable A-1: SS DDAdimaroNo ratings yet

- Subsequence Action To Eliminate Blackout After Detecting Islanding Using Solid State Transfer Switch Implemented in PSCAD/EMTDCDocument8 pagesSubsequence Action To Eliminate Blackout After Detecting Islanding Using Solid State Transfer Switch Implemented in PSCAD/EMTDCAnand Kumar NaleNo ratings yet

- Assignment #3Document6 pagesAssignment #3Morteza ShamsoddiniNo ratings yet

- Design AnalysisDocument22 pagesDesign AnalysisAllanNo ratings yet

- AN282 Systemizing RF Power Amplifier DesignDocument6 pagesAN282 Systemizing RF Power Amplifier DesignfahkingmoronNo ratings yet

- 5042 AppDocument18 pages5042 AppAgustio Sahela BukhariNo ratings yet

- Siemens - CCDocument11 pagesSiemens - CCtrymskvedaNo ratings yet

- Distance Relay ModellingDocument10 pagesDistance Relay ModellingpavanrajhrNo ratings yet

- Weidmuller OptocouplersDocument34 pagesWeidmuller Optocouplersspeedy65No ratings yet

- EE 466 Power System Protection: University of HailDocument22 pagesEE 466 Power System Protection: University of Hailselvithimmarajan@gmail.comNo ratings yet

- Field Wiring and Noise Considerations For Analog SignalsDocument20 pagesField Wiring and Noise Considerations For Analog SignalsrajpecNo ratings yet

- Stabilizing Resistor in Motor Earth-Fault ProtectionDocument12 pagesStabilizing Resistor in Motor Earth-Fault ProtectionSuhas AcharyaNo ratings yet

- 1MRG008054 en Application Note Function Description For High Impedance Busbar ProtectionDocument13 pages1MRG008054 en Application Note Function Description For High Impedance Busbar ProtectionOsama Ahmad Chaudhary100% (1)

- Permanent Insulation MonitoringDocument5 pagesPermanent Insulation MonitoringschandntpcNo ratings yet

- Role of DSTATCOM in Distribution Network Under Various Fault ConditionsDocument9 pagesRole of DSTATCOM in Distribution Network Under Various Fault ConditionsPRACHI KATARENo ratings yet

- Schneider Tech Vol04Document4 pagesSchneider Tech Vol04Sarah BreckenridgeNo ratings yet

- Vector Surge Relay - MRG20000Document20 pagesVector Surge Relay - MRG20000t_syamprasadNo ratings yet

- Omicron - Synchronous Multi-Channel PD Measurements and The Benefits For PD AnalysesDocument8 pagesOmicron - Synchronous Multi-Channel PD Measurements and The Benefits For PD AnalysesNguyen Vu Nhat HaNo ratings yet

- Arc FlashDocument24 pagesArc FlashKVRamananNo ratings yet

- Modelling and Simulation of Online Partial Discharge Measurement For Medium Voltage Power CableDocument9 pagesModelling and Simulation of Online Partial Discharge Measurement For Medium Voltage Power Cablesamart94No ratings yet

- Partial Discharge Measurement and Monitoring On High Voltage XLPE CablesDocument14 pagesPartial Discharge Measurement and Monitoring On High Voltage XLPE CableskarakoukasNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- PD Measurements On Power CablesDocument2 pagesPD Measurements On Power CablesJuan Sebastian Juris ZapataNo ratings yet

- Differential Partial Discharge MeasurementsDocument2 pagesDifferential Partial Discharge MeasurementsJuan Sebastian Juris ZapataNo ratings yet

- ACO PACIFIC INC - 7012 - Hoja TecnicaDocument6 pagesACO PACIFIC INC - 7012 - Hoja TecnicaJuan Sebastian Juris ZapataNo ratings yet

- Control Hydro AlumnosDocument42 pagesControl Hydro AlumnosJuan Sebastian Juris ZapataNo ratings yet

- Electrical Conduit and Fitting Layout:-Notes:-: STP17/OTH/333 STP17/OTH/230Document1 pageElectrical Conduit and Fitting Layout:-Notes:-: STP17/OTH/333 STP17/OTH/230Satya Vamsi DorapalliNo ratings yet

