Professional Documents

Culture Documents

Wang 2009

Uploaded by

tapashrautrayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wang 2009

Uploaded by

tapashrautrayCopyright:

Available Formats

Wang et al.

Manufacture and Cytotoxicity of a Piezoelectric Ceramic

Manufacture and Cytotoxicity of a Lead-free Piezoelectric

Ceramic as a Bone Substitute—Consolidation of Porous Lithium

Sodium Potassium Niobate by Cold Isostatic Pressing

Qi Wang1,3, Jun Yang2, Wu Zhang3, Roxanne Khoie3, Yi-ming Li3, Jian-guo Zhu2, Zhi-qing Chen1*

1

State Key Laboratory of Oral Diseases, West China College of Stomatology, Sichuan University, Chengdu, China

2

College of Materials Science and Engineering, Sichuan University, Chengdu, China

3

Center for Dental Research, School of Dentistry, Loma Linda University, Loma Linda, USA

Abstract made by from conventional pressing procedures. The

Qi Wang, Jun Yang, Wu Zhang, Roxanne Khoie, Yi-ming Li, effects of the ceramic on the attachment and proliferation of

Jian-guo Zhu, Zhi-qing Chen. Manufacture and Cytotoxi- osteoblasts isolated from the cranium of 1-day-old Sprague-

city of a Lead-free Piezoelectric Ceramic as a Bone Substi- Dawley rats were examined by a scanning electron micro-

tute—Consolidation of Porous Lithium Sodium Potassium scopy (SEM) and methylthiazol tetrazolium (MTT) assay.

Niobate by Cold Isostatic Pressing. International Journal of Results The results showed that CIP enhanced piezoelec-

Oral Science, 1(2): 99–104, 2009 tricity and biological performance of the niobate specimen,

and also promoted an extracellular matrix-like topography

Aim The piezoelectric properties and cytotoxicity of a

of it. In vitro studies showed that the CIP-enhanced material

porous lead-free piezoelectric ceramic for use as a direct

had positive effects on the attachment and proliferation of

bone substitute were investigated.

osteoblasts.

Methodology Cold isostatic pressing (CIP) was applied

Conclusion Niobate ceramic generated by CIP shows a

to fabricate porous lithium sodium potassium niobate

promise for being a piezoelectric composite bone substitute.

(Li0.06Na0.5K0.44) NbO3 specimens using a pore-forming

method. The morphologies of the CIP-processed specimens Keywords lead-free piezoelectric ceramic, cold isostatic

were characterized and compared to those of specimens pressing (CIP), cytocompatibility, osteoblast

Document code: A CLC number: TB39 Received Mar. 2, 2009; Revision accepted Mar. 30, 2009

Introduction that alkaline niobate is able to enhance the depo-

sition of hydroxyapatite and formation of a mine-

A variety of biomaterials for repairing bone ralized matrix (Wang, 2006). Furthermore, based

defects have significantly increased since lead-free on the homogenization theory, a “smart system”

piezoelectric ceramics were introduced (Feng et al., consisting of an inert perforated piezoelectric

1997) on account of their stable piezoelectricity. matrix filled with living osteoblasts may help the

There is evidence that stress-generated potentials process of bone regeneration (Miara et al., 2005).

produced by piezoelectric ceramics can stimulate The idea of a porous lead-free piezoelectric

bone regeneration in situ. For example, barium ceramic was founded on these theories. Previously,

titanate implants promoted osteogenesis in dog we reported a fabrication method for making a

femurs (Park et al., 1981). Lithium sodium biologically stable lead-free piezoelectric ceramic

potassium niobate, a new generation of lead-free with pores and wetability favorable for nutrient

piezoelectric ceramics, has expanded its scope of exchange and osseointegration (Wang et al., 2008).

reperaing bone defects owing to its better and Two particulate pore-forming agents (PFAs), ammo-

more stable piezoelectricity compared with barium nium oxalate monohydrate (AOM) and poly (methyl

titanate (Saito et al., 2004). Studies have shown methacrylate) (PMMA), were compared for the

International Journal of Oral Science, 1(2): 99–104, 2009 - 99 -

Manufacture and Cytotoxicity of a Piezoelectric Ceramic Wang et al.

ρ Th − ρ B

fabrication of the porous lithium sodium pota- P= × 100%

ρ Th

ssium niobate (LNKN). We found that AOM was

a better porogen than PMMA in producing ceramics The constitution and microstructure of the sam-

with a range of porosity between 30% and 50% ples were examined by X-ray diffraction (XRD)

(Wang et al., 2008). (X'Pert Pro MPD, Philips, Holland) and SEM

To expand on previous findings, in this study (S-2460N, Hitachi, Japan), respectively.

we aimed to evaluate the pressure changes during

sample preparation by cold isostatic pressing (CIP) Piezoelectric properties

and the effects of CIP on piezoelectricity and

biological performance. The piezoelectric strain The specimens were polarized under a dc elec-

factor (d33) and the electromechanical coupling tric field of 2.2–2.4 kV/mm in air for 50 minutes at

factor (Kp) were measured as parameters of piezo- 20–25℃ using copper sheets as electrodes tightly

electric properties. Furthermore, the attachment clamped to the flat surfaces. d33 was measured with

and proliferation of osteoblasts were examined as a model d33 piezometer (ZJ-3A, China Science and

measures of biological behavior by using scanning Technology Institution, China). Kp was measured

electron microscopy (SEM) and the methylthiazol using an impedance analyzer (PV70A, Jiangsu

tetrazolium (MTT) assay. Instrument Company, China). All three specimens

were tested for each composite, and an average of

at least six measurements over the surface of each

Materials and methods was taken.

