Professional Documents

Culture Documents

Conducting Transverse and Concentrated Load Tests On Panels Used in Floor and Roof Construction

Uploaded by

Adán Cogley CantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conducting Transverse and Concentrated Load Tests On Panels Used in Floor and Roof Construction

Uploaded by

Adán Cogley CantoCopyright:

Available Formats

Designation: E 2322 – 03 (Reapproved 2009)

Standard Test Method for

Conducting Transverse and Concentrated Load Tests on

Panels used in Floor and Roof Construction1

This standard is issued under the fixed designation E 2322; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the following procedures for 2.1 ASTM Standards:2

determining the structural properties of segments of floor and C 109/C 109M Test Method for Compressive Strength of

roof constructions: Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

Section Specimens)

Test Specimens 5 E 4 Practices for Force Verification of Testing Machines

Loading 6

Deformation Measurements 7

E 72 Test Methods of Conducting Strength Tests of Panels

Report 8 for Building Construction

Precision and Bias 9 E 73 Practice for Static Load Testing of Truss Assemblies

Testing Floors

Transverse Load 10

E 196 Practice for Gravity Load Testing of Floors and Low

Concentrated Load 11 Slope Roofs

Testing Roofs E 455 Test Method for Static Load Testing of Framed Floor

Transverse Load 12

Concentrated Load 13 or Roof Diaphragm Constructions for Buildings

E 575 Practice for Reporting Data from Structural Tests of

1.2 This test method serves to evaluate the performance of Building Constructions, Elements, Connections, and As-

floors and roofs panels subjected to (1) Uniform loading, and semblies

(2) Concentrated static loading, which represent conditions E 631 Terminology of Building Constructions

sustained in the actual performance of the element. The E 661 Test Method for Performance of Wood and Wood-

standard is not intended for the evaluation of individual Based Floor and Roof Sheathing Under Concentrated

structural framing or supporting members (floor joist, rafters, Static and Impact Loads

and trusses), or both. E 695 Test Method of Measuring Relative Resistance of

1.3 The text of this standard references notes and footnotes Wall, Floor, and Roof Construction to Impact Loading

which provide explanatory material. These notes and footnotes, E 1592 Test Method for Structural Performance of Sheet

excluding those in tables and figures, shall not be considered as Metal Roof and Siding Systems by Uniform Static Air

requirements of the standard. Pressure Difference

1.4 This standard is not intended to cover concrete floor

slabs. 3. Terminology

1.5 The values stated in SI units are to be regarded as 3.1 Definitions—Refer to Terminology E 631 for definitions

standard. No other units of measurement are included in this of terms used in these test methods.

standard.

1.6 This standard does not purport to address all of the 4. Significance and Use

safety concerns, if any, associated with its use. It is the 4.1 Transverse Load—The procedures outlined will serve to

responsibility of the user of this standard to establish appro- evaluate the performance of floor and roof segments for

priate safety and health practices and determine the applica- deflection, permanent set and ultimate capacity. Performance

bility of regulatory limitations prior to use. criteria based on data from these procedures can ensure

structural adequacy and effective service.

1

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.11

2

on Horizontal and Vertical Structures/Structural Performance of Completed Struc- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tures. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved April 1, 2009. Published May 2009. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 2003. Last previous edition approved in 2003 as E 2322 – 03. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

--`,,`,,``,,,,`````,,,````,`,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/02/2015 01:57:15 MST

E 2322 – 03 (2009)

4.2 Concentrated Load—This concentrated load test shall deformation curves. Maintain complete load-deformation time

be used to evaluate surface indentation of structural framing records throughout the test. If application of a given load is

members. required for a certain period, such as 24 h, take deformation

4.3 These procedures will serve to evaluate performance of readings at the end of this period, to allow the satisfactory

roof and floor segments under simulated service conditions. plotting of a time-deformation curve for the complete period.

Diaphragm shear loading of roof and floor segments shall be NOTE 1—Reason for the 5-min application of constant-level increment

evaluated under Test Method E 455. Impact loading shall be loads are as follows:

evaluated under Test Methods E 661 or E 695. (1) To permit the assembly to come to a substantial rest prior to taking

the second set of readings. (Depending on the method employed for

5. Test Specimens applying the test load, it may be necessary to continue, at a reduced rate,

5.1 Specimens—There shall be at least three replicate speci- the motion of the loading device in order to maintain the constant load

mens for each test. Specimens shall be constructed to represent level during the 5-min period.)