- Weighing Indicator WE2107: Operating ManualDocument140 pagesWeighing Indicator WE2107: Operating ManualDamian LaskiNo ratings yet

- TimersDocument3 pagesTimersClein Alexander SarmientoNo ratings yet

- MANUAL XTREME 24.06.08 Cornelius Maquina de HieloDocument60 pagesMANUAL XTREME 24.06.08 Cornelius Maquina de HieloamadorNo ratings yet

- Product Specifications: DBXLH-6565S-T0MDocument4 pagesProduct Specifications: DBXLH-6565S-T0MRaluca Roxana SzaszNo ratings yet

- DV 06 ActuationDocument6 pagesDV 06 ActuationAbhishek SaraswatNo ratings yet

- HT CatalogueDocument48 pagesHT CatalogueHydrotechnik UK LtdNo ratings yet

- Catalog Vod RecorderDocument7 pagesCatalog Vod RecorderAbdiyasa Dharma Inovasi100% (1)

- Instrument Junction BoxDocument12 pagesInstrument Junction Boxshabbirtechnical100% (1)

- Catalog Lampi Xe-HgDocument16 pagesCatalog Lampi Xe-HgAdrianAndreiNo ratings yet

- VLSI Interview QuestionsDocument41 pagesVLSI Interview QuestionsKarthik Real Pacifier0% (1)

- ATENA TroubleshootingDocument63 pagesATENA TroubleshootingAlvaro Hernandez LopezNo ratings yet

- SWOLE o CLOCK MANUAL !!!Document2 pagesSWOLE o CLOCK MANUAL !!!Aleksandar DimovskiNo ratings yet

- Valhalla Repair ManualDocument8 pagesValhalla Repair ManualKirby AllenNo ratings yet

- D10T Track-Type Tractor Power Train System: Rjg1-UpDocument2 pagesD10T Track-Type Tractor Power Train System: Rjg1-UpJHOSMAR_22No ratings yet

- Anti-Static and Clean-Room Equipment: Static Eliminator General CatalogueDocument44 pagesAnti-Static and Clean-Room Equipment: Static Eliminator General Cataloguesangaji hogyNo ratings yet

- ELECTRIC MOTOR DRIVES Modelling, Analysis and ControlDocument652 pagesELECTRIC MOTOR DRIVES Modelling, Analysis and ControlMustafa Dursun50% (2)

- Would You Like Eddy Current, Video & Strip Chart in One Portable Case?Document2 pagesWould You Like Eddy Current, Video & Strip Chart in One Portable Case?Daniel Jimenez MerayoNo ratings yet

- BP SX 150: Proven Materials and ConstructionDocument4 pagesBP SX 150: Proven Materials and ConstructionEdwin ManNo ratings yet

- 020 100031 01 Christie CP2000 X User ManualDocument164 pages020 100031 01 Christie CP2000 X User ManualDSERPAXNo ratings yet

- AMF Panel Control WiringDocument43 pagesAMF Panel Control WiringAnthony Robert XNo ratings yet

- DCS A-10c Flight ManualDocument672 pagesDCS A-10c Flight ManualLetícia IsomuraNo ratings yet

- Abstract of Price Quotation: Supplier ParticularsDocument2 pagesAbstract of Price Quotation: Supplier ParticularsJaleann EspañolNo ratings yet

- PLC Traction Temporary Run Manual PDFDocument13 pagesPLC Traction Temporary Run Manual PDFfreddyjoertyNo ratings yet

- 25 Greatest Business IdeasDocument2 pages25 Greatest Business Ideasmeenaakka2000100% (4)

- RFID in MotionDocument12 pagesRFID in MotionyusinovskyNo ratings yet

- Student Name:-Ali Bilal Sultan: Teacher: - Naqaa Luqman MohammedDocument11 pagesStudent Name:-Ali Bilal Sultan: Teacher: - Naqaa Luqman Mohammedالزهور لخدمات الانترنيتNo ratings yet