Ceramic preparation Biological analyses

The properties of the starting materials are given Cell culture

in Table 1. LNKN powder was mixed with 5%

(mass %) aqueous poly vinyl alcohol (PVA) as a Osteoblasts isolated from the cranium of 1-day-

binder. AOM was added to the LNKN powder in a old Sprague-Dawley rats (SDO, West China Ani-

proportion of 50% or 60% (volume %), as fully- mal Center, China) were cultured routinely at

densed LNKN. The mixture was then ball-milled 37°C in a humidified atmosphere of 5% CO2, and

without alcohol. Large particles of the AOM pow- maintained in F12 (Gibco Life Technologies,

ders were screened out using standard stainless USA) supplemented with 10% fetal bovine serum

steel sieves. The powder mixtures were divided into (FBS; Hyclone Co., USA), 50 IU/mL penicillin and

two groups with one group diepressed at 20 MPa 50 mg/mL streptomycin (Luneng antibacterial Lt.

(Chen et al., 2007) and another at 100 MPa (CIP, Co., China). Cells were sub-cultured 1:2 before

LDJ200/ 600-300I, Shanxi Machine Works, China) reaching confluence using PBS and trypsin/EDTA

in a mold of 15 mm in diameter and 1 mm in (Gibco Life Technologies, USA) (Freshney, 1987).

thickness. Specimens of each composition were Four pieces each of polarized (d33–100 pc/N) and

then sintered in air at 1075℃ for 2 hours in a unpolarized (negative control) ceramic samples were

loosely covered Al2O3 crucible to ensure complete sterilized by autoclave and pretreated with culture

burnout of the porogens. Bulk density (ρB) was B

media for 4 hours prior to cell implantation. Sam-

determined by Archimedes’ method in which: ples with 50% (volume %) AOM after 100 MaP

porosity (P) was calculated from the ratio of the cold isostatic pressure were used in the in vitro

bulk density to the theoretical density (ρTh) using study. Passage two isolated osteoblasts were seeded

the following equation: on the negative side of pretreated ceramics in 24-well

Table 1 Starting materials used for making porous LNKN ceramics

LNKN Ammonium oxalate monohydrate (AOM)

Chemical composition Li0.06Na0.5K0.44NbO3 (NH4)2C2O4·H2O

Particle size (μm) 0.97 250–300

Density (g/mL) 4.255 1.50

Decomposition point (℃) – 75

Source Synthesized Kelong Chemical Co., China

- 100 - International Journal of Oral Science, 1(2): 99–104, 2009

Wang et al. Manufacture and Cytotoxicity of a Piezoelectric Ceramic

5

cell culture plates at a density of 1×10 cells/ ceramics under 20 MPa conventional pressure and

sample for MTT assay and at 5×105 cells/sample 100 MPa cold isostatic pressures at 50% (volume %).

for SEM analysis. Cells were incubated in 1 mL of Only one crystalline phase of perovskite structure

the same medium used for maintenance culture for was detected in each case.

the duration of the experiment. Four 24-well culture Figure 2 shows SEM images of the surface

dishes without ceramics were used as positive topographies at 50% (volume %) AOM at two

controls for the MTT assay. different pressures. Pores 150–250 µm in diameter

were present, being somewhat smaller than the

Attachment and proliferation of osteoblasts

porogen particles. The pores were seen to be

SEM analyses were performed to study the mor- continuous. Large pores interconnected with each

phology of osteoblasts grown for 72 hours on the other through small pores and some small pores

surface of both test and negative control disks after became incorporated into larger pores. In the walls

cell seeding. The first step involved dehydration of of the pores (×1000), micropores 1–3 µm in

the cells attached to the disk surface. The disks diameter could be observed. In ceramics generated

were placed in ethanol at 30%, 50%, 70%, 80%, under low pressure, small cracks were evident in

90%, 95% and 100%, immersed for 15 minutes the matrix (Figures 2A and 2B) and the grains

at each step. The second step was to substitute were only loosely in contact with each other which

ethanol with acetone (Kelong Chemical Co., inhibited grain growth. However, in the ceramics

China). After the critical point drying of these generated under high pressure, the average grain

samples, SEM images were collected at ×1000 and size was about 10 µm and the cubic-shaped grains

×2000 magnification on a Hitachi S-2460N SEM were in close contact with each other (Figures 2C

(Hitachi, Japan) to view the morphology of the and 2D) leaving only some small micropores

cells attaching to the surfaces of the control and which served as channels for nutrition.

polarized disks.

Cell proliferation was assessed using MTT assay Piezoelectric properties

after growing cells in 24-well plates at a density of

Both the d33 and the mean Kp values decreased

1×105 cells/well for 1, 3, 5 or 7 days. For the MTT

with increasing porosity (Table 2) owing to the

assay, 10 µL of MTT stock solution (5 mg/mL of

volume fraction effect, which was consistent with

MTT in PBS) was added to each culture. After

previous reports (Gupta and Venkatesh, 2006;

incubation for 4 hours, 100 µL DMSO (Kelong

Wang et al., 2008). However, the ceramics with

Chemical Co., China) was added to each well

50% porogens demonstrated piezoelectric proper-

and the plate was shaken evenly for 10 minutes.

ties relatively higher than the theoretical value

The solution was allowed to solubilize for another

(–90 pC/N) after CIP.