sections of the floor, or roof assembly including the means of (2) To observe any time-dependent deformation or load redistribution,

the attachment when the load direction is away from the or both, and to record accurately the load level when time-dependent

deformation starts, that is, at the divergence of the immediate and delayed

supports. The specimens shall be representative in width and

load-deformation curves. This load level may, under certain conditions,

length as to the material and workmanship. The test specimen have an important bearing on the design load.

shall not be less than the width and length of the tributary load (3) To be able to stop the test, if this should be desirable, prior to total

area under actual conditions. If the tributary load area for the failure, after initial failure has been anticipated as a result of the

test specimen exceeds the test equipment, a reduced specimen observations.

that is representative in proportional width and length shall be (4) To assure uniformity in test performance and consistency in test

tested. Unsymmetrical assemblies shall be tested in each axis. results.

If the structural properties of a particular construction are to be

compared with another construction, widths of the specimens 7. Deformation Measurements

shall be of comparable size. 7.1 Measure the deformations with sufficient precision to

5.2 Age—Constructions, which include concrete and ma- define the load-deformation relationship, and report at least to

sonry for which the structural properties depend upon the age the nearest 0.25 mm.

of the specimen, shall be aged not less than what is indicated

by the manufacturer or national standard, or both. The age of 8. Report

the specimen shall be recorded in the report. 8.1 Prepare the report in accordance with Recommended

6. Loading Practice E 575.

6.1 Apparatus—The testing machine or load-measuring ap- 9. Precision and Bias

paratus shall comply with the requirements prescribed in

Practices E 4. 9.1 It is not possible to specify the precision of the proce-

6.2 Application of Load—Apply the load to each individual dure in this standard for measuring these test methods because

specimen in increments so that a sufficient number of readings of the variety of materials and combinations of materials

will be obtained to determine definitely the load-deformation involved.

curve (see 6.3) using the following sequence:

6.2.1 Prior to testing, apply a small initial load not greater TESTING FLOORS

than 5 % of the ultimate capacity load expected and hold for

5 min (6 1 min) and then release. Zero all measuring devices 10. Transverse Load—Floor

and begin the test. 10.1 Test Specimen(s)—Test specimen(s) shall be con-

6.2.2 Record the initial load and deformation reading of the structed in accordance with Section 5.

specimen and then increase the load on the specimen to the first 10.2 Apparatus—The apparatus shall be capable of apply-

predetermined increment. ing a uniform load (such as air bag load or vacuum load),

6.2.3 Record the load and deformation reading and release gravity load or two point load and shall conform to the

the load back to the initial load and then record the set of the requirements prescribed in 10.2.1 through 10.2.3 or the equiva-

specimen. lent.

6.2.4 Increase the load to the next predetermined increment 10.2.1 Uniform Load—Uniformly distributed loading is a

and record the information as indicated in the first load satisfactory test method. Uniformly distributed load shall be

increment above. Follow this sequence of loading and reading applied by air pressure, either in a bag or in a vacuum chamber.

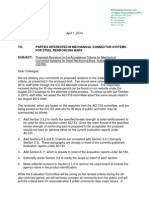

for all predetermined load increment(s). 10.2.1.1 The bag method of loading is schematically shown

6.3 Duration of Load Application—After each increment of in Fig. 1. Connect a reaction platform parallel to the face to be

load is applied, maintain the load level as constant as possible loaded and wider than the specimen to the supports by tie rods.

for a period of 5 min (see Note 1). Take deformation readings Place an airtight bag as wide as the specimen and as long as the

as soon as practical after load application, at the end of the span between the specimen and the reaction platform. Apply

5-min period under constant load, and immediately and at the transverse load to the specimen by increasing the air pressure

end of the 5-min period after any partial or complete load in the bag. Measure the difference in pressure by means of a

release. Plot initial and 5-min readings in the form of load- manometer or other pressure measuring device. The error of

--`,,`,,``,,,,`````,,,````,`,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/02/2015 01:57:15 MST

E 2322 – 03 (2009)

--`,,`,,``,,,,`````,,,````,`,,,,-`-`,,`,,`,`,,`---

FIG. 1 Apparatus for Uniformly Distributed Transverse Load (Bag Method)

the pressure reading shall not exceed 1 % of the full-scale load on the specimen shall include the weight of the specimen

reading. Deflection measurement shall be measured following between the supports. Apply the transverse loads to the upper

10.4. See Fig. 1. (finish floor) face for three of the symmetrical specimens. For

10.2.1.2 When the vacuum chamber method of loading is asymmetrical assemblies, the bottom face for three of the

used, place the specimen near the test frame to create an specimens must also be tested. Deflection measurements shall

airtight vacuum chamber. An airtight frame or curb shall be measured following 10.4. See Fig. 3.

