Professional Documents

Culture Documents

Execution - Planning SFNDO CARPARK

Uploaded by

Ryan Sooknarine0 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

Execution_Planning SFNDO CARPARK

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesExecution - Planning SFNDO CARPARK

Uploaded by

Ryan SooknarineCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

1.

Execution & Logistics; Site Access:

Entry/Exit off the site

Around the Site/Building

Western road access – is it really necessary? Leaning towards not including it

now as itll be costly.

Logistic Facilities & Staging Area, Handling, Concrete Mixing

Include washout for conc trucks near wheel wash area (should be close to

existing drainage).

Additional staging area for concrete boom pump. (WNW, NNE, SSE)

2. Retaining Wall (Soil Nail Wall)

Materials Lay Down, Office Container(s); location (efficiently/conveniently)

i. Rods

ii. Accessories

iii. Grout plant for injecting into anchors – On site

1. Raw Material Storage; provided by Subcontractor

2. Access

3. Specific area

iv. Shotcrete Access (engage local concrete supplier; types of equipment)

v. Concrete Mixes

1. Mix Design

2. Trial mixes

vi. Movement of equipment around site especially in bad weather; mat

traction

3. Foundation

Strip Footings

i. Shoring – Contiguous Piling

ii. Finalize Method – Symon forms

iii. Resources

1. Material -

2. Labour -

iv. Form Systems (Sketches/

1. Symon Form

2. Aluma Shutters

Stub Columns

Building retaining wall

4. Superstructure

Suspended Beam & Deck

i. Garage Beam System

1. Beam

2. Deck

ii. Aluma Support System

1. Beam

2. Deck

Columns

Shearwalls

You might also like

- Foundation BBS Schedule DWG V3-C1GL3&4-D.6Document1 pageFoundation BBS Schedule DWG V3-C1GL3&4-D.6Ryan SooknarineNo ratings yet

- Bs 8666 2005 Shapes Guidepdf CompressDocument8 pagesBs 8666 2005 Shapes Guidepdf CompressRyan SooknarineNo ratings yet

- Foundation BBS Schedule DWG V3-C1GL3&4-C.6Document1 pageFoundation BBS Schedule DWG V3-C1GL3&4-C.6Ryan SooknarineNo ratings yet

- Foundation BBS Schedule DWG V3-C1GL2B-DDocument1 pageFoundation BBS Schedule DWG V3-C1GL2B-DRyan SooknarineNo ratings yet

- Foundation BBS Schedule DWG V3-C1GL3&4-D-E-F-GDocument1 pageFoundation BBS Schedule DWG V3-C1GL3&4-D-E-F-GRyan SooknarineNo ratings yet

- BS8666 Shape Codes - KB Rebar LimitedDocument10 pagesBS8666 Shape Codes - KB Rebar LimitedRyan SooknarineNo ratings yet

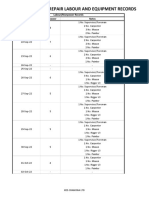

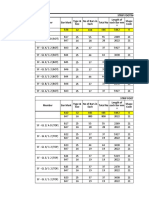

- Labour & Equipment Record - Beam Repair 2Document3 pagesLabour & Equipment Record - Beam Repair 2Ryan SooknarineNo ratings yet

- Preconcreting Notice & Inspection Sheet: Project Qa/Qc Plan R0Document1 pagePreconcreting Notice & Inspection Sheet: Project Qa/Qc Plan R0Ryan SooknarineNo ratings yet

- Section 7a - Prelim DesignDocument15 pagesSection 7a - Prelim DesignRyan SooknarineNo ratings yet

- Request For Information And/or Query Sheet: Kee-Chanona LTDDocument1 pageRequest For Information And/or Query Sheet: Kee-Chanona LTDRyan SooknarineNo ratings yet

- Internal Meeting/Conversation Record: Record Of: San Fernando Multi Storey Car Park SFMSCPDocument2 pagesInternal Meeting/Conversation Record: Record Of: San Fernando Multi Storey Car Park SFMSCPRyan SooknarineNo ratings yet

- Post-Concrete Inspection SheetDocument1 pagePost-Concrete Inspection SheetRyan SooknarineNo ratings yet

- Sections For Setting Out-ModelDocument1 pageSections For Setting Out-ModelRyan SooknarineNo ratings yet

- Additional Mathematics SbaDocument9 pagesAdditional Mathematics SbaRyan SooknarineNo ratings yet

- Strip Footing Bottom Steel Location Member Bar Mark Total No Type & Size No of Bars in Each Length of Each Bar MM + Shape CodeDocument4 pagesStrip Footing Bottom Steel Location Member Bar Mark Total No Type & Size No of Bars in Each Length of Each Bar MM + Shape CodeRyan SooknarineNo ratings yet

- This Is A Text File For ScribidDocument1 pageThis Is A Text File For ScribidRyan SooknarineNo ratings yet

- Truck TrackingDocument4 pagesTruck TrackingRyan SooknarineNo ratings yet

- Inertia FormulasDocument1 pageInertia FormulasrohitkapyarNo ratings yet

- Conc Mix DesignDocument2 pagesConc Mix DesignRyan SooknarineNo ratings yet

- Concrete Grout Washout AreasDocument1 pageConcrete Grout Washout AreasRyan SooknarineNo ratings yet

- MatLab Dev For Civil EngDocument182 pagesMatLab Dev For Civil EngRyan SooknarineNo ratings yet

- Downey (2011) - Physical Modelling With MatlabDocument157 pagesDowney (2011) - Physical Modelling With MatlabGeorges Kouroussis100% (5)

- Downey (2011) - Physical Modelling With MatlabDocument157 pagesDowney (2011) - Physical Modelling With MatlabGeorges Kouroussis100% (5)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)