30 minutes in the incubator. The absorbance of

each well was determined using the Microplate

Cell attachment

Reader (Benchmark, Bio-Rad, USA) at 570 nm.

Figure 3 shows SEM images of osteoblasts seeded

Statistical analysis on the surfaces of the porous LNKN after cell

seeding for 72 hours on both polarized and

Data are presented as means and standard errors

unpolarized samples. The cells on the polarized

of means. Statistical analysis was performed using

sample covered 40% of the surface and appeared

one-way ANOVA for the MTT assay. P-values

expanded with a well defined three-dimensional

<0.05 were considered statistically significant.

structure. However, cells on the surface without

polarization showed less than 30% coverage and

Results were flat, implying that osteoblasts had better cell

behavior on the negative polarized surface than on

Microstructure the unpolarized surface.

Stable 3–3 porous disks with average porosity

Cell proliferation

of from about 47%–55% were generated using

AOM as porogen under both compressive pre- Figure 4 shows the proliferation of osteoblasts

ssures. Figure 1 shows the XRD patterns of the on the surfaces of the porous LNKN and cell

International Journal of Oral Science, 1(2): 99–104, 2009 - 101 -

Manufacture and Cytotoxicity of a Piezoelectric Ceramic Wang et al.

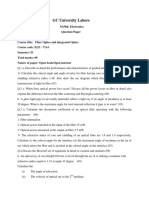

Figure 1 XRD patterns of the sintered LNKN porous ceramics

Figure 2 SEM images of the ceramics at 50% AOM at different pressures

A, C: 20 MPa cold isostatic pressure; B, D: 100 MPa cold isostatic pressure.

Table 2 Piezoelectricity of the porous LNKN barium titanate (BaTiO3) (Park et al., 1980). Lithium

under two different compressive pressures ( χ ± SD) sodium potassium niobate has broadened the scope

of lead-free piezoelectric ceramics owing to its

50% PFA 60% PFA

better and more stable piezoelectricity than barium

d33 Kp d33 Kp

titanate (Saito et al., 2004). In this study, the

20 Mpa 87±5 0.23±0.02 69±6 0.18±0.03

manufacturing method for porous LNKN ceramics

100 Mpa 117±6 0.24±0.03 76±8 0.23±0.02

was modified by CIP, a method for consolidation

culture plates on days 1, 3, 5 and 7 after cell seeding. under a uniform pressure in a flexible envelope. The

The living cells showed more proliferation on the process was applied to pre-shaped LNKN-AOM

polarized than on the unpolarized porous surfaces. samples resulting in a high degree of uniformity in

The proliferation of the cells on the polarized density after sintering.

specimen surfaces was greater on days 3, 5 and 7 The SEM images of the ceramics at two different

(P<0.05) which is consistent with the SEM results. pressures were compared and no defects or flaws

This indicated that both polarized and unpolarized were evident in the walls of the pores generated by

lead-free piezoelectric ceramic samples did not CIP (Figures 2A and 2B). This is because high

show cytotoxicity during the testing period. pressure makes the matrix much firmer and stiffer

compared to conventional pressure. CIP-generated

ceramics consisted of fine and coarse grains and

Discussion had a smaller grain size than ordinary ceramics

(Figures 2C and 2D), indicating that grain growth

Piezoelectric materials have made contributions was promoted by CIP. Porous ceramics can be

to many different fields (Chen et al., 2004). Their regarded as pore-solid composites with pores being

first application to the biomaterials area was with the second phase. Those with independent pores

the discovery of lead-free piezoelectric ceramic can be classified as 0–3 and those with continuous

- 102 - International Journal of Oral Science, 1(2): 99–104, 2009

Wang et al. Manufacture and Cytotoxicity of a Piezoelectric Ceramic

Figure 3 SEM images of osteoblasts seeded on the surfaces of the porous LNKN after cell seeding for 72 hours

on both polarized and unpolarized samples

A, C: 20 MPa cold isostatic pressure; B, D: 100 MPa cold isostatic pressure.

more easily, further increasing the piezoelectric

constant. Therefore, the CIP procedure compensates

for the reduction in piezoelectricity caused by the

modified polarization condition necessary for

biocompatibility (Wang et al., 2008).

In vitro results showed that the lead-free piezo-

electric ceramic samples had no cytotoxicity

during the testing period. As shown previously,

the pH value of ceramics in culture media remains

stable for up to 5 months. Therefore, it could be

predicted that no changes would occur in the

Figure 4 MTT assay of proliferation of osteo- extracellular environment if the ceramics were

blasts cultured on different substrates implanted for a longer period (Wang et al., 2008).