surround the specimen closely and be flush with the upper 10.3 Loading Application—The application of load is found

surface of the specimen. An air resistant blanket covers the in 6.2. The application of load shall be compatible with the test

specimen, overlaps the frame, and is sealed so that it is apparatus indicated in 10.2.

reasonably airtight. Use a vacuum pump or positive action 10.4 Deflection Measurement Device—The deflection mea-

exhaust blower to reduce air pressure between the specimen surement device shall be compatible with the test apparatus

and floor/wall. Measure the difference in pressure by means of indicated in 10.2. A frame shall be placed on the upper face of

a manometer or other pressure measuring device. The error of the specimen in a manner such that the frame shall not deform

the pressure reading shall not exceed 1 % of the full scale as the specimen deforms under load. Two deflection measuring

reading. Deflection measurement shall be conducted following devices, one near each longitudinal edge of the specimen, shall

10.4. See Fig. 2. be attached to the frame at the mid span.

10.2.2 Gravity Load—Gravity load testing shall be con- 10.4.1 Method A—Deflection Measuring Device Top of

ducted in accordance with Practice E 196. Panel—Mid span deflection shall be measured on the top of the

10.2.3 Two Point Load—The two point (quarter-point) load- panel. The deflection measurement should be referenced to the

ing method is used for transverse load tests. Test the specimen panel deflection at the end supports.

as a simple beam (Fig. 3) on a span 150 mm less than the 10.4.2 Method B—Deflection Measuring Device Bottom of

specimen length. Apply two equal loads, each at a distance of Panel—Mid span deflection shall be measured on the bottom

one-quarter of the span from the supports, toward the middle of of the panel. The deflection measurement should be referenced

the span. For floor specimens tested horizontally (Fig. 1), the to the panel deflection at the end supports.

FIG. 2 Apparatus for Uniformly Distributed Transverse Load (Vacuum Bag)

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/02/2015 01:57:15 MST

E 2322 – 03 (2009)

FIG. 3 Quarter Point Loading

--`,,`,,``,,,,`````,,,````,`,,,,-`-`,,`,,`,`,,`---

10.5 Calculations and Report: 10.5.2 Data Presentation—Report the results in the form of

10.5.1 Load-Deflection Data—For each deflection measur- a graph in accordance with Section 8.

ing device, calculate the deflection under a given load as the

difference between the reading when the load is applied and the 11. Concentrated Load—Floor

initial reading. Calculate the deflection of the specimen for the

span as the average of the deflections obtained from each of the 11.1 Test Specimens—Tests shall be made on each of the

measuring devices. Calculate the sets under the initial load by transverse specimens after the transverse tests are completed.

using a similar method. Record the maximum load for each 11.2 Apparatus—The apparatus shall be assembled as

specimen. shown in Fig. 4 and shall conform to the requirements for

FIG. 4 Typical Concentrated Load Apparatus

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/02/2015 01:57:15 MST

E 2322 – 03 (2009)

component parts prescribed in 11.2.1 through 11.2.3 or the 11.4.2 Deflection—Calculate the amount of deflection at a

equivalent. given load to the nearest 0.025 mm as the difference between

11.2.1 Steel Bar—Steel bar having a diameter of 25.4 mm the displacement for the load and the initial reading of the

and the edge of the face contacting the specimen rounded to a deflection measuring device before a load has been applied to

radius of 1.3 mm. When testing for decking deflection, place a the specimen.

25.4 mm diameter flat disk between the steel load bar and the 11.4.3 Data Presentation—Report the results in the form of

decking surface. a graph in accordance with Section 7.

11.2.2 Depth Gauge—The depth gauge shall consist of a TESTING ROOFS

measuring device that is capable of indicating displacement to

0.025 mm and is mounted on a support. The support shall be 12. Transverse Load—Roof

notched to permit placing the measuring device directly 12.1 Test Specimens—Test specimen(s) shall be constructed

adjacent to the bar and shall be long enough to permit placing in accordance with Section 5.

the supporting elements on undisturbed areas of the face of the 12.2 Apparatus—The test apparatus shall conform to the

specimen. requirements of 10.2.

11.2.3 Loading Device—Any convenient means for apply- 12.3 Procedure—Conduct the test in accordance with

ing a compressive load up to 5 kN and means for measuring the 10.2.1 through 10.2.3 for the transverse load tests of the roof.

load within 1 %. See Fig. 4. Apply the load to the upper roof surface when testing for

11.3 Procedure: inward loading. Apply the load to the inner roof surface when

11.3.1 Loading—Place the entire specimen or portion of the testing for outward loading. Application of load is found in 6.2.

specimen on a horizontal support and level the specimen. 12.4 Calculations and Report—Report the results as indi-

Apply the loads on the face of the specimen. Place the steel bar cated in Section 8 and 10.5.

on the surface of the specimen at what is judged to be the 13. Concentrated Load—Roof

weakest place and, also, at what is judged to be the strongest

place. Apply a load vertically downward to the upper surface of 13.1 Test Specimens—Tests shall be made on each of the

the bar. Continue loading until maximum load or 4.45 kN is transverse specimens after the transverse tests are completed.

attained on the steel bar. Application of load is found in 5.2. 13.2 Apparatus—The apparatus shall conform to the re-

quirements of 11.2.

11.3.2 Depth of Indentation—Measure the depth of inden-

13.3 Procedure—Conduct the test in accordance with 11.3

tation, by means of the depth gauge, and record the reading of

on concentrated load tests of floors, except apply the loads only

the gauge to the nearest 0.025 mm.

to the upper face of the specimen. Application of load can be

11.4 Calculations and Report: found in 6.2.

11.4.1 Depth of Indentation—Calculate the depth of inden- 13.4 Calculations and Report—Report the results as indi-

tation (set) after a given load has been applied and the bar cated in Section 8 and 10.5.

removed to the nearest 0.025 mm as the difference between the

depth for that load and the initial reading of the deflection 14. Keywords

measurement device before a load has been applied to the 14.1 concentrated loads; deformation; floors; load duration;

specimen. roofs; sheathing; strength tests; transverse loads

APPENDIXES

--`,,`,,``,,,,`````,,,````,`,,,,-`-`,,`,,`,`,,`---

(Nonmandatory Information)

X1. COMMENTARY ON TEST METHOD

X1.1 This standard was originally part of a larger standard estimated ultimate load carrying capacity of the specimen. This

test method, Test Method E 72. Due to difficulties in maintain- load can be estimated by means of calculations or previous

ing the large and cumbersome test method, the floor and roof experience based on historical tests or analysis.

sections of Test Method E 72 were modified and placed in this

new standard to help aid in maintaining an up-to-date standard X1.3 Estimate the number of increments for application of

test method. load. This number of increments when applying load can be

estimated by means of calculation or previous experience

X1.2 Estimating Ultimate Load Carrying Capacity of based on historical test or analysis. The minimum number

Specimen—The loading schedule of 6.2 is based on the should be between 3–10.

Copyright ASTM International

Provided by IHS under license with ASTM

5Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/02/2015 01:57:15 MST

E 2322 – 03 (2009)

X2. TECHNICAL INTERPRETATION

X2.1 It is the purpose of these test methods to provide a mation and set, simulated, to some extent, the conditions of

systematic basis for obtaining comparable engineering data on repeated loading under service conditions. Therefore, results

various construction elements and structural details of value to by such a method of loading may be more useful than those

professionals, designers, builders, building officials, and others obtained by increasing the load continuously throughout the

interested in this field. test. The results from increment loading tests may show

whether different portions of a construction act as a unit under

X2.2 Subjecting complete structures to known loads is very load, whether the fastening or bonds have adequate strength, or

expensive and requires much time; therefore, that method of whether they rupture under repeated loads. For any engineering

carrying out investigations to establish structural properties is structure, including small house, it is necessary not only that

not likely to be used to any great extent. Such tests have the the strength be adequate, but also that the deformation under

further disadvantage that only the strength of the weakest load shall not appreciably decrease the usefulness of the

elements of a particular structure could be measured. structure. If the working load and the allowable deformation

for an element for a structure are known, constructions

X2.3 For these reasons, it seems more practicable to apply

complying with these requirements may be selected by inspec-

loads to specimens that accurately reproduce a structural

tion of the graphs from tests of such constructions.

portion of a finished building. These portions of a building

have been designated as “elements;” for example, floor, roof, X2.5 A structure is elastic if, after a load has been applied

etc. For the procedure described in these test methods, the and then removed, the set is inappreciable. If the set is small for

elements have been restricted to those most important struc- an element of a building, it may be assumed that the construc-

turally. For each element, methods of loading are described that tion has neither been damaged nor appreciably deformed by the

simulate the loads to which the element would be subjected load. The set, therefore, is another property that may be used

under service conditions. It is believed that the results of these when comparing different constructions and may be useful

measurements on the structural elements will be more useful to when selecting construction for a particular purpose.