Osteogenesis is thought to be promoted by piezo-

Error bar represent χ ± SD, n=4, *P<0.05.

electric material. Fundamentally, new bone forma-

pores as 3–3 (Della et al., 2006). Interconnected tion is mediated by pressure-generated electrical

pores could be observed in the SEM images of the current and surface electronic charges (Zhang et

ceramics after CIP, indicating that a 3–3 porous al., 2007). Furthermore, new bone formation

pore-solid structure was obtained with pore sizes depends on the piezoelectric constants (Braden et

favorable for cell growth and nutrition exchange. al., 1966). d33 is the polarization generated per unit

The piezoelectric properties of 3–3 composites of mechanical stress and Kp is the factor for the

can be predicted by theoretical models (Banno, electric field in the direction parallel to which a

1987) and as previously reported, those of porous ceramic is polarized (Du et al., 2007). In living

LNKN closely matched theoretical models (Wang beings, polar materials like collagen, ions and

et al., 2008). However, in this study, the samples active cells grow in a definite direction. Cells were

with 50% porogens demonstrated a relatively higher more active on negative polarized surfaces than on

d33 value than the theoretical value (–90 pC/N) unpolarized ones because of the electronic cellular

after CIP. The reason may be that the crystals reaction between osteoblasts and the electric domain

grew better after CIP and the increased stiffness of both on the surface and inside the pores. The range

the matrix enabled the electric domain to reverse in which cells will exhibit their best behavior for

International Journal of Oral Science, 1(2): 99–104, 2009 - 103 -

Manufacture and Cytotoxicity of a Piezoelectric Ceramic Wang et al.

osteogenesis is still unknown. However, based on electric composites with a porous non-piezoelectric

our findings, the osetoblasts worked well on the matrix. Acta Mater, 56(4): 754–761.

best polarized surface. Further studies are needed Du HL, Tang F, Luo F, Zhou W, Qu S, Pei Z (2007).

to determine the most optimum surface. Long-term Effect of poling condition on piezoelectric properties

and animal studies are also needed to verify the of (K0.5Na0.5)NbO3–LiNbO3 lead-free piezoelectric

osteoinductive properties and in vivo status of the ceramics. Materials Science and Engineering B, 137

new porous lead-free piezoelectric ceramics. (1–3): 175–179.

Feng J, Yuan H, Zhang X (1997). Promotion of osteo-

genesis by a piezoelectric biological ceramic. Bioma-

Conclusion terials, 18(23): 1531–1534.

Freshney RI (1987). Culture of animal cells: a manual of

Lead-free piezoelectric ceramics with 3–3 porous basic technique. New York: Alan R. Liss, Inc.,

structure with the potential for use as bone pp.275–277.

substitutes can be generated using AOM. Cold Gupta RK, Venkatesh TA (2006). Electromechanical res-

isostatic pressure of 100 MPa may enhance their ponse of porous piezoelectric materials. Acta Materialia,

piezoelectric properties by improving their inert 54(15): 4063–4078.

structure. The positive effects shown in our in Miara B, Rohan E, Zidi M, Labat B (2005). Piezomaterials

vitro study on the attachment and differentiation of for bone regeneration design-homogenization approach.

SD osteoblasts on porous materials demonstrated J Mecha Physic Solids, 53(11): 2529–2556.

good cytocompatibility, indicating that piezo- Park JB, Recum AF, Kenner GH, Kelly BJ (1980).

Piezoelectric ceramic implants: a feasibility study. J

electric composites show promise for use as bone

Biomed Mater Res, 14(3): 269–277.

substitutes.

Park JB, Kelly BJ, Kenner GH, Recum AF (1981).

Piezoelectric ceramic implants: in vivo results. J

Acknowledgements Biomed Mater Res, 15(1): 103–110.

Saito Y, Takao H, Tani T, Nonoyama T, Takatori K,

This work was financially supported by the Homma T, et al. (2004). Lead-free piezoceramics.

National Natural Science Foundation of China Nature, 432(7013): 84–87.

(59972020). Wang P (2006). Study on lithium sodium potassium

niobate novel biological piezoelectric ceramic.

Chengdu, China: Sichuan University.

References

Wang PY, Zhang XZ, Yang P, Tian BM, Liu ZL, Chen ZQ

Banno H (1987). Effects of shape and volume fraction of (2008). Biocompatibility if a novel biological piezo-

closed pores on dielectric, elastic, and electromecha- electric ceramic to the rat periosteum derived osteobalst.

nical properties of dielectric and piezoelectric ceramics: West China J Stoma, 26(2): 133–137.

a theoretical approach. Ceram Bull, 66(9): 1332–1337. Wang Q, Chen Q, Zhu J, Huang C, Darvell BW, Chen Z

Braden M, Bairstow A, Beider I, Ritter B (1966). Electrical (2008). Effects of pore shape and porosity on the

and piezoelectrical properties of dental hard tissues. properties of porous LNKN ceramics as bone substitute.

Nature, 212: 1565–1566. Mater Chem and Physic, 109(2–3): 488–491.

Chen Q, Chen L, Li Q, Yue X, Xiao DQ, Zhu JG (2007). Wang Q, Chen X, Zhu J, Darvell BW, Chen Z (2008).

Piezoelectric properties of K4CuNb8O23 modified Porous Li–Na–K niobate bone-substitute ceramics:

(Na0.5K0.5)NbO3 lead-free piezoceramics. J Applied microstructure and piezoelectric properties. Mater

Phys, 102(10): 104–109. Letter, 62(20): 3506–3508.

Chen YC, Wu S (2004). Piezoelectric composites with 3–3 Zhang H, Li J, Zhang B (2007). Microstructure and

connectivity by injecting polymer for hydrostatic electrical properties of porous PZT ceramics derived

sensors. Ceramics Inter, 30(1): 69–74. from different pore-forming agents. Acta Mater, 55(1):

Della CN, Shu D (2006). The performance of 1–3 piezo- 171.