architects and engineers than the results of tests of the

individual structural members. Although it may be impractical X2.6 The variations in the properties of a construction as

to determine all of the structural properties of each element of used commercially for buildings, in all probability, will be

a building, it is believed that the more important properties greater than the variations for the three specimens tested as

may be determined by tests described in these test methods. directed in these test methods. Reason being, these specimens

will be all fabricated at the same time by the same workers and

X2.4 The test method, involving the application of the from the same lot of material. This fact should be clearly

loads in increments and the concurrent measurement of defor- indicated in any general report based on these test procedures.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`,,`,,``,,,,`````,,,````,`,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

6Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/02/2015 01:57:15 MST

You might also like

- E488 15Document20 pagesE488 15picott100% (1)

- Astm e 754Document8 pagesAstm e 754Mauricio RiquelmeNo ratings yet

- Astm C900 06Document10 pagesAstm C900 06abualamalNo ratings yet

- AISC DG11 2nd Edition Example 001 PDFDocument12 pagesAISC DG11 2nd Edition Example 001 PDFMohamed Abo-ZaidNo ratings yet

- Aluminum Design Manual 2015Document505 pagesAluminum Design Manual 2015Marcin KrólNo ratings yet

- ASTM A615-A615M-06aDocument6 pagesASTM A615-A615M-06aNadhiraNo ratings yet

- Sheet Metal Screws Through Gypsum Board Wall Sheathing: RecentlyDocument4 pagesSheet Metal Screws Through Gypsum Board Wall Sheathing: Recentlytigani brigdarNo ratings yet

- Astm A 615M 14Document7 pagesAstm A 615M 14Ravi Teja Polisetti100% (1)

- WRI Slab On Ground TF - 700-R-03 UpdateDocument8 pagesWRI Slab On Ground TF - 700-R-03 Updatebobwhite2000No ratings yet

- Neoprene-Concrete Friction Relationships For Seismic Assessment of Existing PDFDocument7 pagesNeoprene-Concrete Friction Relationships For Seismic Assessment of Existing PDFrasika nNo ratings yet

- Schedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Document2 pagesSchedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Caolboy ButchNo ratings yet

- Ac133 2014Document10 pagesAc133 2014Eddie ChanNo ratings yet

- Evaluation and Repair of Bridge Truss Gusset PlatesDocument16 pagesEvaluation and Repair of Bridge Truss Gusset PlatesLAM CONo ratings yet

- E6.370238-1 (Definitions Related To Tension Test)Document12 pagesE6.370238-1 (Definitions Related To Tension Test)alejandroNo ratings yet

- Standard Purlins Manual PDFDocument76 pagesStandard Purlins Manual PDFamazonNo ratings yet

- A1003Document6 pagesA1003hamidharvardNo ratings yet

- Rebound Number of Hardened Concrete: Standard Test Method ForDocument3 pagesRebound Number of Hardened Concrete: Standard Test Method ForSNOWTOOSNo ratings yet

- 5 Precast in Seismic AreasDocument50 pages5 Precast in Seismic AreasMuhammad Arif RachmanNo ratings yet

- Astm D245Document16 pagesAstm D245angelomarinilliNo ratings yet

- ASCE Standard 20-96Document3 pagesASCE Standard 20-96faumijkNo ratings yet

- E1680 PDFDocument6 pagesE1680 PDFOscar Gutiérrez-Junco100% (1)

- BooksDocument1 pageBooksnotevaleNo ratings yet

- Stability of SpeedCore Walls Under Fire Loading Summary of Numerical AnalysesDocument13 pagesStability of SpeedCore Walls Under Fire Loading Summary of Numerical Analysesjackcan501No ratings yet

- 441r - 96 ACI 441R-96 High-Strength Concrete Columns State of The Art PDFDocument13 pages441r - 96 ACI 441R-96 High-Strength Concrete Columns State of The Art PDFSoe SoeNo ratings yet

- Astm A185-02 Steel Welded Wire Reinf For Concrete PDFDocument5 pagesAstm A185-02 Steel Welded Wire Reinf For Concrete PDFCharwin PicaoNo ratings yet

- Ansi Sdi RD 2017 StandardDocument12 pagesAnsi Sdi RD 2017 StandardAlekNo ratings yet

- Changes in ANSI/TIA-222-H StandardDocument1 pageChanges in ANSI/TIA-222-H StandardAlemayehu Kebede100% (1)