*Corresponding author: Zhi-qing Chen

Address: State Key Laboratory of Oral Diseases, West China College of Stomatalogy, Sichuan University, No.14, 3rd Section,

Renmin South Road, Chengdu 610041, China

Tel: 86 28 85502407 Fax: 86 28 85502401 Email: ChenZhiQing40@126.com

- 104 - International Journal of Oral Science, 1(2): 99–104, 2009

You might also like

- Lin, Feng Yan, Cheng Adam, Clayton JDocument5 pagesLin, Feng Yan, Cheng Adam, Clayton JMario Misael Machado LòpezNo ratings yet

- Enhanced Mechanical Properties and Osseointegration Features of CaNb2O6 - PNb9O25 - Ca3 (PO4) 2Document9 pagesEnhanced Mechanical Properties and Osseointegration Features of CaNb2O6 - PNb9O25 - Ca3 (PO4) 2Jean AndradeNo ratings yet

- Carbon Plasma Immersion Ion Implantation of Nickel-Titanium Shape Memory AlloysDocument8 pagesCarbon Plasma Immersion Ion Implantation of Nickel-Titanium Shape Memory AlloysDodiNo ratings yet

- Filtro CsPANDocument7 pagesFiltro CsPANSeras VictoriaNo ratings yet

- Characterization of Cobalt Chromium HAPDocument10 pagesCharacterization of Cobalt Chromium HAPmasinski fakultetNo ratings yet

- Osorio Cantillo 2012Document4 pagesOsorio Cantillo 2012shridharNo ratings yet

- As Gary 2008Document4 pagesAs Gary 2008Vincenzo TrentadueNo ratings yet

- International Symposium On Zeolites and Microporous Crystals 2015Document6 pagesInternational Symposium On Zeolites and Microporous Crystals 2015Fernando AmoresNo ratings yet

- Carlan (Serban) - Beatrice - Adriana - Art7Document9 pagesCarlan (Serban) - Beatrice - Adriana - Art7Liviu BadeaNo ratings yet

- Fabrication and Evaluation of Poly (Lactic Acid), Chitosan, and Tricalcium Phosphate Biocomposites For Guided Bone RegenerationDocument10 pagesFabrication and Evaluation of Poly (Lactic Acid), Chitosan, and Tricalcium Phosphate Biocomposites For Guided Bone RegenerationJuan Pablo BulaciosNo ratings yet

- Journal of The Mechanical Behavior of Biomedical MaterialsDocument10 pagesJournal of The Mechanical Behavior of Biomedical MaterialsClaudia DumitriuNo ratings yet

- Chai 2011Document10 pagesChai 2011hayet debbichNo ratings yet

- Characterization 2Document6 pagesCharacterization 2Rajeshwari MalliNo ratings yet

- 11 Guzel PDFDocument9 pages11 Guzel PDFcansuNo ratings yet

- Electrospun Eri Silk Fibroin Scaffold Coated With Hydroxyapatite For Bone Tissue Engineering ApplicationsDocument11 pagesElectrospun Eri Silk Fibroin Scaffold Coated With Hydroxyapatite For Bone Tissue Engineering ApplicationsSenthil KumarNo ratings yet

- Applied Surface Science: A.W. Tan, R. Ismail, K.H. Chua, R. Ahmad, S.A. Akbar, B. Pingguan-MurphyDocument10 pagesApplied Surface Science: A.W. Tan, R. Ismail, K.H. Chua, R. Ahmad, S.A. Akbar, B. Pingguan-Murphyey_mieNo ratings yet

- 9.apatite-Forming Ability (Bioactivity) of ProRoot MTADocument13 pages9.apatite-Forming Ability (Bioactivity) of ProRoot MTAMihaela TuculinaNo ratings yet

- Biosynthesis of gold nanoparticles using diatomsDocument10 pagesBiosynthesis of gold nanoparticles using diatoms'Amalia' Choirin SyavawiNo ratings yet

- Ent 151145Document5 pagesEnt 151145tire farrokhzadNo ratings yet

- Fabrication and Morphology Study of Electrospun Cellulose Acetate/polyethylenimine NanofiberDocument18 pagesFabrication and Morphology Study of Electrospun Cellulose Acetate/polyethylenimine Nanofiberomeraijaz599No ratings yet

- Nanoparticle Filtration by Electrospun Polymer FibersDocument9 pagesNanoparticle Filtration by Electrospun Polymer FibersAndrésAlfaroCerazoNo ratings yet

- Corrosion Characteristics of Tinbmomnfe High Entropy Thin Film Deposited On Aisi316L For Biomedical ApplicationsDocument12 pagesCorrosion Characteristics of Tinbmomnfe High Entropy Thin Film Deposited On Aisi316L For Biomedical Applications2021MEP004 BIBHASNAYAKNo ratings yet

- V 10 P 1068Document5 pagesV 10 P 1068Ruxandra-Elena BratuNo ratings yet

- Starch-based biodegradable film properties with nano-SiO2Document6 pagesStarch-based biodegradable film properties with nano-SiO2sakshiNo ratings yet

- Characteristics of SiO2-TiO2Document17 pagesCharacteristics of SiO2-TiO2Isna NurhidayatiNo ratings yet

- Ali2014 Article ZeinCelluloseAcetateHybridNanoDocument7 pagesAli2014 Article ZeinCelluloseAcetateHybridNanoFco. Javier Echegoyán DelgadoNo ratings yet

- Characterization of Acetone-Solution Casting Films of PMMA Using DSC and Py-GC/MSDocument3 pagesCharacterization of Acetone-Solution Casting Films of PMMA Using DSC and Py-GC/MSSyiera MujibNo ratings yet

- Wang Et AlDocument7 pagesWang Et AlomNo ratings yet

- Acta Biomaterials 6.2010.1248-1257Document10 pagesActa Biomaterials 6.2010.1248-1257Shan LuNo ratings yet

- In Situ and Ex Situ Studies of Platinum Nanocrystals: Growth and Evolution in SolutionDocument6 pagesIn Situ and Ex Situ Studies of Platinum Nanocrystals: Growth and Evolution in SolutionVishakha GaurNo ratings yet

- 10 1016@j Prosdent 2019 08 027Document10 pages10 1016@j Prosdent 2019 08 027Bharath KondaveetiNo ratings yet

- Materials 06 05700 PDFDocument13 pagesMaterials 06 05700 PDFsbhushanarya2546No ratings yet

- Research Article Immobilization of Alpha-Chymotrypsin On The Surface of Magnetic/Gold Core/Shell NanoparticlesDocument9 pagesResearch Article Immobilization of Alpha-Chymotrypsin On The Surface of Magnetic/Gold Core/Shell NanoparticlesMalka ShahidNo ratings yet

- Inceased OsteoblastDocument8 pagesInceased OsteoblastJose AndradeNo ratings yet

- Synthesis of Size-Controlled and Shaped Copper NanoparticlesDocument6 pagesSynthesis of Size-Controlled and Shaped Copper NanoparticlesardiNo ratings yet

- Advanced Bio Materials VIDocument3 pagesAdvanced Bio Materials VIBalgonda PatilNo ratings yet

- Diamond As A Scaffold For Bone Growth: Please Do Not Remove This PageDocument23 pagesDiamond As A Scaffold For Bone Growth: Please Do Not Remove This PageSozharajan BNo ratings yet

- Artigo MAt. CHEm. Phys. v. 130Document6 pagesArtigo MAt. CHEm. Phys. v. 130taifisicaNo ratings yet

- XD ERI SilkDocument11 pagesXD ERI SilkSanjib BaglariNo ratings yet

- Coatings 10 00491Document17 pagesCoatings 10 00491JulioNo ratings yet

- Soares 2014Document6 pagesSoares 2014kionnysNo ratings yet

- Baoanan Et Al. Synthesis of Silver Nanoparticles On Stainless Steel PDFDocument4 pagesBaoanan Et Al. Synthesis of Silver Nanoparticles On Stainless Steel PDFmanduNo ratings yet

- Effect of SiO2@polydopamine Core-Shell Nanoparticles As Multifunctional Filler For An Aeronautical Epoxy ResinDocument4 pagesEffect of SiO2@polydopamine Core-Shell Nanoparticles As Multifunctional Filler For An Aeronautical Epoxy ResinOussama El BouadiNo ratings yet

- AbstractsDocument146 pagesAbstractsAnibal RodriguezNo ratings yet

- Nano Patterned SERS Substrate ApplicatioDocument7 pagesNano Patterned SERS Substrate ApplicatioEliezer BecziNo ratings yet

- Electrophoretic Deposition of Porous Hydroxyapatite Coatings Using Polytetrafluoroethylene Particles As TemplatesDocument5 pagesElectrophoretic Deposition of Porous Hydroxyapatite Coatings Using Polytetrafluoroethylene Particles As TemplatesMario Misael Machado LòpezNo ratings yet

- Physicochemical Basis of The Biologic Properties of Mineral Trioxide AggregateDocument4 pagesPhysicochemical Basis of The Biologic Properties of Mineral Trioxide AggregateHeather DuncanNo ratings yet

- Implications of Sandblasting of 316 LVM Stainless Steel On Its Ion Release, in Vitro Corrosion Behavior and BiocompatibilityDocument1 pageImplications of Sandblasting of 316 LVM Stainless Steel On Its Ion Release, in Vitro Corrosion Behavior and BiocompatibilityJuan Carlos GalvanNo ratings yet

- Antibacterial Activity of Chitosan Tripolyphosphate Nano Particles Loaded WithDocument5 pagesAntibacterial Activity of Chitosan Tripolyphosphate Nano Particles Loaded WithdheepaganNo ratings yet

- Biomaterials 1Document8 pagesBiomaterials 1C_rovereNo ratings yet

- Journal Pre-Proof: Journal of Materials Research and TechnologyDocument33 pagesJournal Pre-Proof: Journal of Materials Research and TechnologyrendydunNo ratings yet

- Cahyaningrum 2018 IOP Conf. 68373793764884Document6 pagesCahyaningrum 2018 IOP Conf. 68373793764884syamsu nurNo ratings yet

- Porous Magnetic Nanocomposites Using Corncob Powders for EM Wave AbsorptionDocument7 pagesPorous Magnetic Nanocomposites Using Corncob Powders for EM Wave AbsorptionAsih RahmatNo ratings yet

- Facile Method To Synthesize Oleic Acid-Capped Magnetite NanoparticlesDocument4 pagesFacile Method To Synthesize Oleic Acid-Capped Magnetite Nanoparticles122866No ratings yet

- Paper1 - Tape CastingDocument5 pagesPaper1 - Tape CastingApple TimakulNo ratings yet