- C955 09Document4 pagesC955 09jacr27No ratings yet

- Steel Deck Institute Design Manual For Composite Decks Form DeckDocument53 pagesSteel Deck Institute Design Manual For Composite Decks Form DeckAhmed LepdaNo ratings yet

- Astm A615Document5 pagesAstm A615Jose M-hNo ratings yet

- Aashto Agc ArtbaDocument23 pagesAashto Agc ArtbaIshtiak Kabir AnikNo ratings yet

- Astm F 1145Document12 pagesAstm F 1145Amine Hamdi100% (1)

- ASTM A1034 A1034M 2010a (Reapproved 2015)Document5 pagesASTM A1034 A1034M 2010a (Reapproved 2015)Mukesh kumarNo ratings yet

- A641 PDFDocument5 pagesA641 PDFandresNo ratings yet

- SEI - ASCE - 7-16 - Snow Loads - DRAFT - FrontDocument12 pagesSEI - ASCE - 7-16 - Snow Loads - DRAFT - FrontrcNo ratings yet

- ASTM A767-A767M - 2016 enDocument5 pagesASTM A767-A767M - 2016 enszafak100% (1)

- Astm C94Document11 pagesAstm C94benzenten0% (1)

- Tek 18-01B5 PDFDocument8 pagesTek 18-01B5 PDFMohamed HNo ratings yet

- Steel Wires For Prestressed Concrete - Catalogue PDFDocument8 pagesSteel Wires For Prestressed Concrete - Catalogue PDFDian Jaka PraharaNo ratings yet

- Astm d4268 1993Document9 pagesAstm d4268 1993dharlanuctcomNo ratings yet

- DIN Standard On Formwork Pressures UpdatDocument3 pagesDIN Standard On Formwork Pressures UpdatTùng HìNo ratings yet

- AISI S211-07 (Raffirmed 2012) - E1Document2 pagesAISI S211-07 (Raffirmed 2012) - E1Jon JacobsNo ratings yet

- Astm A325m PDFDocument8 pagesAstm A325m PDFDastaggir KarimiNo ratings yet

- Ansi Sdi NC 2017 StandardDocument15 pagesAnsi Sdi NC 2017 StandarddijNo ratings yet

- SS EN 1991-1-4-2009 - PreviewDocument16 pagesSS EN 1991-1-4-2009 - PreviewJacopo FrancesconNo ratings yet

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesDocument10 pagesHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesIsaac ZTNo ratings yet

- High-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)Document4 pagesHigh-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)indityoNo ratings yet

- Test Method for Water Penetration of Metal Roof PanelsDocument2 pagesTest Method for Water Penetration of Metal Roof PanelsQadir MohideenNo ratings yet

- C 890 - 91 R99 - Qzg5maDocument5 pagesC 890 - 91 R99 - Qzg5maRafael CardenasNo ratings yet

- C1242Document15 pagesC1242Yaser Al ShabasyNo ratings yet

- Steel Welded Wire Reinforcement, Plain, For ConcreteDocument8 pagesSteel Welded Wire Reinforcement, Plain, For ConcreteBa Lestari WijanarkoNo ratings yet

- Ready-Mixed Concrete: Standard Specification ForDocument15 pagesReady-Mixed Concrete: Standard Specification ForYnmer GallegosNo ratings yet

- Aitc - 119-96 American Institute of Timber Construction PDFDocument39 pagesAitc - 119-96 American Institute of Timber Construction PDFECC100% (1)

- 4084 2012Document8 pages4084 2012rama krishnan100% (1)

- E 72 - 02 RtcyDocument11 pagesE 72 - 02 RtcyLuis Luna JuarezNo ratings yet

- Determining Strength Capacities of Structural Insulated PanelsDocument4 pagesDetermining Strength Capacities of Structural Insulated PanelsEric GozzerNo ratings yet

- Syl Lab I EarthquakeDocument13 pagesSyl Lab I EarthquakezeeshanNo ratings yet

- Astm E72 E72-15Document13 pagesAstm E72 E72-15cristobal aguilar100% (1)

- E 196 - 95 R00 Rte5ng - PDFDocument3 pagesE 196 - 95 R00 Rte5ng - PDFEliasTalaAllcaNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 FT-LBF/FT (2,700 KN-M/M) )Document14 pagesLaboratory Compaction Characteristics of Soil Using Modified Effort (56,000 FT-LBF/FT (2,700 KN-M/M) )Marco RiveraNo ratings yet

- 3941 - Iii - NW San AntonioDocument1 page3941 - Iii - NW San AntonioAdán Cogley CantoNo ratings yet