- Osseointegration of KRF Laser Hydroxylapatite Films On T16A14V Alloy by Mini-Pigs - Loaded Osseointegration of Dental Implants.Document5 pagesOsseointegration of KRF Laser Hydroxylapatite Films On T16A14V Alloy by Mini-Pigs - Loaded Osseointegration of Dental Implants.lyxuannam lyNo ratings yet

- Bhadra Et AlDocument11 pagesBhadra Et Almyousefi127100% (1)

- Micro Nano ChitosanDocument3 pagesMicro Nano ChitosanHạnh DuyênNo ratings yet

- 5. Impovement implant osseointegrationDocument8 pages5. Impovement implant osseointegrationalinagaxiolaariasNo ratings yet

- Biomimetic Principles and Design of Advanced Engineering MaterialsFrom EverandBiomimetic Principles and Design of Advanced Engineering MaterialsNo ratings yet

- NIH Public Access: MERS: Emergence of A Novel Human CoronavirusDocument10 pagesNIH Public Access: MERS: Emergence of A Novel Human CoronavirustapashrautrayNo ratings yet

- NIH Public Access: MERS: Emergence of A Novel Human CoronavirusDocument10 pagesNIH Public Access: MERS: Emergence of A Novel Human CoronavirustapashrautrayNo ratings yet

- Chen2012 NKN MaterialDocument8 pagesChen2012 NKN MaterialtapashrautrayNo ratings yet

- Odia SQP 2020 21Document18 pagesOdia SQP 2020 21tapashrautrayNo ratings yet

- Chen2012 NKN MaterialDocument8 pagesChen2012 NKN MaterialtapashrautrayNo ratings yet

- Microstructure, Electrical Properties of Ceo - Doped (K Na) Nbo Lead-Free Piezoelectric CeramicsDocument5 pagesMicrostructure, Electrical Properties of Ceo - Doped (K Na) Nbo Lead-Free Piezoelectric CeramicstapashrautrayNo ratings yet

- Phase Transition Behavior and High Piezoelectric Properties in Lead-Free Batio - Catio - Bahfo CeramicsDocument8 pagesPhase Transition Behavior and High Piezoelectric Properties in Lead-Free Batio - Catio - Bahfo CeramicstapashrautrayNo ratings yet

- Lead-Free Piezoelectric Ceramics: Alternatives For PZT?Document14 pagesLead-Free Piezoelectric Ceramics: Alternatives For PZT?tapashrautrayNo ratings yet

- Microstructure, Electrical Properties of Ceo - Doped (K Na) Nbo Lead-Free Piezoelectric CeramicsDocument5 pagesMicrostructure, Electrical Properties of Ceo - Doped (K Na) Nbo Lead-Free Piezoelectric CeramicstapashrautrayNo ratings yet

- BaxterDocument12 pagesBaxtertapashrautrayNo ratings yet

- Letters To Nature: Lead-Free PiezoceramicsDocument4 pagesLetters To Nature: Lead-Free PiezoceramicstapashrautrayNo ratings yet

- Letters To Nature: Lead-Free PiezoceramicsDocument4 pagesLetters To Nature: Lead-Free PiezoceramicstapashrautrayNo ratings yet

- SR MG Co SubstitutedDocument20 pagesSR MG Co SubstitutedtapashrautrayNo ratings yet

- Lead-Free Piezoelectric Ceramics: Alternatives For PZT?Document14 pagesLead-Free Piezoelectric Ceramics: Alternatives For PZT?tapashrautrayNo ratings yet

- Electrical Properties of Manganese Modified Sodium Potassium Lithium Niobate Lead-Free Piezoelectric CeramicsDocument5 pagesElectrical Properties of Manganese Modified Sodium Potassium Lithium Niobate Lead-Free Piezoelectric CeramicstapashrautrayNo ratings yet

- How Clean Is Clean OilDocument2 pagesHow Clean Is Clean OilOscar CampoNo ratings yet

- Characterization of Hard Piezoelectric Lead-Free CeramicsDocument5 pagesCharacterization of Hard Piezoelectric Lead-Free CeramicstapashrautrayNo ratings yet

- Fctnov 09Document5 pagesFctnov 09tapashrautrayNo ratings yet

- In Vitro Antibacterial Activity and PhytochemicalDocument6 pagesIn Vitro Antibacterial Activity and PhytochemicaltapashrautrayNo ratings yet

- Food and Chemical ToxicologyDocument5 pagesFood and Chemical ToxicologytapashrautrayNo ratings yet

- Influence of Porosity On Polarisation and Electric 2Document10 pagesInfluence of Porosity On Polarisation and Electric 2tapashrautrayNo ratings yet

- Coin-IJPAP 41 92004) 319Document4 pagesCoin-IJPAP 41 92004) 319tapashrautrayNo ratings yet

- Influence of Porosity On Polarisation and Electric 2Document10 pagesInfluence of Porosity On Polarisation and Electric 2tapashrautrayNo ratings yet

- ARI-Rautray - 69 (2011) 1385-1389Document6 pagesARI-Rautray - 69 (2011) 1385-1389tapashrautrayNo ratings yet

- Current Science PDFDocument6 pagesCurrent Science PDFtapashrautrayNo ratings yet

- Eur Jor Gastro Hepat V18 p999Document5 pagesEur Jor Gastro Hepat V18 p999tapashrautrayNo ratings yet

- AquacultureDocument7 pagesAquaculturetapashrautrayNo ratings yet

- Elemental Analysis of Blood in Oral Cancer: T R Rautray, V Vijayan PkhotaDocument5 pagesElemental Analysis of Blood in Oral Cancer: T R Rautray, V Vijayan PkhotatapashrautrayNo ratings yet

- Behera Et Al.-Appl. Radn. Isot. 68 (12) (2010) 2229-2236Document8 pagesBehera Et Al.-Appl. Radn. Isot. 68 (12) (2010) 2229-2236tapashrautrayNo ratings yet

- JC2 Math Test Solutions Minimum Cone VolumeDocument13 pagesJC2 Math Test Solutions Minimum Cone VolumeTimothy HandokoNo ratings yet

- Lec 21 Brayton CycleDocument18 pagesLec 21 Brayton CycleJunaid KhanNo ratings yet

- Section 5 - PerformanceDocument124 pagesSection 5 - PerformanceflorentNo ratings yet

- Floating-Roof Tank Heel Reduction Options and Heel Turnover EmissionsDocument15 pagesFloating-Roof Tank Heel Reduction Options and Heel Turnover EmissionsHamid MansouriNo ratings yet

- تقرير التوالي والتوازي (1) -2-17Document16 pagesتقرير التوالي والتوازي (1) -2-17sdymabw94No ratings yet

- EM20HBR 220 V 60 HZ 1Document4 pagesEM20HBR 220 V 60 HZ 1Andre MouraNo ratings yet

- Smart PV Controller: SUN2000-100KTL-M1Document2 pagesSmart PV Controller: SUN2000-100KTL-M1Omar TorresNo ratings yet

- Physics SSC I SolutionDocument8 pagesPhysics SSC I SolutionFaisal SamiNo ratings yet

- Sharif International Offers Solar Grid Hybrid System for Jinnah ParkDocument2 pagesSharif International Offers Solar Grid Hybrid System for Jinnah ParkMuhammad SajidNo ratings yet

- Fiiij: DecemberDocument20 pagesFiiij: DecemberYashh GuptaNo ratings yet

- Design of Irregular SlabsDocument5 pagesDesign of Irregular SlabsEngr. Md. Mahmdudul Hasan ShawonNo ratings yet

- Development of Graphitic Carbon NitrideDocument64 pagesDevelopment of Graphitic Carbon NitrideKoorosh IraniNo ratings yet

- TPT-1 Physics CourseDocument6 pagesTPT-1 Physics CourseSantosh SinghNo ratings yet

- Wong Uma Ure 01-01-03 TechnicalDocument5 pagesWong Uma Ure 01-01-03 TechnicalinquillayNo ratings yet

- Specification For Motor Operated Valve (MOVs)Document9 pagesSpecification For Motor Operated Valve (MOVs)prabha haranNo ratings yet

- Fundamentals of Nanotransistors Homework SolutionsDocument14 pagesFundamentals of Nanotransistors Homework SolutionsSuraj Singh YadavNo ratings yet

- Fiber Optics and Integrated OpticsDocument2 pagesFiber Optics and Integrated OpticsMahnoor MaqsoodNo ratings yet

- Lab Manual Microbiology For Allied Health Students 1.3Document115 pagesLab Manual Microbiology For Allied Health Students 1.3IconMaicoNo ratings yet

- 7th Week Performance Task in General ChemistryDocument3 pages7th Week Performance Task in General ChemistryEthan Miles VigilanciaNo ratings yet

- Black Holes Are Some of The Strangest and Most Fascinating Objects in Outer SpaceDocument3 pagesBlack Holes Are Some of The Strangest and Most Fascinating Objects in Outer SpaceAnurag RanaNo ratings yet

- NICOLE HILL - Orbital DiagramsDocument4 pagesNICOLE HILL - Orbital DiagramsNICOLE HILLNo ratings yet

- D4230 Dew Point Hygrometer Amb AirDocument6 pagesD4230 Dew Point Hygrometer Amb AirArunkumar Chandaran100% (1)

- Temporal Stability of Inviscid Incompressible Flows: SabhileshDocument34 pagesTemporal Stability of Inviscid Incompressible Flows: SabhileshSabhilesh SinghNo ratings yet

- Lateral Vibration of Hydro Turbine-Generator Rotor With Varying Stiffness of Guide BearingsDocument15 pagesLateral Vibration of Hydro Turbine-Generator Rotor With Varying Stiffness of Guide BearingsstevebensonNo ratings yet

- Arpit Mishra Project WorkDocument62 pagesArpit Mishra Project WorkarpitNo ratings yet

- Fese2 ProcedureDocument4 pagesFese2 ProcedureZayn曾子豪No ratings yet

- 5th Sem SyllabusDocument19 pages5th Sem SyllabusRaimond RosarioNo ratings yet

- Flashcards - Topic 01 Atomic Structure and The Periodic Table - AQA Chemistry GCSEDocument137 pagesFlashcards - Topic 01 Atomic Structure and The Periodic Table - AQA Chemistry GCSEEva xuNo ratings yet

- Science3 q1 Mod1 Classifyingobjectsandmaterials v2Document38 pagesScience3 q1 Mod1 Classifyingobjectsandmaterials v2ALJEM TUBIGONNo ratings yet

- Sedimentation: Engr. Nadeem Karim BhattiDocument23 pagesSedimentation: Engr. Nadeem Karim BhattiEngr Sarang Khan100% (1)