- Expansion Index of Soils: Standard Test Method ForDocument5 pagesExpansion Index of Soils: Standard Test Method ForAdán Cogley CantoNo ratings yet

- Numero de Rebote en Concreto EndurecidoDocument3 pagesNumero de Rebote en Concreto EndurecidoAdán Cogley CantoNo ratings yet

- Liquid Limit, Plastic Limit, and Plasticity Index of Soils: Standard Test Methods ForDocument16 pagesLiquid Limit, Plastic Limit, and Plasticity Index of Soils: Standard Test Methods ForchavezjuliocesarNo ratings yet

- Astm D 1883 07 Standard Test Method For CBR California BeariDocument9 pagesAstm D 1883 07 Standard Test Method For CBR California Bearialibek111100% (1)

- Extraccion y Compresion de Nucleos de ConcretoDocument6 pagesExtraccion y Compresion de Nucleos de ConcretoAdán Cogley CantoNo ratings yet

- Astm D2434 PDFDocument6 pagesAstm D2434 PDFRoy Franco Velasco100% (2)

- HEC-RAS - 6.0 2DModelingUsersManual (Unlocked by WWW - Freemypdf.com)Document283 pagesHEC-RAS - 6.0 2DModelingUsersManual (Unlocked by WWW - Freemypdf.com)Isabela BalanNo ratings yet

- Permeabilidad Carga VariableDocument23 pagesPermeabilidad Carga VariableAdán Cogley CantoNo ratings yet

- HEC-RAS MapperUsersManualDocument149 pagesHEC-RAS MapperUsersManualFaizal RohmatNo ratings yet

- Building Enclosure Commissioning: Standard Guide ForDocument22 pagesBuilding Enclosure Commissioning: Standard Guide ForAdán Cogley CantoNo ratings yet

- HEC-RAS 6.0 ReferenceManualDocument520 pagesHEC-RAS 6.0 ReferenceManualAdán Cogley CantoNo ratings yet

- Flexion de VigasDocument4 pagesFlexion de VigasAdán Cogley CantoNo ratings yet

- Astm C 136 PDFDocument5 pagesAstm C 136 PDFJuan Jesus Garcia Reyes100% (2)

- WSR-02 Grease Trap Requirements CalculationDocument4 pagesWSR-02 Grease Trap Requirements CalculationAdán Cogley CantoNo ratings yet

- Reinforced Concrete Analysis and DesignDocument556 pagesReinforced Concrete Analysis and DesignRama KrishnaNo ratings yet

- Anchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification ForDocument9 pagesAnchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification ForAdán Cogley CantoNo ratings yet

- Astm F1554-2007 PDFDocument10 pagesAstm F1554-2007 PDFMuhammad Reza SeptyansyahNo ratings yet

- Strength and Protective Coatings On Steel Industrial Fence FrameworkDocument7 pagesStrength and Protective Coatings On Steel Industrial Fence FrameworkAdán Cogley Canto100% (1)

- Determining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, and Rivets (Metric)Document17 pagesDetermining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, and Rivets (Metric)Adán Cogley CantoNo ratings yet

- Building Enclosure Commissioning: Standard Practice ForDocument19 pagesBuilding Enclosure Commissioning: Standard Practice ForAdán Cogley CantoNo ratings yet

- Fence Fittings: Standard Specification ForDocument4 pagesFence Fittings: Standard Specification ForAdán Cogley CantoNo ratings yet

- AASHTO T 258-81 - Determining Expansive Soils - TOAZ - INFODocument9 pagesAASHTO T 258-81 - Determining Expansive Soils - TOAZ - INFOAdán Cogley CantoNo ratings yet

- Design and Performance of Supported Laminated Glass WalkwaysDocument4 pagesDesign and Performance of Supported Laminated Glass WalkwaysAdán Cogley CantoNo ratings yet

- Hardened Steel Washers (Metric) : Standard Specification ForDocument5 pagesHardened Steel Washers (Metric) : Standard Specification ForAdán Cogley CantoNo ratings yet

- Determining The Thickness of Glass in Airport Traffic Control Tower CabsDocument17 pagesDetermining The Thickness of Glass in Airport Traffic Control Tower CabsAdán Cogley CantoNo ratings yet

- General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtDocument16 pagesGeneral Requirements For Steel Bars, Carbon and Alloy, Hot-Wroughtعصام السامرائيNo ratings yet

- Conducting Inspections of Building Facades For Unsafe ConditionsDocument8 pagesConducting Inspections of Building Facades For Unsafe ConditionsAdán Cogley CantoNo ratings yet

- KHOADocument11 pagesKHOAshile9011No ratings yet

- Nia - Semi Automated Intent Based Enterprise ChatbotDocument3 pagesNia - Semi Automated Intent Based Enterprise ChatbotInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Factors Influencing NursesDocument6 pagesFactors Influencing Nursesangel_reign04No ratings yet

- Professor Hamish Low: EmploymentDocument6 pagesProfessor Hamish Low: EmploymentAlexy HondaNo ratings yet

- The 20 Point ScaleDocument7 pagesThe 20 Point ScaleTinskiweNo ratings yet

- Sped Lesson PlansDocument6 pagesSped Lesson Plansapi-264477124No ratings yet

- Kierkegaard's Complex Views on Ethics ExploredDocument14 pagesKierkegaard's Complex Views on Ethics ExploredjuanevaristoNo ratings yet

- Autonomy From ParentsDocument7 pagesAutonomy From ParentsUzair RiazNo ratings yet

- Mountain Man SWOT Analysis and Marketing StrategyDocument3 pagesMountain Man SWOT Analysis and Marketing StrategySebastiaan VesseurNo ratings yet

- TIPINGDocument6 pagesTIPINGSurendar BabuNo ratings yet

- TSL Syllabus - Geography 0460 Yr8 (Ver.2)Document12 pagesTSL Syllabus - Geography 0460 Yr8 (Ver.2)Ezra NathanaelNo ratings yet

- Intuitionistic Hesitant Fuzzy Filters in BE-AlgebrasDocument7 pagesIntuitionistic Hesitant Fuzzy Filters in BE-AlgebrasEditor IJRITCCNo ratings yet

- Pengaruh Teknik Distraksi Dan Teknik Relaksasi Terhadap Nyeri Selama Perawatan Luka OperasiDocument7 pagesPengaruh Teknik Distraksi Dan Teknik Relaksasi Terhadap Nyeri Selama Perawatan Luka OperasiHima IndahNo ratings yet

- ChatGPT Dragged To US Court Over AI Copyright - WorldDocument13 pagesChatGPT Dragged To US Court Over AI Copyright - WorldAlexia JacksonNo ratings yet

- FDFDFDFDFDFDFDocument16 pagesFDFDFDFDFDFDFOcir AyaberNo ratings yet

- Small Business & Entrepreneurship - Chapter 13Document27 pagesSmall Business & Entrepreneurship - Chapter 13Muhammad Zulhilmi Wak JongNo ratings yet

- PQLX System Installation and Configuration GuideDocument42 pagesPQLX System Installation and Configuration GuidecimasukNo ratings yet

- Ilya Prigogine - Creativity in Art and Nature PDFDocument4 pagesIlya Prigogine - Creativity in Art and Nature PDFameliaNo ratings yet

- PAC File StudyDocument13 pagesPAC File Studysagar jainNo ratings yet

- Systems ThinkingDocument69 pagesSystems ThinkingWikus Du ToitNo ratings yet

- FORMAL REPORT Phyphar SolubilityDocument3 pagesFORMAL REPORT Phyphar SolubilityReg LagartejaNo ratings yet

- 101 Daily Dissertation Writing TipsDocument8 pages101 Daily Dissertation Writing TipsHelpWritingAPaperForCollegeLittleRock100% (1)

- A Testing Battery For The Assessment of Fitness in Soccer PlayersDocument12 pagesA Testing Battery For The Assessment of Fitness in Soccer Playersbolebs14No ratings yet

- 2 Decisionmaking 121219225114 Phpapp02Document80 pages2 Decisionmaking 121219225114 Phpapp02Zohaib AhmedNo ratings yet

- Implement Median Filter on FPGA for Noise RemovalDocument1 pageImplement Median Filter on FPGA for Noise RemovalDyana RamlyNo ratings yet

- Sky High 3 CourseDocument7 pagesSky High 3 CourseHiginio von BachNo ratings yet

- System Testing TemplateDocument12 pagesSystem Testing TemplateSE ProjectNo ratings yet

- Phraseological Units, Similes, ProverbsDocument13 pagesPhraseological Units, Similes, ProverbsMarietaNo ratings yet

- Chapter 7 Part 2 Evaluating HRD ProgramDocument30 pagesChapter 7 Part 2 Evaluating HRD ProgramaidilzakwanNo ratings yet

- Sets 1 and 2 contain numbers with the same number of significant figuresDocument35 pagesSets 1 and 2 contain numbers with the same number of significant figuresDionel RizoNo ratings yet